A kind of truck wheel hub cooling system

A technology for cooling systems and trucks, applied in the direction of cooling brakes, vehicle parts, brakes, etc., can solve problems such as increased costs, insufficient small water tanks, and no water filling stations, and achieve the effect of ensuring driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

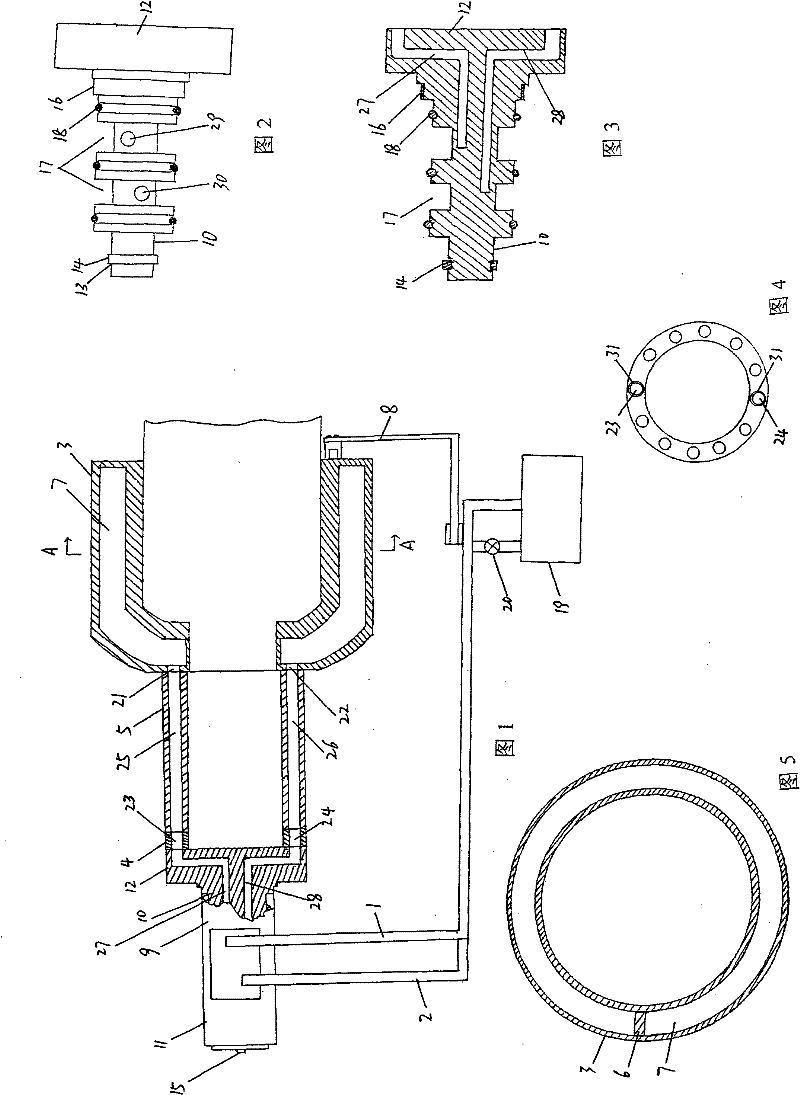

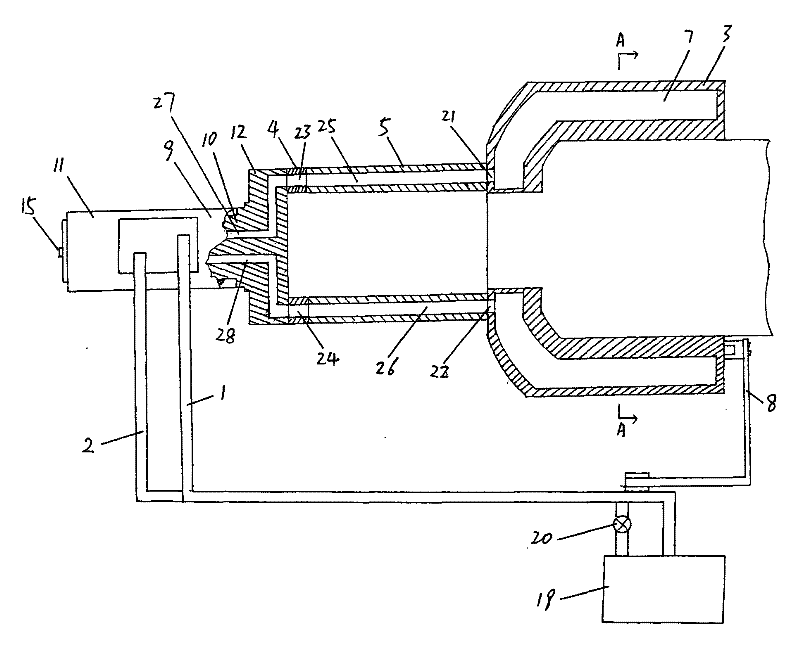

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] As shown in the figure, the present invention includes a water tank 19, a water pump 20, a water inlet pipe 1, a water outlet pipe 2, a wheel hub 3 connected in sequence, a wheel core 5, a half shaft, and a terminal connection device 9. The inside of the wheel hub 3 is provided with a cavity 7, and the side where the wheel hub 3 is connected to the wheel core 5 is provided with a cavity water inlet 21 and a cavity water outlet 22, and the cavity water inlet 21 and the cavity water outlet 22 are connected to the cavity 7. connected. The half shaft base 4 is provided with a half shaft water inlet hole 23 and a half shaft water outlet hole 24 . The side wall of the wheel core 5 is provided with a wheel core water inlet 25 and a wheel core water outlet 26, and the two ends of the wheel core water inlet 25 are respectively connected with the semi-axis wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com