Construction method of large-cantilever inclined-web wide-width box girder

A construction method and inclined web technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problem of low lateral bending load-bearing capacity of box girder structures, and achieve the goal of improving sewage interception effect, reducing difficulty, and reducing pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

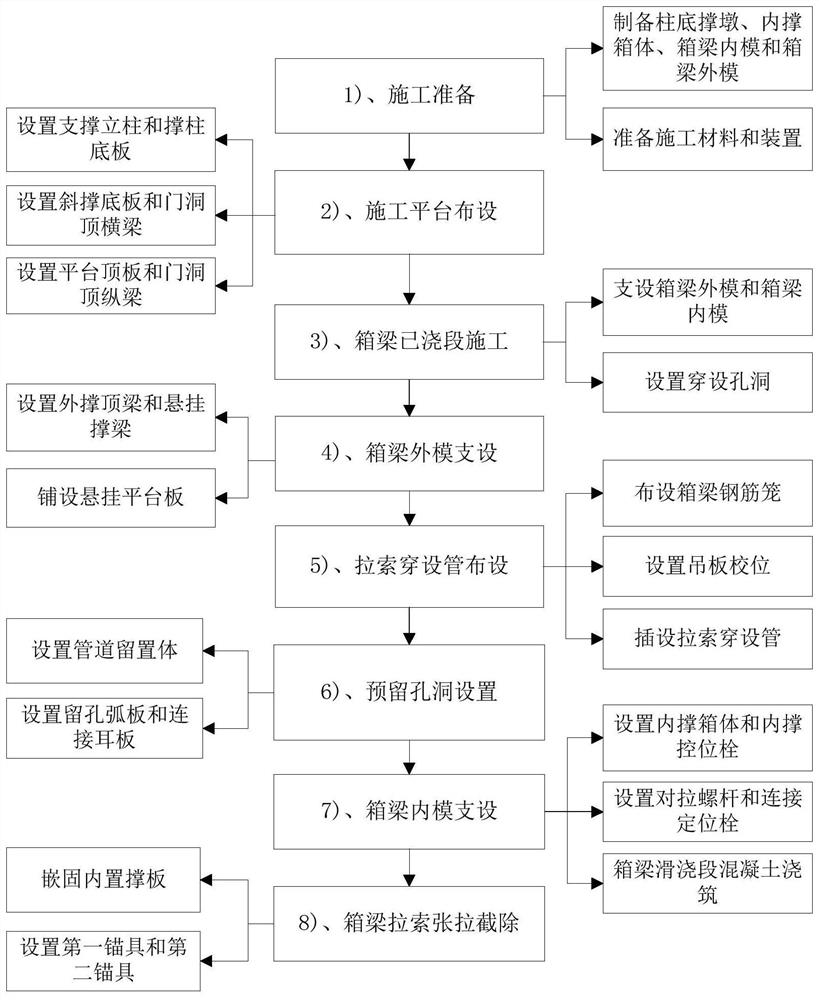

[0038] figure 1 It is the construction flow chart of the construction method of the large cantilever inclined web wide box girder of the present invention, with reference to figure 1 As shown, the construction method of large cantilever inclined web wide box girder includes the following construction steps:

[0039] 1) Construction preparation: prepare the column bottom pier 2, the inner support box 64, the box girder inner formwork 25 and the box girder outer formwork 24, and prepare the materials and devices required for construction;

[0040] 2) Layout of the construction platform: Set up the column bottom support pier 2 on the foundation soil body 1, and insert the bottom end of the support column 3 into the column connection groove 4 on the upper surface of the column bottom support pier 2, and connect the support column through the bottom plate anchor bolt 5 The bottom plate 6 is firmly connected with the pier 2 at the bottom of the column; grouting is injected into the...

Embodiment 2

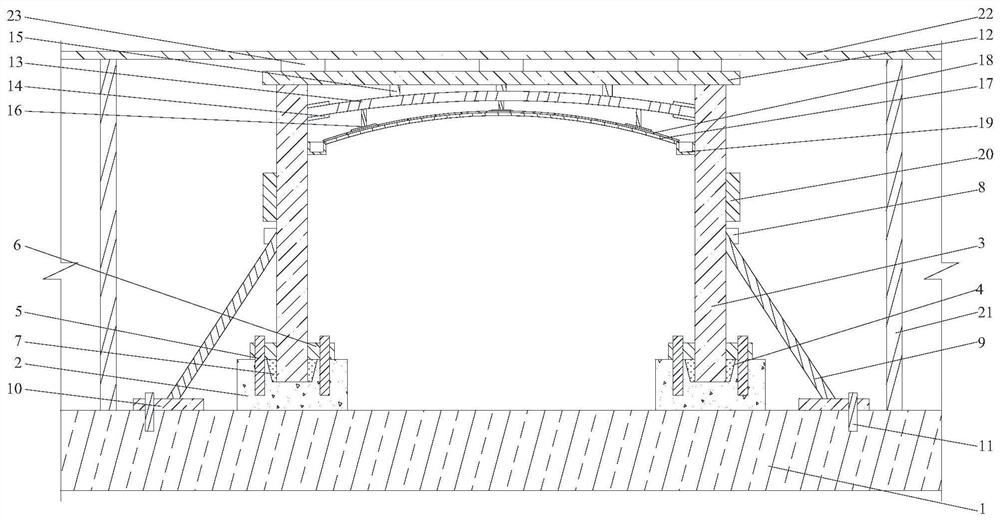

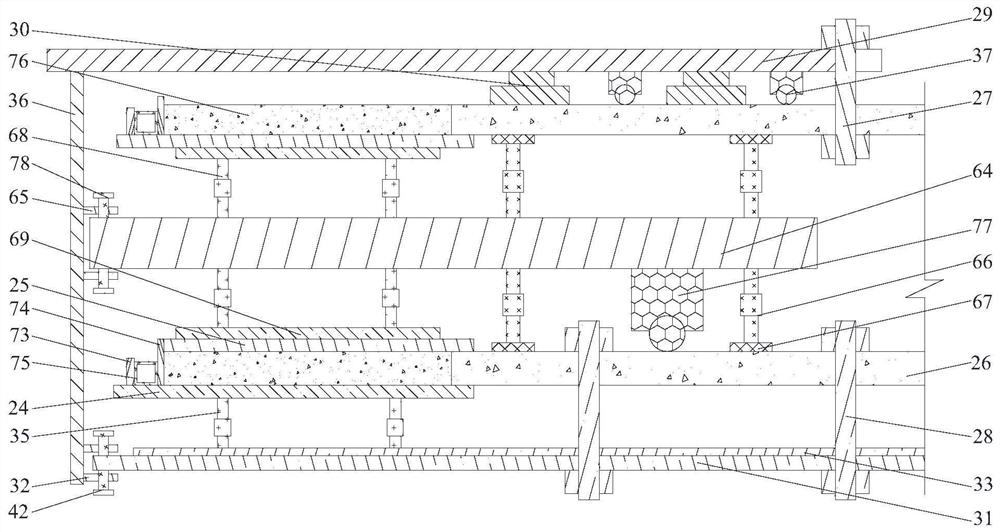

[0048] refer to Figure 2-Figure 7 As shown, for a wide box girder with a large cantilever oblique web, the support column 3 is embedded in the column connection groove 4 on the upper surface of the pier 2 at the bottom of the column, and is connected through the anchor bolt 5 of the bottom plate and the closing body 7 at the bottom of the column; The top of the support column 3 is provided with an upwardly convex doorway top beam 12, a rigid support net 17 and a flexible waterproof cloth 18; a suspension support beam 31 is provided below the casted section 26 of the box girder, and in the box girder cavity of the casted section 26 of the box girder Set the inner support box 64; adopt the assembled inner wall side formwork 60; control the horizontal position of the arc plate positioning rib 50 and the positioning arc plate 48 through the hanging plate alignment bolt 47, and control the positioning of the hanging plate 46 and the positioning arc plate 48 through the hanging plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com