Experimental device for measuring formaldehyde adsorption property of adsorbent and measuring method thereof

An experimental device and formaldehyde adsorption technology, applied in the field of indoor environmental inspection, can solve the problems of inability to control temperature and humidity, difficulty in injecting formaldehyde, time-consuming and other problems, and achieve the effect of avoiding the destruction of adsorption balance and solving the difficulty in determining the amount of formaldehyde injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

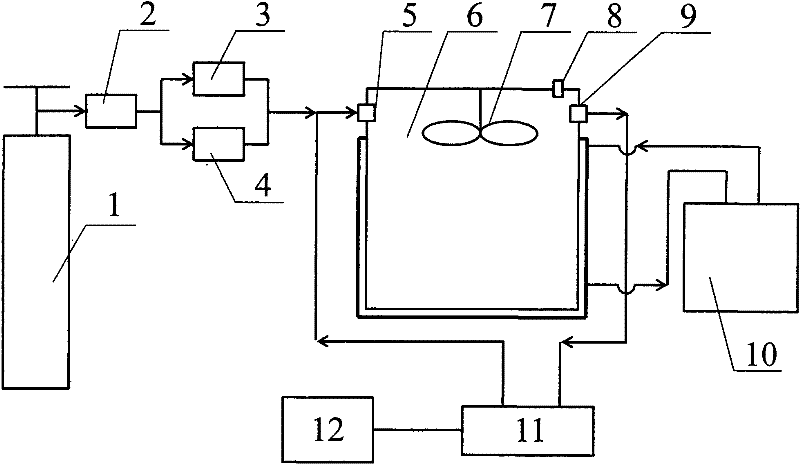

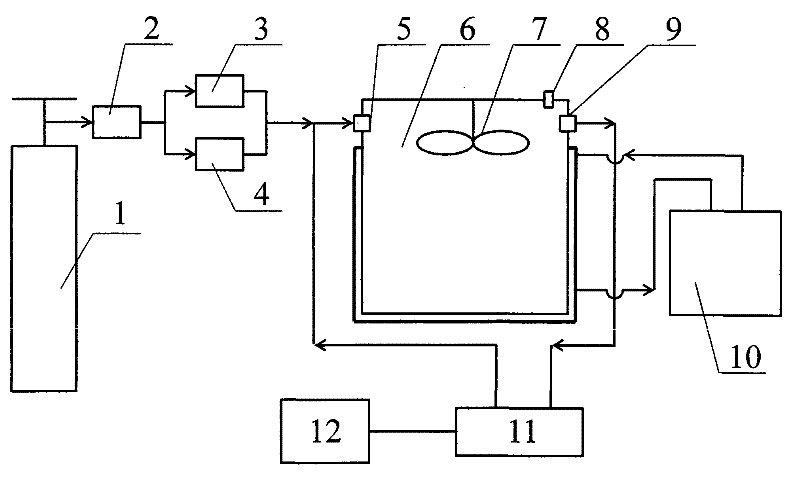

[0020] The present invention proposes due to the experimental method and the device of measuring adsorbent formaldehyde adsorption performance in conjunction with accompanying drawing and embodiment are described in detail as follows:

[0021] The overall schematic diagram of the experimental device of the present invention, as figure 1 As shown, the experimental device includes a constant temperature water bath 10 that can set the temperature, a compressed gas cylinder 1 that provides carrier gas, a main flow controller 2 and a branch flow controller 3 that control and measure the flow of the carrier gas, and a tank filled with distilled water. Gas washing bottle 4, an environmental chamber 6 with a jacket, an acousto-optic gas analyzer 11 and a display 12 for online real-time detection of formaldehyde concentration; an air inlet 5 and an air outlet 9 are provided on the opposite side walls of the environmental chamber 6, and the top Stirring fan 7 is installed and sampling h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com