A fatigue-resistant and anti-rutting steel bridge deck pavement structure and pavement method

A steel bridge deck, anti-rutting technology, used in bridges, bridge construction, bridge parts, etc., can solve problems such as fatigue cracking, and achieve the effect of prolonging life, shortening construction time, and simple and convenient construction conditions and construction methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

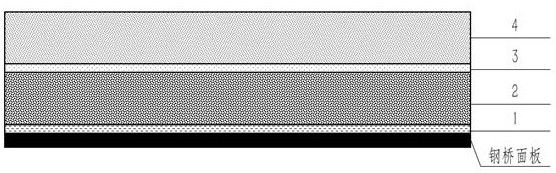

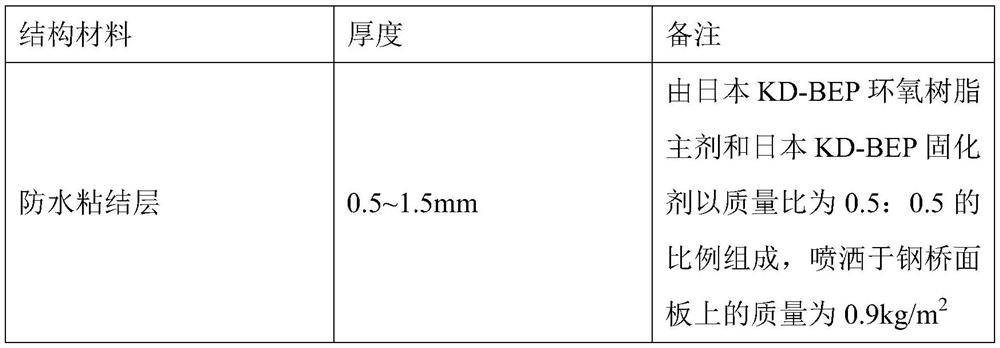

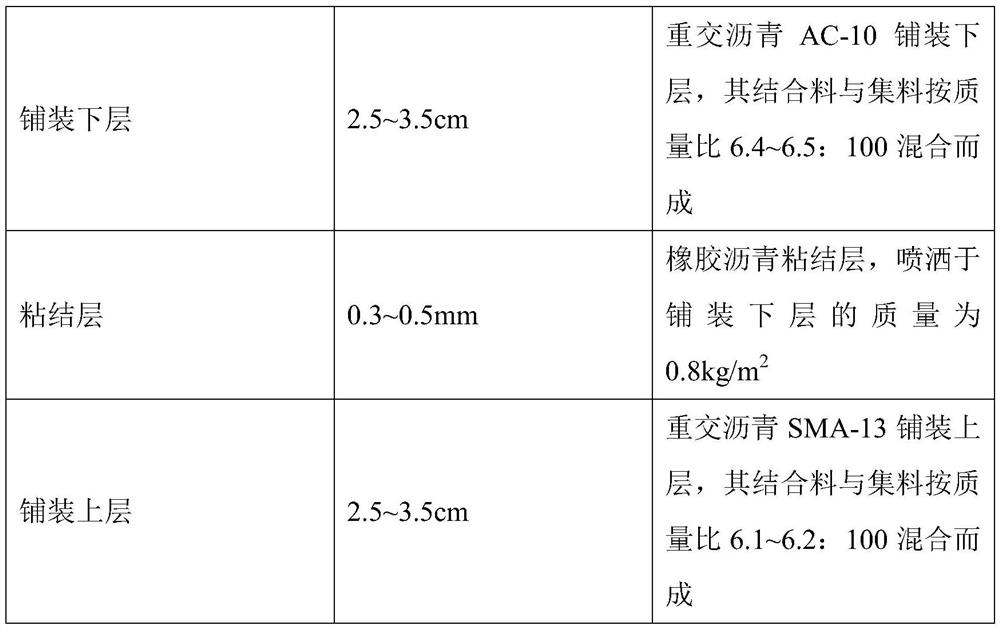

[0053] This example figure 1 As shown, it is a fatigue-resistant and rutting-resistant steel bridge deck pavement structure, which consists of a waterproof adhesive layer 1, a lower pavement layer 2, an adhesive layer 3 and an upper pavement layer 4 from bottom to top. The paving lower layer 2 is laid on the waterproof adhesive layer 1 , the adhesive layer 3 is sprayed on the paving lower layer 2 , and the paving upper layer 4 is laid on the adhesive layer 3 .

[0054] The waterproof adhesive layer 1 is an epoxy resin waterproof adhesive layer, which is composed of Japanese KD-BEP epoxy resin main agent and Japanese KD-BEP curing agent at a mass ratio of 0.5:0.5, under the temperature condition of 30±2°C After stirring for 3 minutes, spray evenly on the steel bridge deck, and the mass sprayed on the steel bridge deck is 0.9kg / m 2 , the thickness is 0.5 ~ 1.5mm. After the waterproof adhesive layer is sprayed, wait for it to solidify at room temperature for 2 to 3 hours before...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com