Flexible circuit board as well as hot-pressed device and method for manufacturing same

A technology of flexible circuit boards and conductive circuits, which is applied to printed circuits, manufacturing tools, printed circuit components, etc., can solve problems such as hot pressing deviation, lower product production yield, hot pressing alignment unevenness, etc., to achieve The effect of smooth contact and improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention relates to a flexible circuit board, a thermocompression bonding device and a thermocompression bonding method for manufacturing the flexible circuit board. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings:

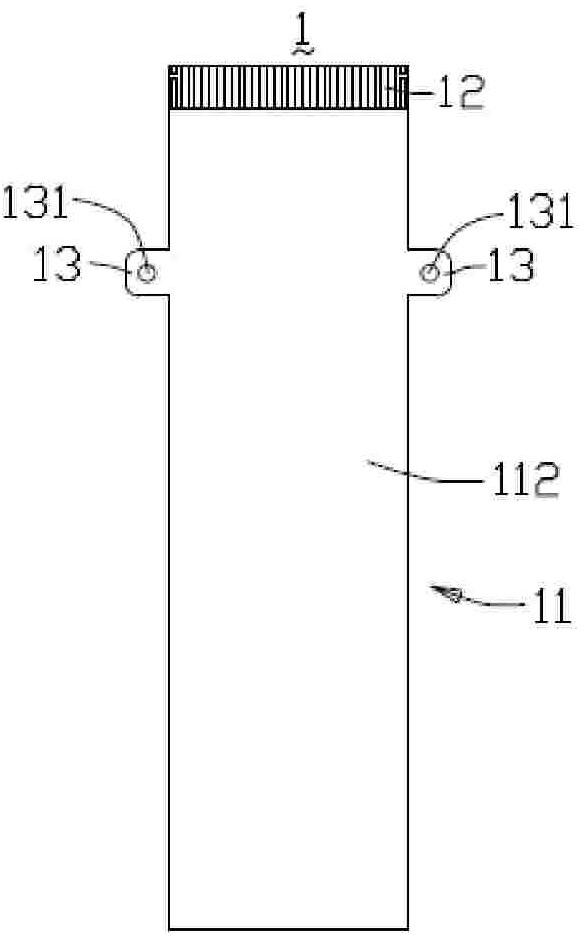

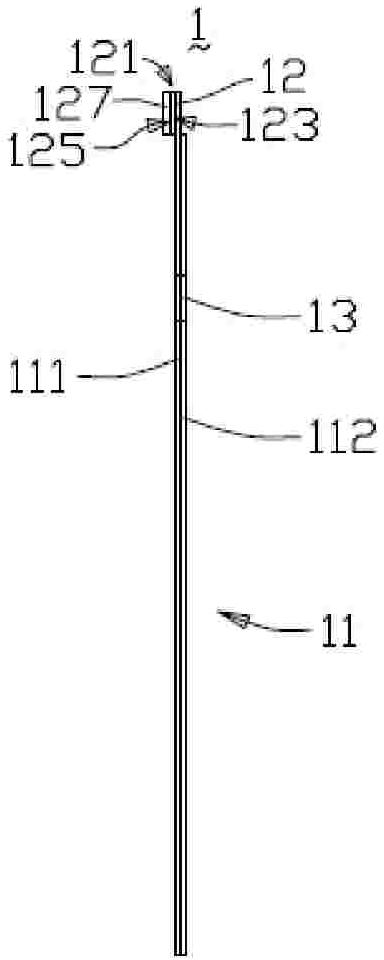

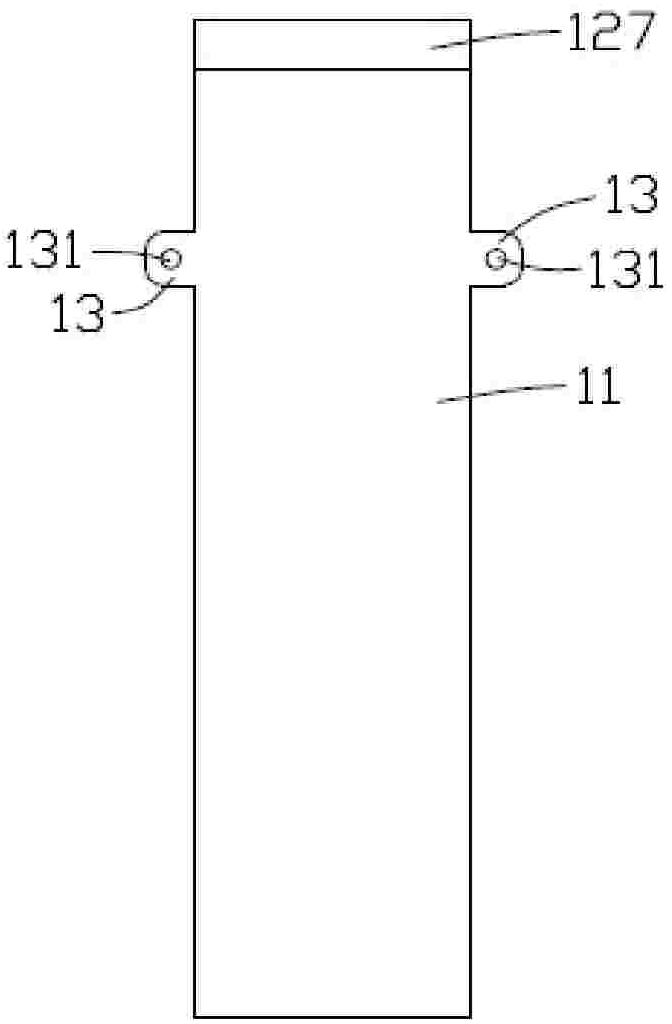

[0026] Please also see figure 1 , figure 2 and image 3 ,in figure 1 It is a front view of the flexible circuit board shown in a preferred embodiment of the present invention, figure 2 yes figure 1 Side view of the flex circuit board shown, image 3 yes figure 1 Rear view of the flex circuit board shown. The flexible circuit board 1 includes a main body 11 , a contact portion 12 and two fixing portions 13 . The contact portion 12 is disposed at one end of the main body 11 , and the two fixing portions 13 are symmetrically disposed on two sides of the main body 11 . The main body 11 includes a first insulating layer 111 , a plurality of conductive lines (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com