Method for monitoring construction of channel bridge demolition

A construction monitoring and bridge technology, applied in building maintenance, special data processing applications, instruments, etc., can solve problems such as difficulty in accurate finite element simulation analysis, difficulty in strength and stability, and lack of special specifications and technical standards, and achieve perfection. The effect of bridge demolition technology, reducing safety risk and improving construction level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A certain bridge was built in the late 1980s. It spans a third-class waterway. The main span is a 94.4-meter oblique-leg solid-end girder. The abutment is a frame structure supported on piles and soil foundations. As a structure, the main bridge is composed of double-width and double-chamber box girders, and the two box girders are connected by 50cm-wide longitudinal post-cast concrete.

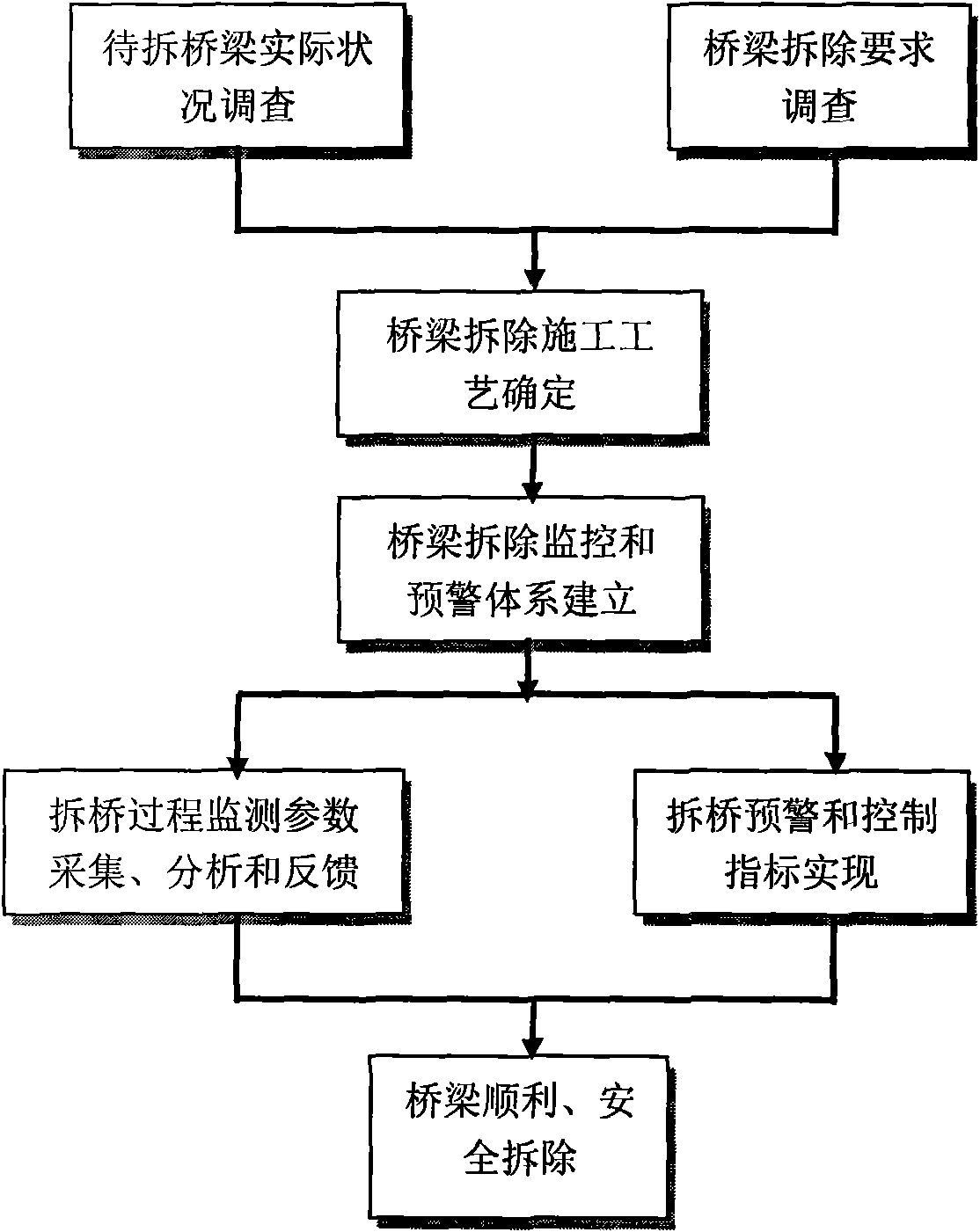

[0024] Considering the actual operation status of the bridge and the widening and reconstruction of urban roads, the bridge was demolished and rebuilt. In order to ensure the quality and safety of the bridge demolition process, a monitoring and early warning system was established during the bridge demolition process, and a monitoring method for channel bridge demolition and construction was implemented.

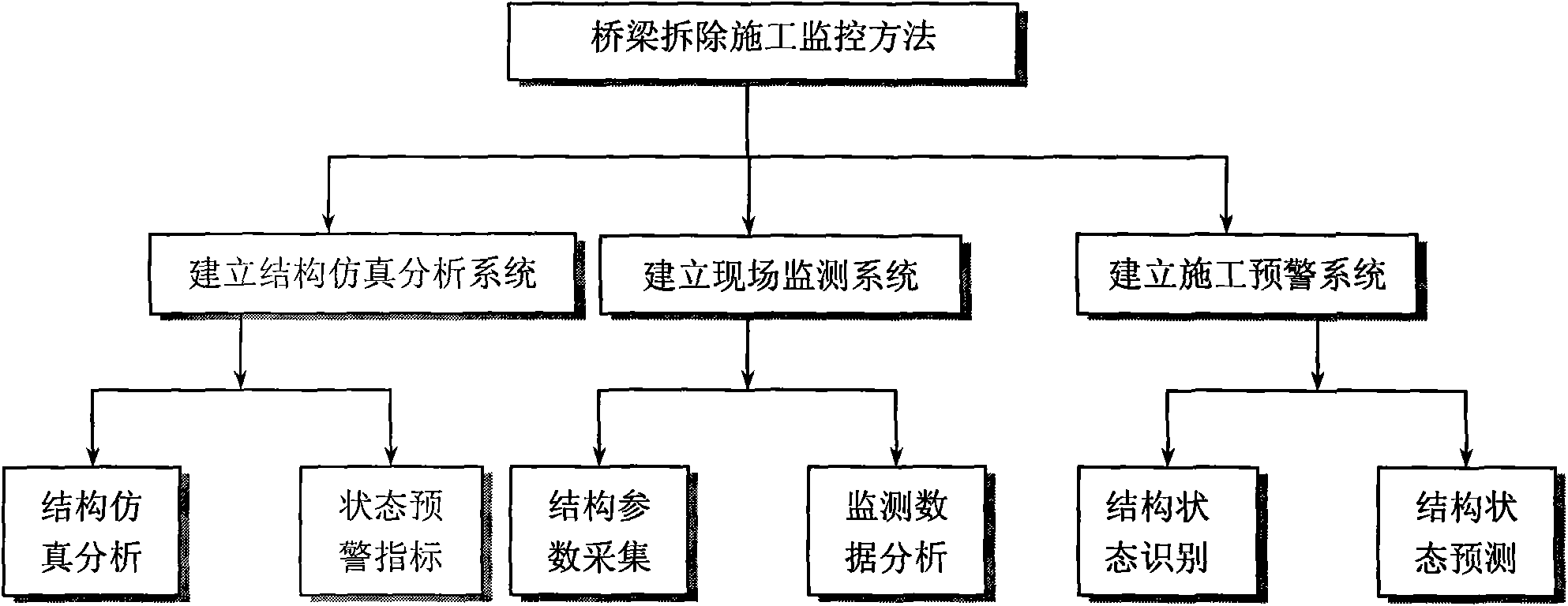

[0025] like figure 1 As shown, the channel bridge demolition construction monitoring method includes the following steps:

[0026] Step (1) Bridge demolition process

[0027] First...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com