Hydraulic driving device

A technology of hydraulic transmission device and drive device, which is applied in the direction of fluid pressure actuation device, etc., which can solve the problems of increased occupied space, low energy utilization rate, and difficult realization of output force work, so as to reduce energy conversion links and facilitate detection and control , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

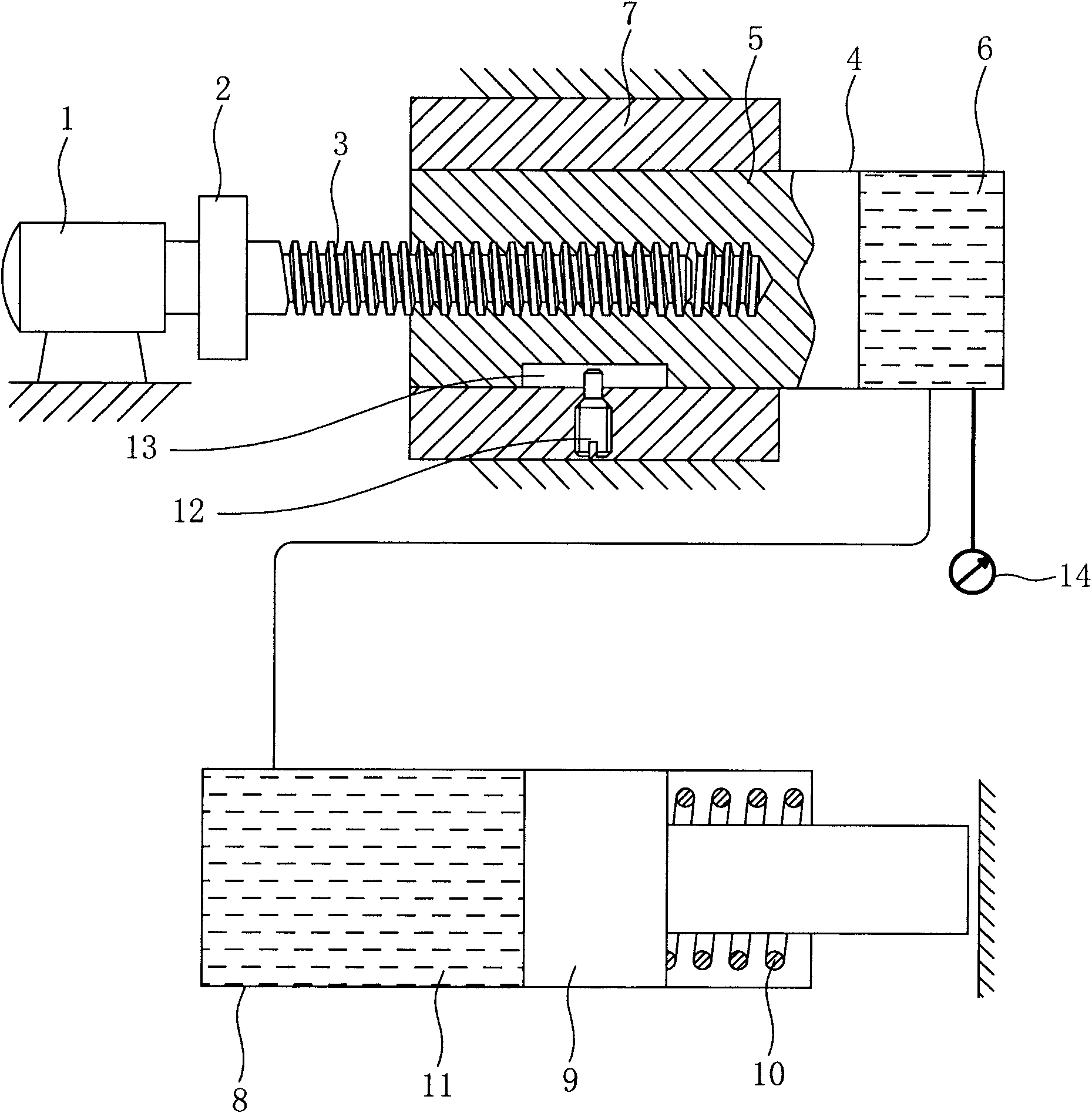

[0029] Embodiment one: see figure 1 As shown, a hydraulic transmission device includes a driving device, an input device and an output device, the driving device includes a servo motor 1, and the output end of the servo motor 1 is connected to a sliding screw 3 through a coupling 2; The input device includes an input cylinder 4, a plunger 5 is arranged in the input cylinder 4, one end of the plunger 5 is connected with the sliding screw 3, and the other end is formed between the input cylinder 4. The input hydraulic chamber 6 is provided with a hydraulic medium inside, and a guide block 7 is provided on the outside of the input cylinder 4, and a limit pin 12 is arranged on the guide block 7, and the limit pin 12 is matched with the plunger 5 A limit chute 13 is opened on the top to form a limit structure; the output cylinder 8 is provided with an output piston 9, and a return spring 10 is provided between the output side of the output piston 9 and the output cylinder 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com