Construction method of all casing precessing isolation pile

A construction method and isolation pile technology, applied in the direction of rotary drilling, drilling equipment and method, sheet pile wall, etc., can solve the problem that it is difficult to ensure the verticality of the hole and the quality of the pile, affect the safety of the structure, and the unfavorable soil impact and other issues, to achieve the effects of reducing soil disturbance, preventing piping, and ensuring high verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

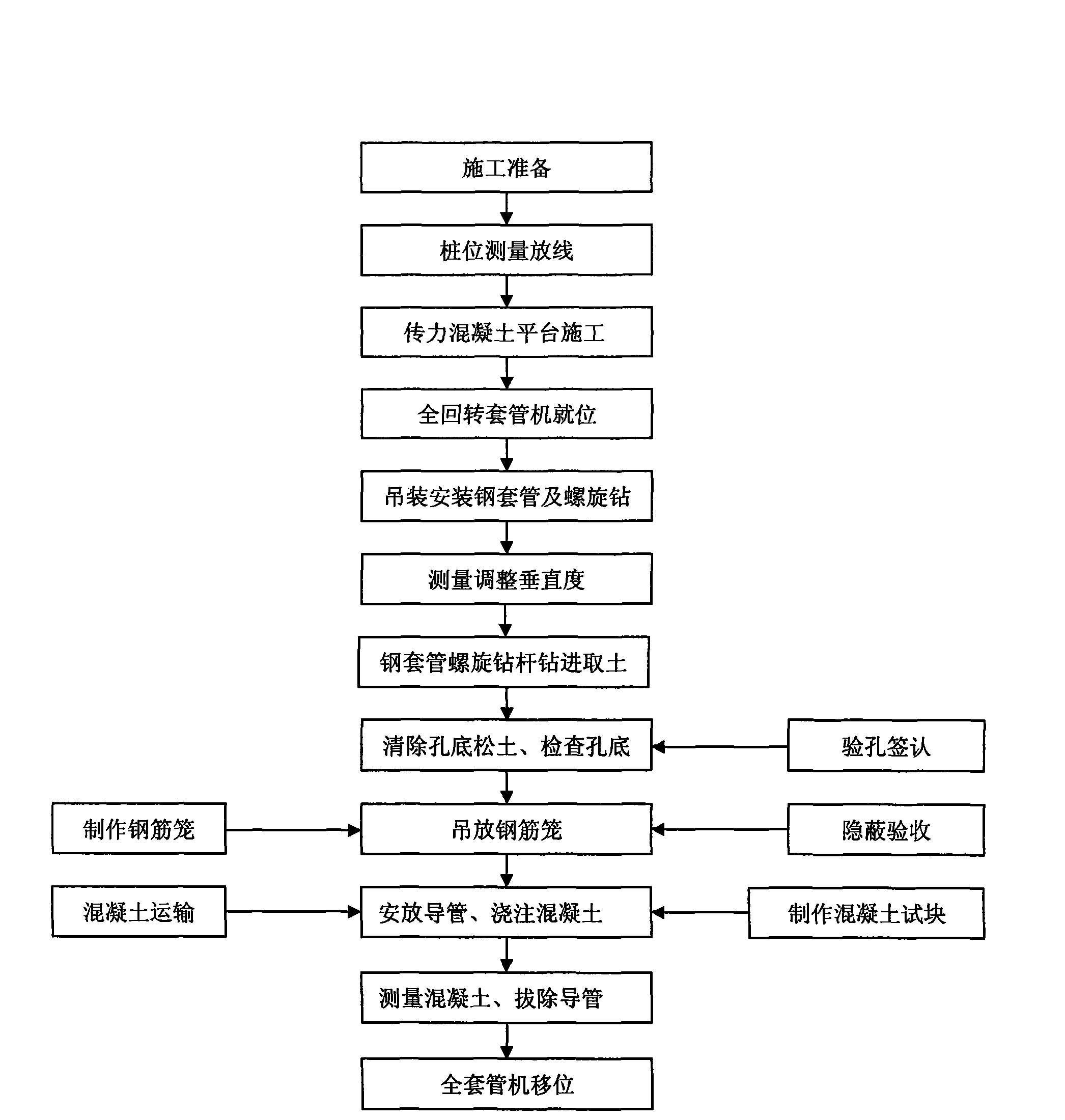

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the construction method of full sleeve pipe screwing into isolation pile of the present invention comprises the following steps:

[0023] (1), construction preparation:

[0024] In order to ensure the smooth progress of the project, civilized construction and safety, the construction area is fenced and isolated; personnel are organized to enter the site and equipment to enter the site for debugging.

[0025] (2), pile position measurement and setting out:

[0026] Release the center position of the pile according to the drawing, remove the concrete pavement at the pile location, dig a trench and backfill it with plain soil, release the pile location again before placing it in place, and drive a cross control pile, and then put it in place with the full set of pipe pile machine.

[0027] (3), the full-rotary casing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com