Mechanical speed-increasing booster of anti-explosion diesel engine

A diesel engine, mechanical technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of insufficient compressor pressure, unable to meet the needs of diesel engines to increase power and speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

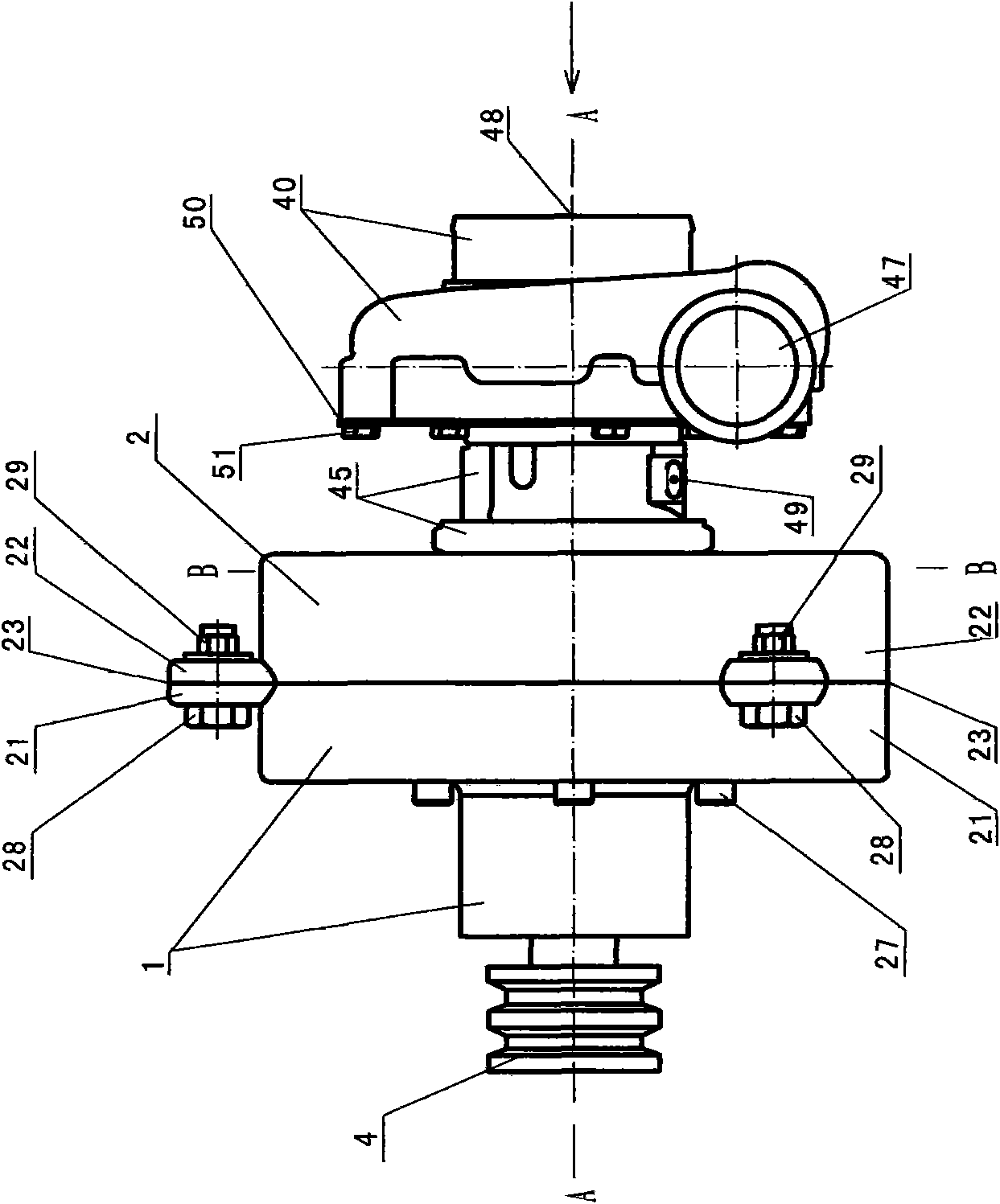

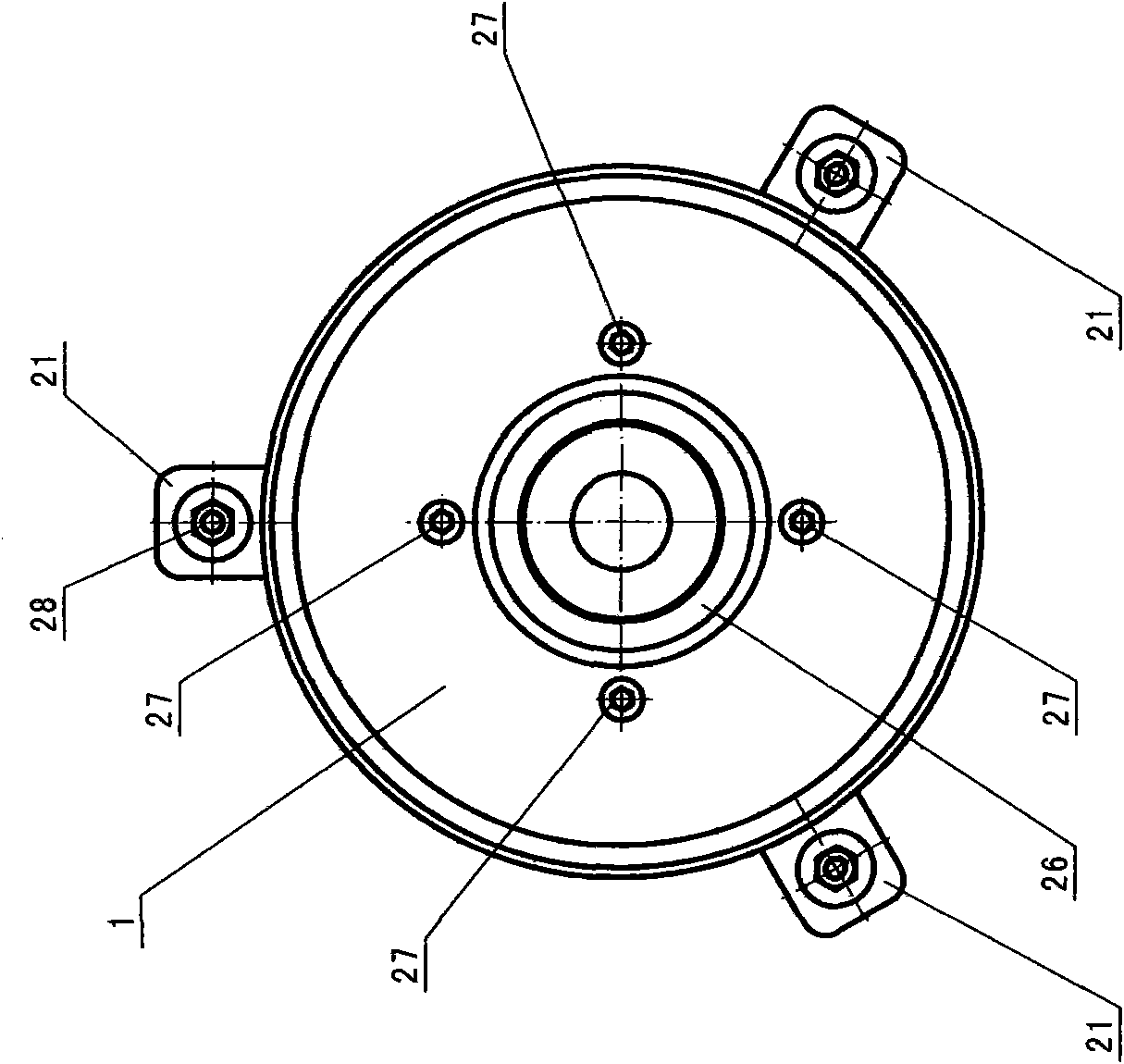

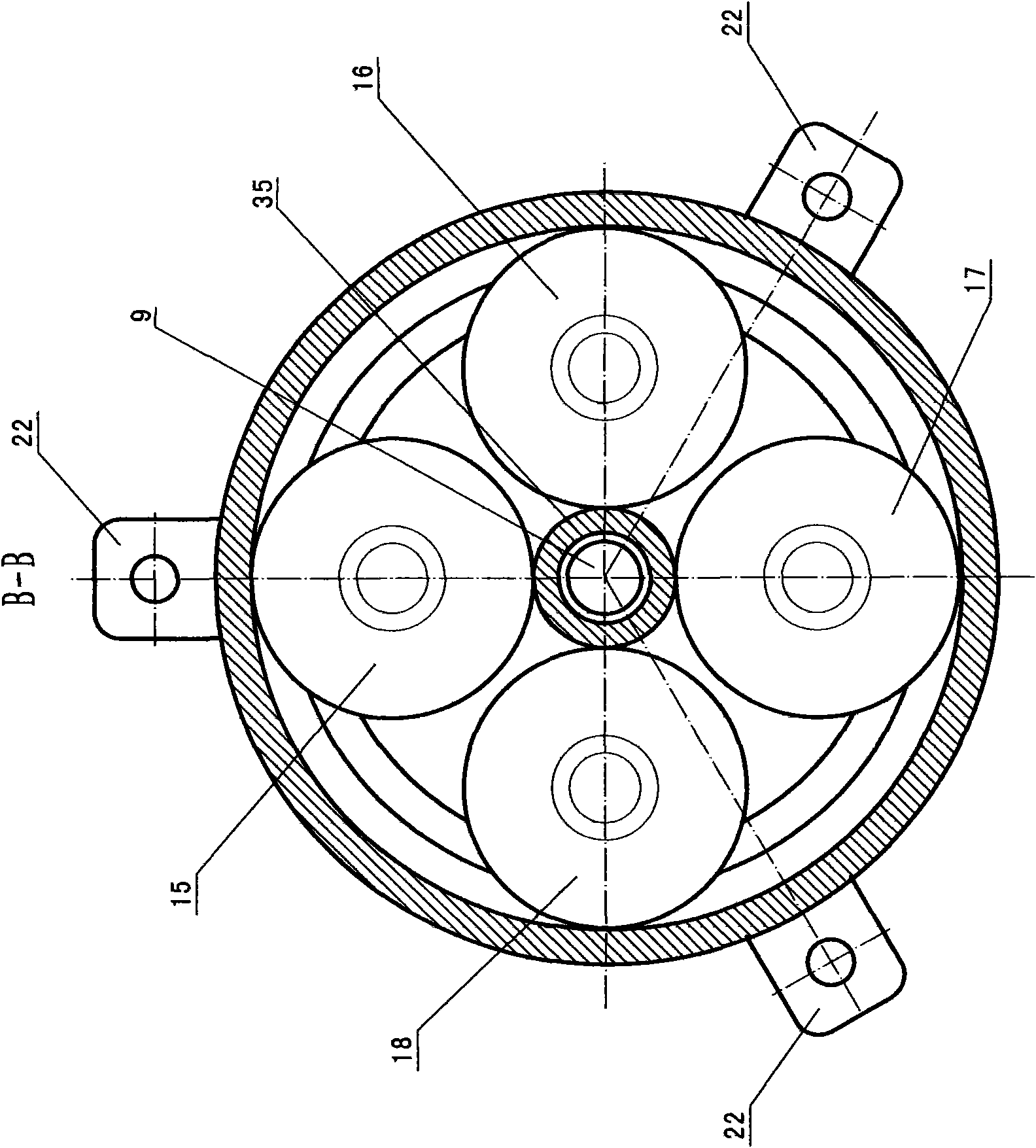

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] figure 1 , 2 , 3, and 4 show the overall structure diagram, the position and connection relationship of each part must be correct, and the installation should be firm.

[0023] The left and right boxes should be strictly sealed and fully lubricated without oil leakage.

[0024] The planetary chambers in the left and right boxes should be clean, and the planetary gears, sun gears, and ring gears in them should mesh accurately and rotate flexibly.

[0025] The left and right boxes, compressor casing, gears, pulleys, planetary carrier, and inner ring gear should have good strength, and should be made of alloy structural steel and hardened.

[0026] The transmission speed ratio of inner ring gear, double planetary gear and sun gear is 24:1.

[0027] The connection between the compressor and the sun gear shaft must be firm, and the inner impeller of the compressor mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com