Polycarbonate composition and polycarbonate composite material formed by composition

A technology of polycarbonate and composition, which is applied in the field of polycarbonate composite materials, can solve the problems of poor physical properties, processing and fluidity, and achieve the effects of good melt flow and good notched impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

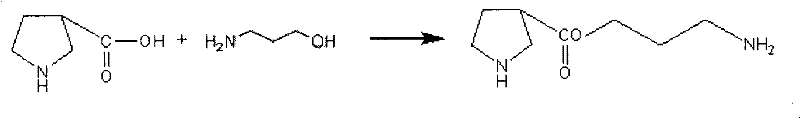

[0068] This implementation is used to illustrate the NHC 4 h 7 COO(CH 2 ) 3 NH 2 preparation.

[0069] Put 3-carboxypyrrolidine and 3-aminopropanol in a molar ratio of 1:1 into a three-necked flask, stir and react for 240 minutes at 120°C under nitrogen protection, and wash the filter cake with ethanol for 3 times after suction filtration. Drying at 70 °C gives NHC 4 h 7 COO(CH 2 ) 3 NH 2 .

Embodiment 2

[0071] This implementation is used to illustrate the NHC 4 h 7 COO(CH 2 ) 12 NH 2 preparation.

[0072] Put 3-carboxypyrrolidine and dodecylamine into a three-necked flask at a molar ratio of 1:1, and stir and react for 240 minutes at 120°C under nitrogen protection. After suction filtration, wash the filter cake with ethanol for 3 times. Drying under the hood yields NHC 4 h 7 COO(CH 2 ) 12 NH 2 .

Embodiment 3

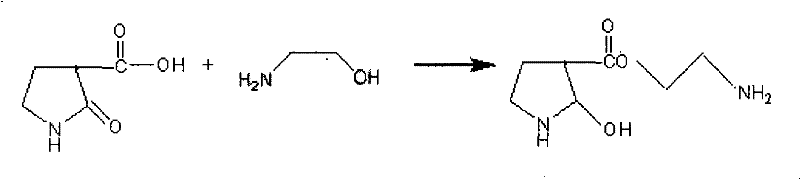

[0074] This implementation is used to illustrate the NHC 4 h 6 (OH)COO(CH 2 ) 2 NH 2 Preparation of reactive compatibilizer.

[0075] Put 3-carboxy-2-pyrrolidone and ethanolamine into a three-necked flask at a molar ratio of 1:1, react for 240 minutes at 120°C under nitrogen protection, wash the filter cake with ethanol for 3 times after suction filtration, and dry at 90°C , to get NHC 4 h 6 (OH)COO(CH 2 ) 2 NH 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com