Static strength test method of large vane used for wind power and electrical power and test system thereof

A testing system and testing method technology, applied in the testing of mechanical parts, the use of applied stable tension/pressure to test the strength of materials, the testing of machine/structural parts, etc., can solve the high cost of construction and maintenance, increase the cost of blade manufacturing, Transport time and other issues, to facilitate analysis and evaluation, reduce related costs, and save huge costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

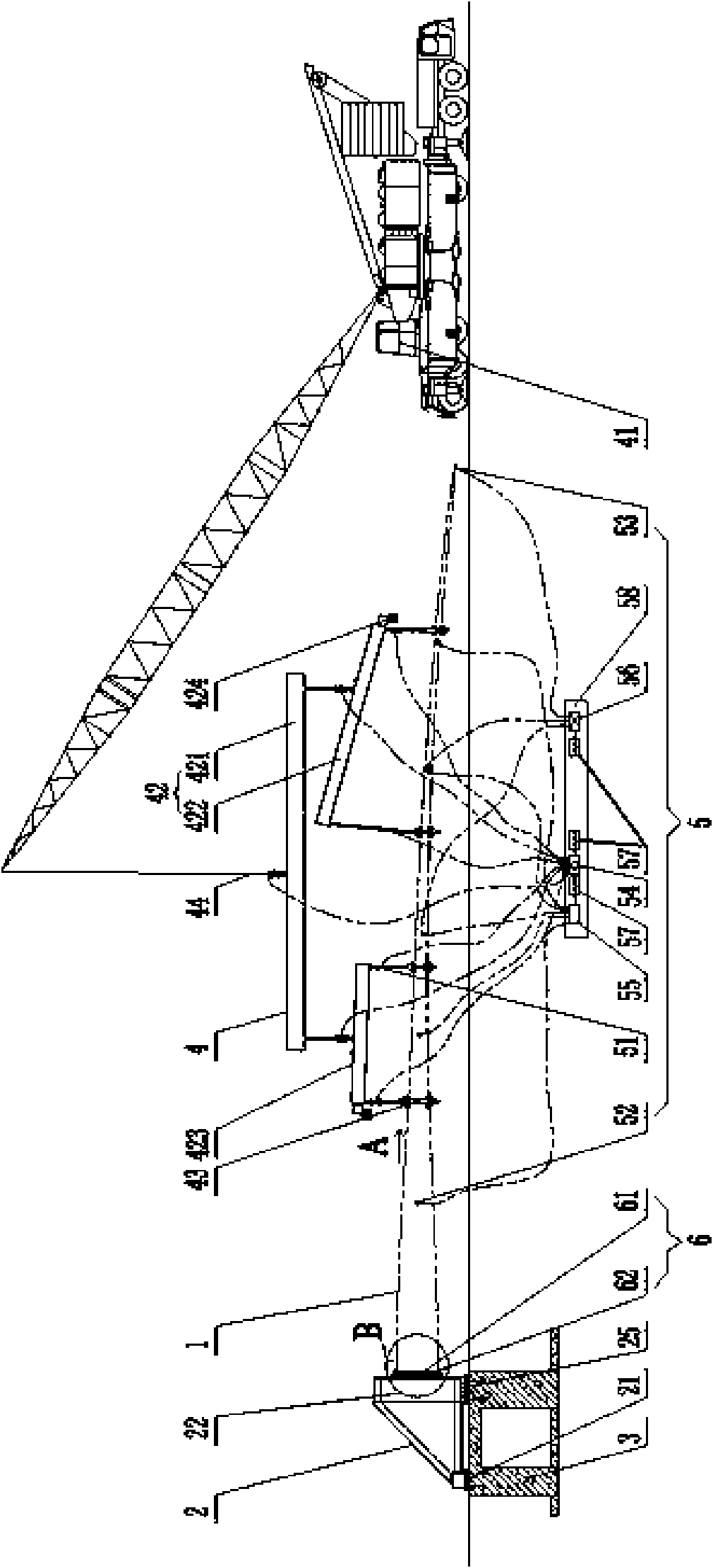

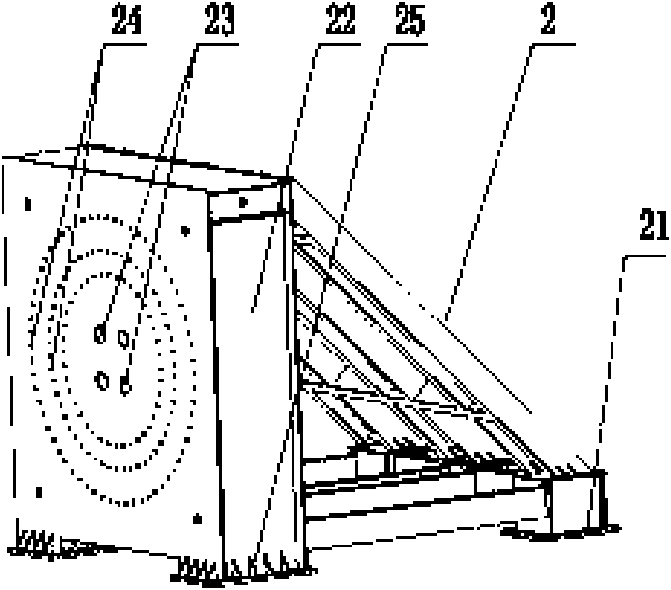

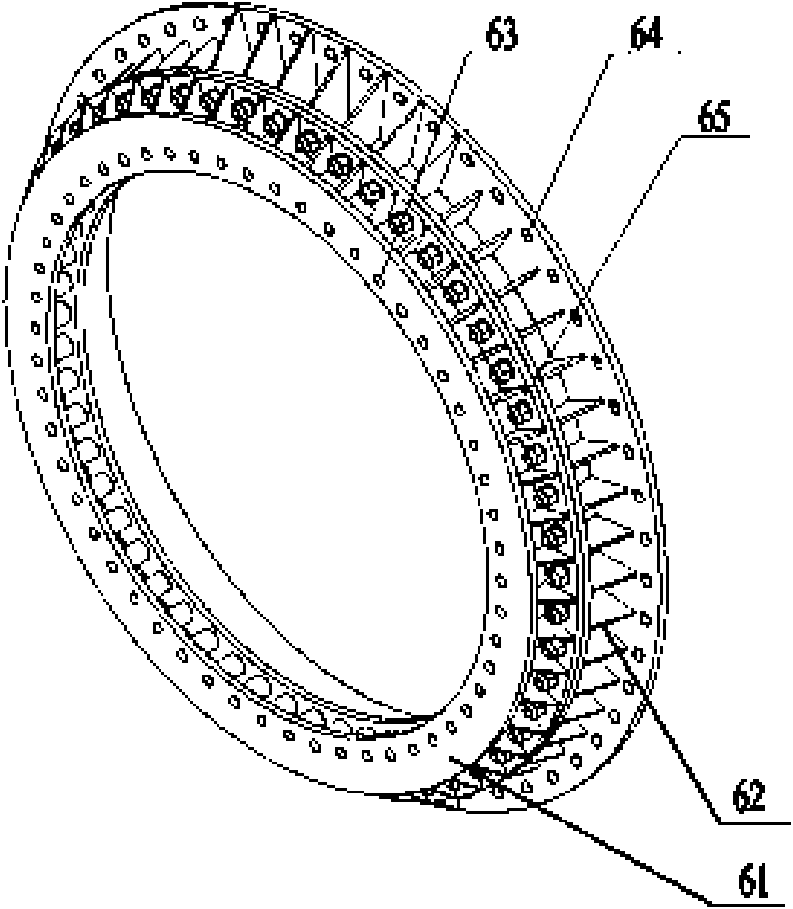

[0022] A kind of static strength test method of wind power large-scale blade (1.5 MW wind generator blade, about 40m long) of the present invention, this test method will be used as figure 1As shown in the static strength test system of the present invention, the test system includes a fixed support 2, a loading system 4 and a data acquisition and processing system 5. During the test, the blade 1 to be tested is placed flat, and one end of the blade root of the blade 1 is connected through a transfer Flange 6 is installed on the fixed support 2 (as Figure 6 As shown), the loading system 4 is installed at the loading point set on the blade 1, and the data acquisition and processing system 5 includes a load sensor 51 installed on the loading system 4, a strain gauge 52 and a displacement sensor 53 installed on the blade 1, The load sensor 51 , the strain gauge 52 and the displacement sensor 53 are respectively connected with respective data processing terminals.

[0023] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com