Stable combustion method of coal water slurry boiler and device thereof

A technology for stable combustion and coal-water slurry, which is applied in the field of boiler combustion, can solve the problems of stable combustion that must be accompanied by oil, difficult to ignite stable combustion, and difficult to ignite coal-water slurry boilers, and achieves easy ignition, stable combustion, and small furnace. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing,

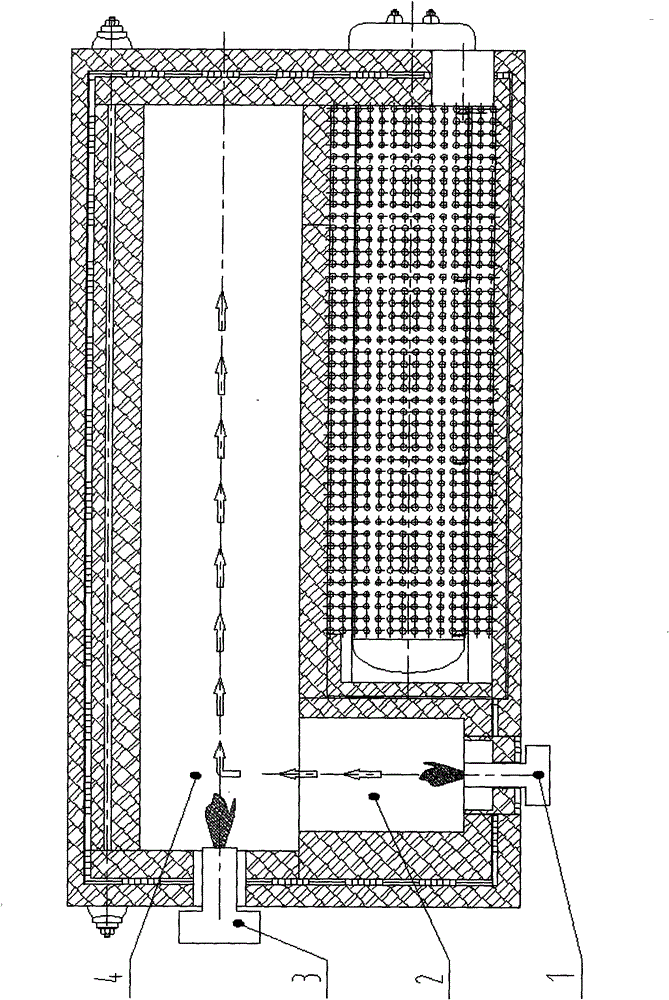

[0015] As shown in the figure, the present invention is a method for stable combustion of a coal-water slurry boiler. The furnace of the coal-water slurry boiler is divided into two, and a double furnace structure is adopted to form two combustion chambers, which are divided into a main combustion chamber and an auxiliary combustion chamber. Combustion chamber, the two combustion chambers are arranged in a "7" shape, the main combustion chamber is larger than the auxiliary combustion chamber, the load of the main combustion chamber accounts for 65-75% of the total boiler load during the boiler combustion process, and the auxiliary combustion chamber is 25% of the total boiler load -35%. The outlet of the auxiliary combustion chamber is arranged on the front side of the main combustion chamber. A certain number of water-cooled walls are arranged in the main combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com