Radiating structure of magnetron

A heat dissipation structure and magnetron technology, applied in the field of magnetron, can solve problems such as heat dissipation, loud noise, and product failure, and achieve the effects of increasing heat transfer efficiency, reducing working noise, and accelerating heat transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

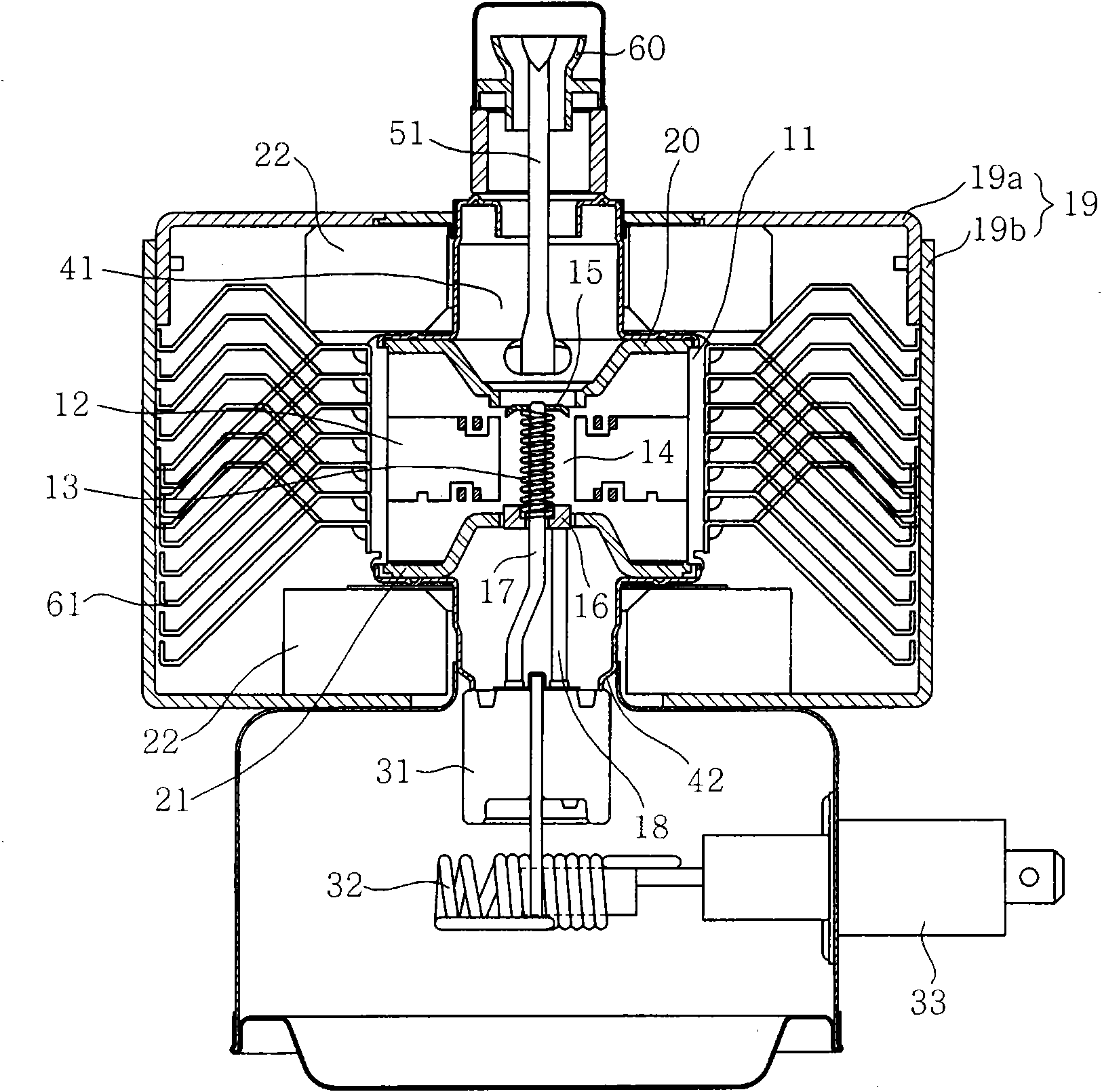

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

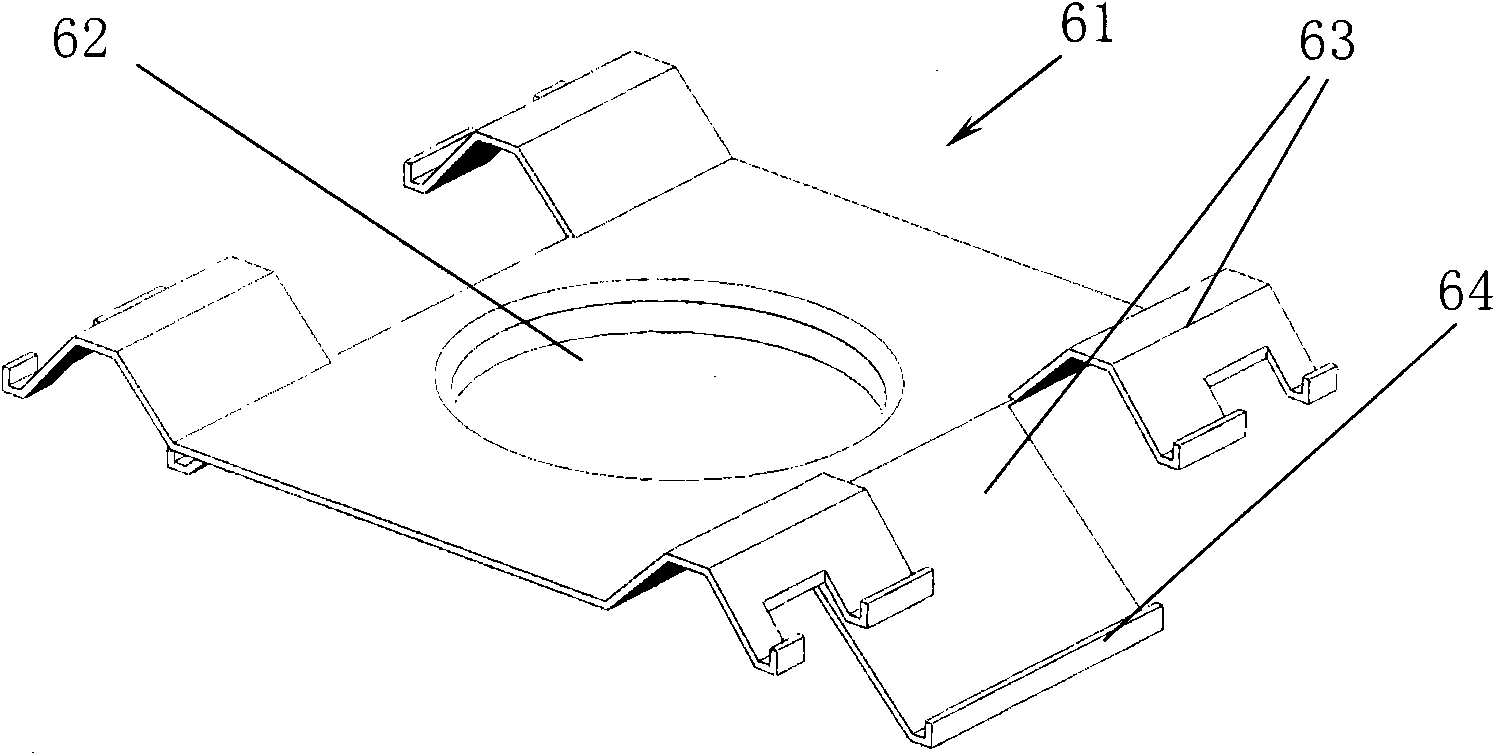

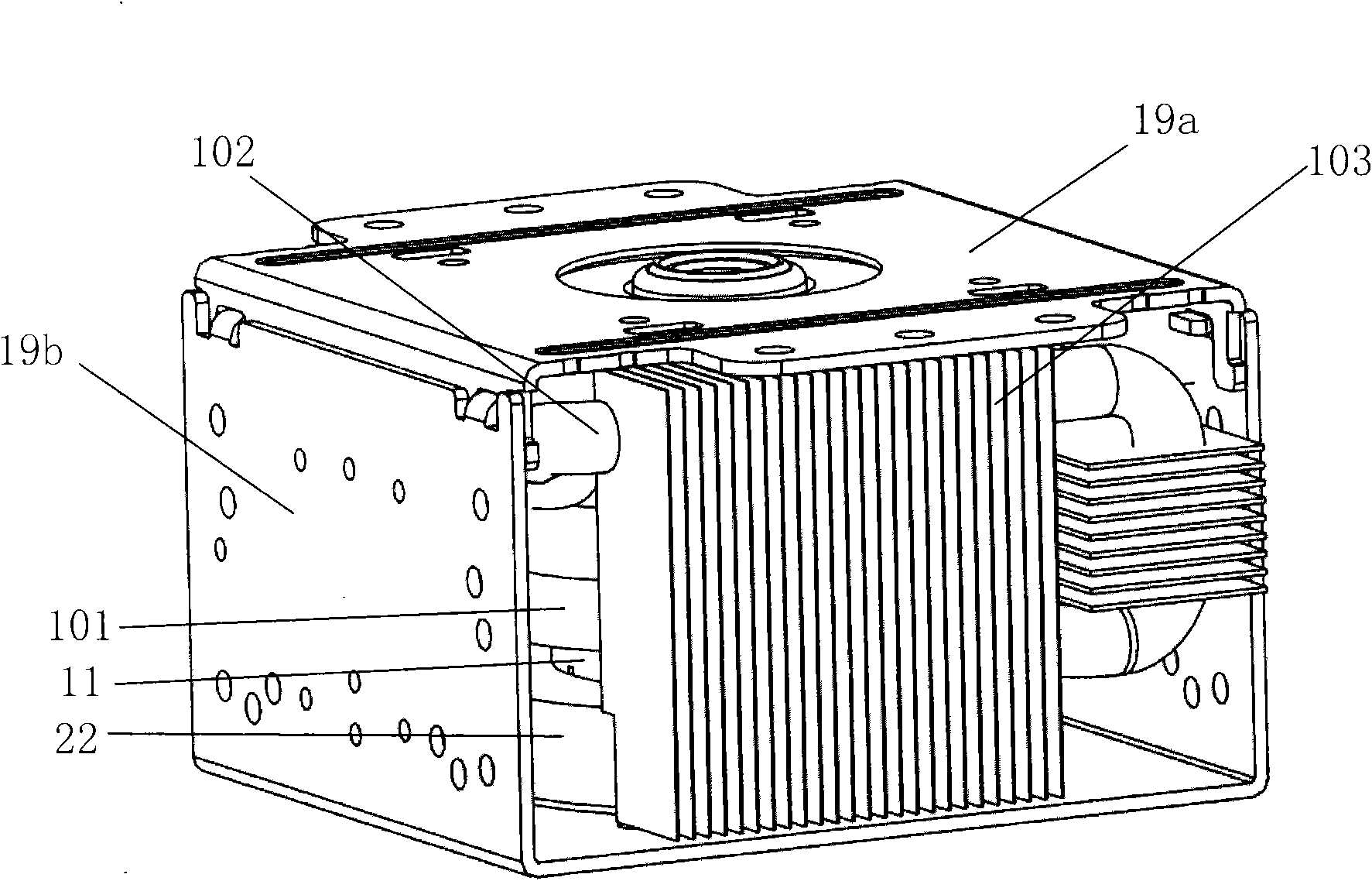

[0028] image 3 is a schematic diagram of the heat dissipation structure of the magnetron of the present invention; Figure 4 It is a schematic diagram of the back side of the heat dissipation structure of the magnetron of the present invention.

[0029] like image 3 , Figure 4 As shown, the heat dissipation structure of the magnetron of the present invention adopts a heat pipe to dissipate heat, and the diameter of the heat pipe 100 is 7 mm. In the space formed between the upper shell 19a and the lower shell 19b of the magnetron, the evaporation section 101 of the heat pipe spirals upwards and coils on the positive pole shell 11 of the magnetron, and is located between the upper and lower magnets 22. The evaporation section can be Flat tubes are used, which are tightly spiraled, and there is no gap between adjacent pipes to contact each other, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com