Denim foam arranging device

A technology of foam finishing and denim, which is applied in fiber processing, textiles and papermaking, etc., can solve the problem of uneven treatment liquid, achieve the effect of flexible and simple control, and reduce production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

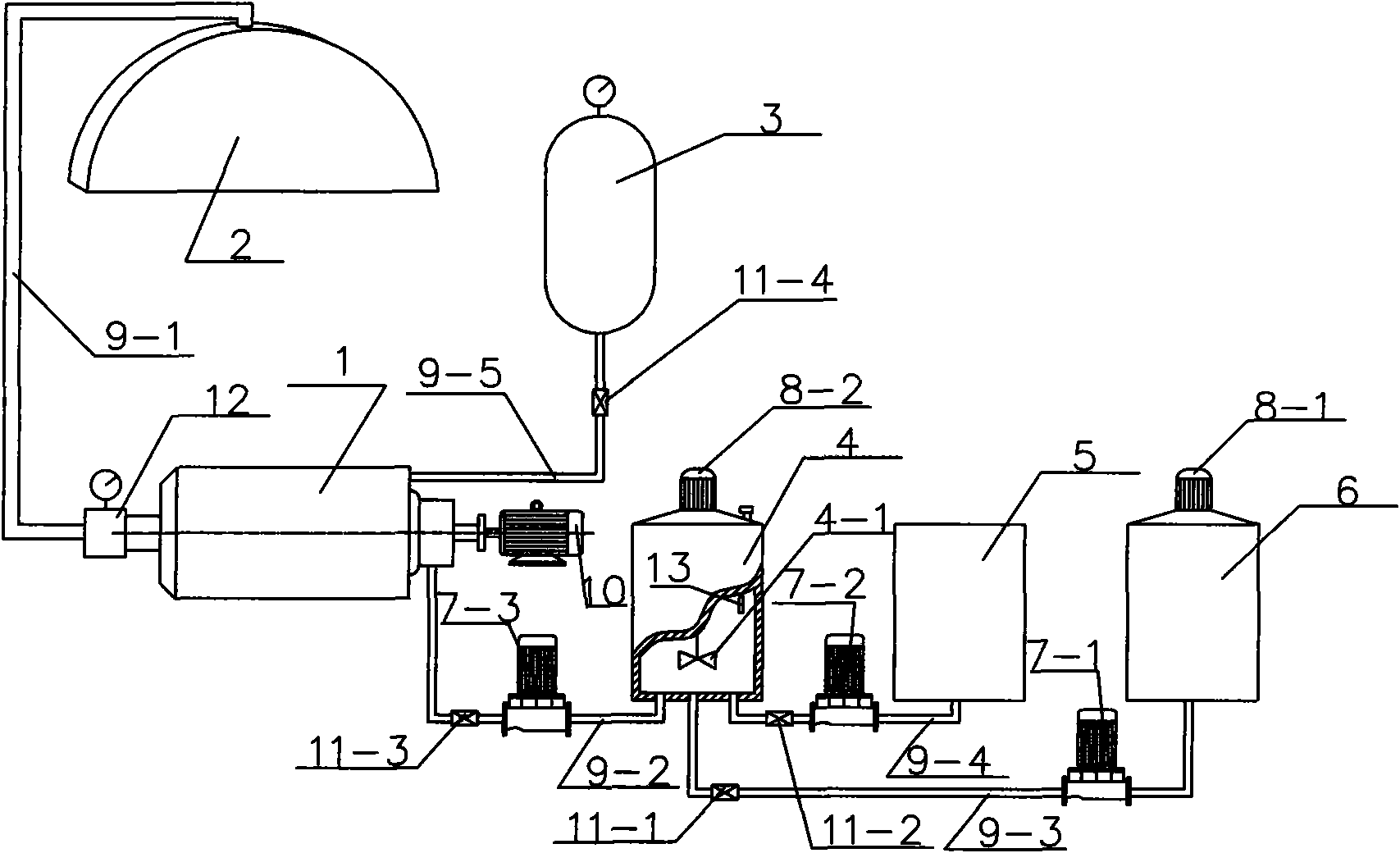

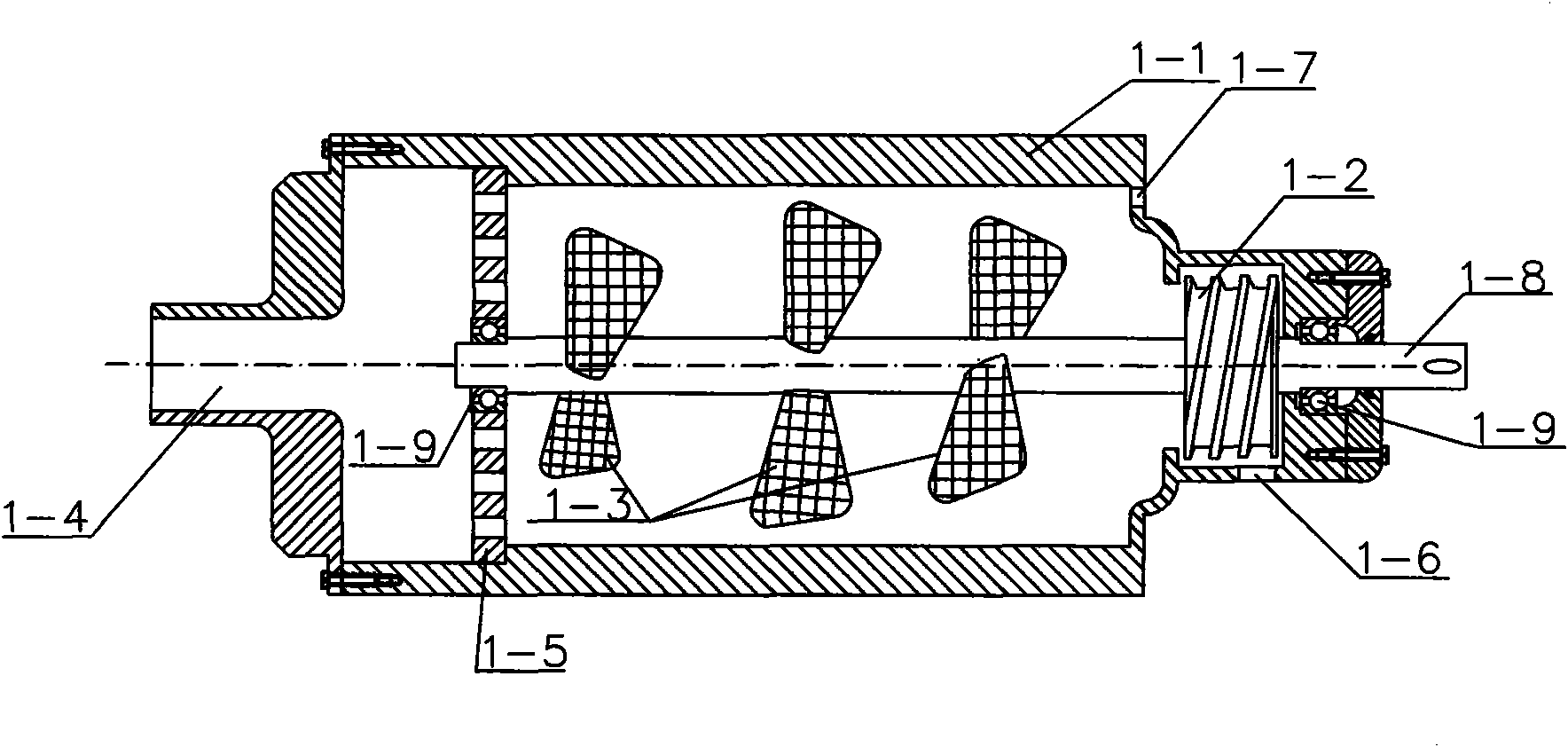

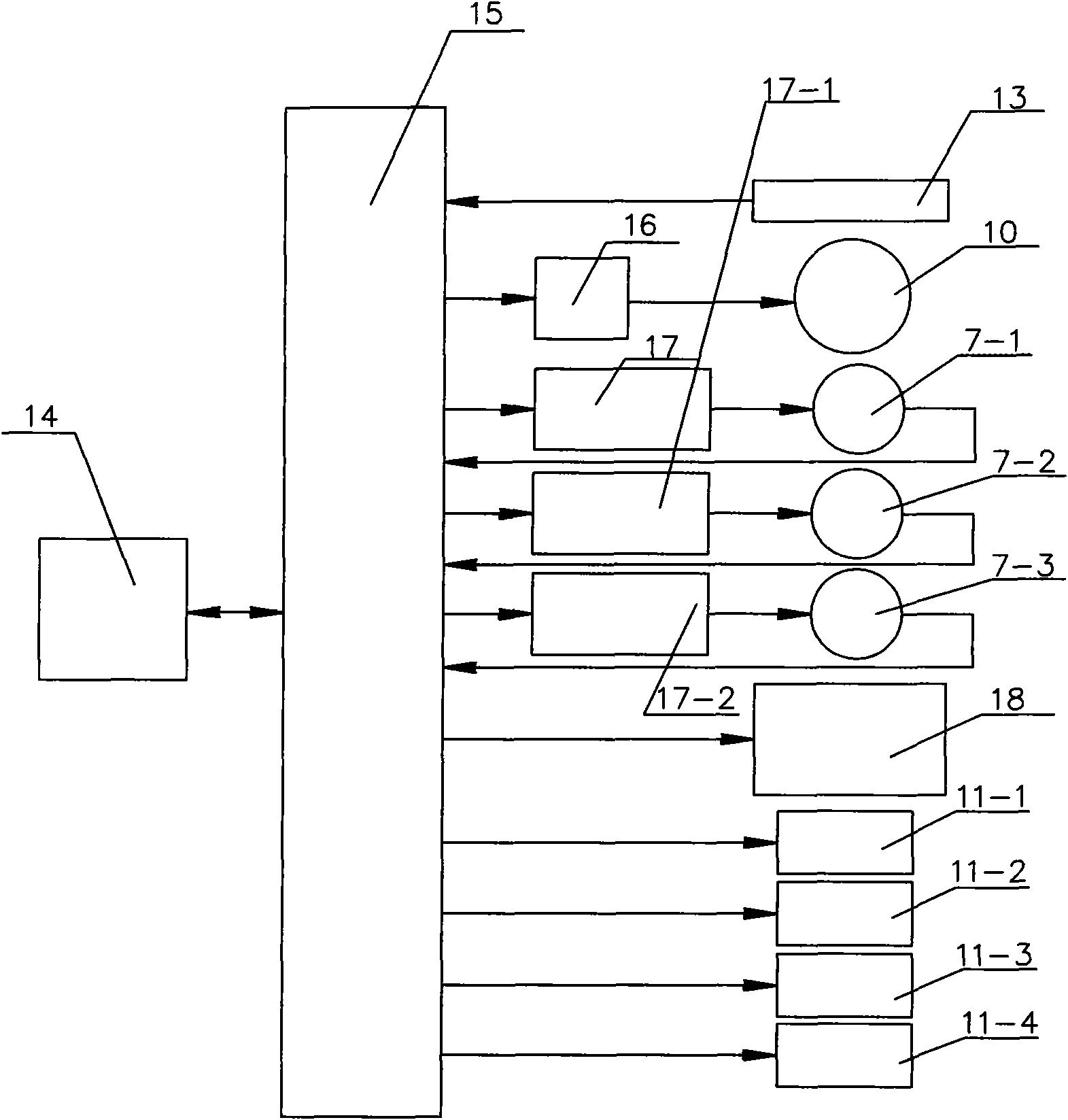

[0011] This embodiment adopts the following technical solutions: it is composed of dynamic foaming machine 1, foam applicator 2, constant pressure gas tank 3, mixing tank 4, foaming agent storage tank 5, treatment liquid storage tank 6, liquid pump 7 , high-precision metering pump 7-1~7-3, stirring motor 8-1~8-2, pipeline 9-1~9-5, frequency conversion motor 10, solenoid valve 11-1~11-4, flow meter 12 and The liquid concentration monitor 13 is composed of; the upper end of the processing liquid storage tank 6 is equipped with a stirring motor 8-1, and the lower end is connected with the input port of the high-precision metering pump 7-1 through a pipeline 9-3, and the output port of the high-precision metering pump 7-1 is passed through a pipeline 9-3 is connected with the solenoid valve 11-1, and the output port of the solenoid valve 11-1 is connected with the mixing tank 4 through the pipeline 9-3; the foaming agent storage tank 5 is connected with the high-precision metering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com