Novel vertical type thermocouple detecting furnace

A technology for calibrating furnaces and thermocouples, applied in the direction of measuring heat, measuring devices, instruments, etc., can solve problems such as difficult heat dissipation, uniformity and symmetry, and achieve the effect of ensuring accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

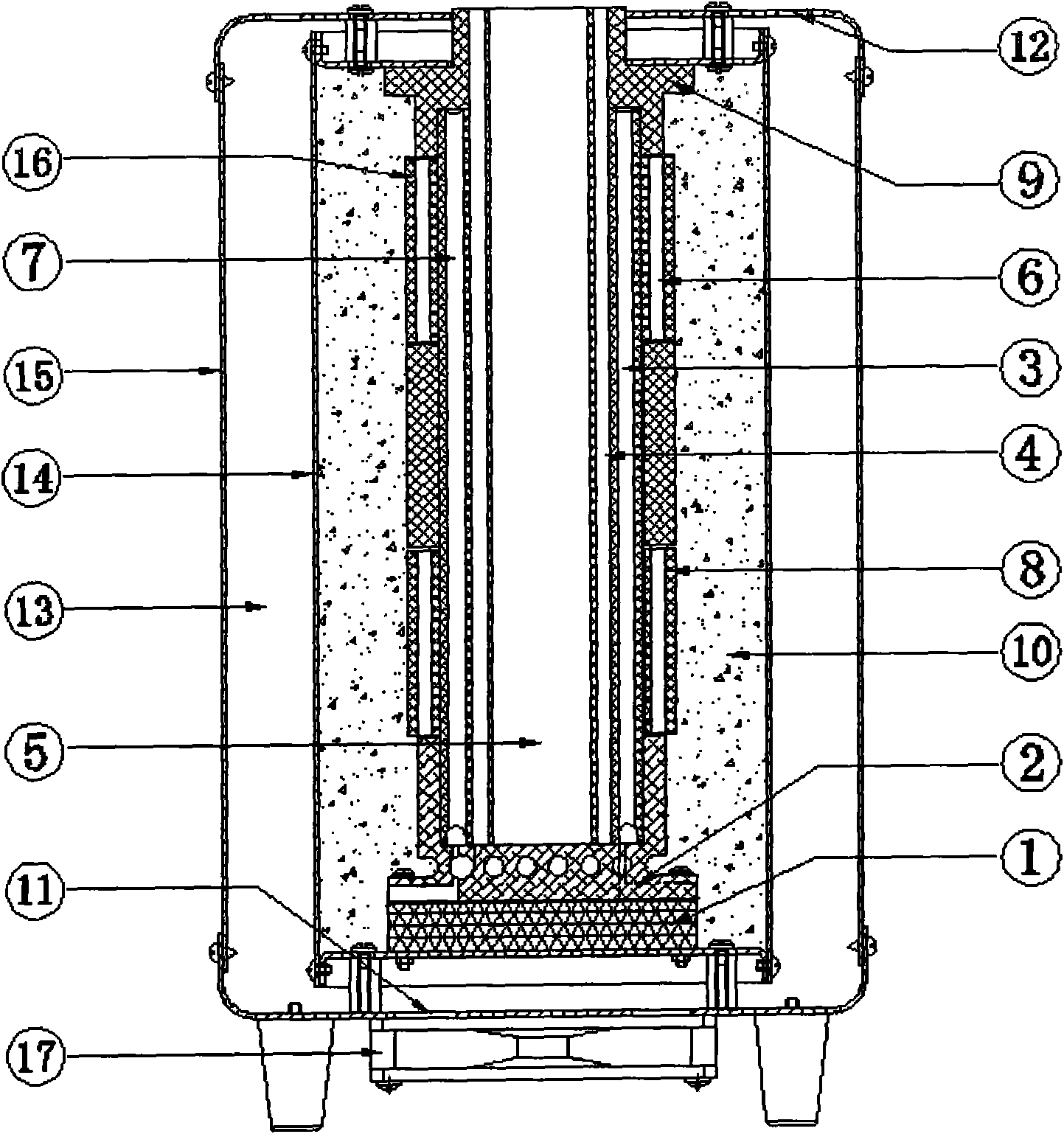

[0011] Such as figure 1 The structure schematic diagram of the new vertical thermocouple verification furnace is shown, the vertical new thermocouple verification furnace 5 is composed of the vertical main furnace tube 3, the lower auxiliary furnace tube 8, the upper auxiliary furnace tube 16, the upper end 9, the insulation layer 10, and the verification furnace The shell 15, the inner barrel 14, the fan 17, the ventilation channel 13, the heat chassis 2 and the heat insulation pad 1 are composed of the main furnace tube prefabricated with heating holes 7, which are evenly distributed on the outside of the heating furnace tube, and can be used for small diameter spiral tube type The heating wire is arranged in a circular manner through the tube, and the helical pitch in the axial direction is sparse and dense so that the highest temperature zone is at the bottom; the main furnace tube 3 is also prefabricated with multi-directional temperature measurement holes 4, which can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com