Pure electric vehicle power assembly system

A pure electric vehicle and powertrain technology, applied in electric vehicles, electric power devices, electric traction, etc., can solve the problem that a single motor cannot meet the requirements of vehicle acceleration performance and maximum speed at the same time, so as to improve the utilization rate, extend the The effect of driving mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

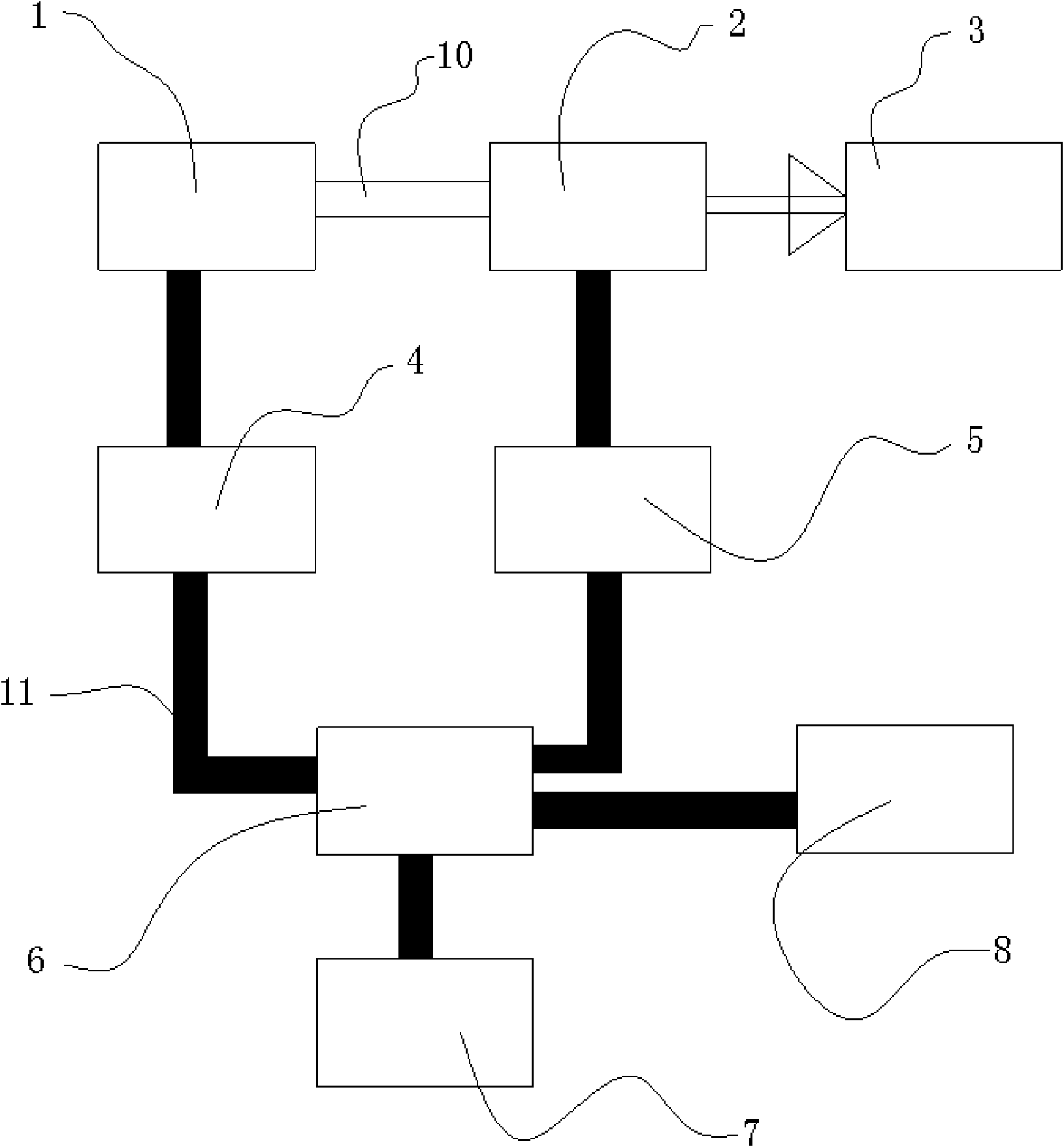

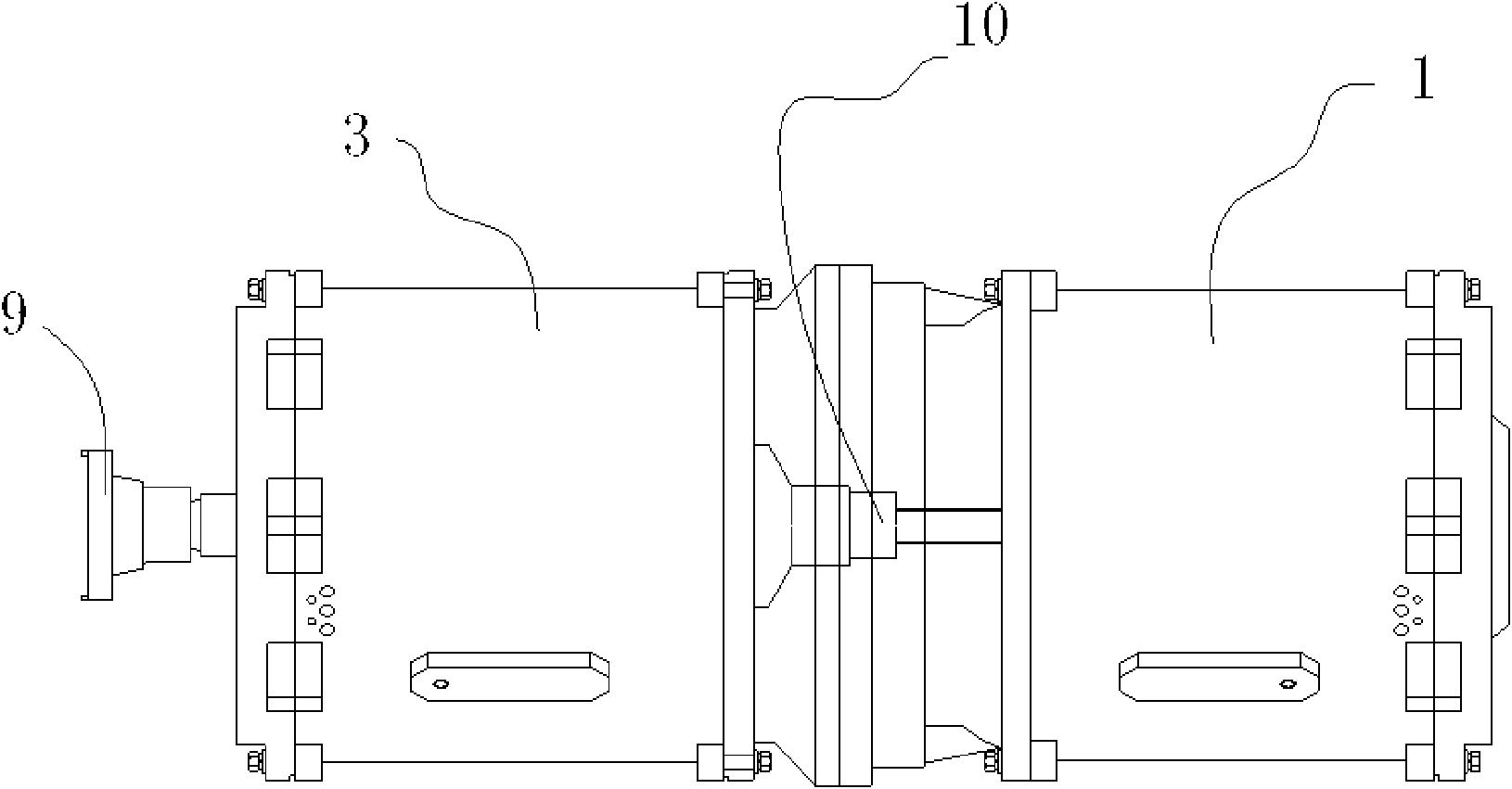

[0018] Embodiment: a kind of pure electric vehicle power assembly system (referring to appendix figure 1 attached figure 2 ), the assembly system is set on the electric bus, the front axle is the steering axle, which adopts electric power steering, the rear axle is the drive axle, and the pure electric dual-motor power drive system is used. The assembly system mainly includes two motors and a power battery. One motor is a high-speed motor 1, and the other motor is a low-speed motor 2. The high-speed motor and the low-speed motor are connected by a spline shaft 10. The high-speed motor and the low-speed motor are coaxially arranged. The high-speed motor and the low-speed motor are respectively connected to motor controllers. , the motor controller is divided into two types, one is that the high-speed motor controller 4 is connected with the high-speed motor through a cable 11, and the other is that the low-speed motor controller 5 is connected with the low-speed motor through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com