Manufacturing method of electrostatic shielding multilayer film

A multi-layer structure, electrostatic shielding technology, applied in the fields of magnetic/electric field shielding, chemical instruments and methods, lamination, etc., can solve the limitations of saleability, the high cost of the sealable polyolefin layer 1b, and the difficulty of commercializing new materials, etc. problems, to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

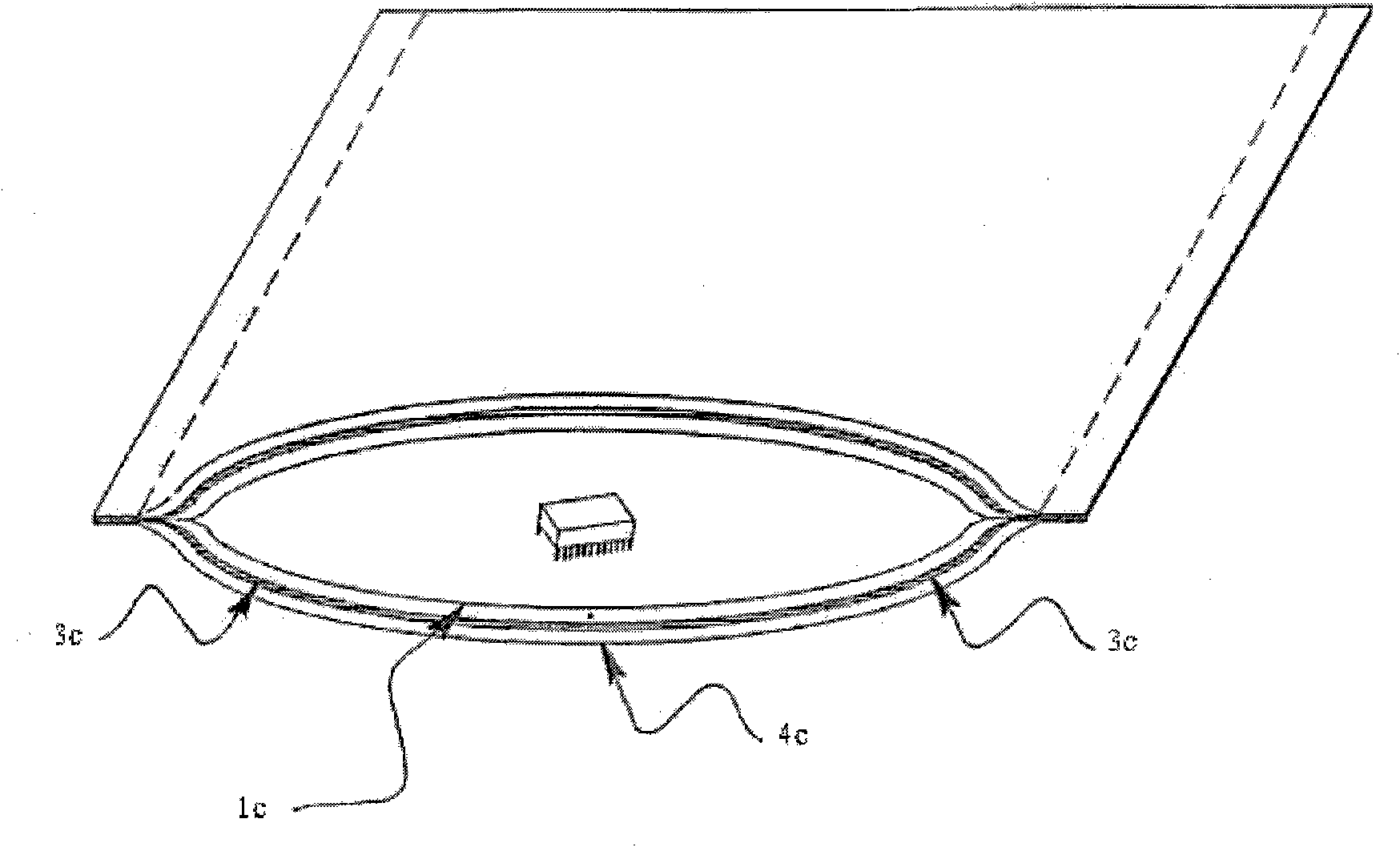

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

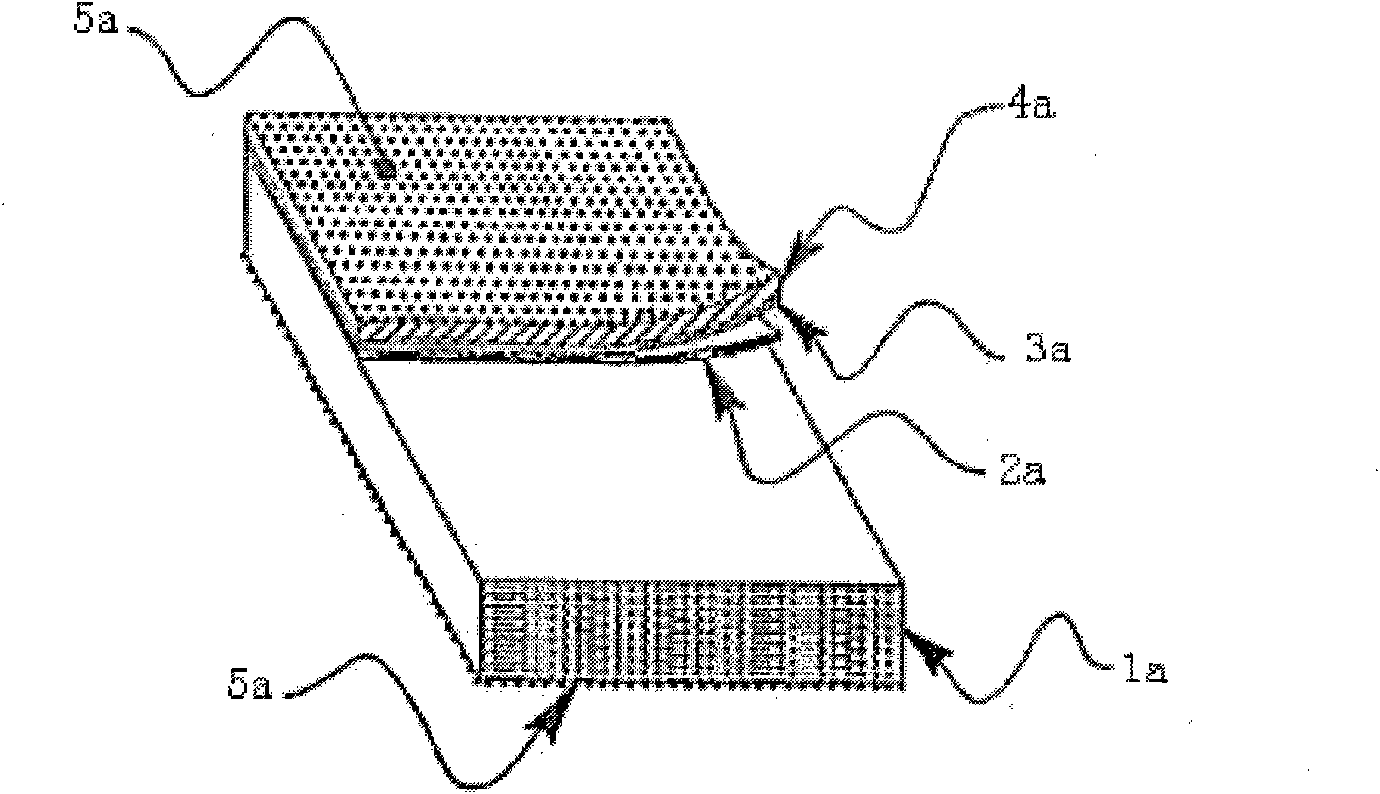

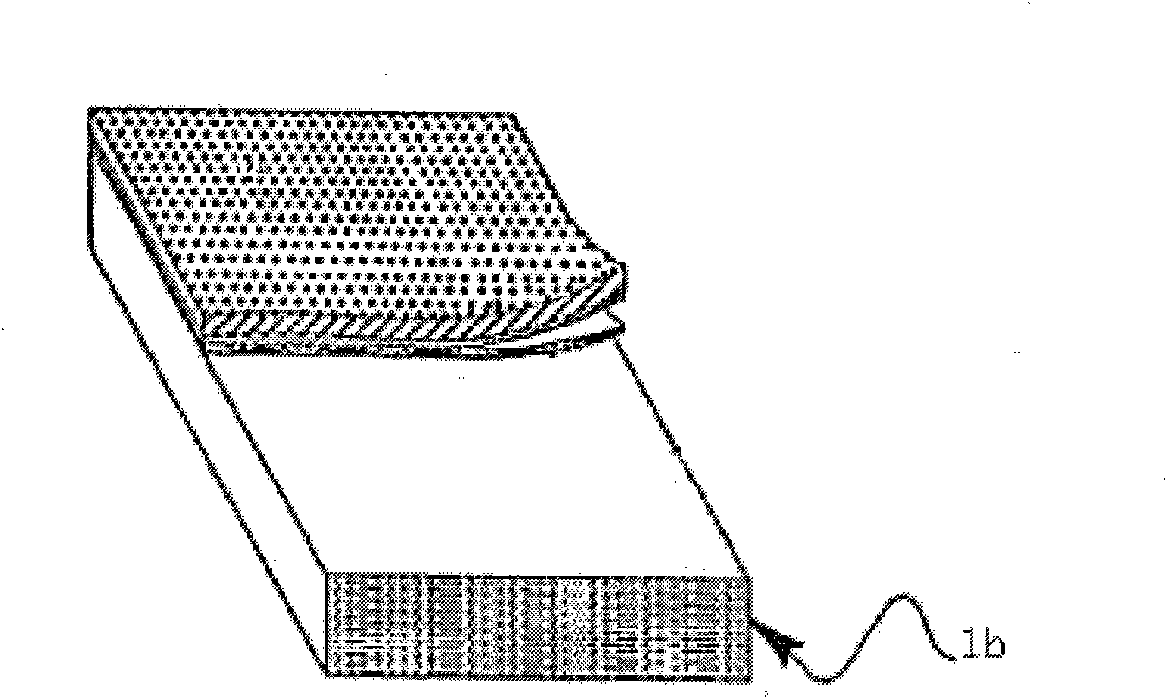

[0036] As shown in Figure 1, in order to realize the electrostatic shielding multilayer structure film of the first embodiment of the invention, the specific manufacturing method is as follows:

[0037] The polyolefin layer 1 and the innermost skin layer 6 are coextruded from two sublayers of different materials in a single blown film extruder, the coextrusion of the innermost skin layer having a thickness between 5 microns and 25 microns gives the polyolefin base layer and The innermost surface layer, wherein a permanent non-migrating antistatic chemical additive is added in the innermost surface layer, and the permanent antistatic chemical additive is a polymeric material based on polyamide / polyether block material, and the concentration of the chemical additive is 5 % to 20%, such as pelestat made by Sanyo, will give 10 7 to 10 11 ohm permanent antistatic properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com