Split-type bridge frame

A spliced and bridge technology, applied in electrical components and other directions, can solve the problems of inconvenient installation, transportation, and inconvenient use of bridges, and achieve the effect of beautiful surface, convenient transportation, and increased hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with specific embodiments.

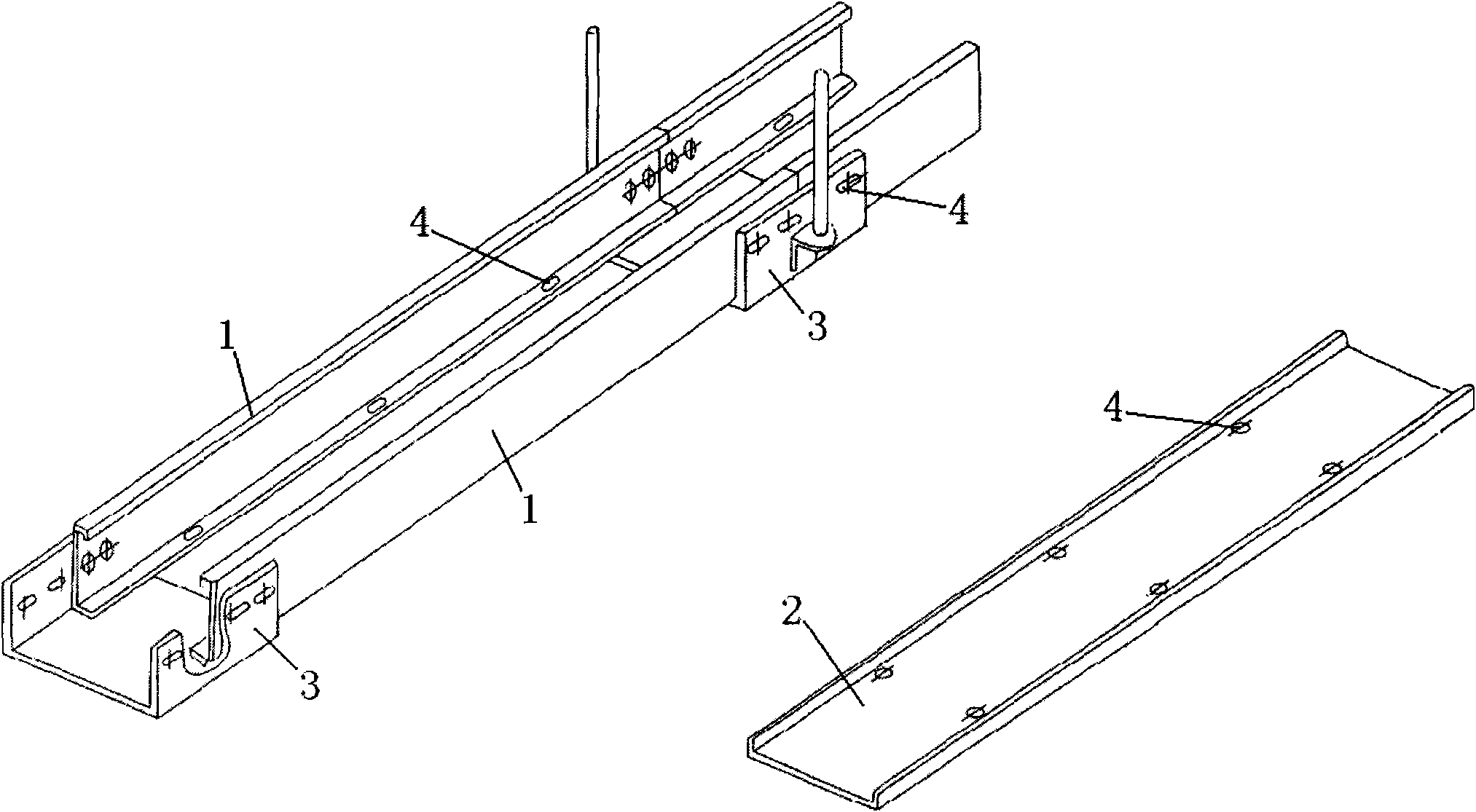

[0010] The combined bridge frame is composed of a U-shaped side plate 1, a bottom plate 2, and a U-shaped connector 3. The side plate 1, the bottom plate 2, and the U-shaped connector 3 are independent of each other. The 3 sides of the connector are provided with oblong connecting holes 4, the side plate 1 is connected to the U-shaped connector 3 through the oblong connecting holes 4, and the bottom plate 2 is connected to the side plate 1 through the oblong connecting holes 4. For occasions with high installation requirements and inaccurate test dimensions, the overall U-shaped connector 3 can make up for measurement errors.

[0011] In order to further meet the occasions with high installation requirements and inaccurate test dimensions, the width of the bottom plate 2 and the U-shaped connector 3 can be adjusted.

[0012] In order to obtain decorative protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com