Numerical control and energy saving bean-product forming machine

A bean product and molding machine technology, applied in the field of numerical control energy-saving bean product pressing and molding machine, can solve the problems of high labor intensity, unscientific control of extrusion force, uneven thickness of bean products, etc., and achieves a simple structure and a degree of automation. High, quality and productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing:

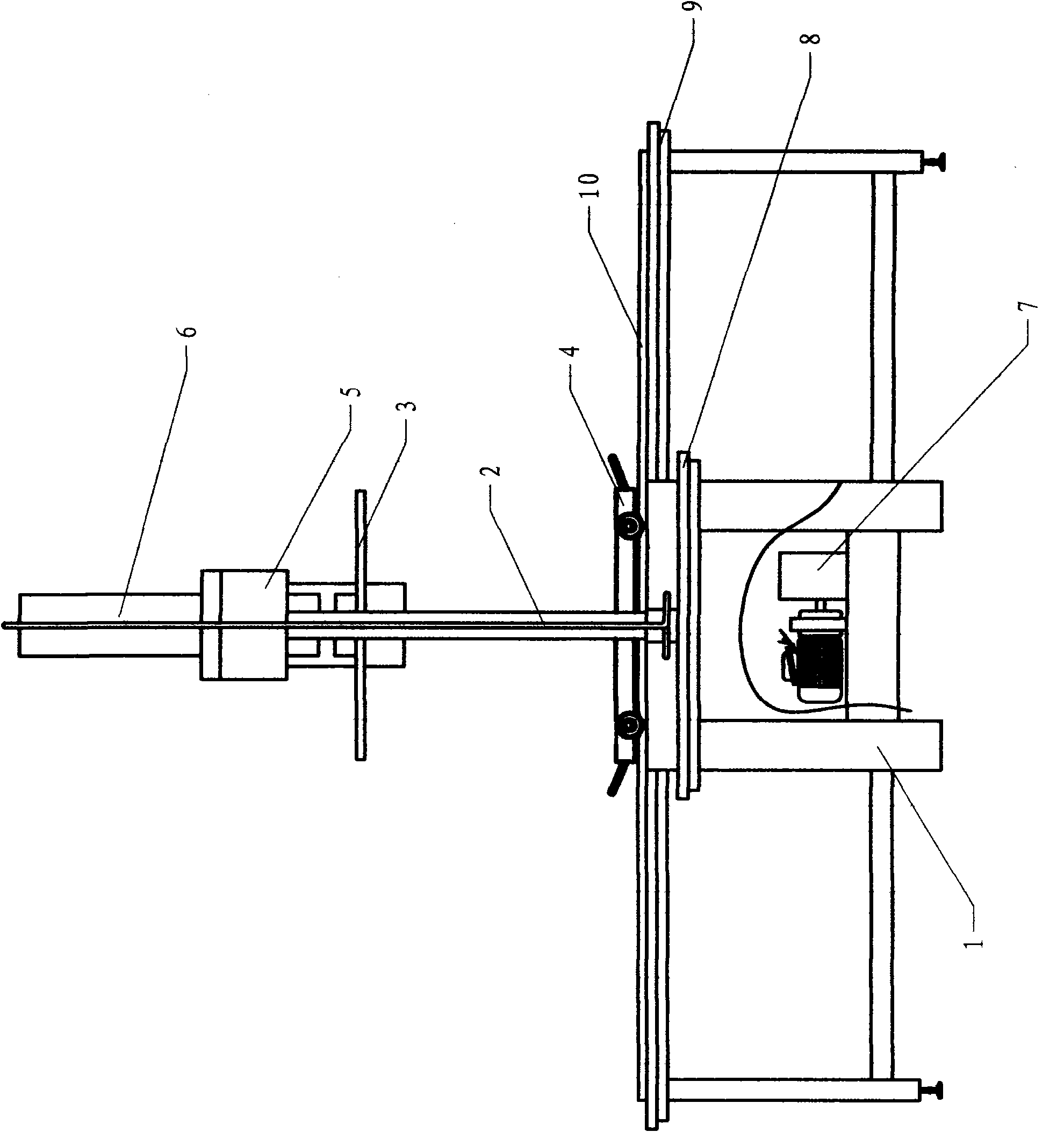

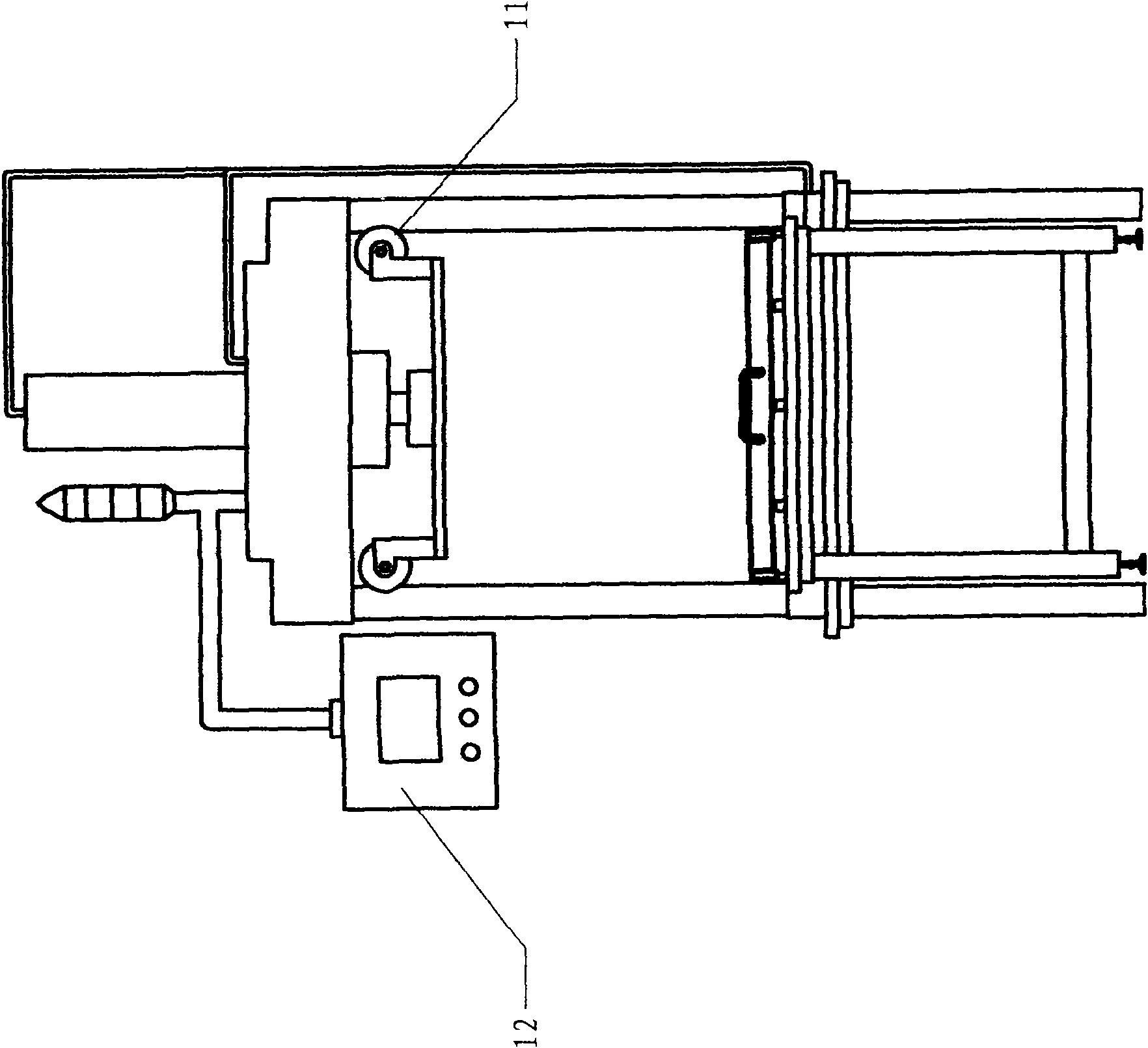

[0012] The numerically controlled energy-saving bean product press molding machine includes a workbench base 1, two front and rear columns 2 fixedly arranged at the front and rear ends of the workbench base 1, an upper beam 5 fixedly arranged at the upper ends of the front and rear two columns 2, and an electric control box 12, An independent hydraulic pump 7 is fixedly arranged in the base of the workbench 1, and an oil cylinder 6 is fixedly arranged on the upper beam 5. The two ends of the oil cylinder 6 are respectively provided with an upper oil pipe and a lower oil pipe, and the upper oil pipe and the lower oil pipe are respectively provided with There is an electric control valve electrically connected with the electric control box 12, and an oil pressure sensor is arranged on the oil pipe, and the oil pressure sensor is electrically connected with the electric control box 12, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com