Lift with dual traction pulley

A technology of traction pulleys and elevators, applied to elevators in buildings, lifting equipment in mines, transportation and packaging, etc., can solve the problem of limiting the maximum size of the car and achieve the effect of limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

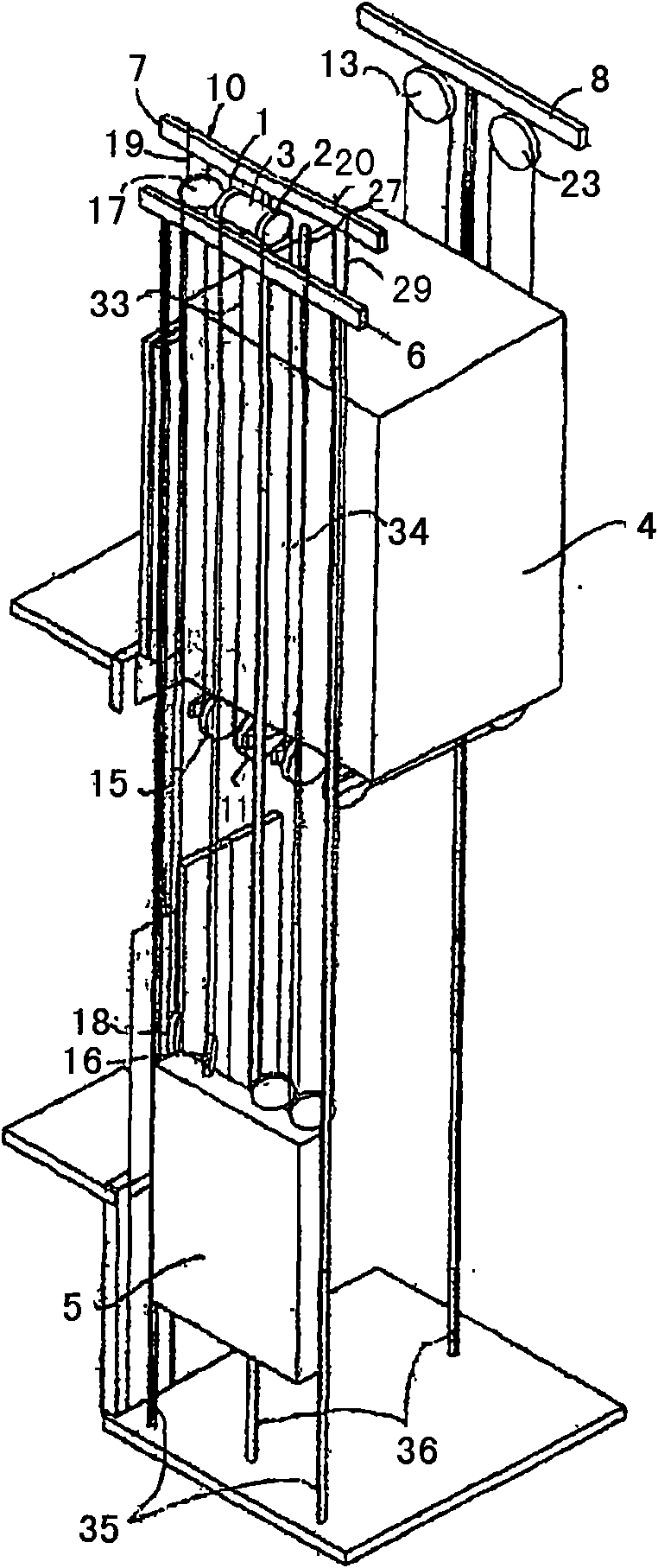

[0018] The description of the sling path shown below is illustrative, not restrictive, and represents one of many options that can be used to achieve the objects of the invention.

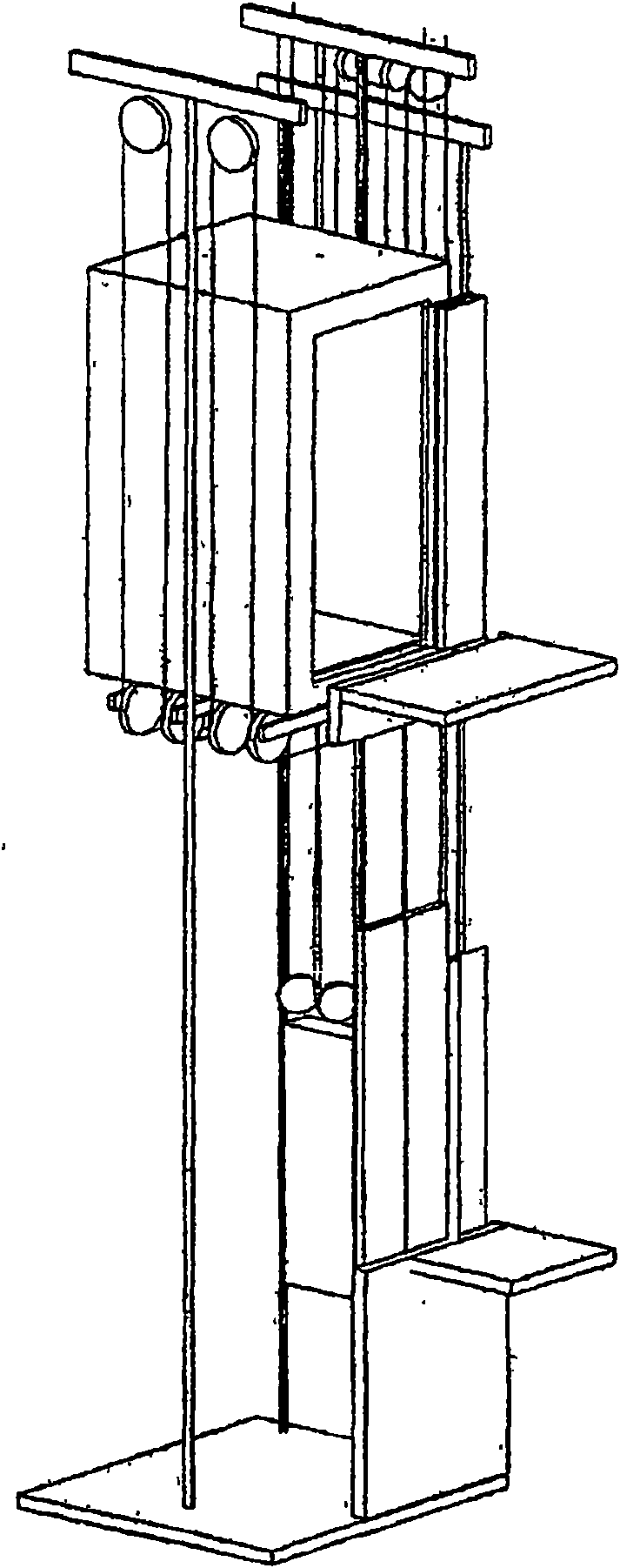

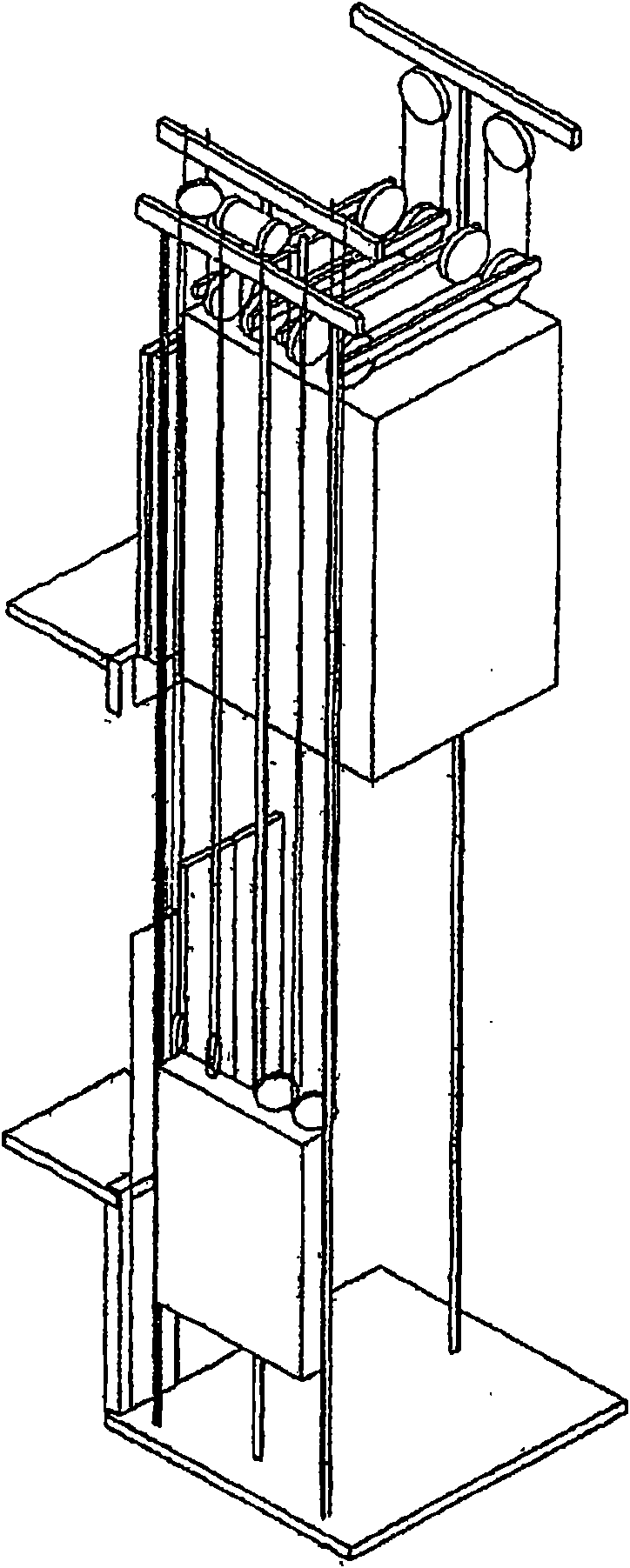

[0019] refer to figure 1 and 2 Describe the present invention, the present invention relates to a kind of suspension ratio is 1:4, is called as MRL (Machine Room Less) machine roomless elevator, wherein, counterweight 5 runs along the guide rail 35 beside car 4, and car 4 run along guide rail 36. In the shown solution, the motor 3 is arranged on the top of the counterweight 5 in the vertical direction and is supported by the support beam 6. The motor 3 has two pulleys 1 and 2, which are arranged on the opposite side of the frame of the motor. Two opposite sides of the drive shaft, with the motor positioned towards the counterweight side. The slings are divided into two groups, each group having at least one sling. In the description, only one sling of each set of slings is mentioned, namely sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com