Liquid refrigerating chip for semiconductor laser and preparation method thereof

A refrigeration chip and laser technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problem of not being able to fully meet the requirements of high-power semiconductor lasers, the difficulty of precision machining of micro-channel refrigerators, and the impact on the service life of power electronic devices, etc. problem, to achieve the effect of simple structure, low risk of corrosion, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation process of this liquid refrigeration sheet is as follows:

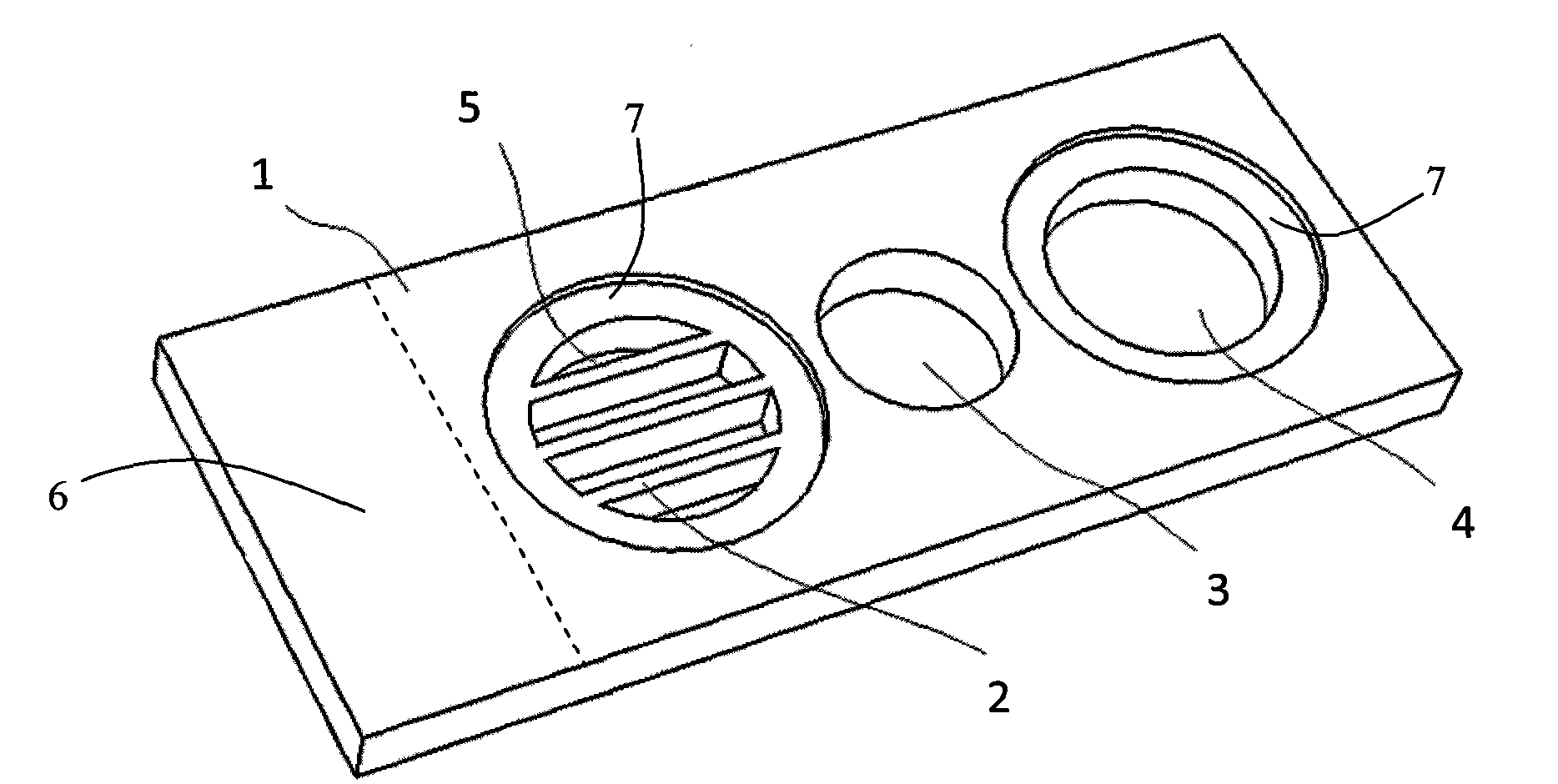

[0040] 1) if figure 1 , select a suitable material, process it into a rectangular sheet-shaped refrigeration sheet main body 1, and polish its surface, and prepare a fixing through hole 3 and a liquid outlet through hole 4 thereon;

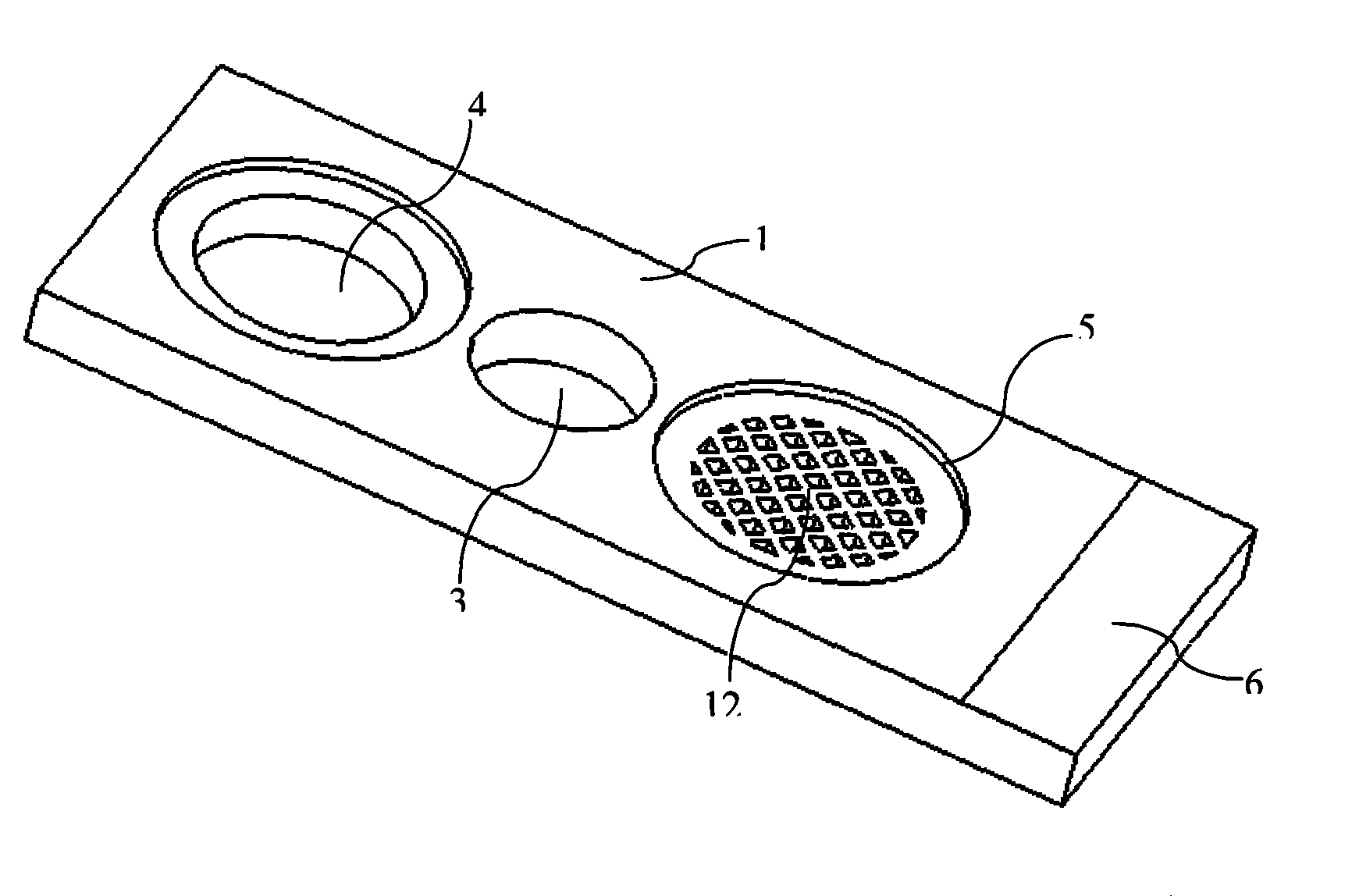

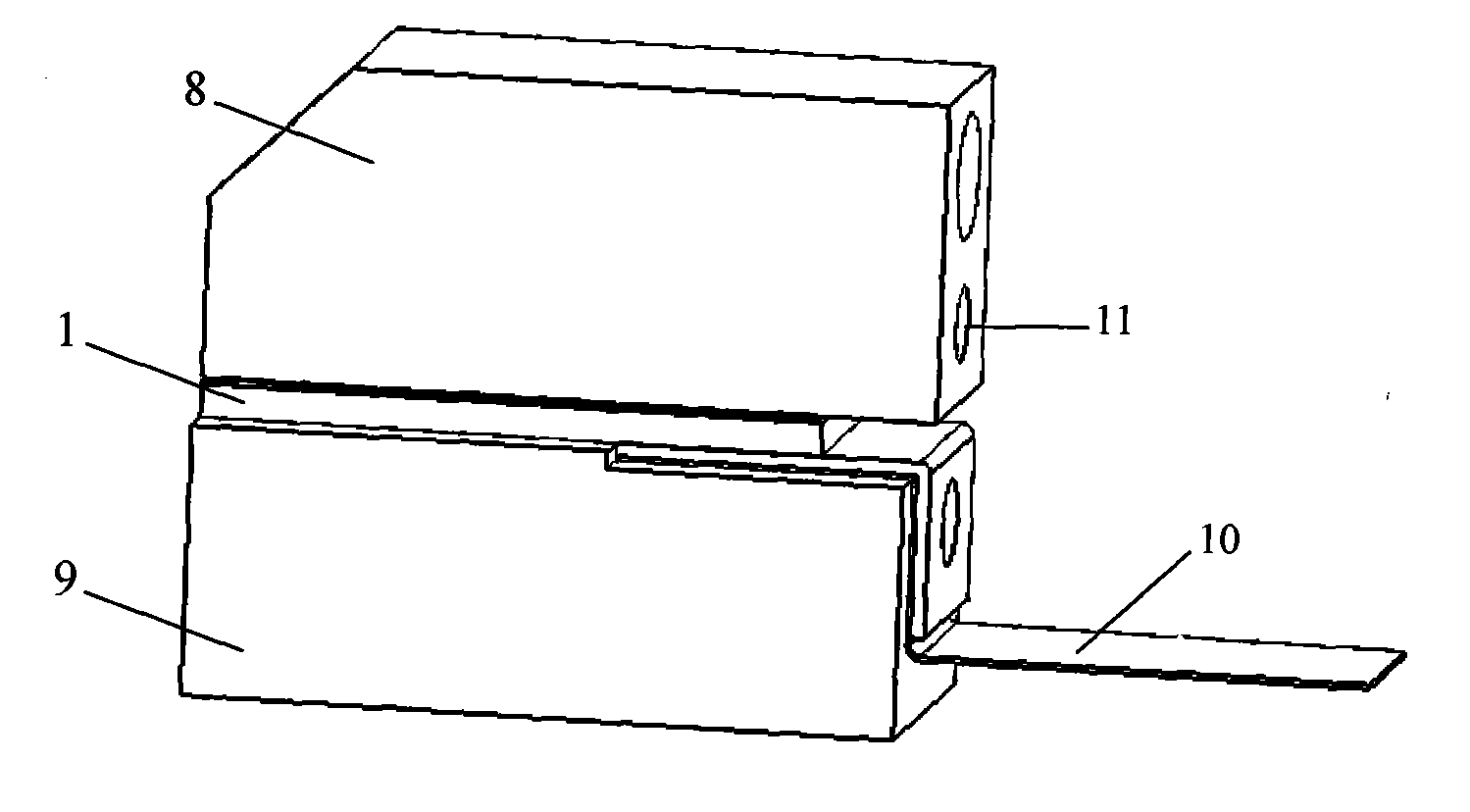

[0041] 2) Prepare liquid inlet and outlet through holes 5 and heat dissipation fins 2 on the main body 1 of the cooling fin. The position of the liquid inlet through hole 5 should be a certain distance from the end of the main body 1 of the cooling chip, and this section is the reserved chip mounting area 6 . The number of heat dissipation fins can be processed into one or more than one piece, and the heat dissipation fins 2 can be processed at the same time when the liquid inlet through hole 5 is processed. In this way, the cooling fins 2 and the liquid inlet through holes 5 are integral structures. It is also possible to process the cooling fins and the main st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com