Running air extraction system for vacuum pipeline rapid transit

A vacuum pipeline and air extraction system technology, applied in tunnel systems, roads, tracks, etc., can solve problems such as hindering vehicle speed and increasing vehicle power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

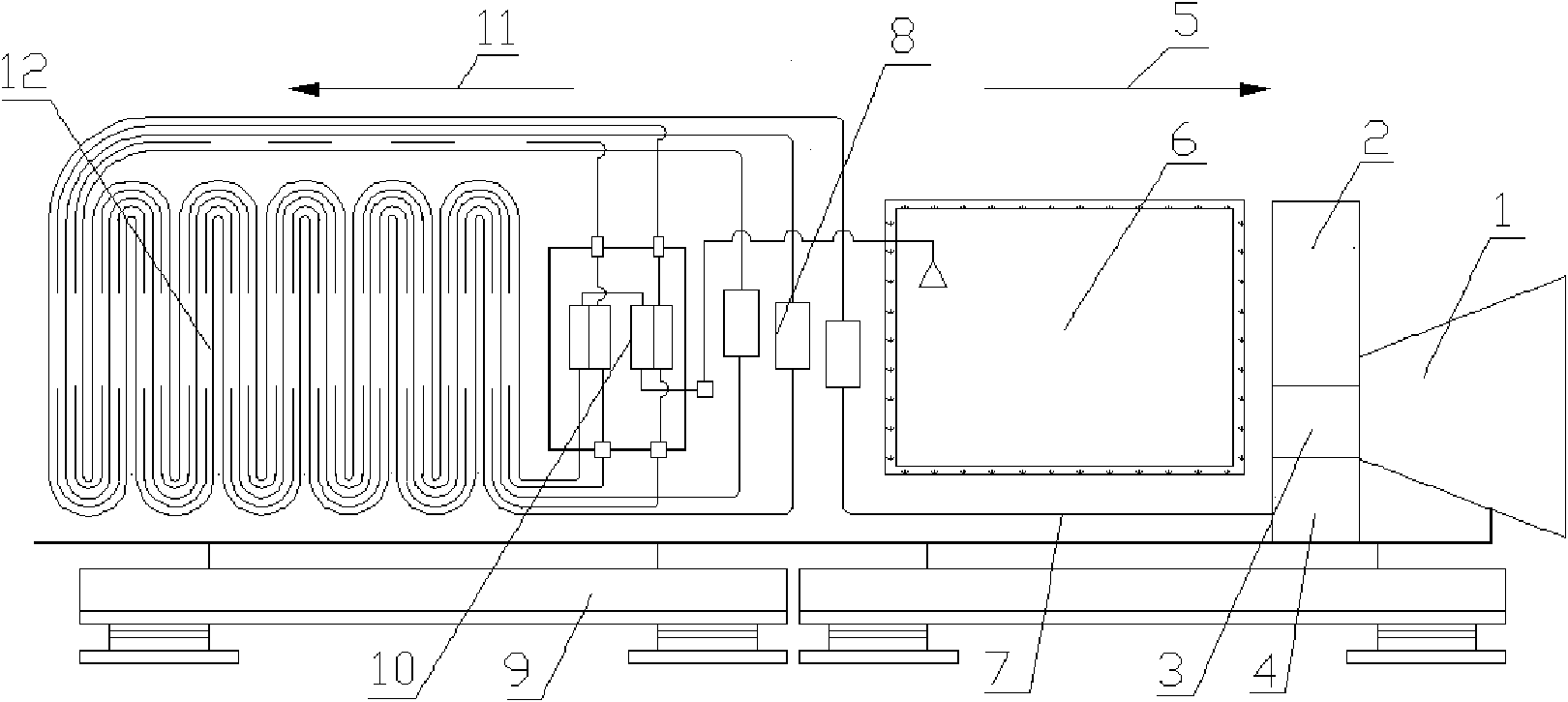

[0014] The specific implementation of the operation air extraction system in this case is as follows:

[0015] When the car body is running, start the running air extraction system given in this case. Due to the high-speed running of the car body (running direction (5) such as figure 1 As shown in ), the gas in front of the car body is compressed, and the compressed gas enters the air extraction device through the air inlet (1).

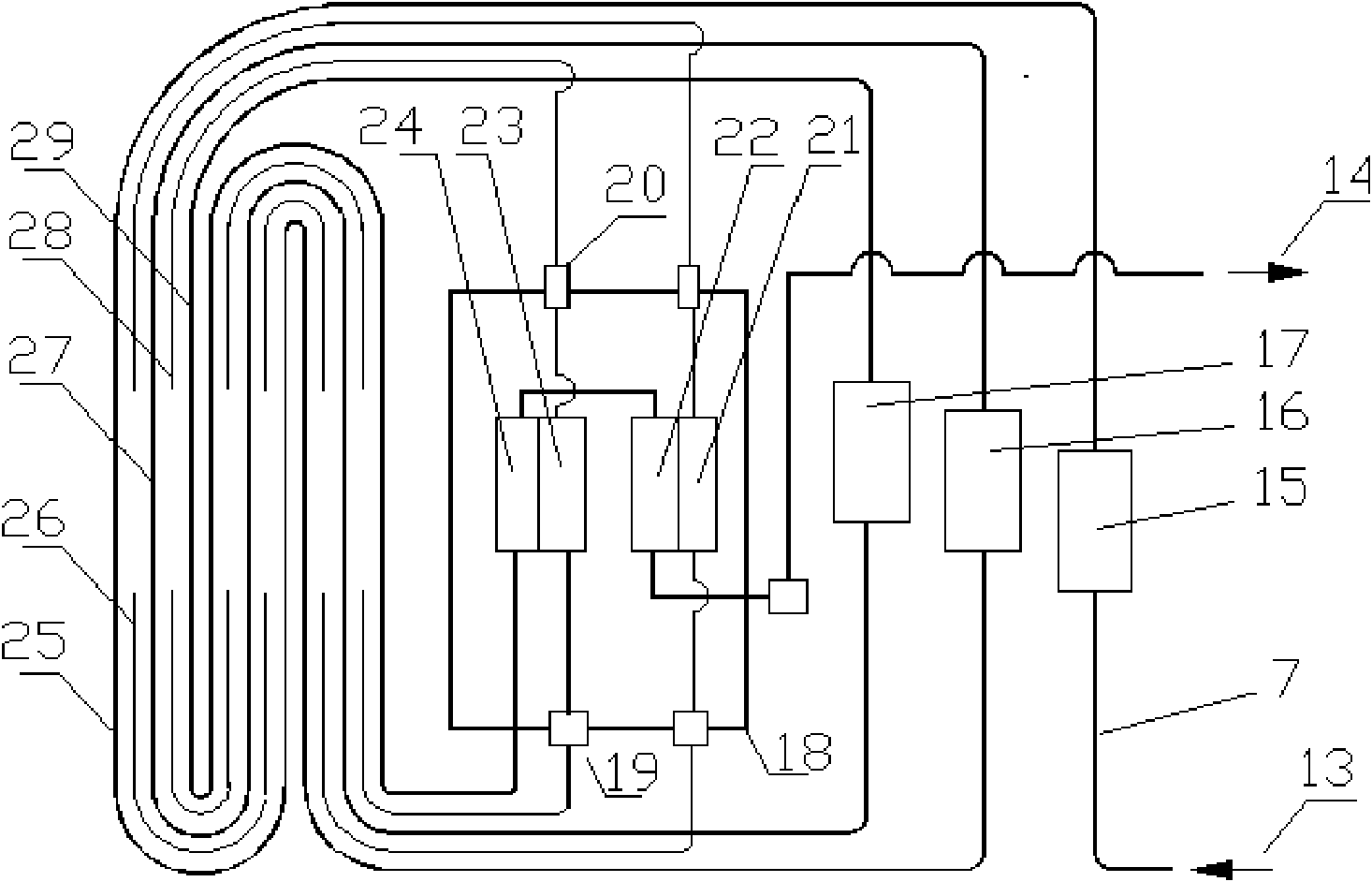

[0016] For the gas entering the extraction device, such as figure 2 Shown is a multi-stage compression, radiant cooling approach to achieve the desired final compression ratio.

[0017] After the first stage (1# compressor (15)) adiabatic compression, along with the raising of gas density and the raising of temperature, the pressure of gas is also improved relatively substantially. When the (density) compression ratio is 80, the temperature reaches 1286K, and the air pressure increases nearly 350 times. However, if the air pressure in the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com