Emergency facility glass crushing device

A technology of glass and facilities, which is applied in the field of glass crushing devices, can solve problems such as inability to use tools, low efficiency, and missed opportunities for self-rescue and rescue, and achieve the effects of small size, easy installation, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

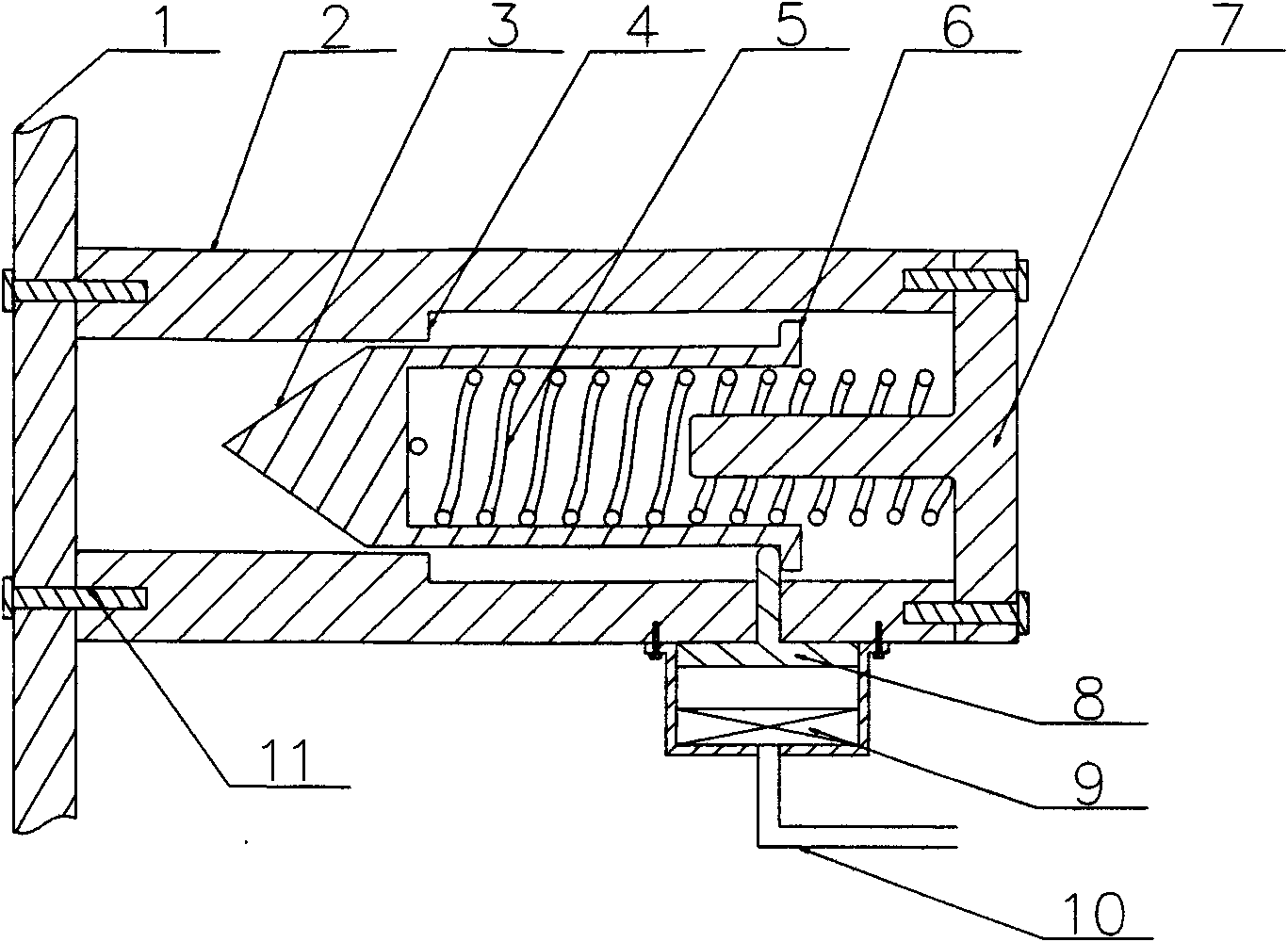

[0018] see figure 1 , is the first embodiment of the glass crushing device for emergency facilities, and is composed of the following parts: a housing 2, an end cover 7, an impact body 3, a drive device for the impact body—a spring 5 and a controller for the drive device. The controller of the driving device includes an energy release actuator—a “T”-shaped locking lever 8 and an energy release controller 9 . Described shell 2 is a hollow cylinder, is installed perpendicular to glass plane 1, and one end of shell 2 is vertically fixed on glass plane 1 with bolt 11, and the other end is connected on the end cover 7 with bolt 11. A shoulder 4 is also formed on the inner wall of the housing 2 to limit the sliding of the impact body to the glass plane 1 . The impact body 3 is installed inside the casing 2 and axially slides and fits with the inner wall of the casing 2 . The front end of the impact body 3 is a solid cone corresponding to the glass plane 1; the rear end is a hollow...

Embodiment approach

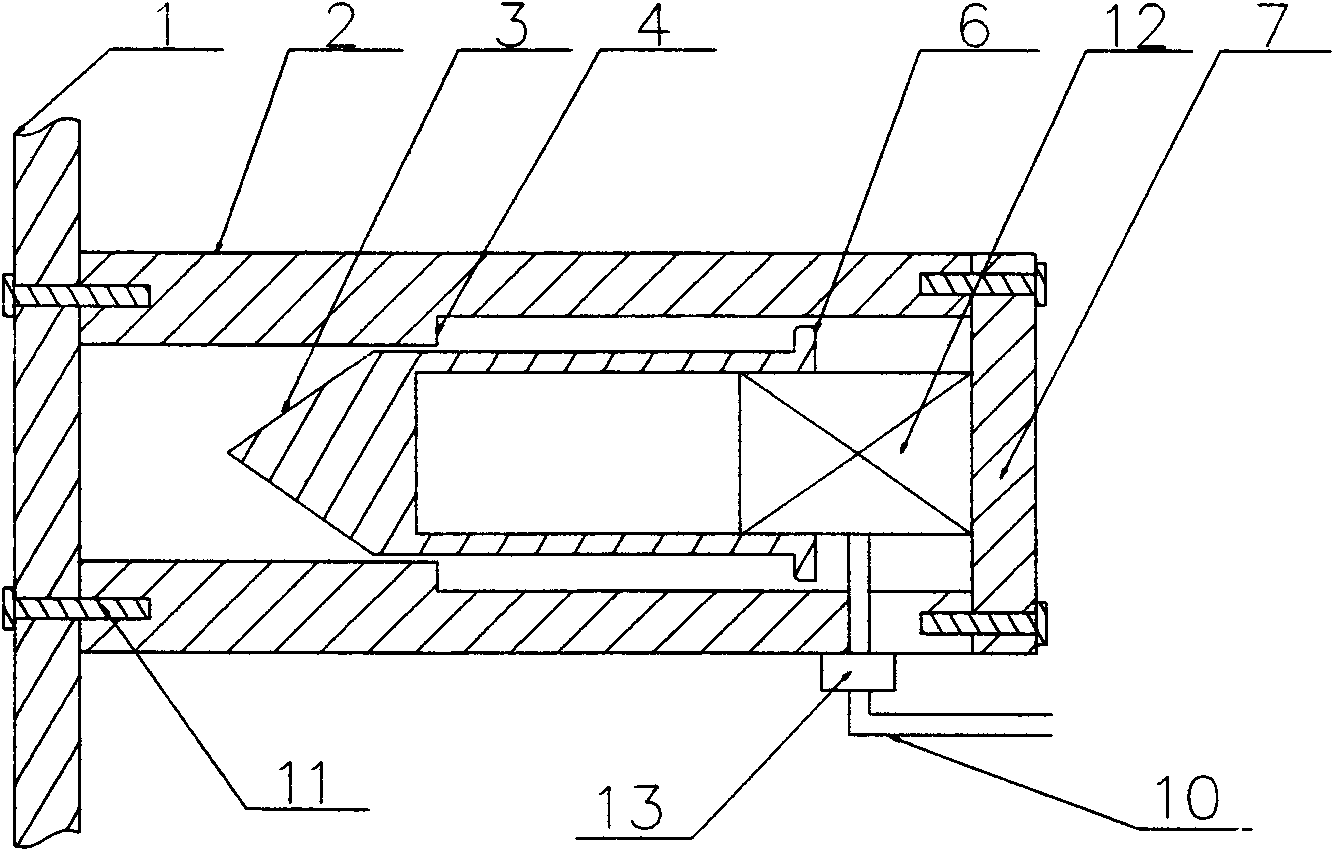

[0021] see figure 2 , is the second embodiment of the emergency facility glass smashing device, which is composed of the following parts: a housing 2, an impact body 3, a drive device 12 for chemical energy storage, and an electronic switch 13. The housing 2 is perpendicular to the glass plane 1 , and one end of the housing 2 is vertically fixed on the glass plane 1 with a bolt 11 , and the other end is connected to the end cover 7 with a bolt 11 . The inner wall of the shell body 2 is also formed with a shoulder 4 that limits the sliding of the impact body to the glass plane 1 . The impact body 3 is installed in the center of the housing 2 and axially slidably fits with the inner wall of the housing 2 . The front end of the impact body 3 is a solid cone corresponding to the glass plane 1; the rear end is a hollow cylinder. A collar extends from the bottom of the hollow cylinder at the rear end of the impact body 3 toward the inner wall of the housing 2 , corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com