Liquid control valve with double control ports

A technology of mouth fluid and valve body, applied in the hydraulic field, can solve the problems of increasing the complexity, volume and cost of the system, and achieve the effect of reducing the complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

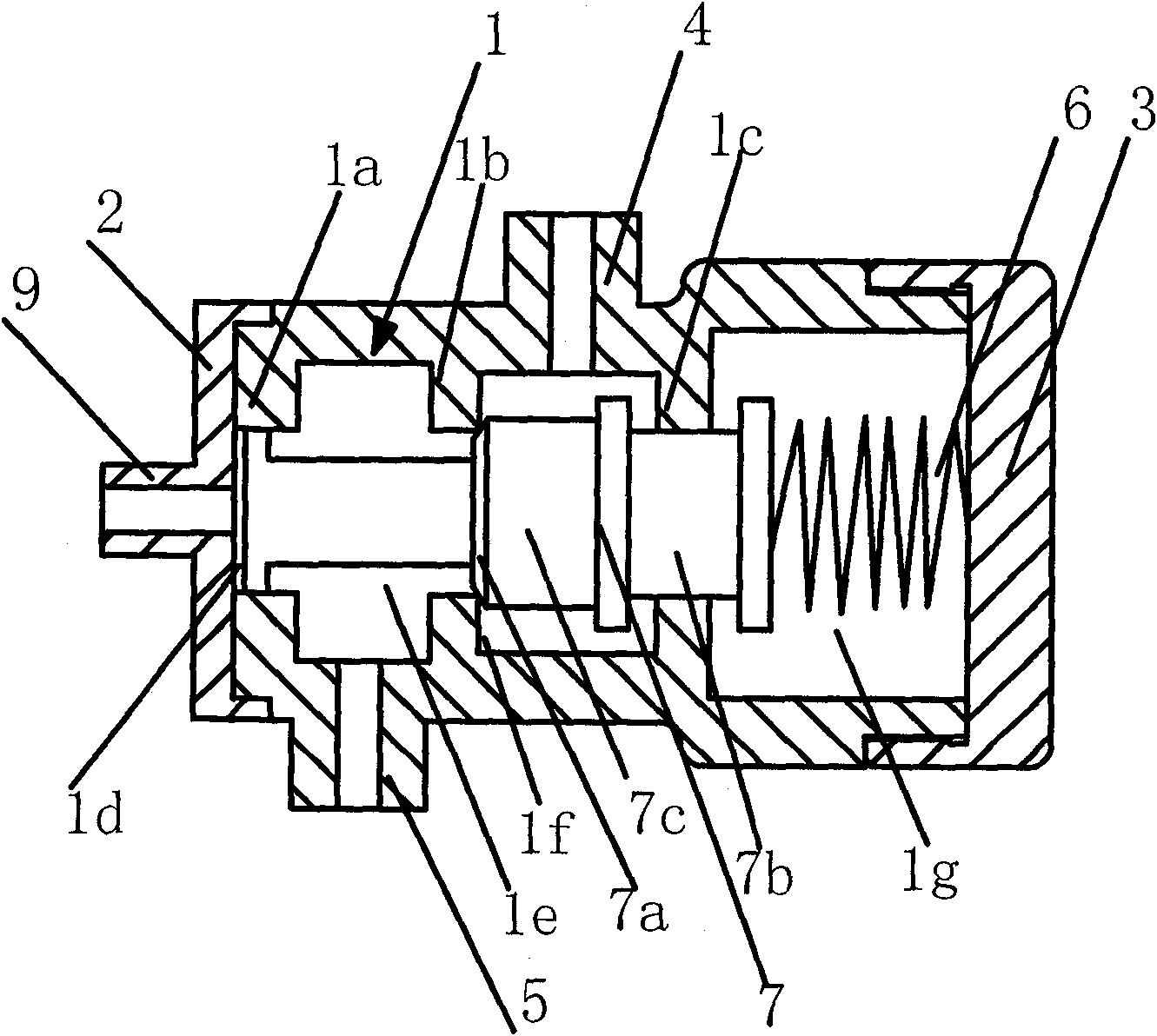

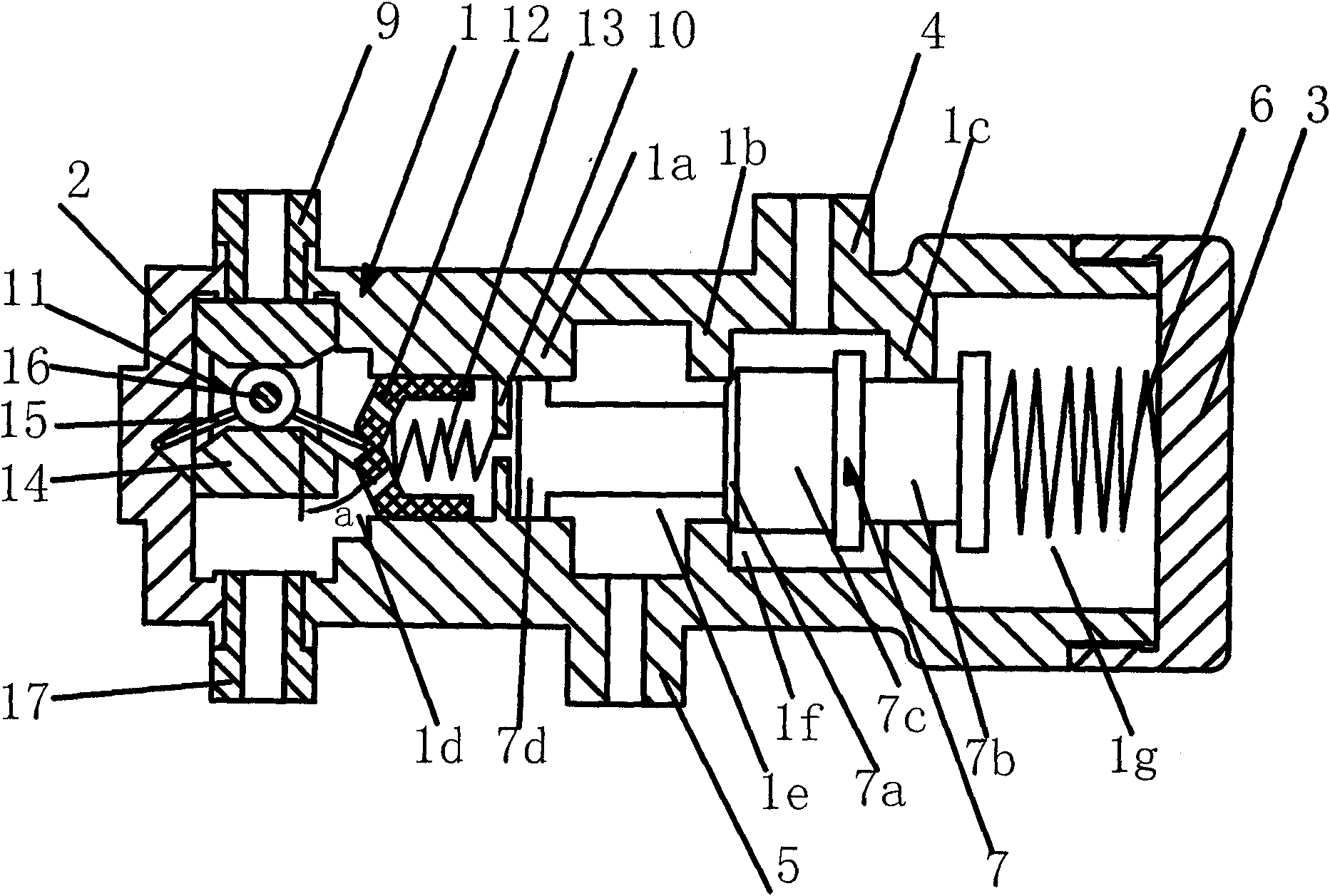

[0008] The present invention will be described in further detail below. see figure 1 , a double control port hydraulic control valve, including a shell composed of a valve body 1 with a central hole through the left and right end faces, a left end cover 2 and a right end cover 3, the left end cover 2 and the left port of the valve body 1 are connected by screws or threads Connection, the right end cover 3 is connected with the right port of the valve body 1 by screws or threads, and there are first annular boss 1a, second annular boss 1b and third annular boss arranged in sequence from left to right in the valve body 1 1c, the above three annular bosses divide the inner chamber of the valve body 1 into four parts, from left to right are the control chamber 1d, the first oil inlet and outlet chamber 1e, the second oil inlet and outlet chamber 1f and the spring chamber 1g, the first One inlet and outlet nozzle 5 communicates with the first inlet and outlet chamber 1e, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com