High-power LED lamp

An LED lamp, high-power technology, used in the cooling/heating device, lighting and heating equipment, electrical components and other directions of lighting devices, can solve the problems of short service life, pollute the environment, easy to damage, etc., to improve the heat dissipation effect, volume Small, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

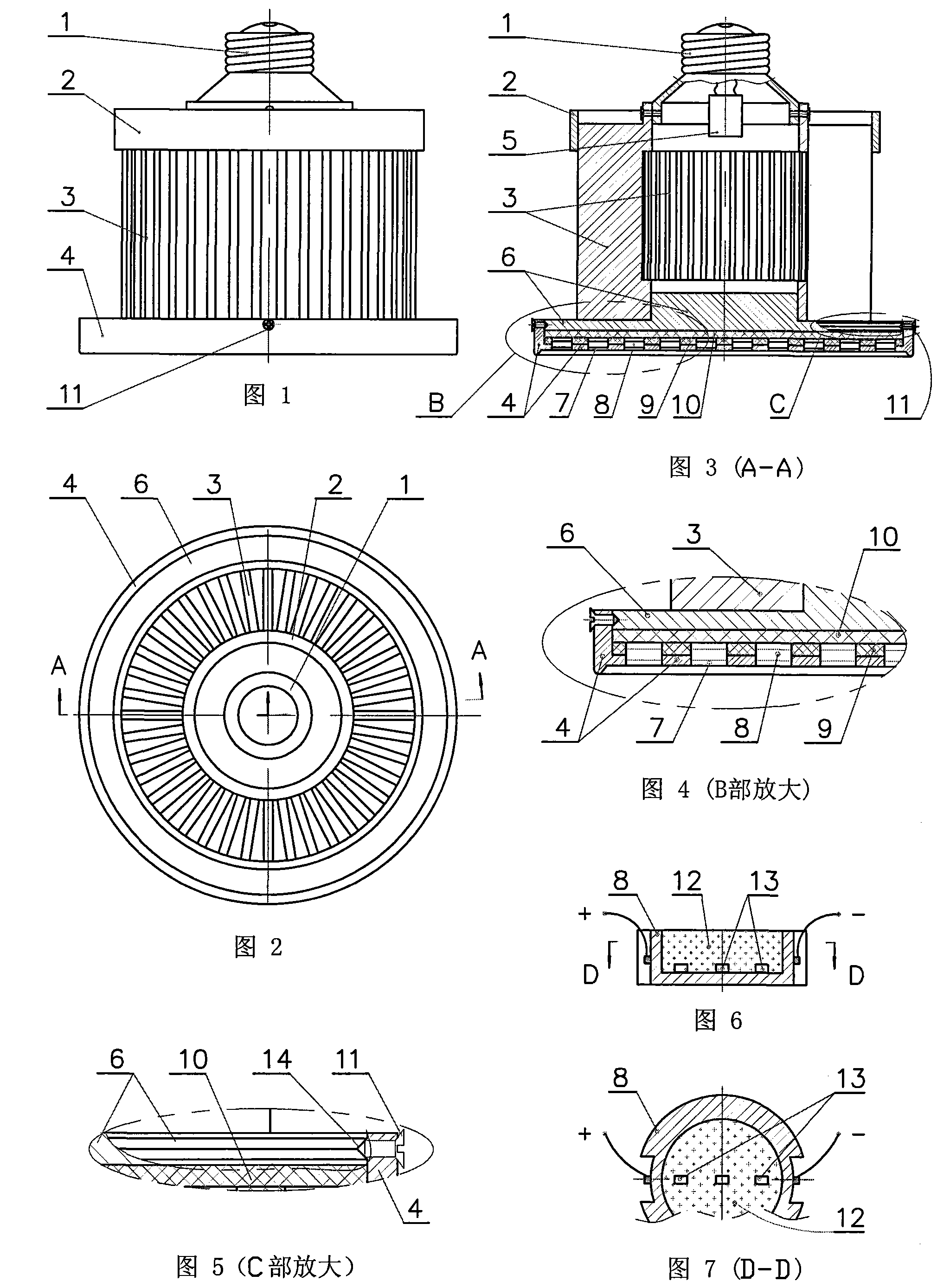

[0016] Example 1 as figure 1 Shown in -7: a high-power LED lamp, including a lamp cap 1 and a constant current drive circuit board 5 located therein, a heat sink 3, a thermally conductive insulating sheet, a reflector 4 and an LED chip packaging bracket 8; the heat sink 3 is It consists of the upper part and the lower part of the inner cavity respectively connected into one, and the metal sheets arranged radially upright to form a cylinder. The heat dissipation tube 3 is positioned and connected with the lamp head 1; the inner diameter of the middle part of the cylindrical inner cavity of the heat dissipation tube 3 is larger than the inner diameter of the upper end and the lower end. , There is a gap between the metal sheets in the middle of the inner cavity of the cooling tube 3, and they are not close to each other. The inner cavity of the cooling tube 3 is transparent to the outer wall through the gap between the metal sheets arranged radially upright, so as to facilitate a...

Embodiment 2

[0017] Embodiment 2: A high-power LED lamp as described in Embodiment 1, the apron at the bottom of the heat-conducting bottom plate 6 is rectangular. The LED chip 13 and the fluorescent powder and the silica gel mixture 12 covering the LED chip 13 are placed in the LED chip packaging bracket 8. The bottom area of the fluorescent powder and the silica gel mixture 12 coverage area is 20 times the surface area of the LED chip 13, which can be greatly improved. Improve luminous efficiency and reflective efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com