Emulsifier, preparation method and application thereof

A technology of emulsifier and main emulsifier, which is applied in the direction of building components, building insulation materials, construction, etc., can solve the problems of poor bonding performance and low viscosity of asphalt, and achieve strong bonding, high asphalt content, and good performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

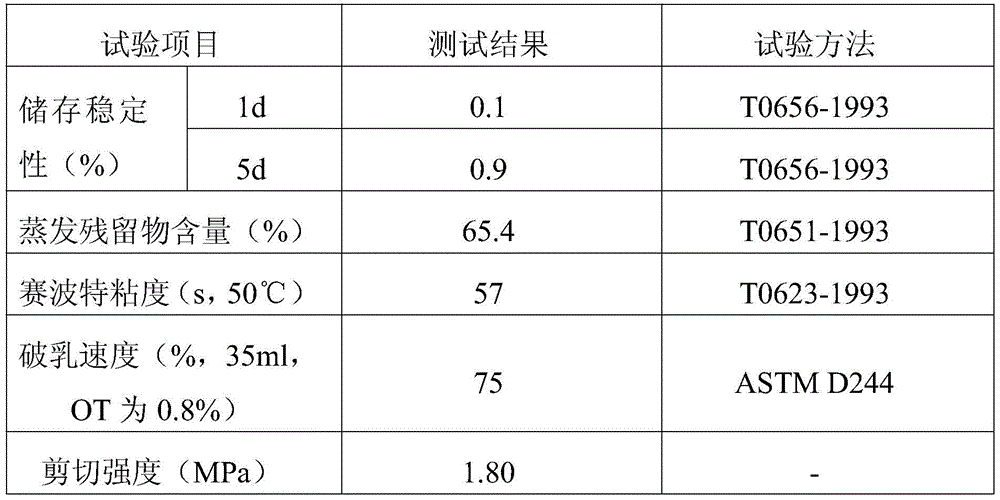

Embodiment 1

[0026] Preparation of primary emulsifier:

[0027] (1) Dissolve 51.58g of diethylenetriamine in 50ml of ethanol solvent, raise the temperature to 60°C, start the mixer, set the stirring speed at 40r / min, and slowly add 44.64g of formaldehyde solution (37% formaldehyde aqueous solution ), the dropwise addition was completed within 1 hour, and the reaction temperature was kept constant at 60°C for 1.5 hours before taking out to obtain the aldehyde amine intermediate and set aside.

[0028] (2) Dissolve 110g of nonylphenol in 200ml of ethanol solvent, raise the temperature to 60°C, start the mixer, set the stirring speed at 60r / min, and drop the aldehyde amine intermediate prepared in step (1) into the nonyl In the phenol-ethanol solution, the dropwise addition was completed within 1 hour, keeping the temperature constant, and reacted for 4 hours to obtain the product solution of the main emulsifier, and 50% of the solvent was removed by rotary evaporation to obtain the main emul...

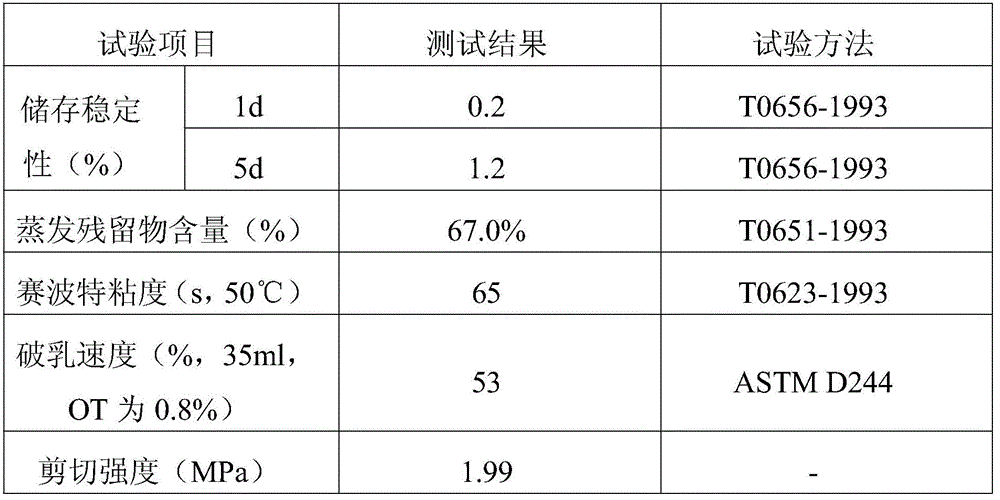

Embodiment 2

[0037] Preparation of primary emulsifier:

[0038] (1) Dissolve 73.15g of triethylenetetramine in 60ml of ethanol solvent, raise the temperature to 60°C, start the mixer, set the stirring speed at 40r / min, and slowly add 50g of formaldehyde solution (37% mass fraction formaldehyde aqueous solution) dropwise , the dropwise addition was completed within 1 hour, and the temperature was kept constant at 60°C for 1 hour, and then taken out to obtain the aldehyde amine intermediate, which was set aside.

[0039] (2) Dissolve 110g of nonylphenol in 200ml of ethanol solvent, raise the temperature to 60°C, start the mixer, set the stirring speed at 60r / min, add the aldehyde amine intermediate prepared in step (1) dropwise to the nonyl In the phenol-ethanol solution, the dropwise addition was completed within 1 hour, keeping the temperature constant, and reacting for 3 hours to obtain the main emulsifier product solution, and 50% of the solvent was removed by rotary evaporation to obtai...

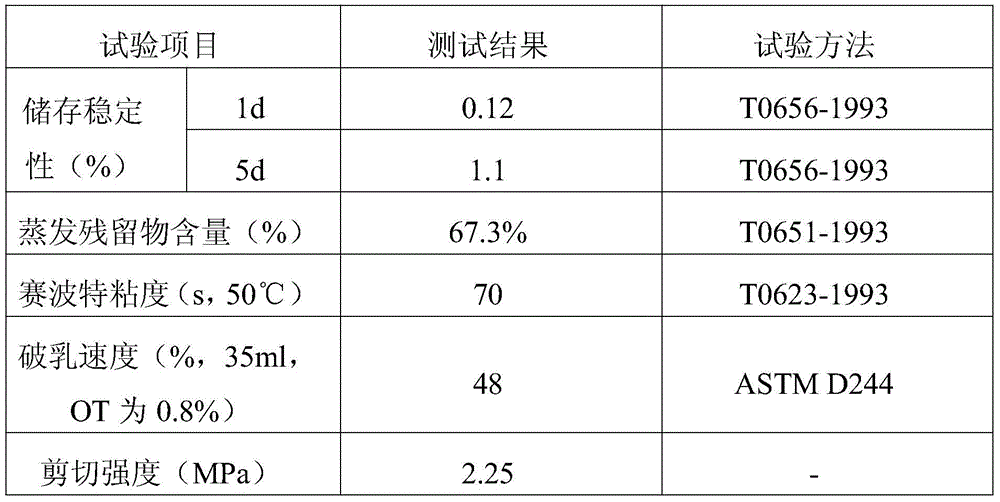

Embodiment 3

[0053] Preparation of primary emulsifier:

[0054] (1) Dissolve 64.6g of aminoethylpiperazine in 50ml of ethanol solvent, raise the temperature to 60°C, start the mixer, set the stirring speed at 60r / min, and slowly add 48g of formaldehyde solution (37% mass fraction formaldehyde aqueous solution ), the dropwise addition was completed within 1 hour, and the temperature was kept constant at 60°C. After 2 hours of reaction, it was taken out to obtain the aldehyde amine intermediate, which was set aside.

[0055] (2) Dissolve 131g of dodecylphenol in 200ml of ethanol solvent, raise the temperature to 60°C, start the mixer, set the stirring speed at 60r / min, add the aldehyde amine intermediate prepared in step (1) dropwise to In the dodecylphenol ethanol solution, the dropwise addition was completed within 1.5 hours, keeping the temperature constant, and reacting for 5 hours to obtain the main emulsifier product solution, and 50% of the solvent was removed by rotary evaporation to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com