Process bearing block for flapping test of steam turbine rotor shaft

A steam turbine rotor and bearing seat technology, which is applied in mechanical bearing testing, measuring devices, instruments, etc., can solve the problems of rotors that cannot meet the requirements of 100 tons, poor interchangeability of structural bearing shells, and poor manufacturing process, and achieves compact structure and easy operation. , Good interchangeability of bearing bushes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

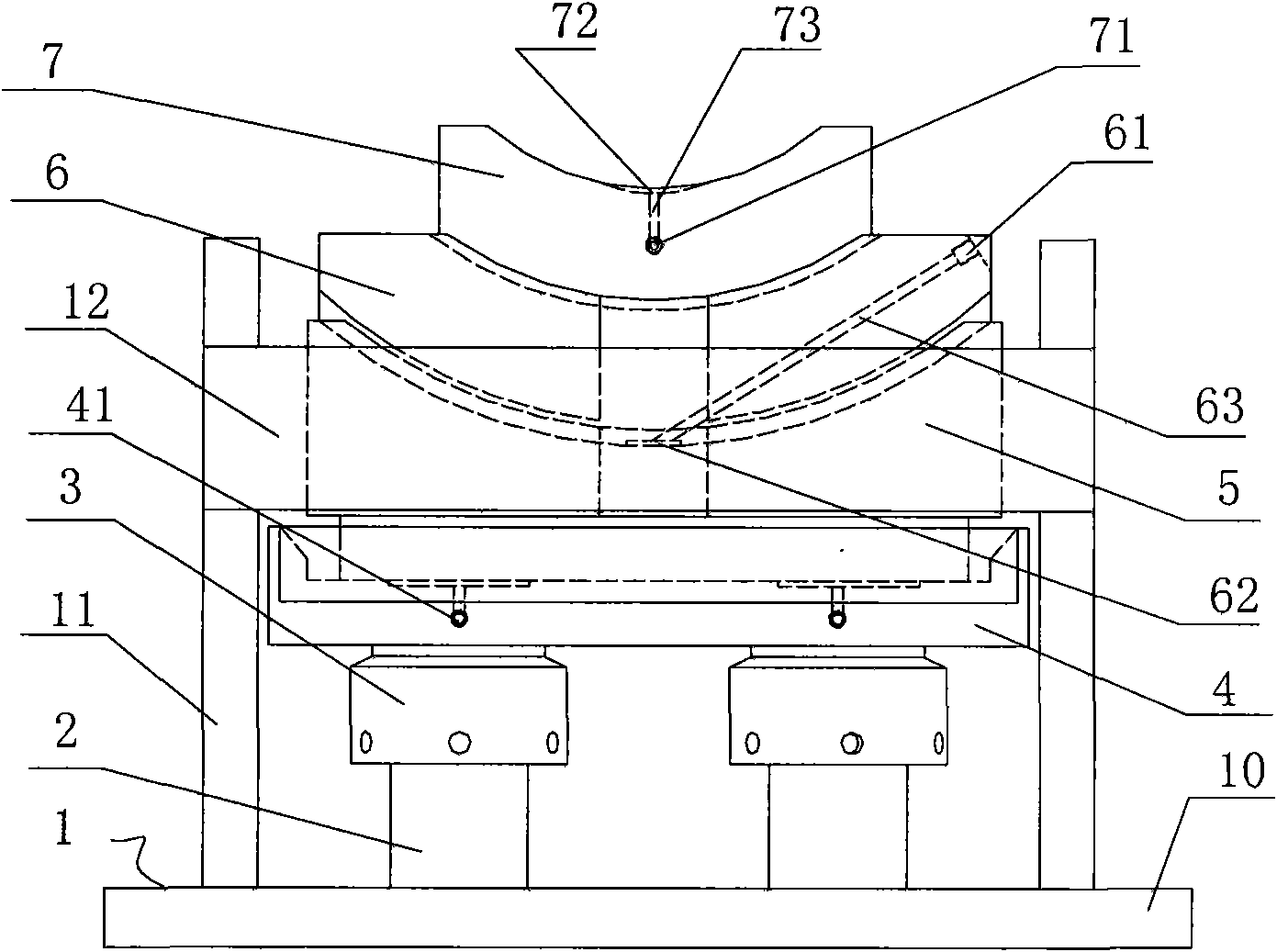

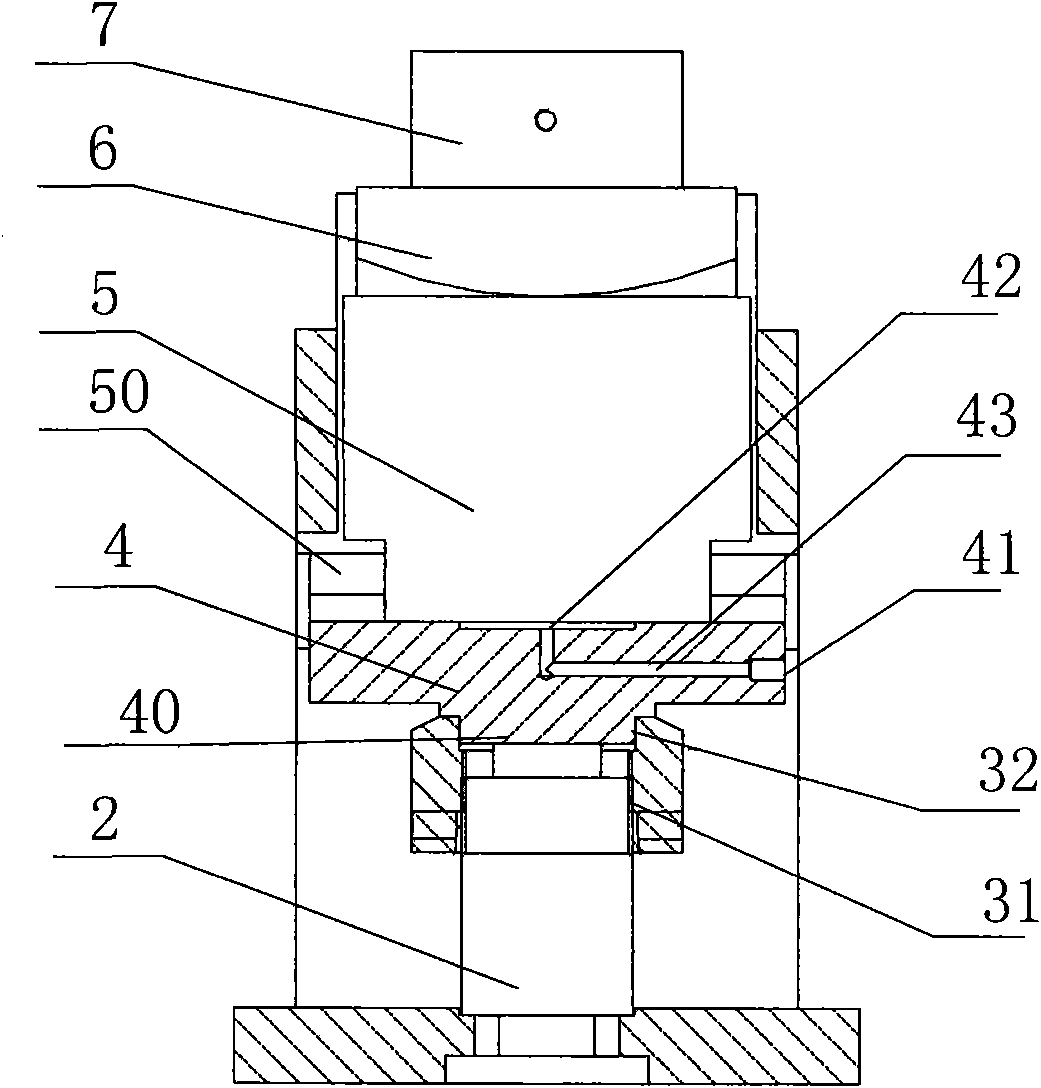

[0019] see figure 1 with figure 2 , the process bearing block for steam turbine rotor shaft float test of the present invention comprises a base 1, an up and down float adjustment mechanism, a horizontal float adjustment mechanism, a kneading degree self-adjustment mechanism and a bearing bush 7, wherein,

[0020] The base 1 includes a bottom plate 10, two side frame plates 11 whose bottom ends are fixed on the bottom plate 10, and front and rear baffle plates 12 located in the middle and whose two ends are respectively fixed on the two side frame plates 11;

[0021] The up and down floating adjustment mechanism includes: two hydraulic jacks 2 and two lock nuts 3,

[0022] The two hydraulic jacks 2 have the same structure and are fixed on the bottom plate 10 of the base 1 in p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com