Method for preparing barium titanate nano-powder

A technology of nano-powder and barium titanate, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of difficult separation and control of products, many impurities, and high cost, and achieve shortened preparation cycle, simple production process, and high cost. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

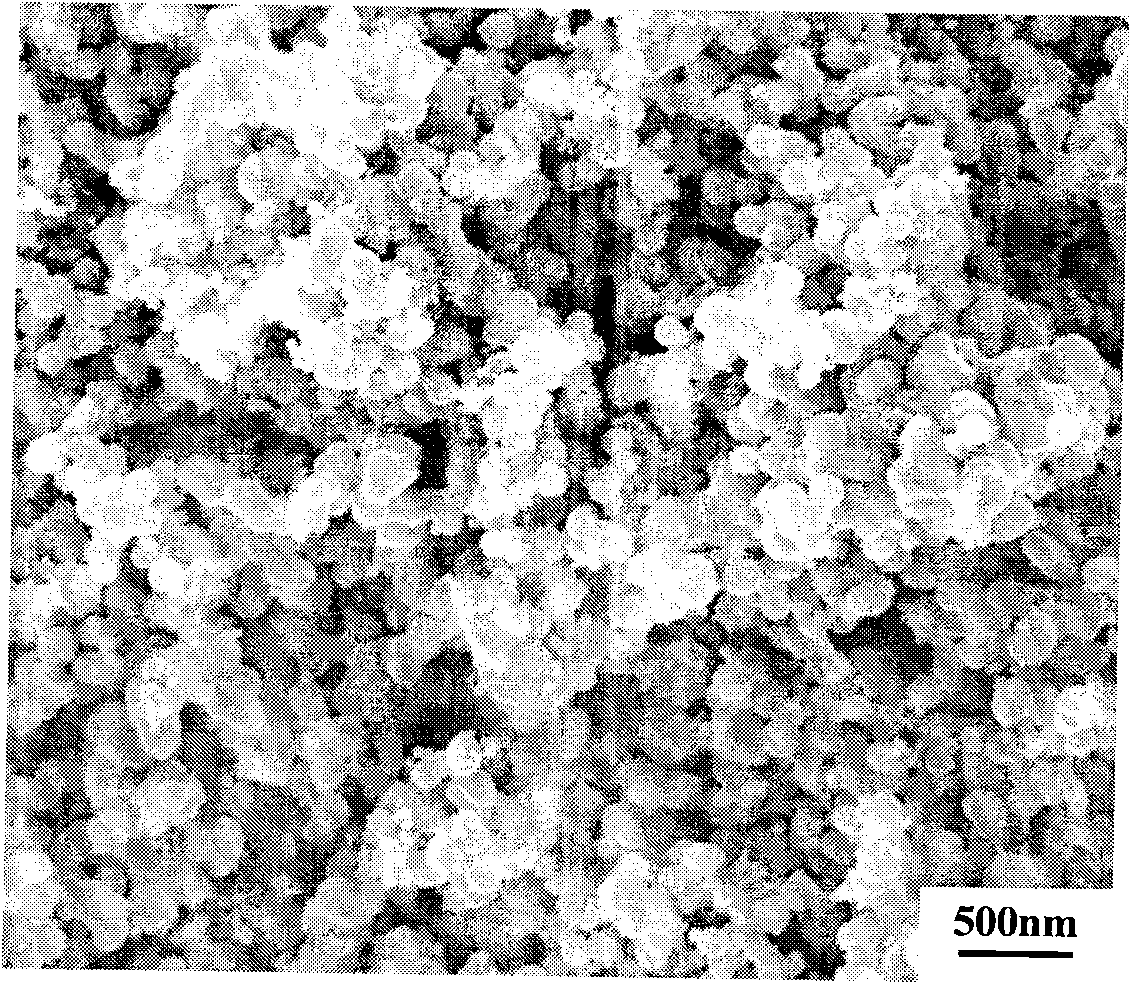

Image

Examples

Embodiment 1

[0013] 1) Dissolving citric acid in absolute ethanol, the amount of absolute ethanol is based on the amount of citric acid that can be dissolved, and then adding butyl titanate to the absolute ethanol solution dissolved in citric acid, stirring and dissolving to prepare solution 1, wherein, Butyl titanate: the mol ratio of citric acid=1: 1.5;

[0014] 2) dissolving citric acid in ammonia water and then adding barium acetate to prepare solution 2, the amount of ammonia water is based on the ability to dissolve citric acid, wherein barium acetate: citric acid=1: 2 molar ratio;

[0015] 3) Mix solution 1 and solution 2 according to the molar ratio of butyl titanate and barium acetate as 1:1, heat to 60° C. and stir, then add polyethylene glycol three times the mass of citric acid to prepare a precursor solution;

[0016] 4) Evaporate the precursor solution in a water bath at 80°C to a wet gel, transfer it to an oven to dry and foam at 140°C to form a xerogel;

[0017] 5) Put the...

Embodiment 2

[0020] 1) Dissolving citric acid in absolute ethanol, the amount of absolute ethanol is based on the amount of citric acid that can be dissolved, and then adding butyl titanate to the absolute ethanol solution dissolved in citric acid, stirring and dissolving to prepare solution 1, wherein, Butyl titanate: the molar ratio of citric acid=1:2;

[0021] 2) dissolving citric acid in ammonia water and then adding barium acetate to prepare solution 2, the amount of ammonia water is based on the ability to dissolve citric acid, wherein barium acetate: citric acid=1: 1 molar ratio;

[0022] 3) Mix solution 1 and solution 2 according to the molar ratio of butyl titanate and barium acetate as 1:1, heat to 50°C and stir, then add polyethylene glycol twice the mass of citric acid to prepare a precursor solution;

[0023] 4) Evaporate the precursor solution in a water bath at 80°C to a wet gel, transfer it to an oven to dry and foam at 130°C to form a xerogel;

[0024] 5) Put the dry gel ...

Embodiment 3

[0026] 1) Dissolving citric acid in absolute ethanol, the amount of absolute ethanol is based on the amount of citric acid that can be dissolved, and then adding butyl titanate to the absolute ethanol solution dissolved in citric acid, stirring and dissolving to prepare solution 1, wherein, Butyl titanate: the mol ratio of citric acid=1: 1.8;

[0027] 2) dissolving citric acid in ammonia water and then adding barium acetate to prepare solution 2, the amount of ammonia water is based on the ability to dissolve citric acid, wherein barium acetate: citric acid = 1: 1.5 molar ratio;

[0028] 3) Mix solution 1 and solution 2 according to the molar ratio of butyl titanate and barium acetate as 1:1, heat to 55°C and stir, then add polyethylene glycol 2.5 times the mass of citric acid to prepare a precursor solution;

[0029] 4) Evaporate the precursor solution in a water bath at 80°C to a wet gel, transfer it to an oven to dry and foam at 138°C to form a xerogel;

[0030] 5) Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com