Automatic darkening and glare reducing liquid crystal mirror

A reflective mirror and liquid crystal technology, applied in the field of reflective mirrors, can solve the problems that reflective mirrors are not feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

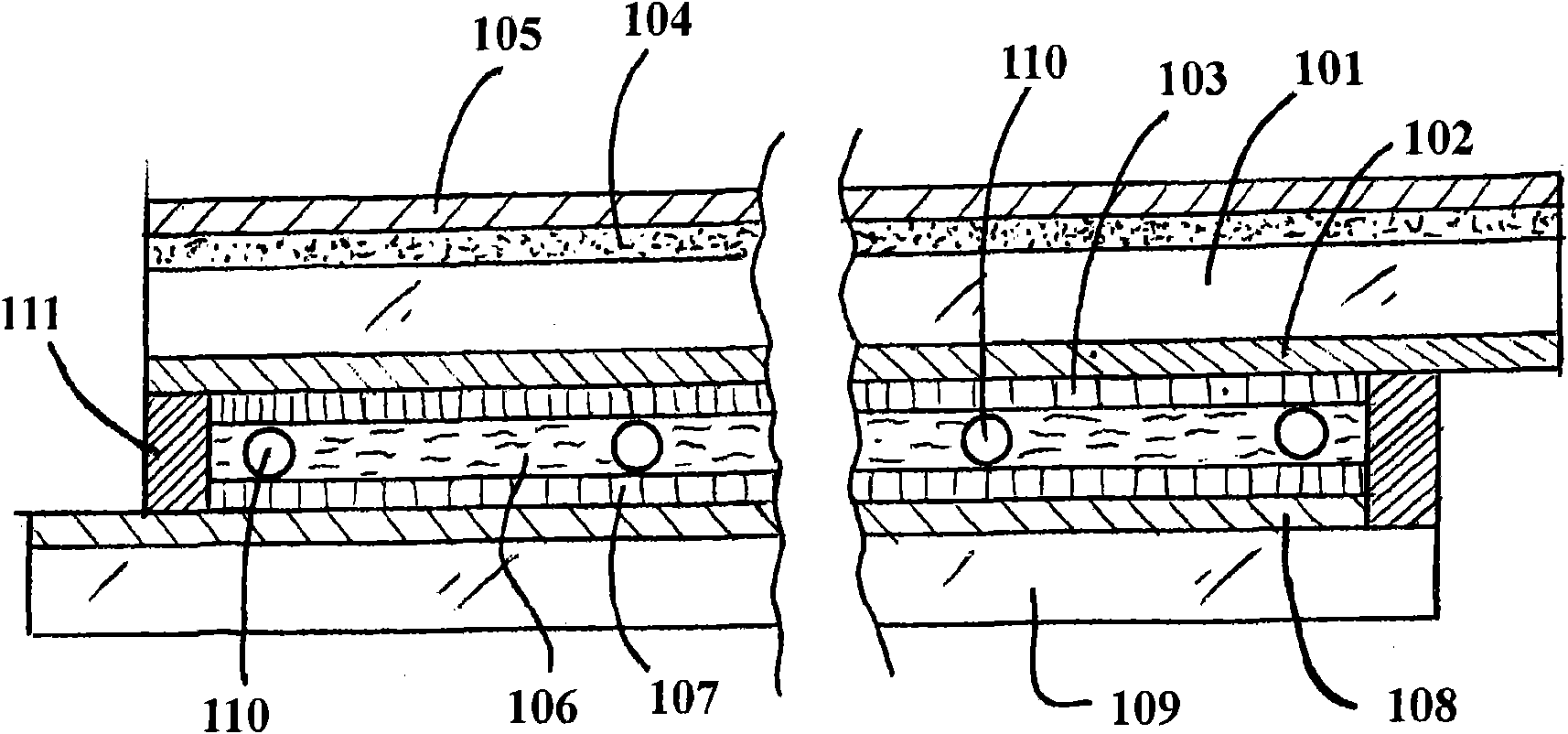

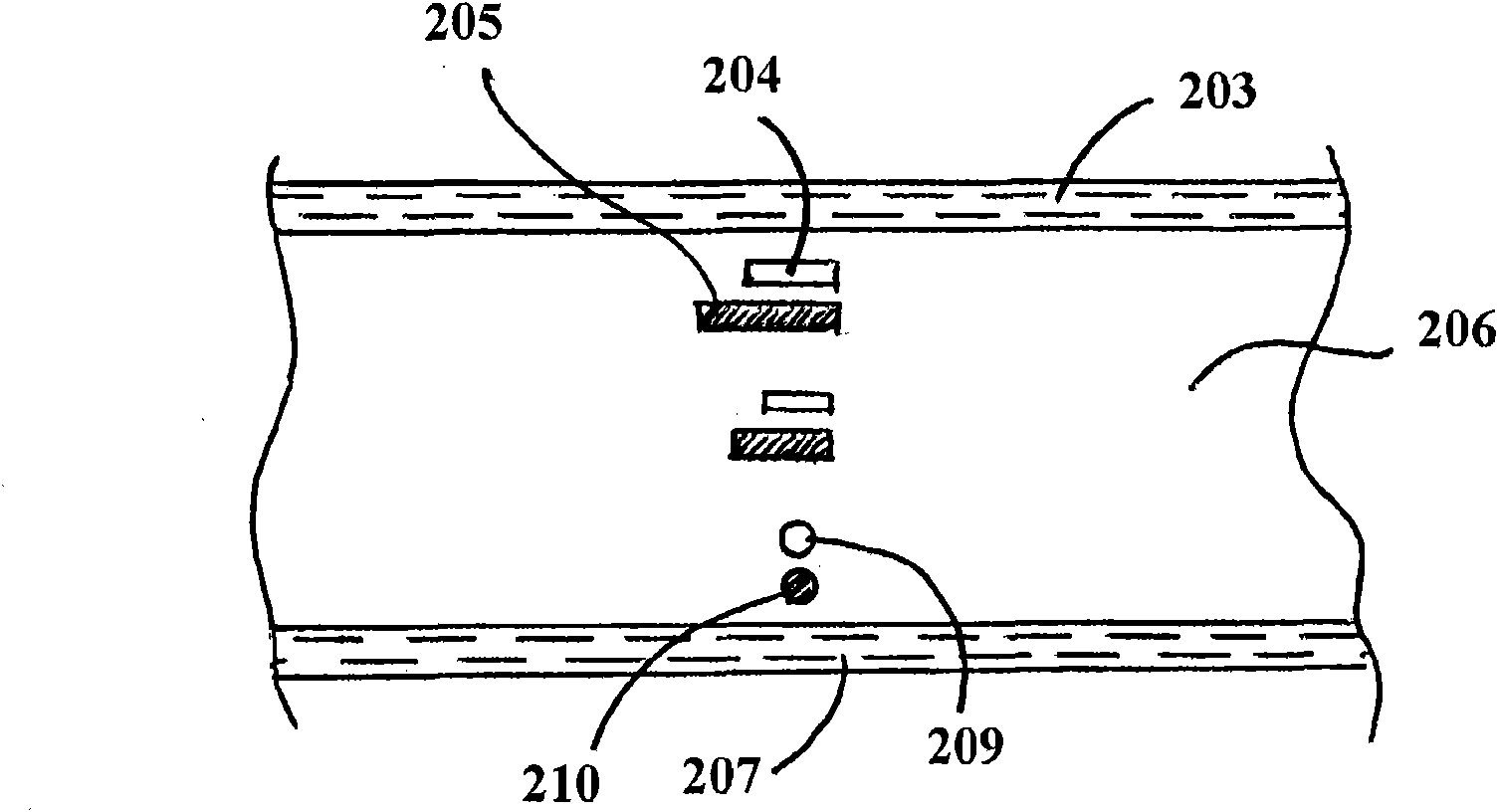

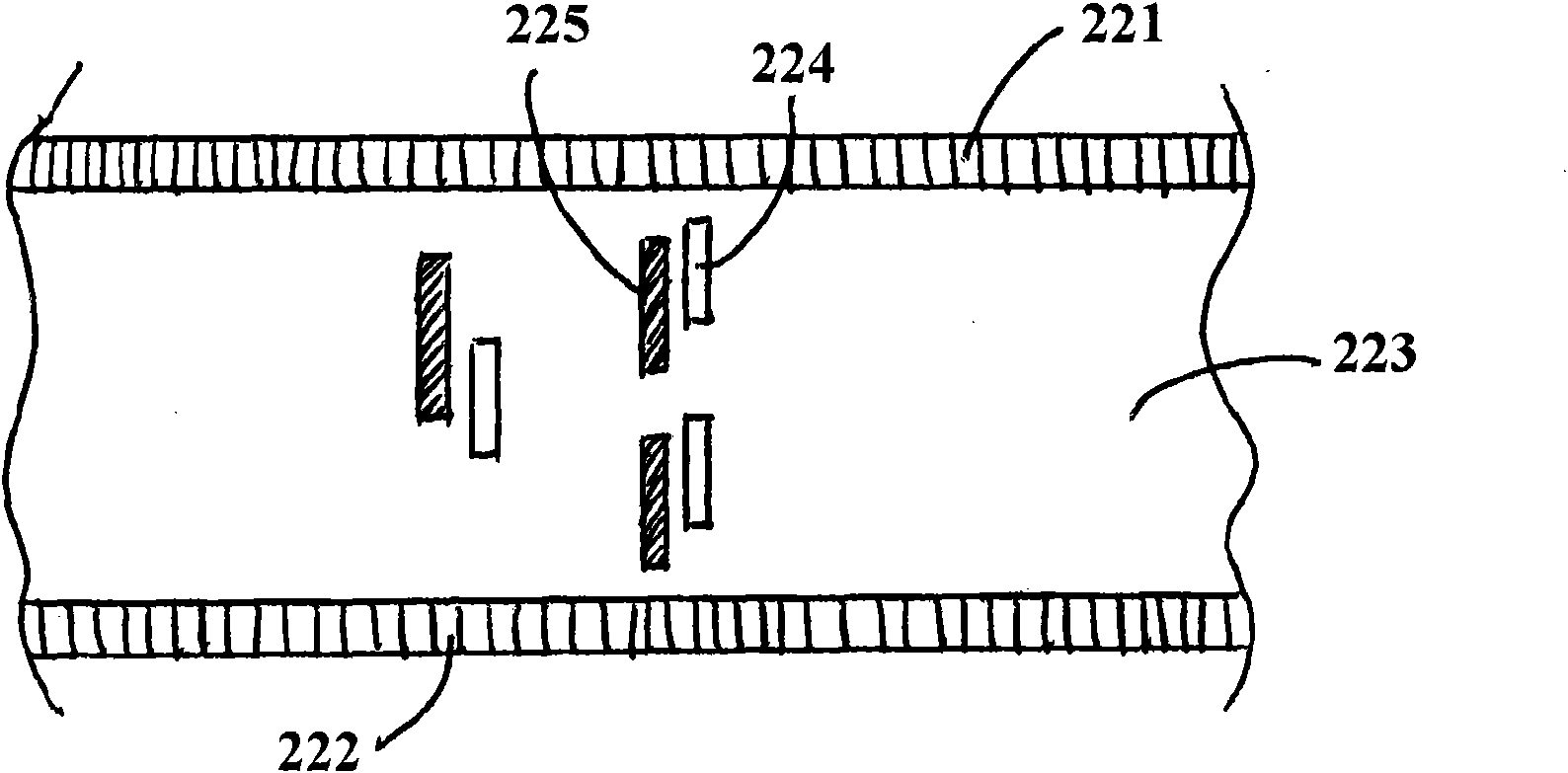

[0017] Before discussing the present invention in detail with reference to the accompanying drawings, several aspects of the mirror system of the present invention and its electronic control system will be described in order to understand the detailed description that follows. These aspects include the various components of the LC chemistry system as well as the mirror control electronics.

[0018] 1. LC chemical system

[0019] The performance of the LC mirrors of the present invention is dependent on the chemical system, which includes the nature and properties of the alignment compounds used for the LC molecules and their closely related LC material formulations. Certain LC fluids with dichroic dyes work consistently with oriented compounds already formed. The two materials must be compatible and mix well to establish the LC molecular orientation required for maximum optical performance. With the LC techniques described herein, two types of LC mirrors can be constructed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com