Alignment positioning method in installation of equipment foundation inner vertical buried tube

An equipment-based and vertical technology, applied in the direction of mechanical equipment, infrastructure engineering, other manufacturing equipment/tools, etc., can solve the problems that affect the installation accuracy of vertical buried pipes, have large mutual influence, and have no measurement methods, etc., to achieve the goal of finding The effect of positive positioning is high, speeding up the construction progress and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings.

[0026] 1) Processing and production of auxiliary center centering tools, the processing and production steps are as follows:

[0027] ① Determine the steel plates and steel pipes used for processing and manufacturing according to the specifications and installation accuracy requirements of the vertical buried pipes in the design drawings,

[0028] ②Choose a cover steel plate with a moderate thickness, enlarge the size by 1cm-2cm according to the outer diameter of the vertical buried pipe, and cut the upper cover plate of the cover.

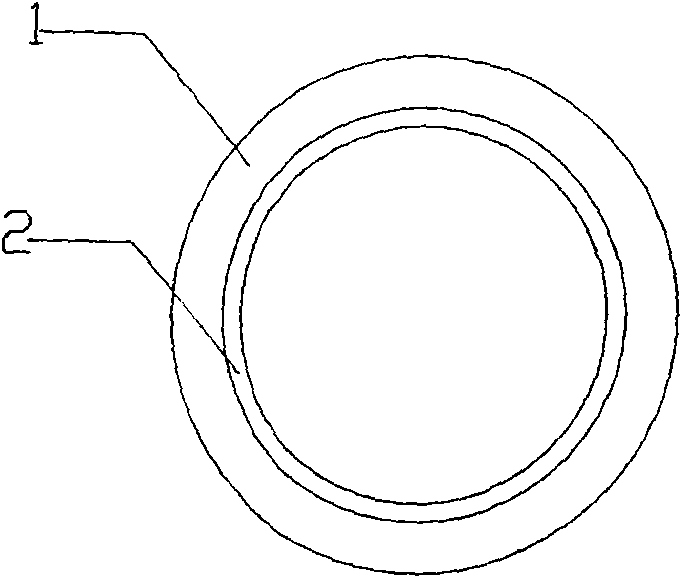

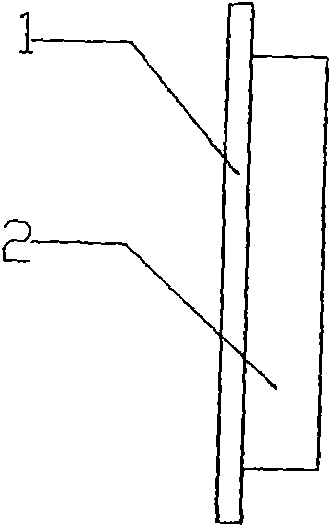

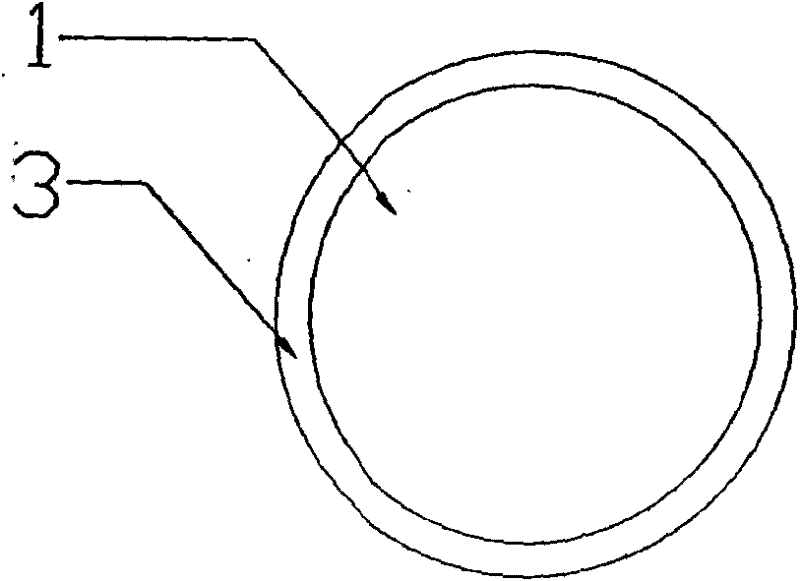

[0029] ③According to the diameter of the vertical buried pipe, process the embedded cover (see figure 1 , 2 ) or wrap-around cover (see image 3 , 4 ), and determine the specification of the steel pipe used in the lower part of the matching cover, usually the length of the tube is 20mm, for the embedded cover, the outer diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com