Concrete production process

A production process and concrete technology, applied in the technical field of producing low-cost concrete, can solve the problems of low-cost concrete manufacturing difficulties, technical obstacles, etc., and achieve the effects of toughness, improved strength, and not easy to be broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Preparation of concrete admixtures

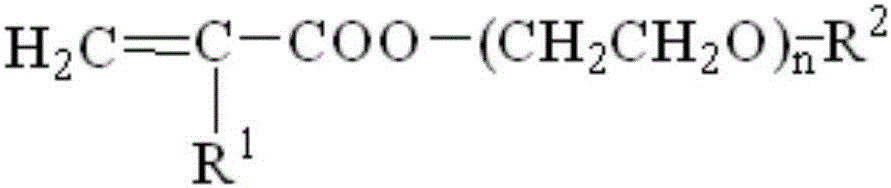

[0056] The chemical structural formula of monomer (I) is:

[0057]

[0058] where R 1 is methyl, R 2 is an ethyl group, n is 5, and this monomer can be prepared by esterifying polyethylene glycol and methacrylic acid according to a conventional esterification method, and then reacting the esterification product with ethoxychloride according to a conventional elimination reaction, or it can be Commercially purchased directly from Sigma-Aldrich;

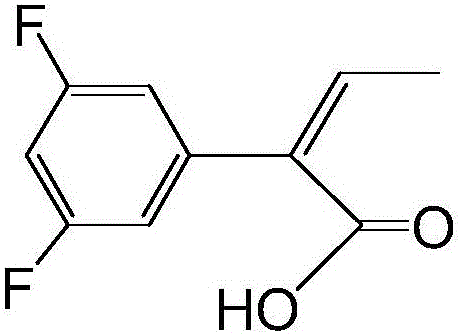

[0059] The chemical structural formula of monomer (II) is:

[0060] This monomer is also commercially available from Sigma-Aldrich;

[0061] Adopt emulsion polymerization method, add 80g monomer (I) and 13g monomer (II) and 200mL deionized water in the 500mL round-bottomed flask that has mechanical stirrer, nitrogen is led under stirring, then add 0.1g ammonium persulfate as The initiator is heated up to the polymerization temperature, the polymerization temperature is 80°C, and the...

Embodiment 2

[0063] Concrete was prepared by mixing the following components: 50 parts by weight of road milling waste, 15 parts by weight of aggregate obtained by crushing bricks and stones in construction waste, the average particle size of which is about 15 mm, 10 parts by weight of finely powdered steel slag, The cement of 20 parts by weight, the admixture prepared by the embodiment 1 of 0.03 parts by weight, and 30 parts of water; The milling waste is the graded aggregate made from the asphalt concrete road milling waste; The graded aggregate obtained from road surface milling waste is obtained through the following steps: (1) milling the asphalt concrete pavement to be refurbished on National Highway 107, the thickness of the first layer of milling is 5cm, and the thickness of the second layer of milling is 10cm; (2) Sieve the first layer of milling material, collect particles of 10-30mm, crush the particles larger than 30mm and sieve again to obtain particles of 10-30mm, which are re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com