Environment-friendly wax and glue removing kiln

A kind of kiln and environmental protection technology, applied in the field of kiln, can solve the problems of insufficient use of heat, unfavorable high temperature sintering, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

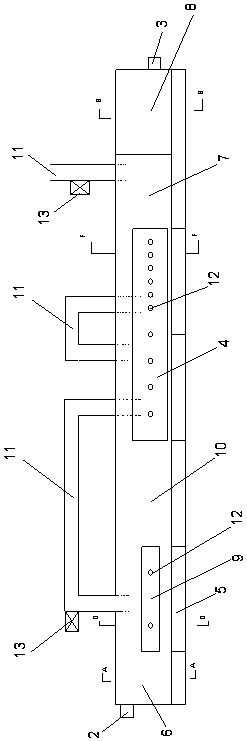

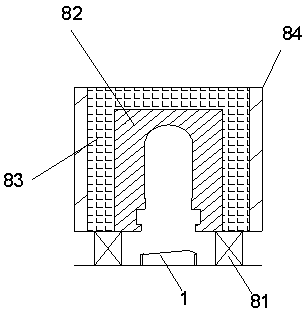

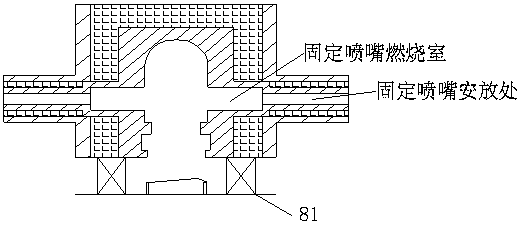

[0028] Such as Figure 1~4 As shown, an environment-friendly wax and deglue kiln includes a kiln body, a track 1 is set at the bottom of the kiln body, a kiln inlet 2 is set on the left side of the kiln body, and a kiln outlet 3 is set on the right side. The kiln body includes Combustion chamber 4, preheating zone 5, flue gas leakage prevention zone 6, cooling zone 7 and cooling flue gas leakage prevention zone 8, preheating zone 5 is provided with preheating combustion chamber 9, and flue gas leakage prevention zone 6 is located in the preheating combustion chamber The left side of 9 is connected with the preheating combustion chamber 9, the preheating zone 5 is located on the left side of the combustion chamber 4, the middle of the preheating zone 5 and the combustion chamber 4 is connected through the non-combustion chamber 10 of the furnace body, and the right side of the combustion chamber 4 is sequentially The cooling zone 7 and the cooling flue gas leakage prevention zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com