Patents

Literature

42 results about "Dark mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High quality-factor Fano metasurface comprising a single resonator unit cell

ActiveUS20170063039A1High quality factorSuppress emissionLaser optical resonator constructionOptical elementsDark modeSpectral filtering

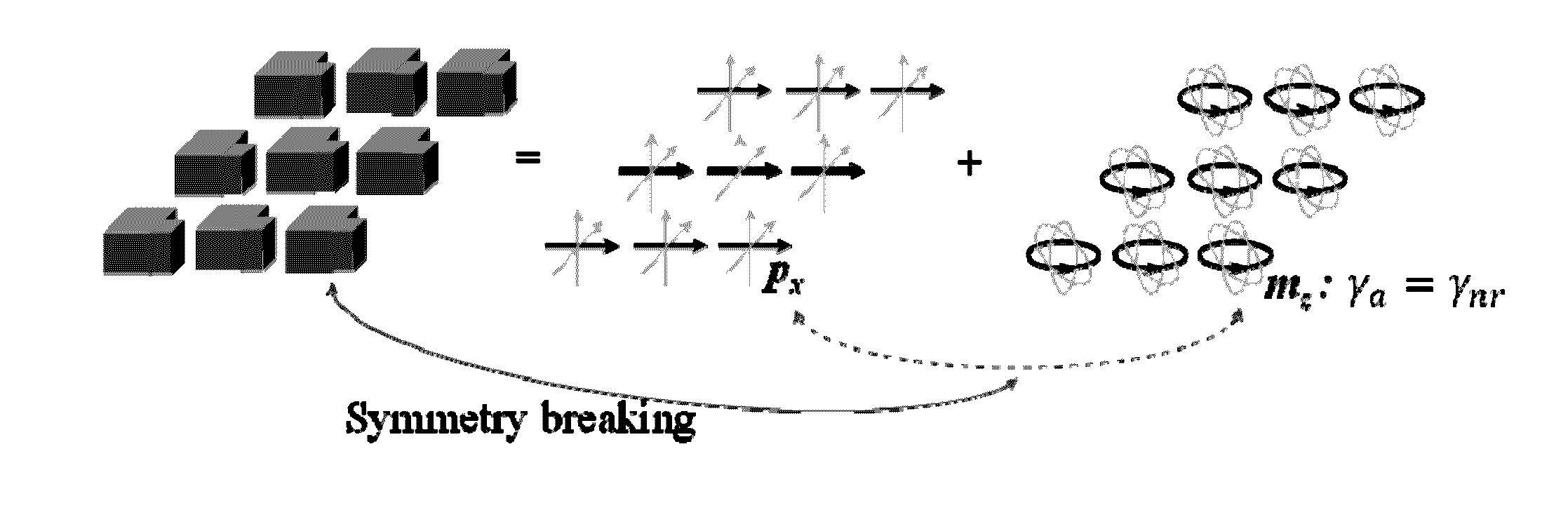

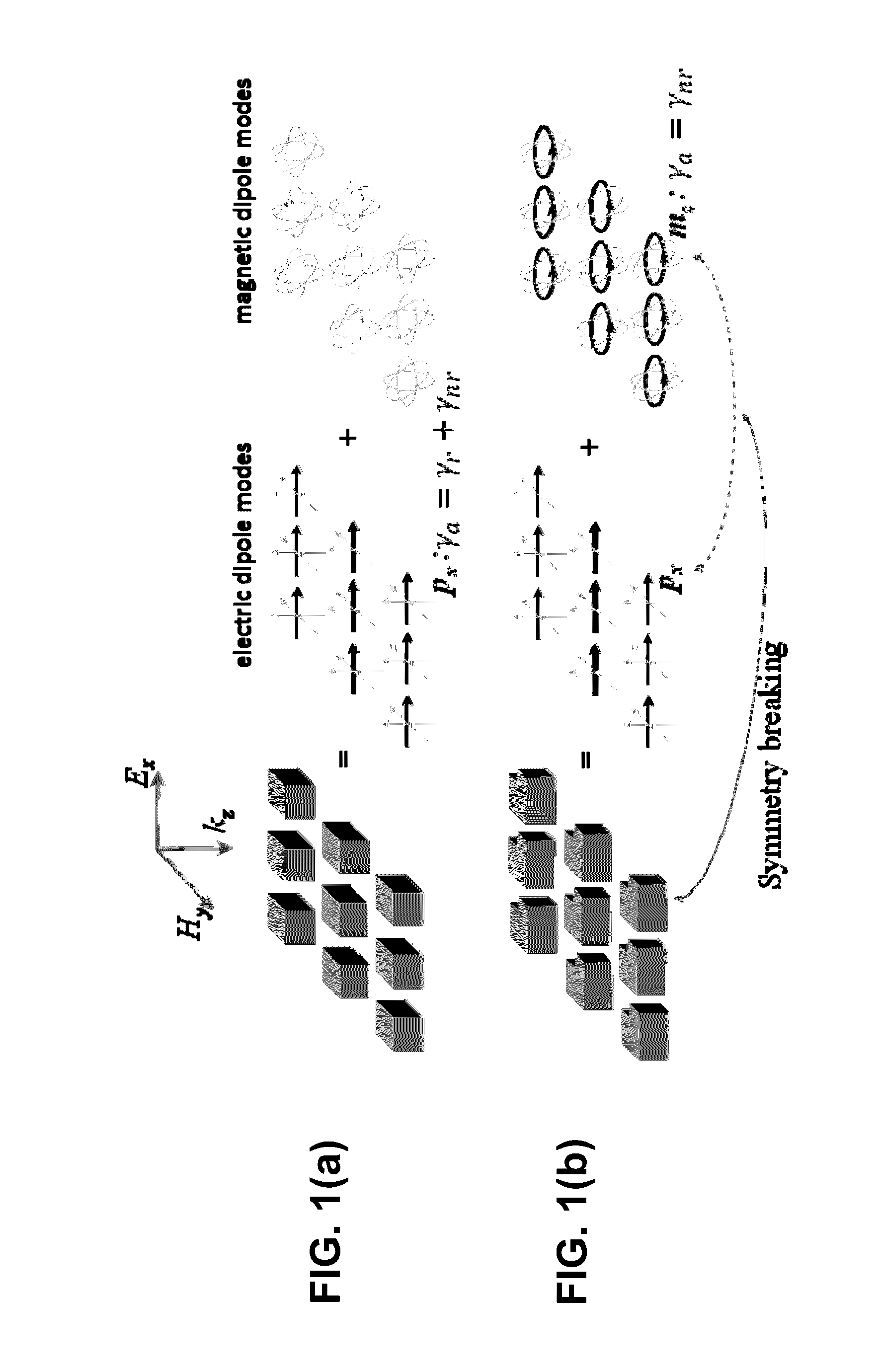

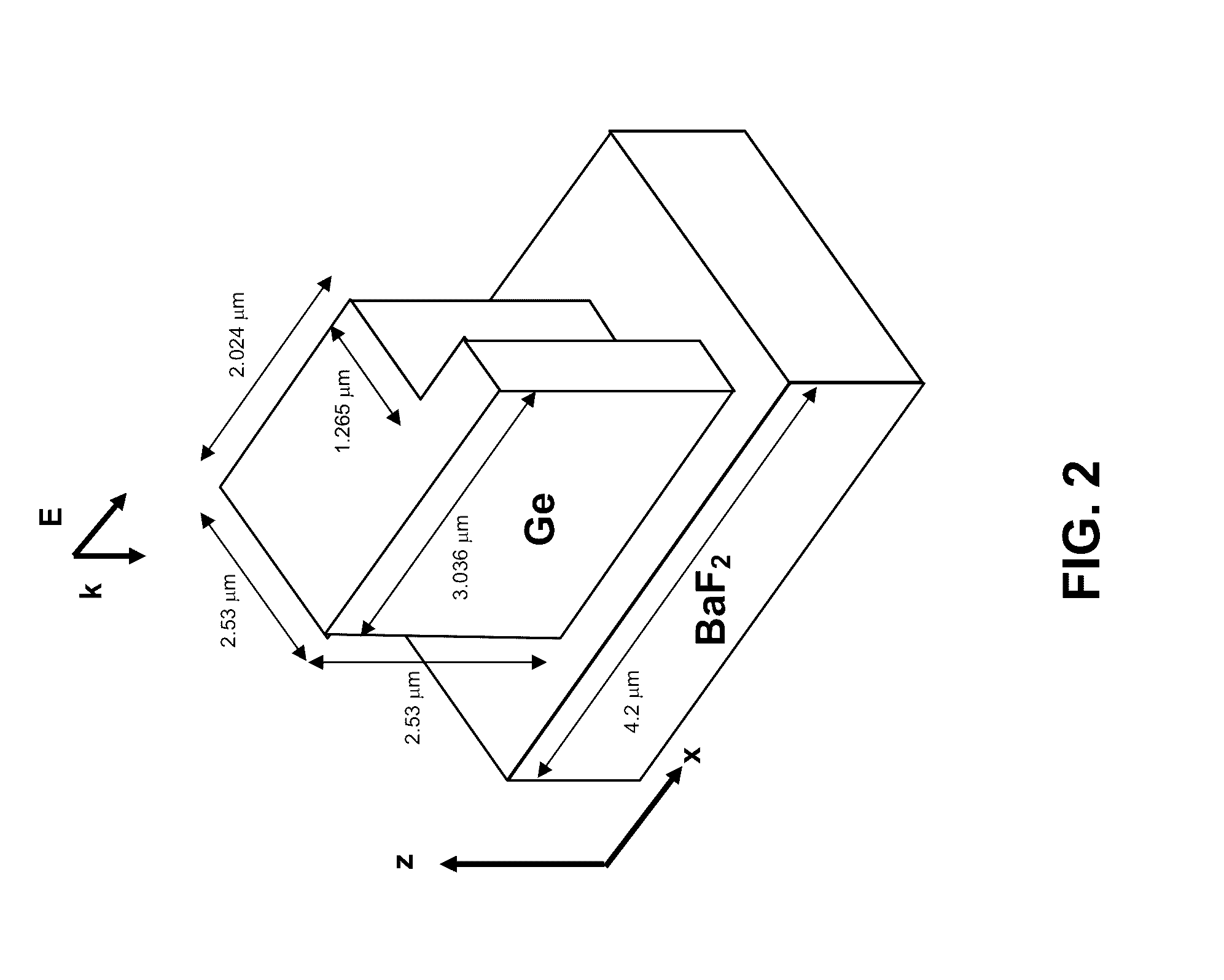

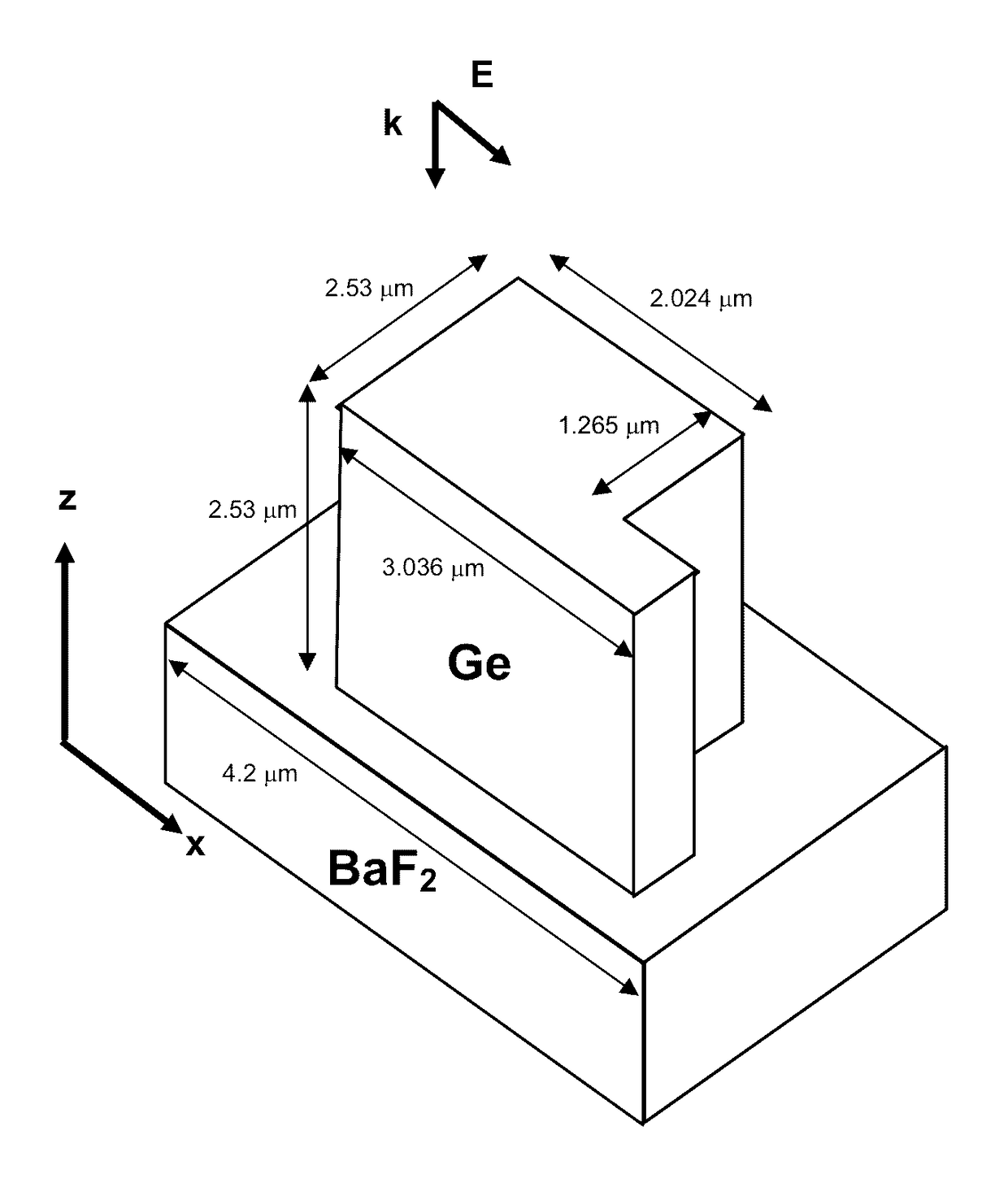

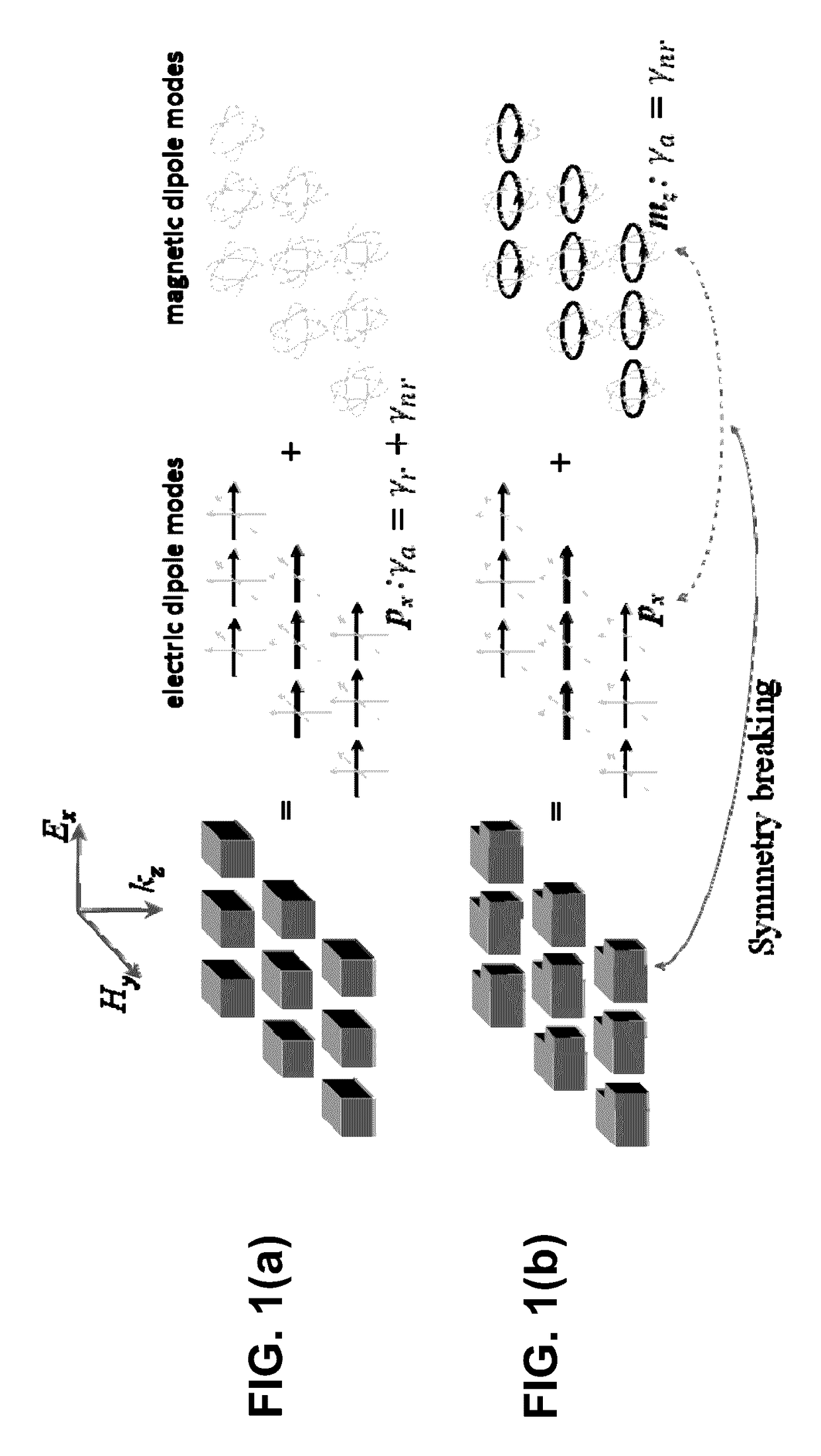

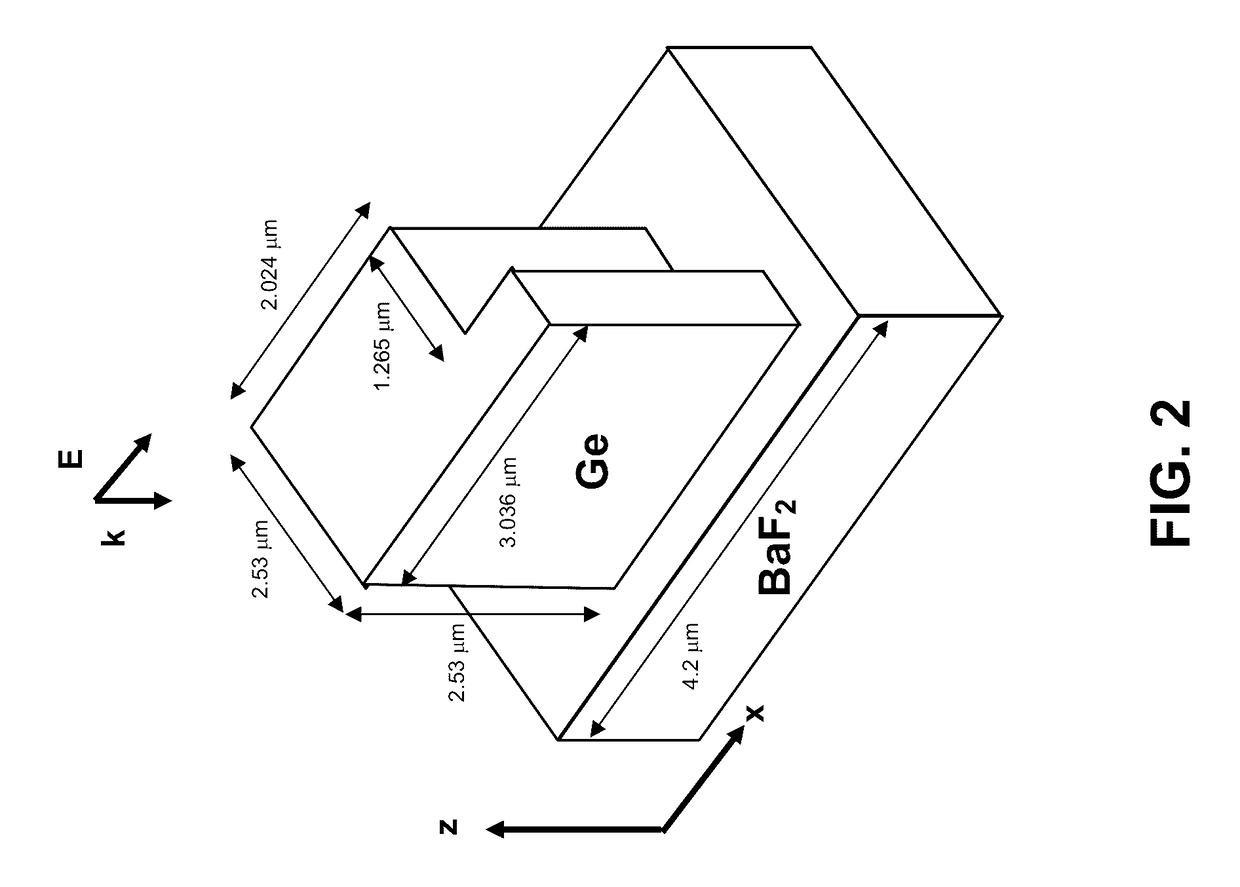

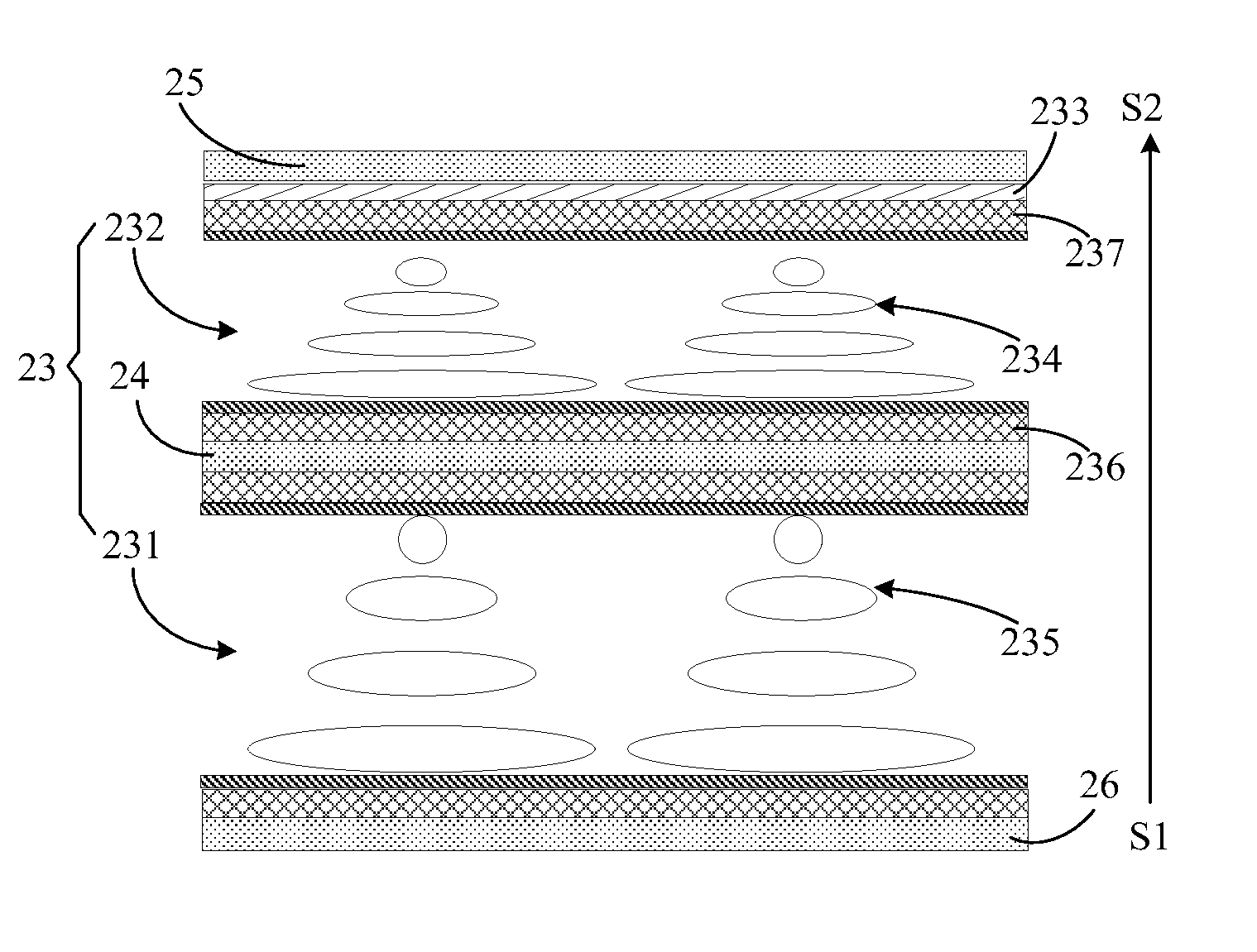

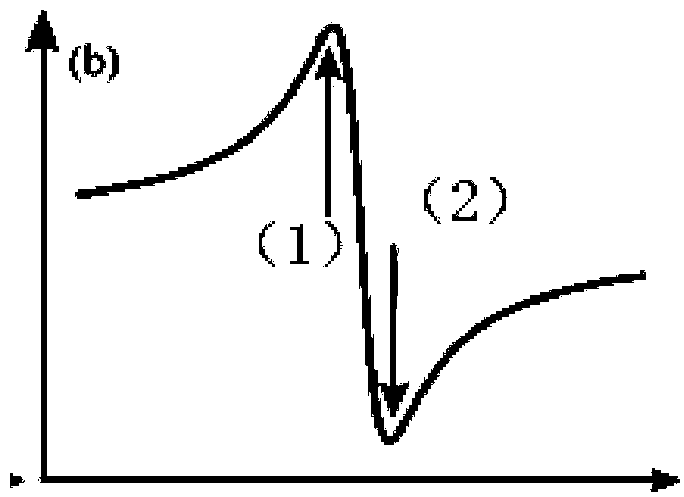

A new monolithic resonator metasurface design achieves ultra-high Q-factors while using only one resonator per unit cell. The metasurface relies on breaking the symmetry of otherwise highly symmetric resonators to induce intra-resonator mixing of bright and dark modes (rather than inter-resonator couplings), and is scalable from the near-infrared to radio frequencies and can be easily implemented in dielectric materials. The resulting high-quality-factor Fano metasurface can be used in many sensing, spectral filtering, and modulation applications.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

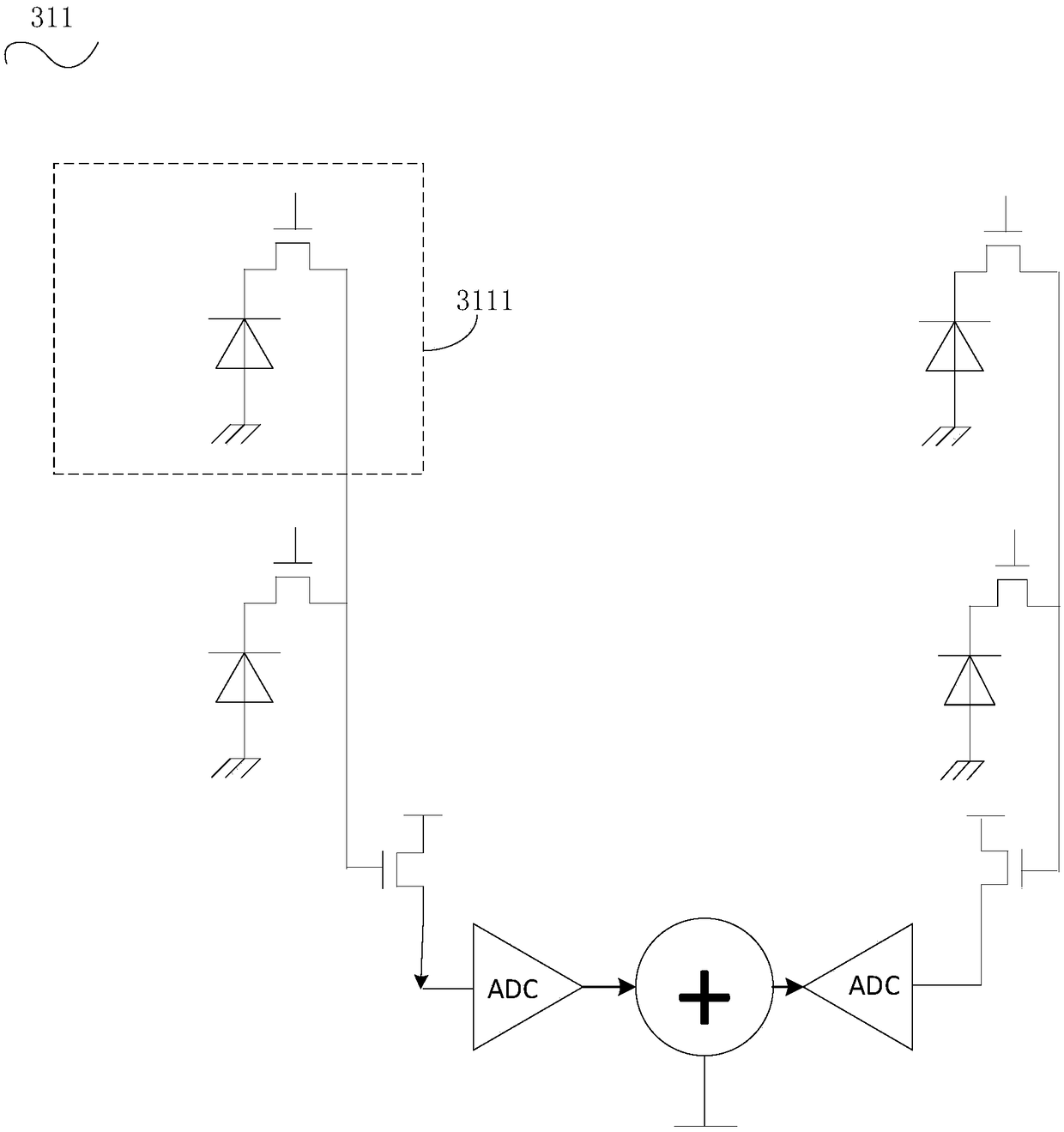

Control method and device, imaging equipment, computer equipment and readable storage medium

ActiveCN108200354AImprove shooting experienceTelevision system detailsColor television detailsWork patternDark mode

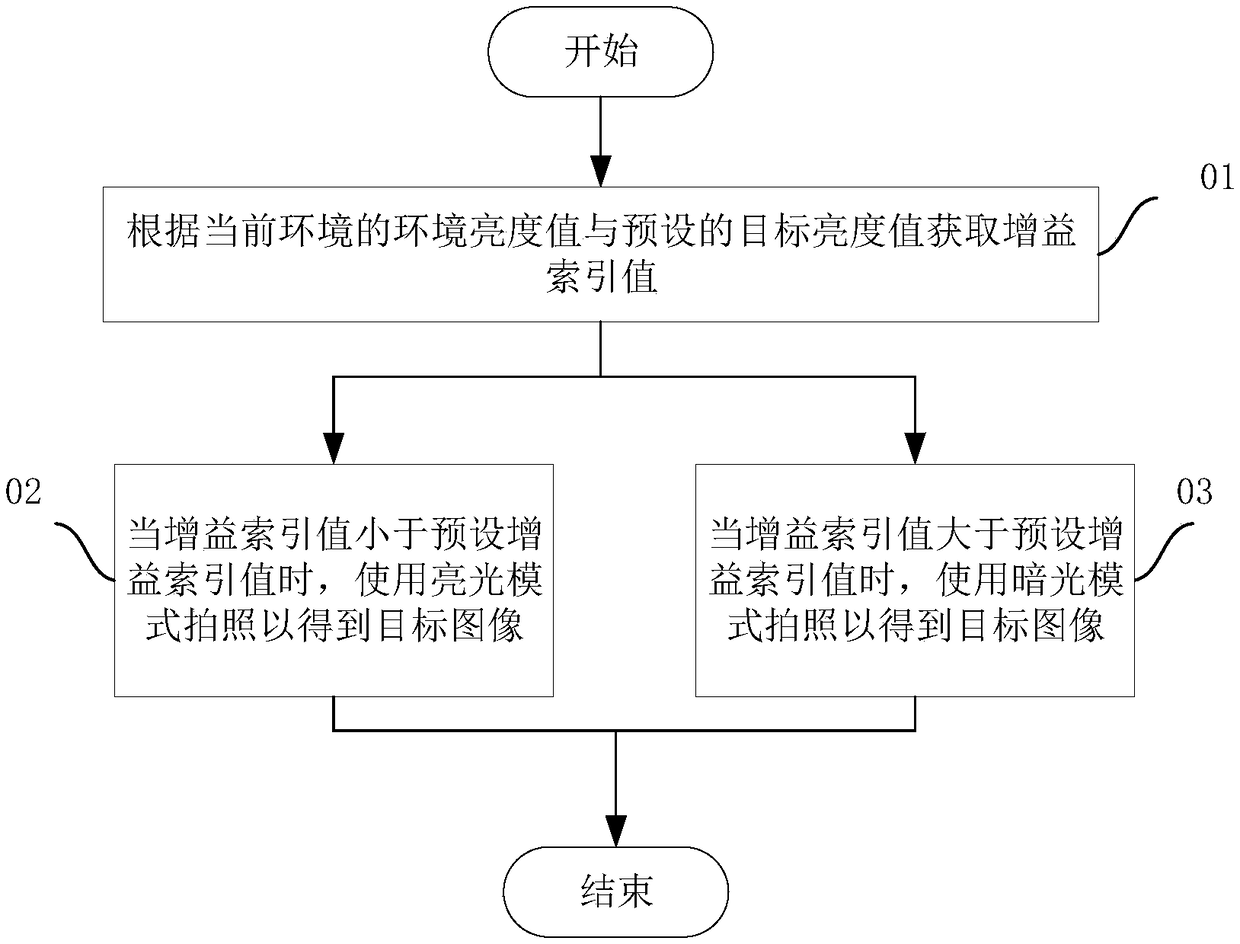

The invention discloses a control method and device, imaging equipment, computer equipment and a non-volatile computer readable storage medium. The imaging equipment comprises a pixel unit array, andthe pixel unit array comprises multiple pixel units; the control method comprises the following steps: acquiring a gain index value according to an ambient brightness value of the current environmentand the preset target brightness value; when the gain index value is less than the preset gain index value, photographing by using a light mode to obtain a target image; when the gain index value is greater than the preset gain index value, photographing by using a dark mode to obtain the target image. Trough the control method and device, imaging equipment, computer equipment and the non-volatilecomputer readable storage medium disclosed by the invention, the light-dark situation of the current environment is judged by acquiring the gain index value for representing the light-dark of the environment, furthermore, the appropriate working mode is selected according to the judgment result to shoot the target image with excellent imaging effect, and the shooting experience of the user is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

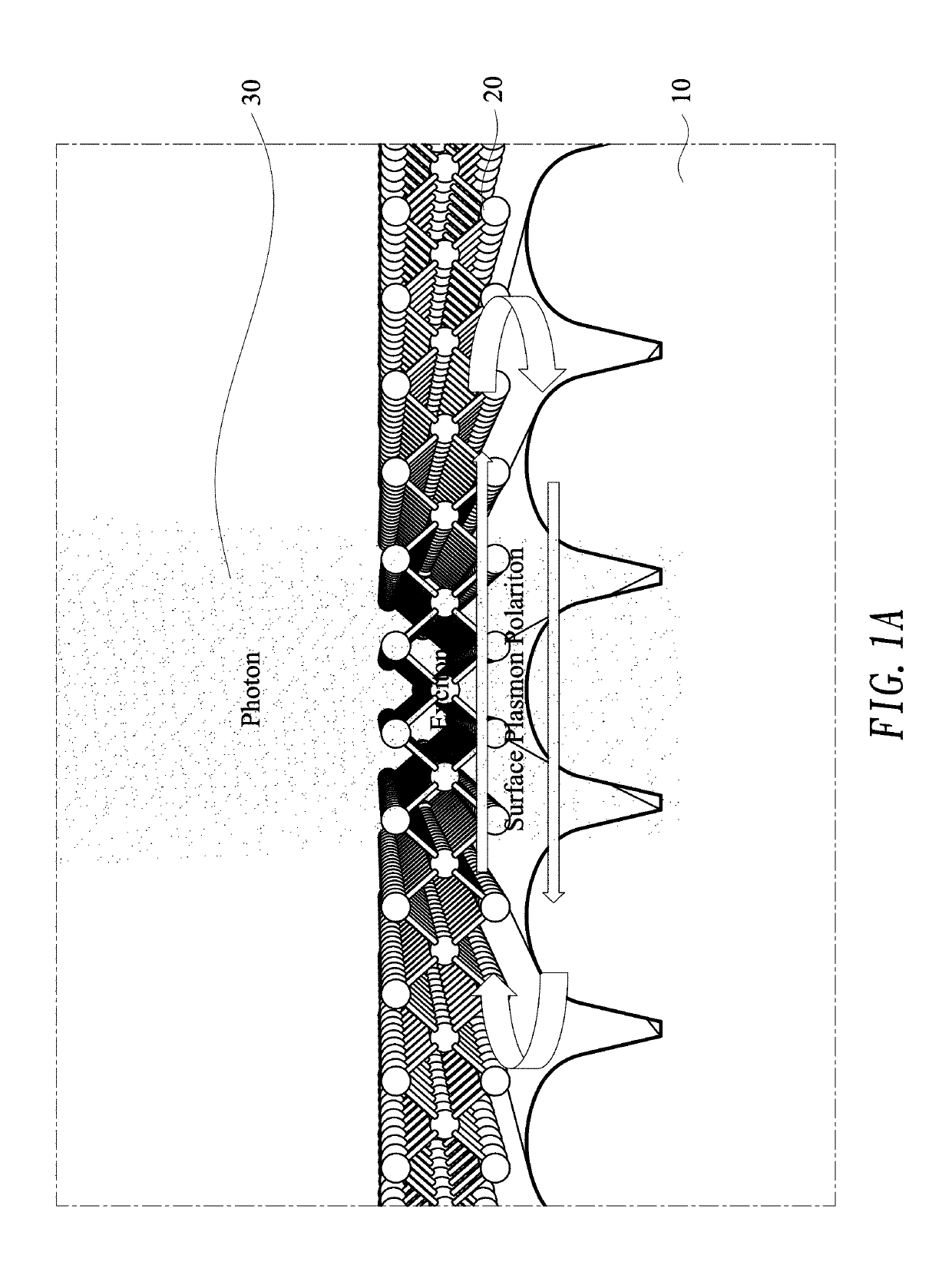

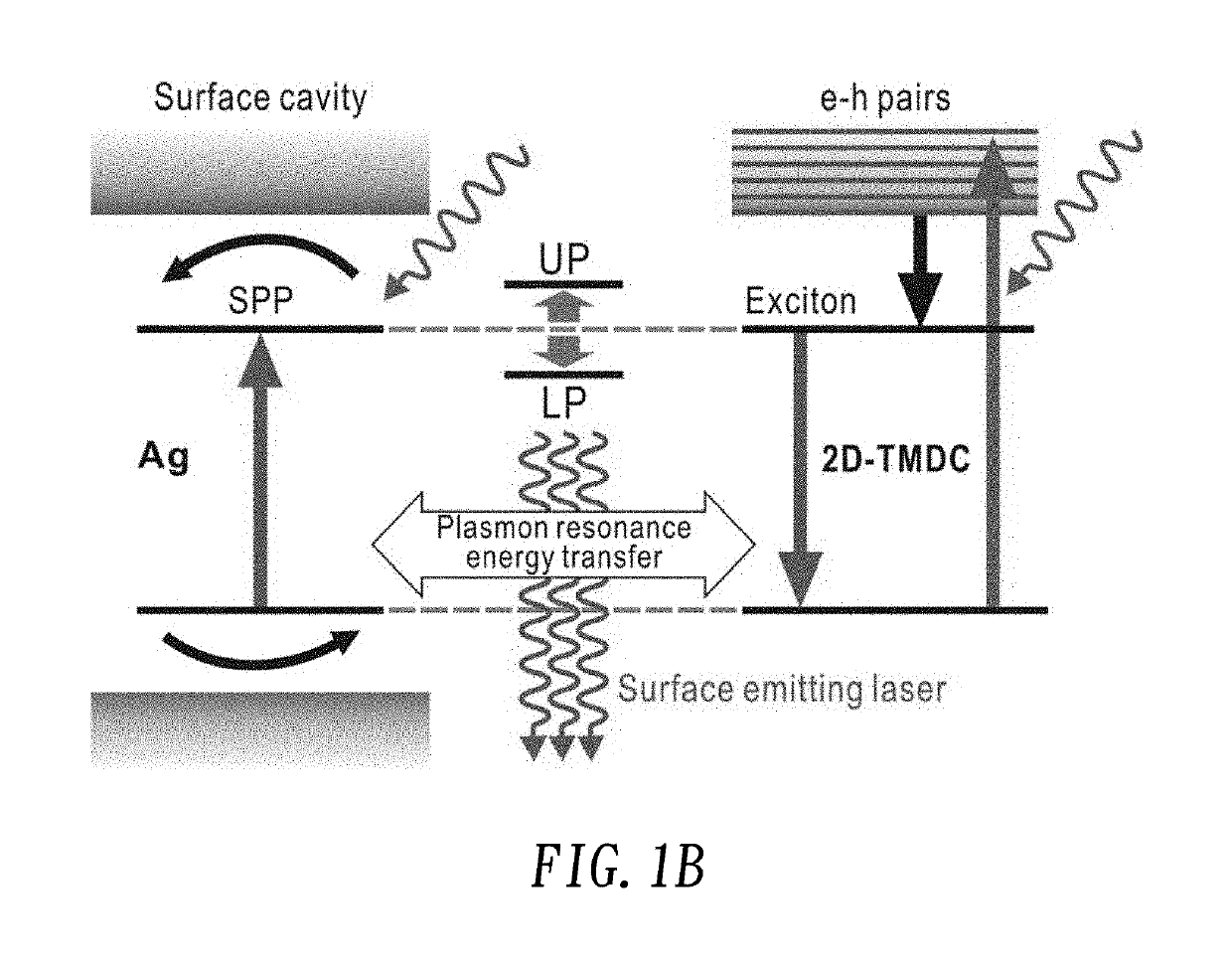

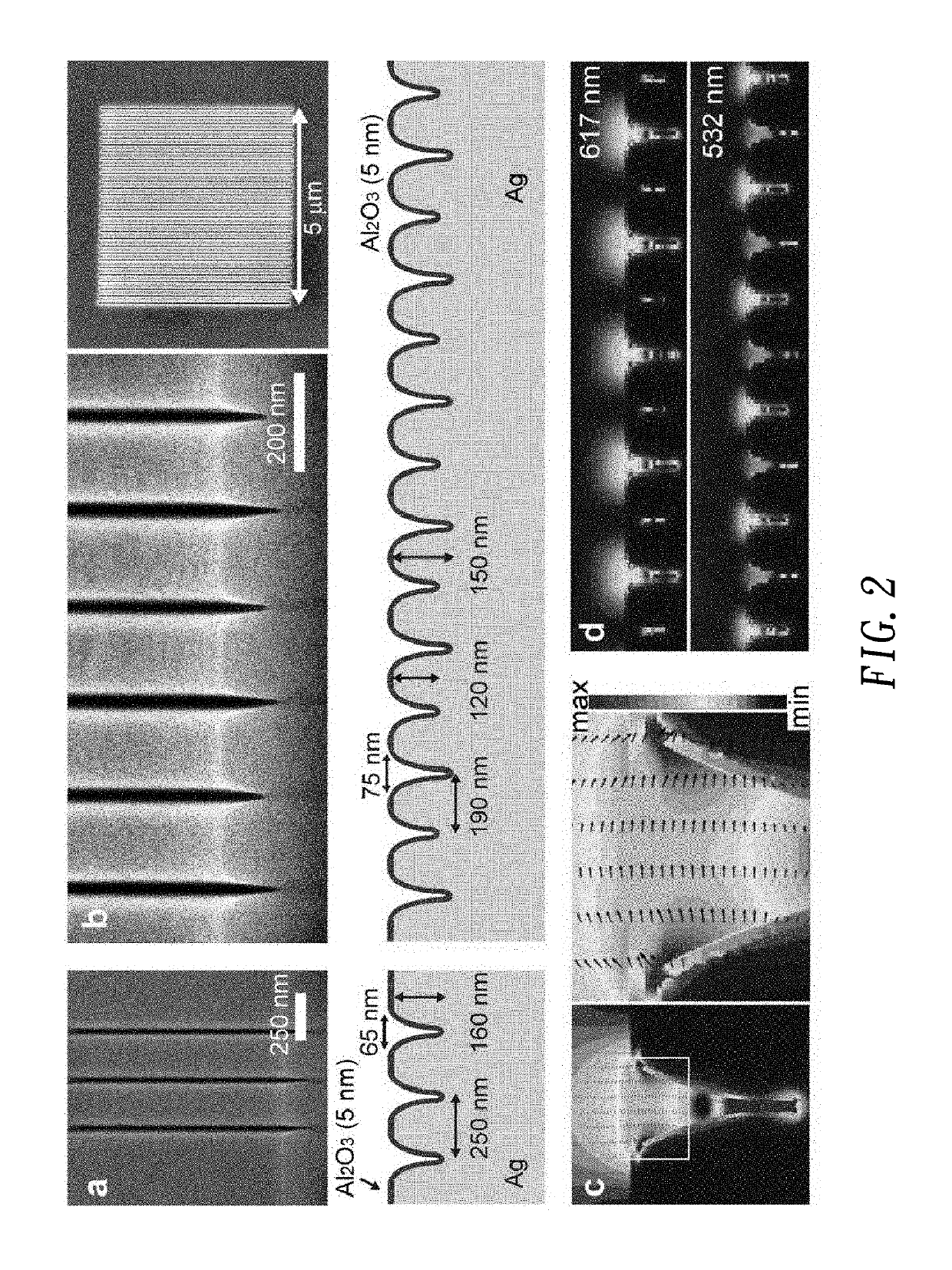

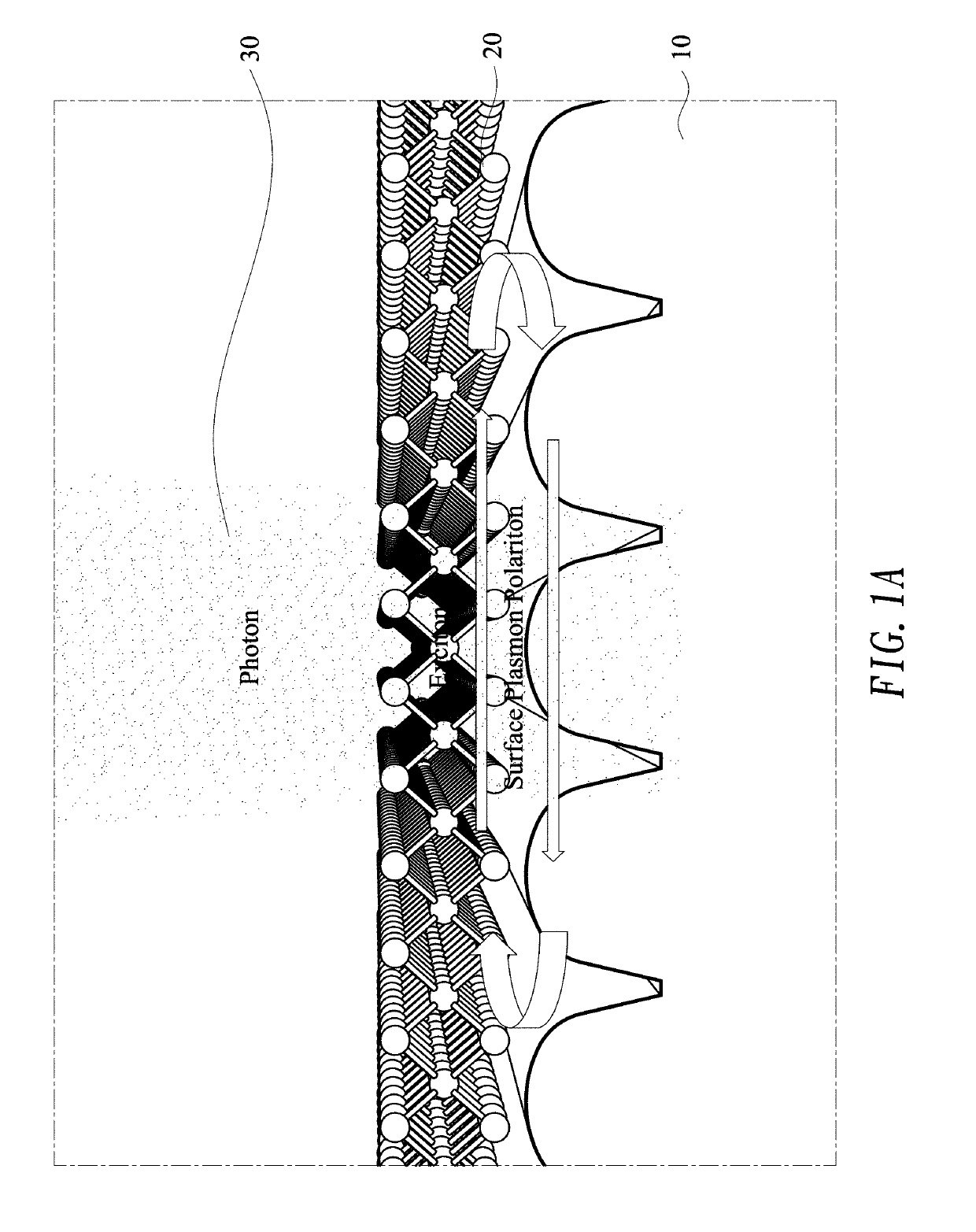

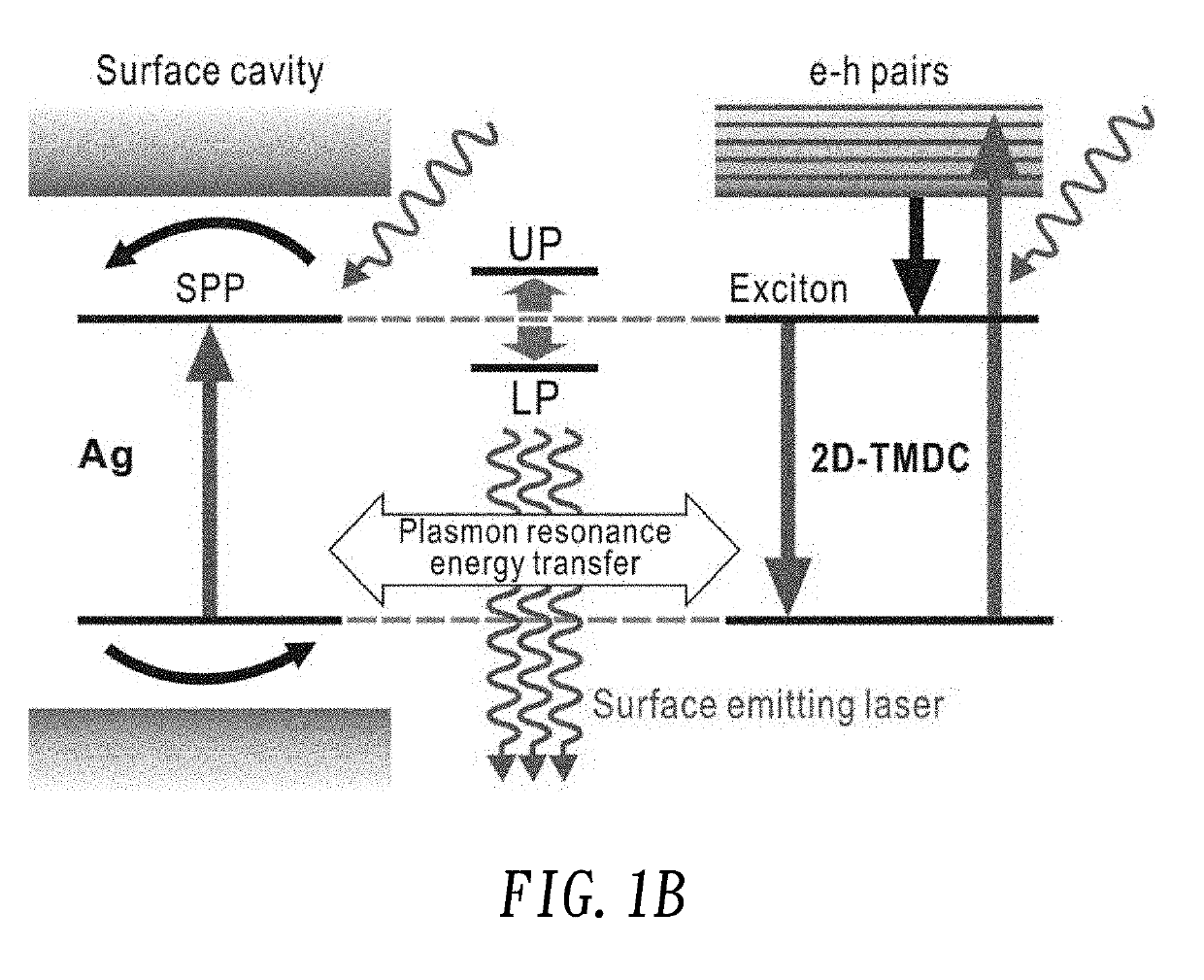

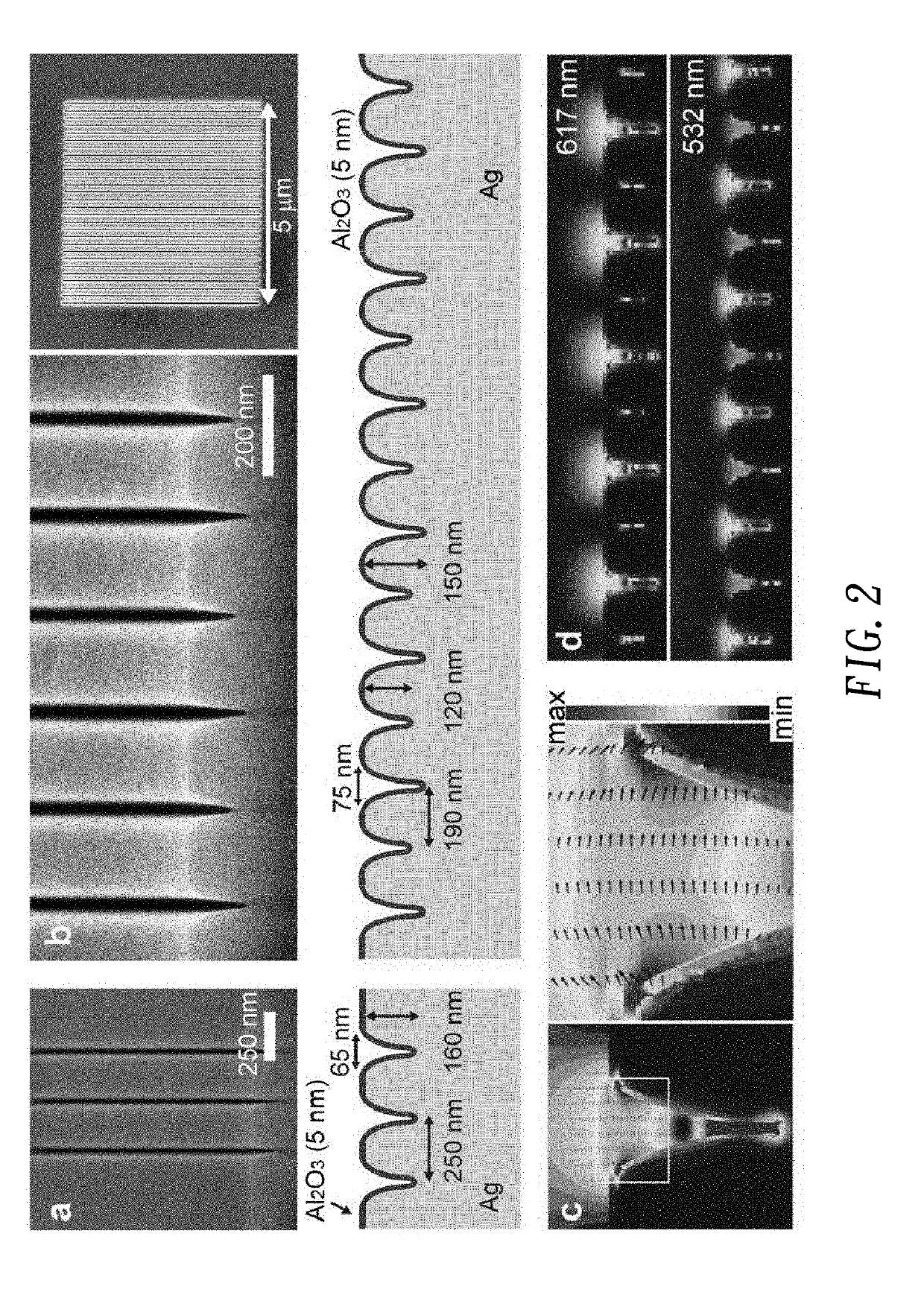

Two-dimensional material plasmonic laser

ActiveUS10348058B1Integrative technologyOptical wave guidanceLaser optical resonator constructionElectron holeOptical pumping

A two-dimensional material plasmonic laser (device) is provided with a surface plasmonic cavity and an atomically thin semiconductor monolayer gain medium disposed on the surface plasmonic cavity. Under optical pumping or electrical pumping, the surface plasmonic cavity provides a laser feedback mechanism by coupling electron-hole pairs confined in the atomically thin semiconductor monolayer gain medium and the surface plasmon modes in the dark-mode surface plasmonic cavity, and a laser light is emitted from the two-dimensional material plasmonic laser.

Owner:NATIONAL TSING HUA UNIVERSITY

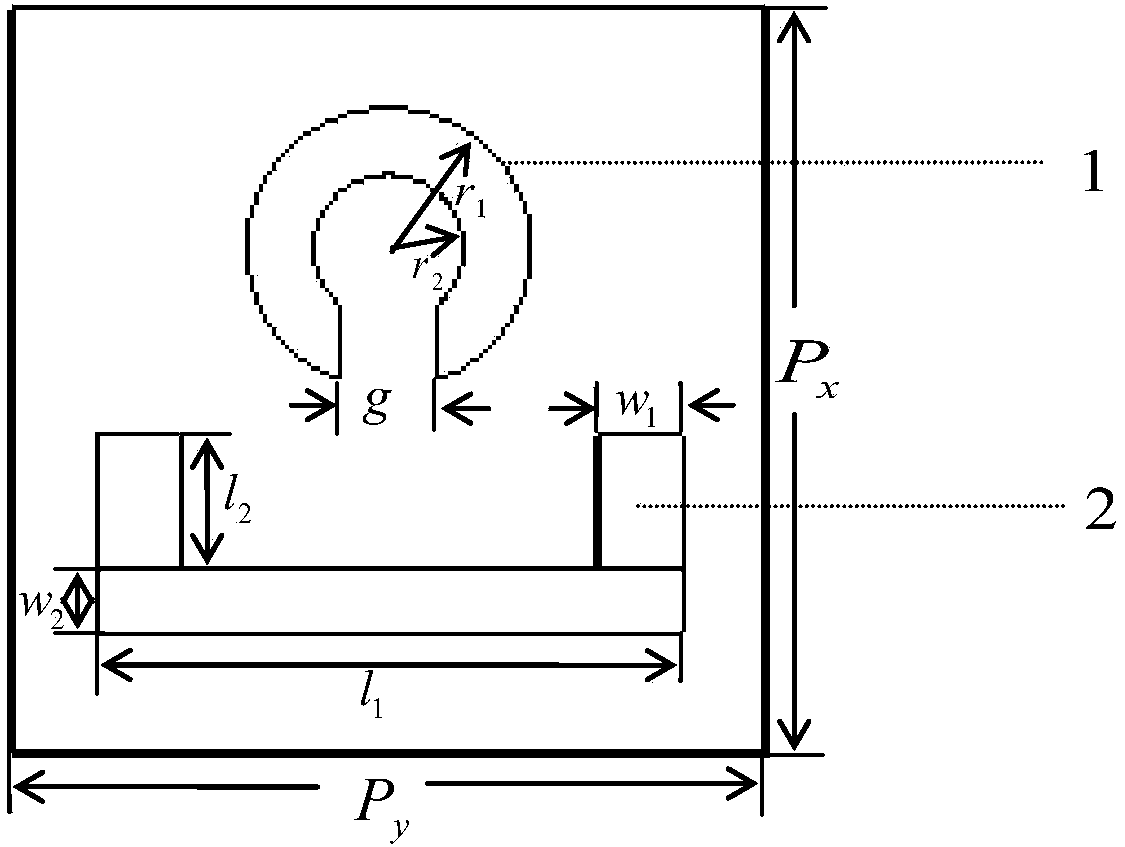

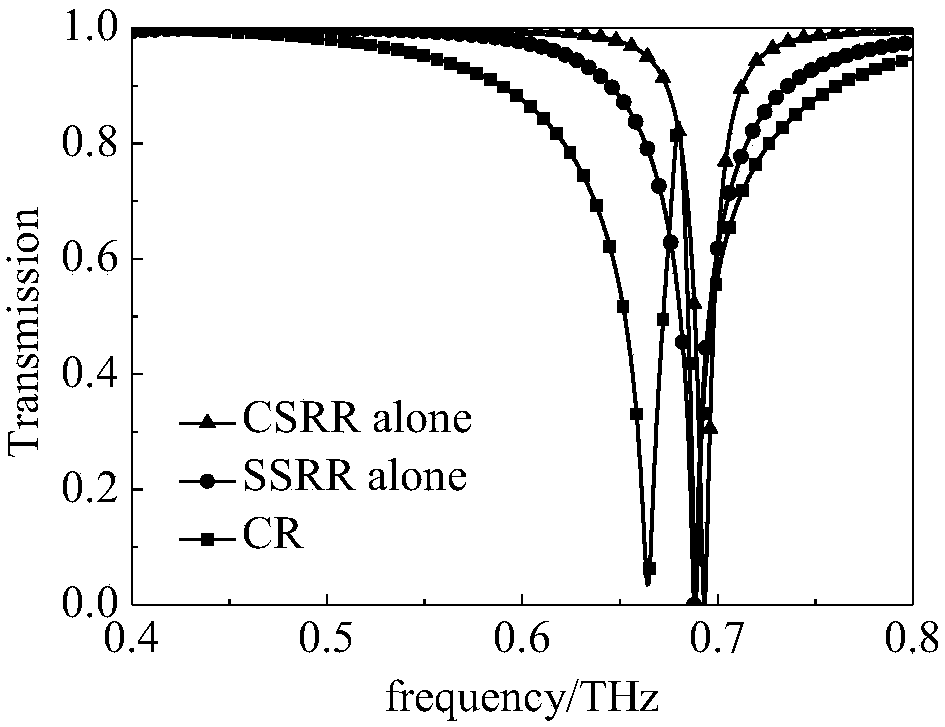

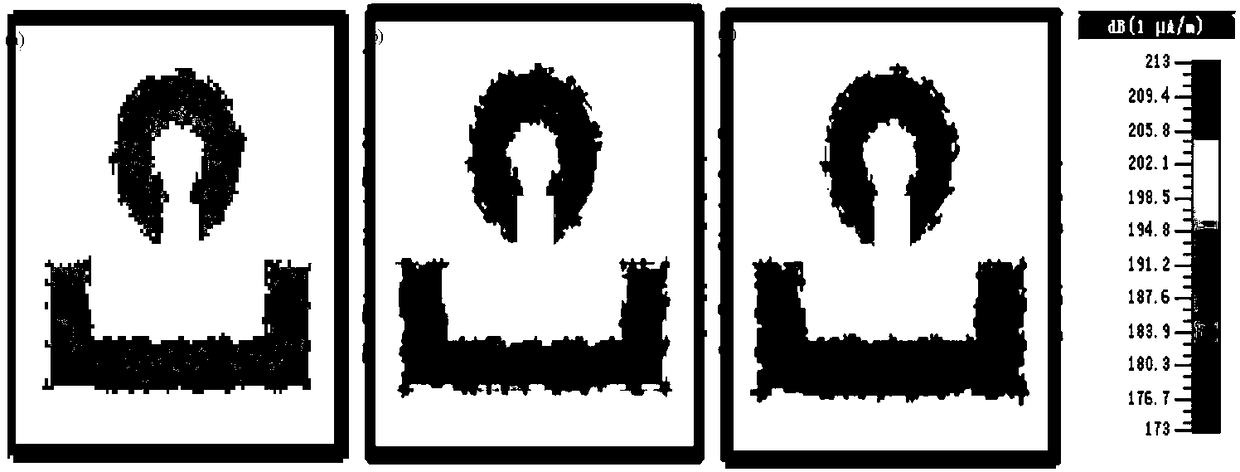

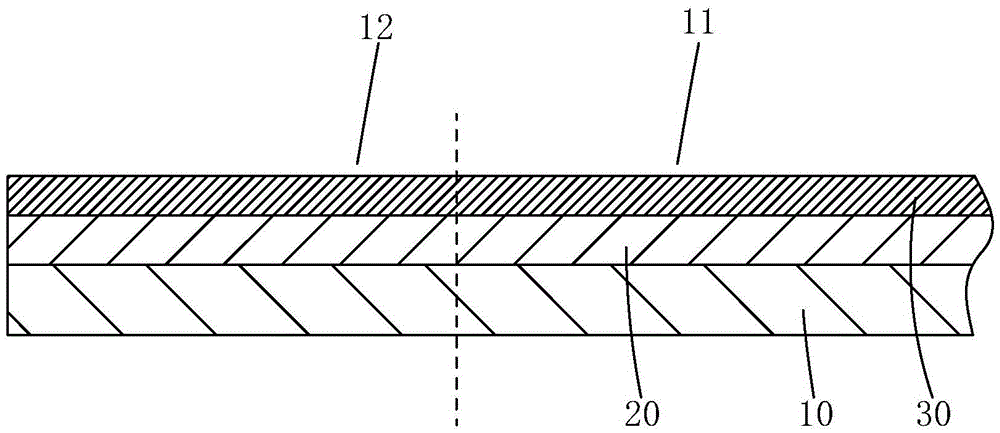

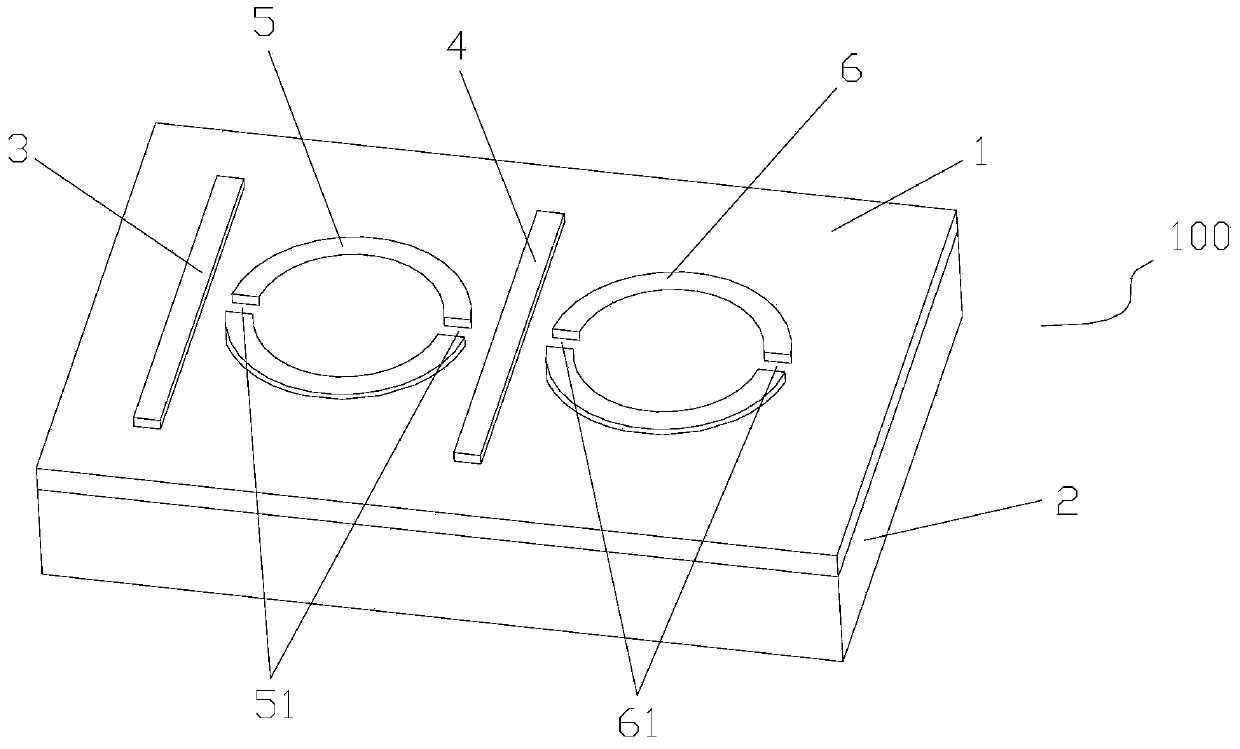

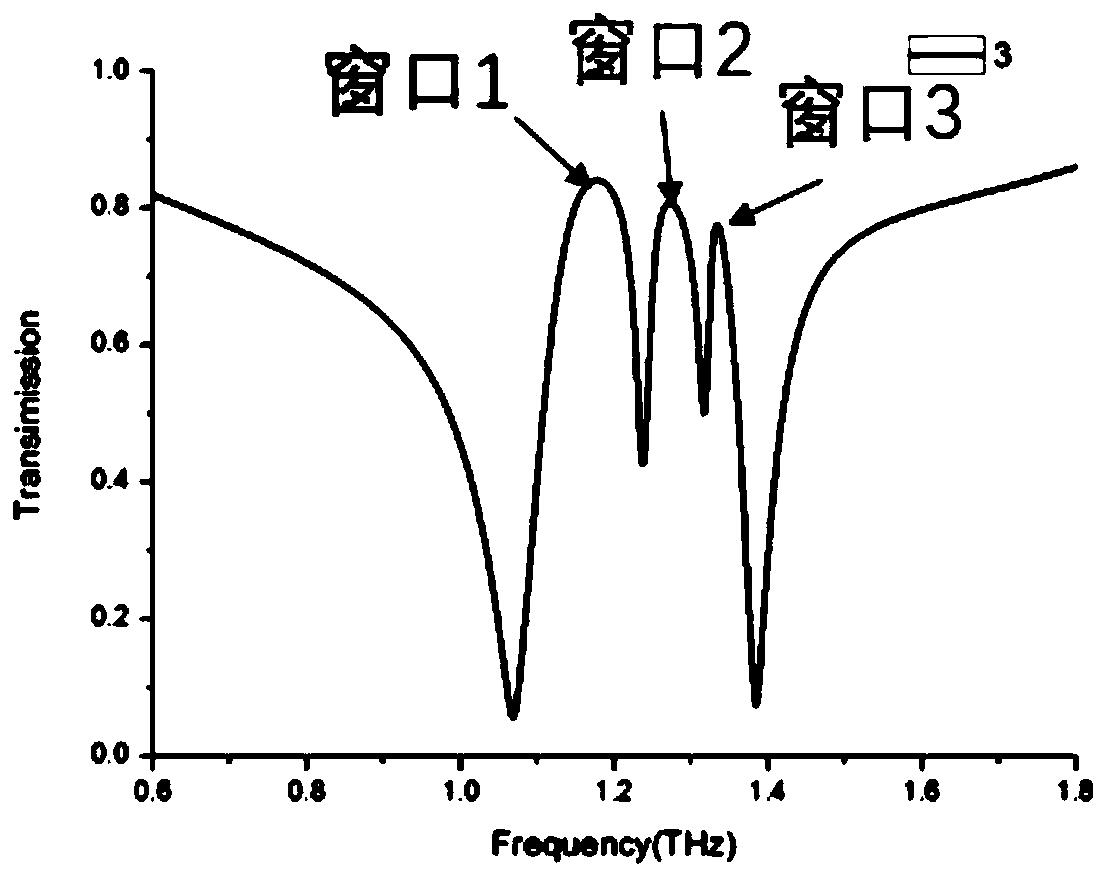

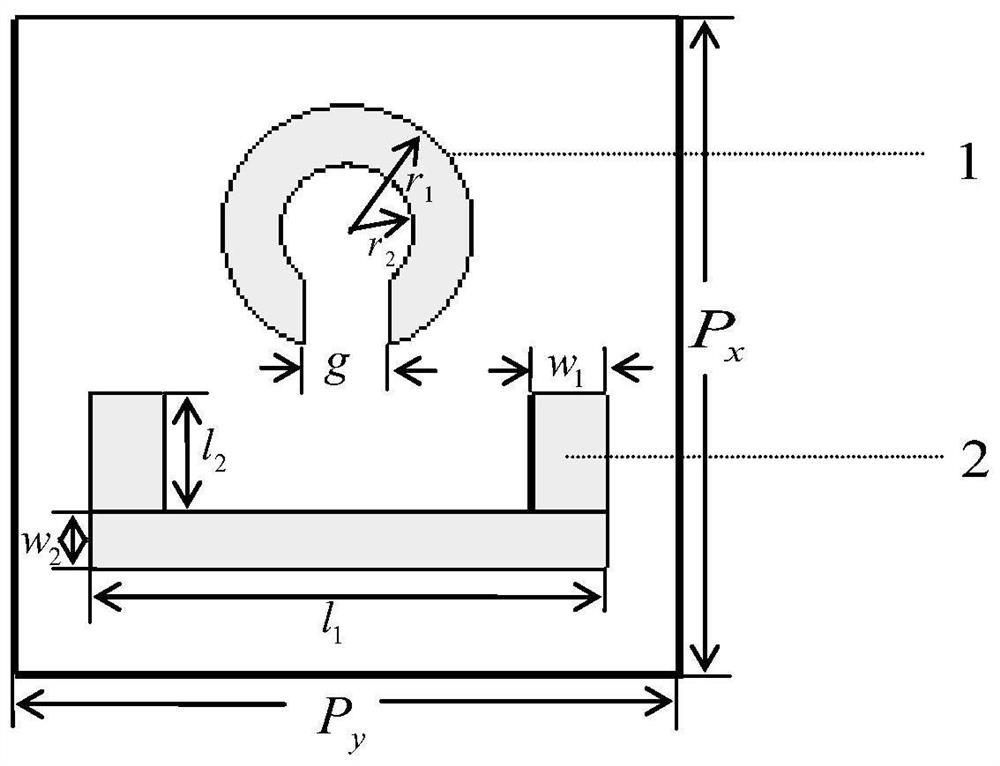

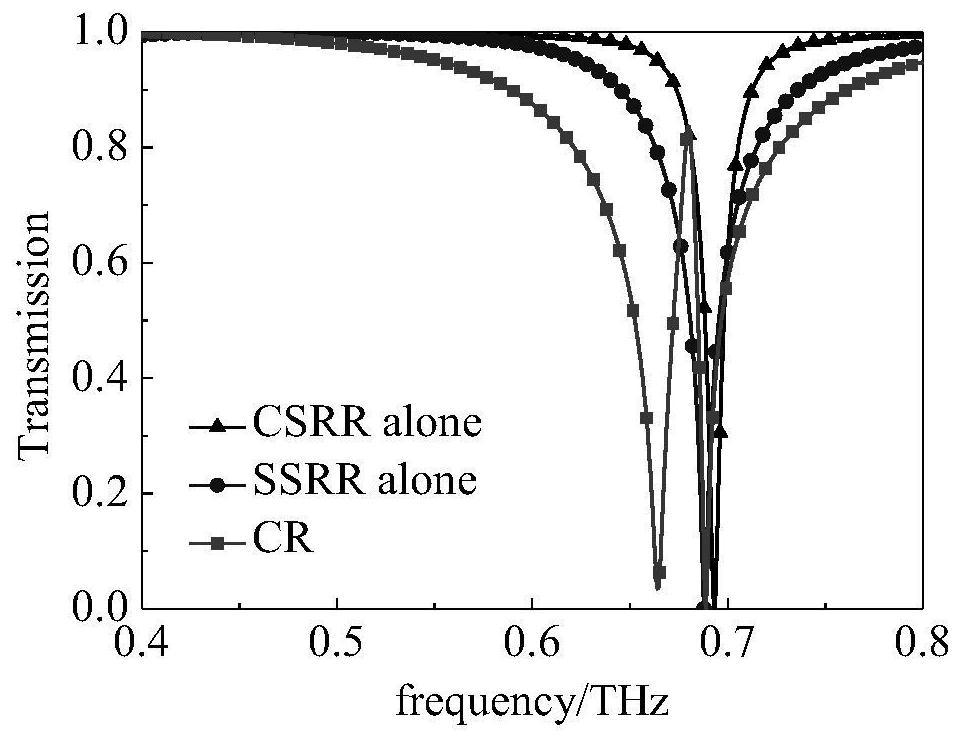

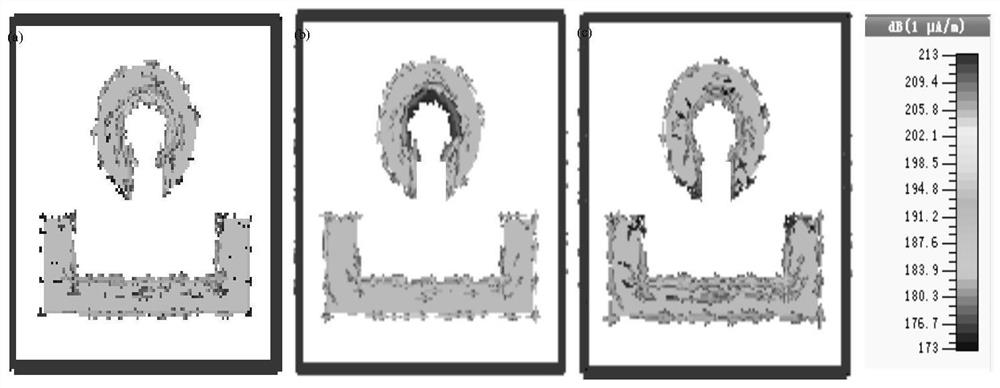

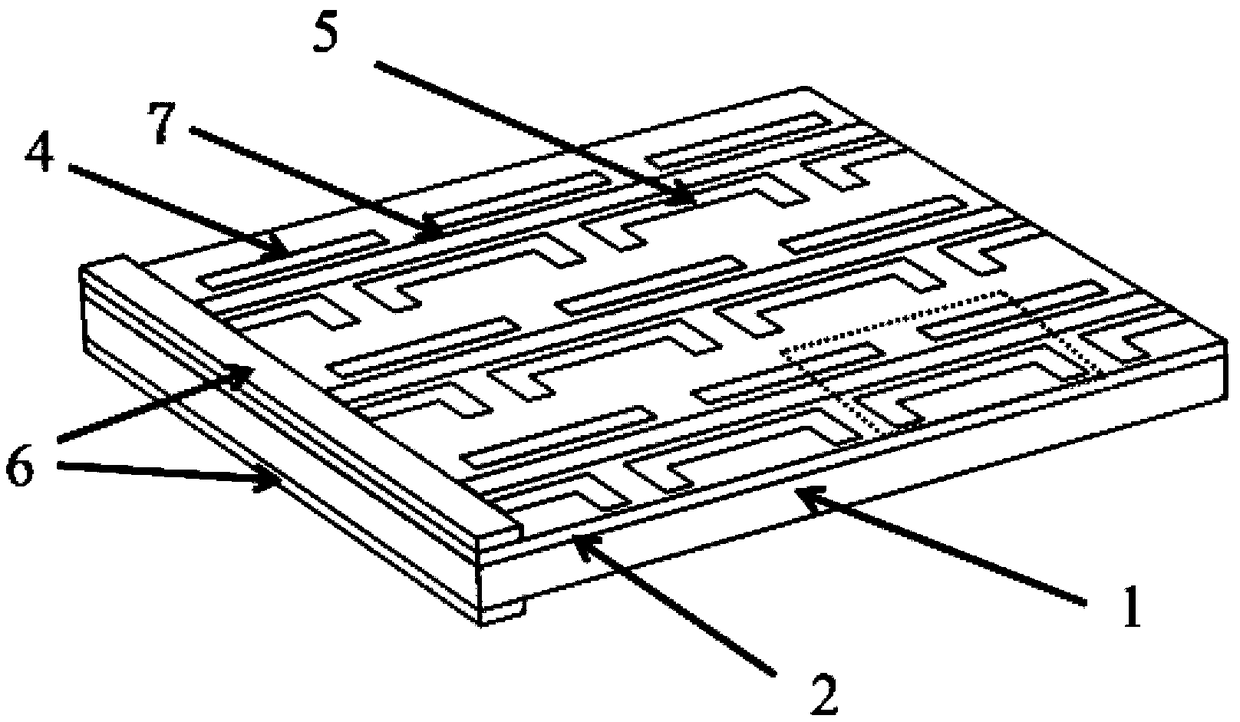

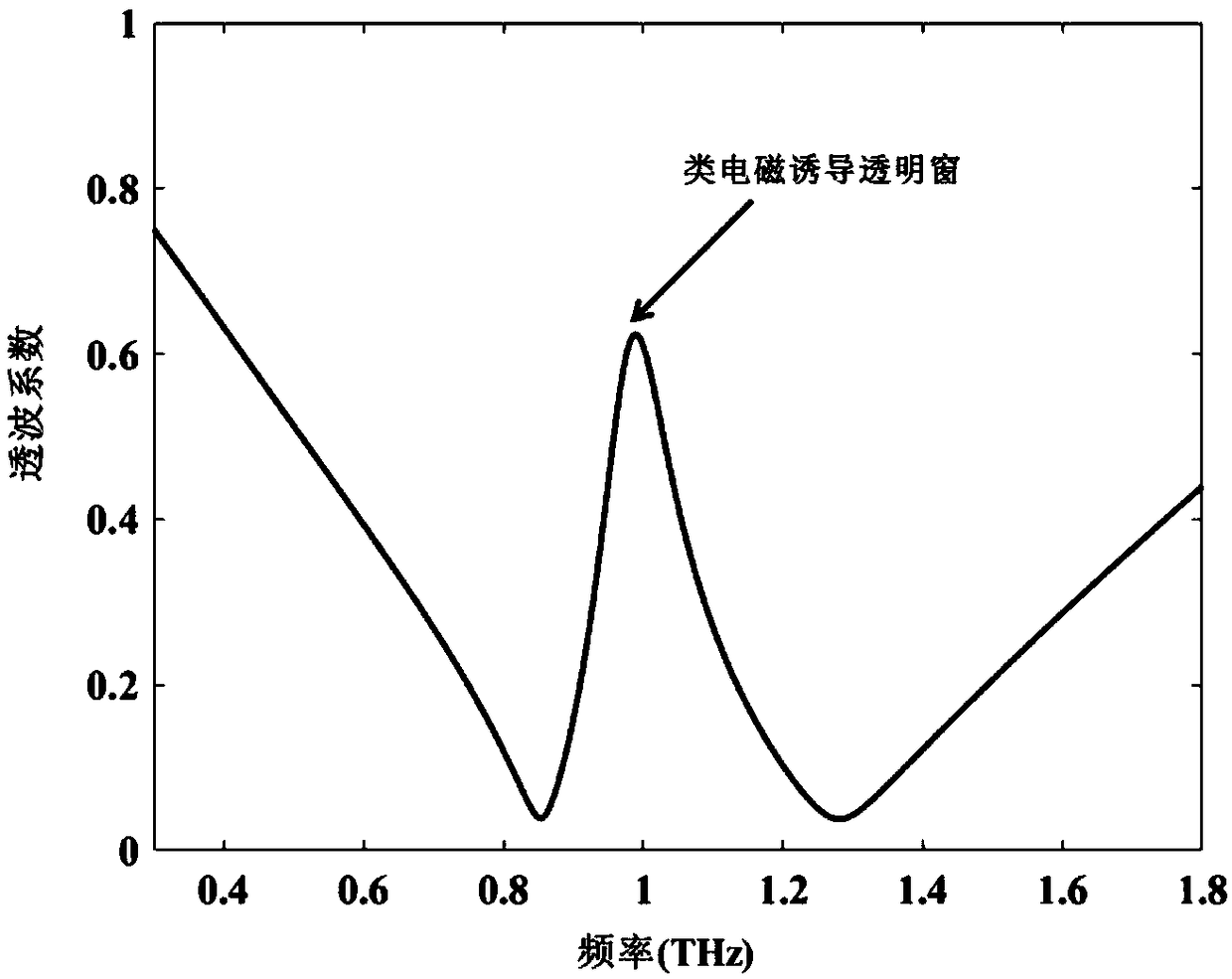

Terahertz band metamaterial sensor based on quasi-electromagnetically induced transparency (quasi-EIT) effect

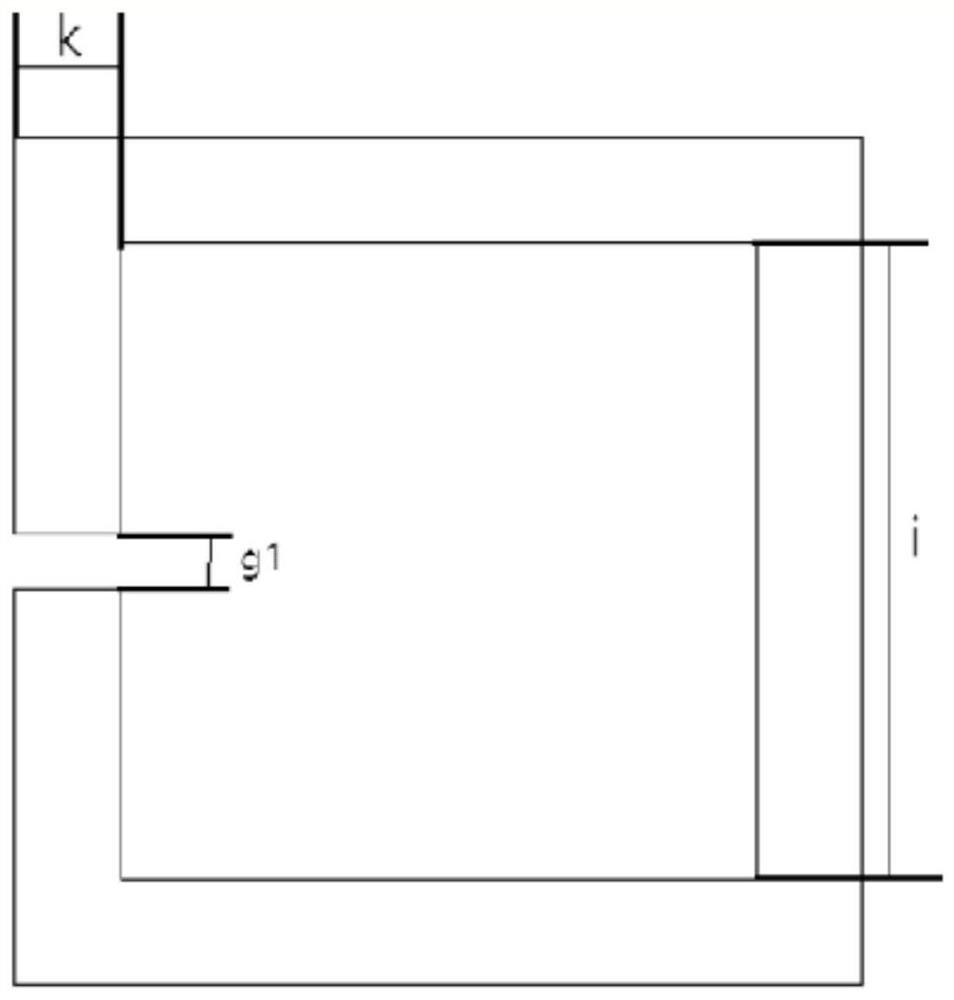

ActiveCN108572162AHigh Q valueHigh Refractive Index SensitivityPhase-affecting property measurementsDark modeMicrometer

The invention claims a terahertz band metamaterial sensor based on quasi-electromagnetically induced transparency (quasi-EIT) effect. The terahertz band metamaterial sensor comprises a dielectric layer and a metamaterial of a sub-wavelength metal array on the dielectric layer, wherein the sub-wavelength metal array is composed of a plurality of open circular resonant rings and open square resonantrings. Under the excitation of terahertz waves, the open circular resonant rings and the open square resonant rings separately exhibit a bright mode and a dark mode; when the two resonant rings are combined and the space between the two is 80.0-85.0 micrometers, the bright and dark modes are coupled to each other, destructive interference is generated, realizing the quasi-EIT effect is realized,and sharp transmission peaks are produced near resonance points. The sensitivity of the terahertz band metamaterial sensor is measured according to the amount of translation of the frequency of the sharp transmission peaks generated by the quasi-EIT effect in the transmittance spectrum within the unit refractive index change, so as to realize the refractive index sensing function in the frequencyrange of 400 GHz to 800 GHz.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

High quality-factor fano metasurface comprising a single resonator unit cell

A new monolithic resonator metasurface design achieves ultra-high Q-factors while using only one resonator per unit cell. The metasurface relies on breaking the symmetry of otherwise highly symmetric resonators to induce intra-resonator mixing of bright and dark modes (rather than inter-resonator couplings), and is scalable from the near-infrared to radio frequencies and can be easily implemented in dielectric materials. The resulting high-quality-factor Fano metasurface can be used in many sensing, spectral filtering, and modulation applications.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

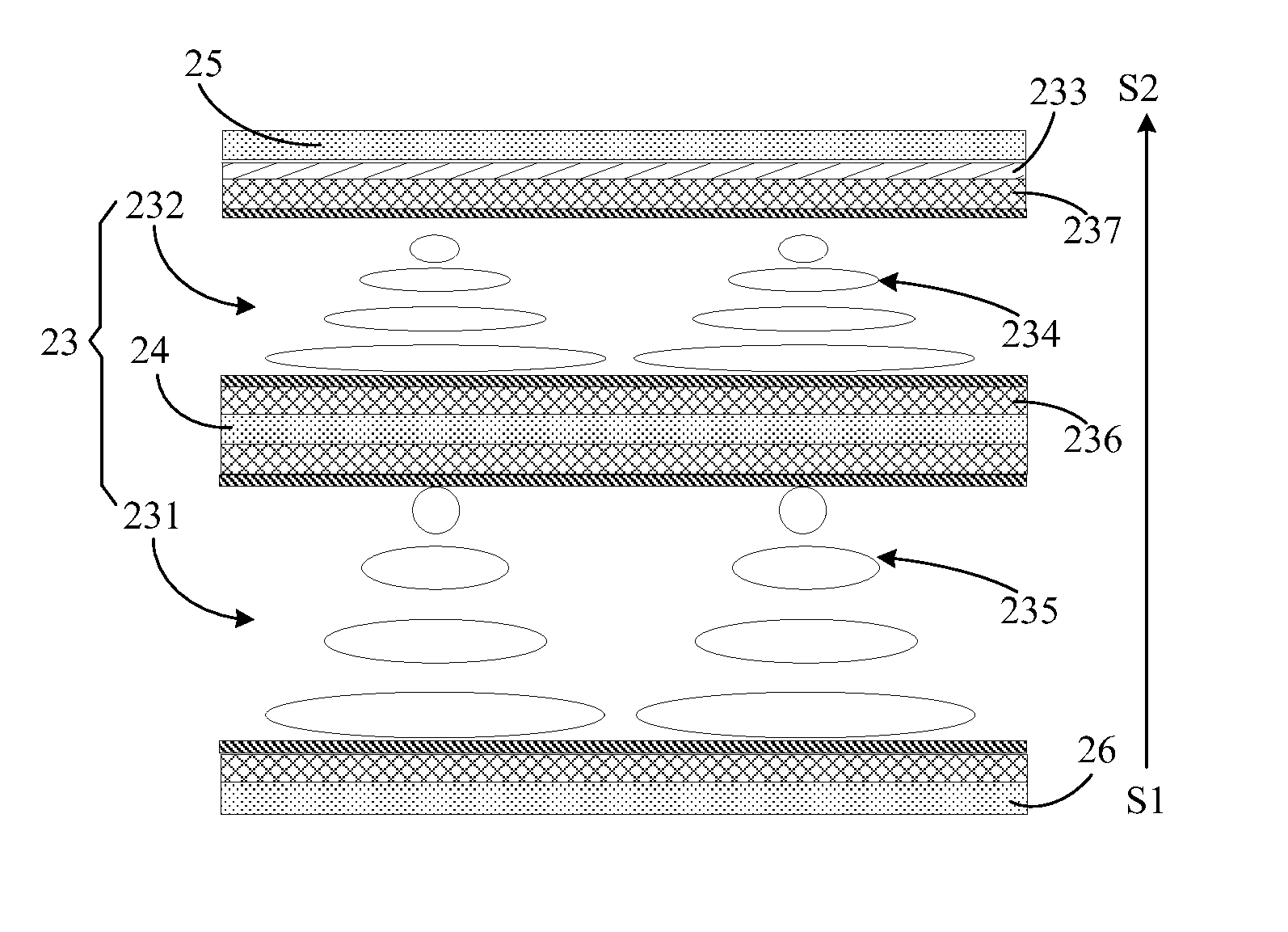

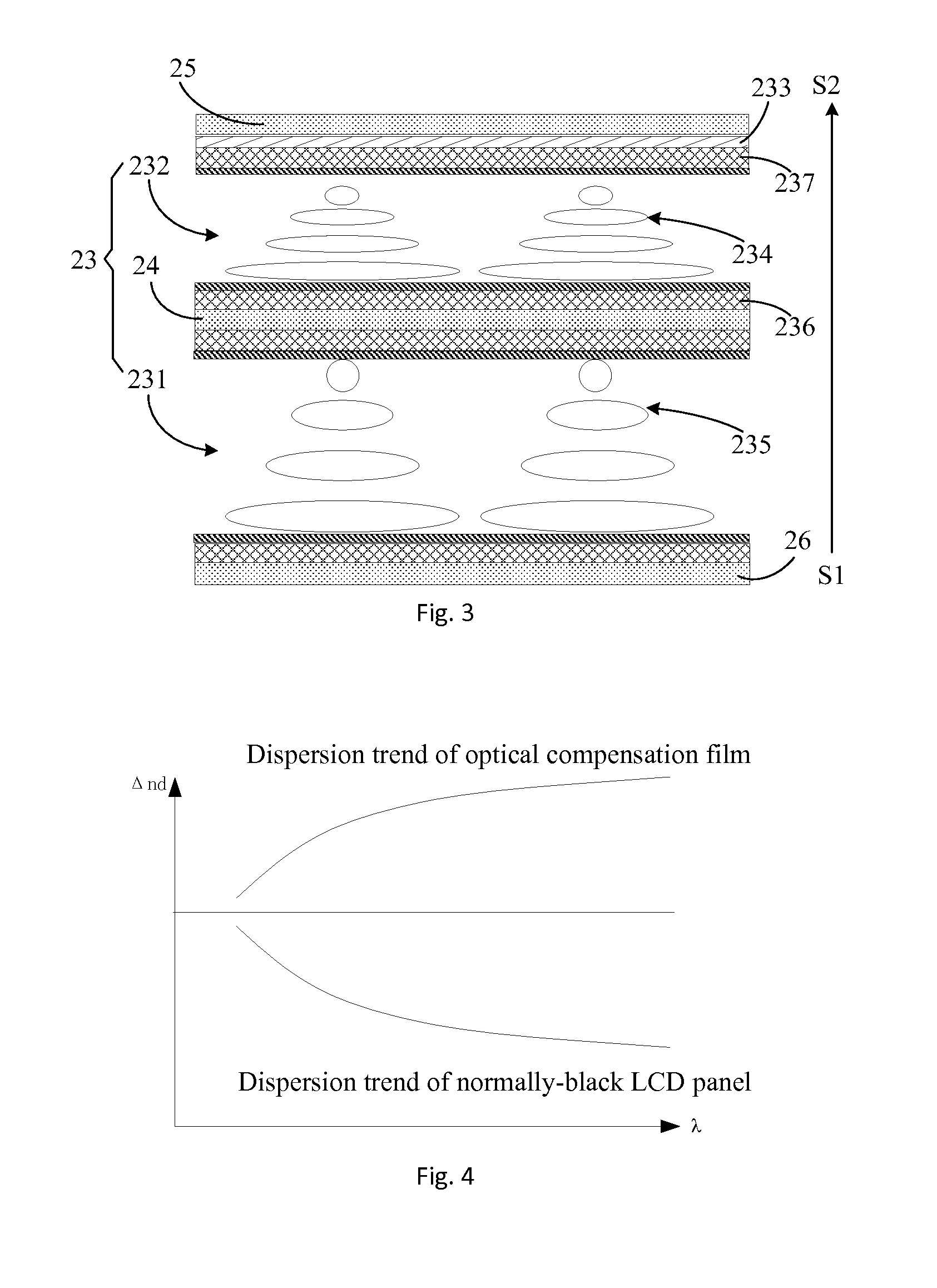

Shutter Glasses and Related 3D Display System

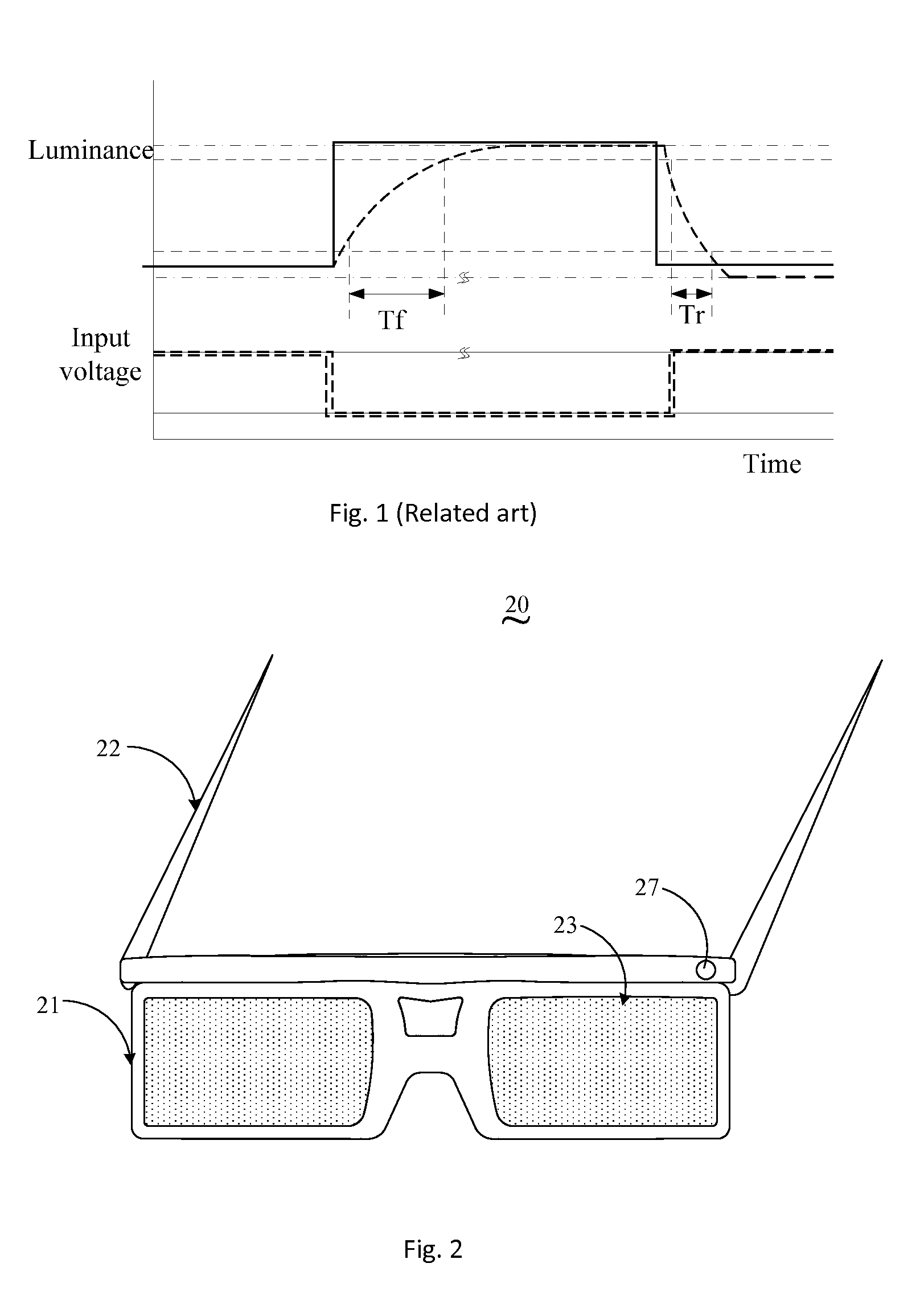

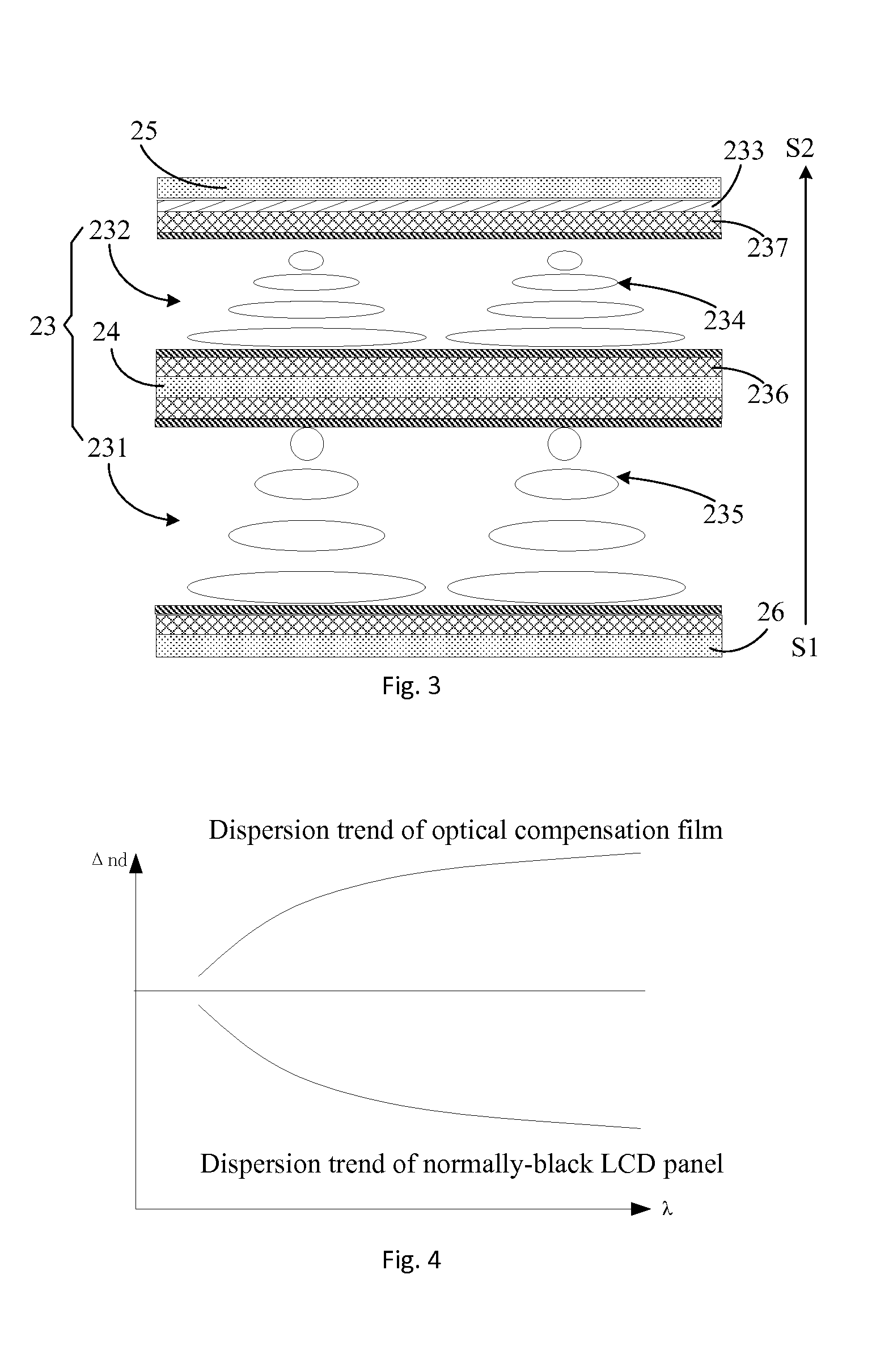

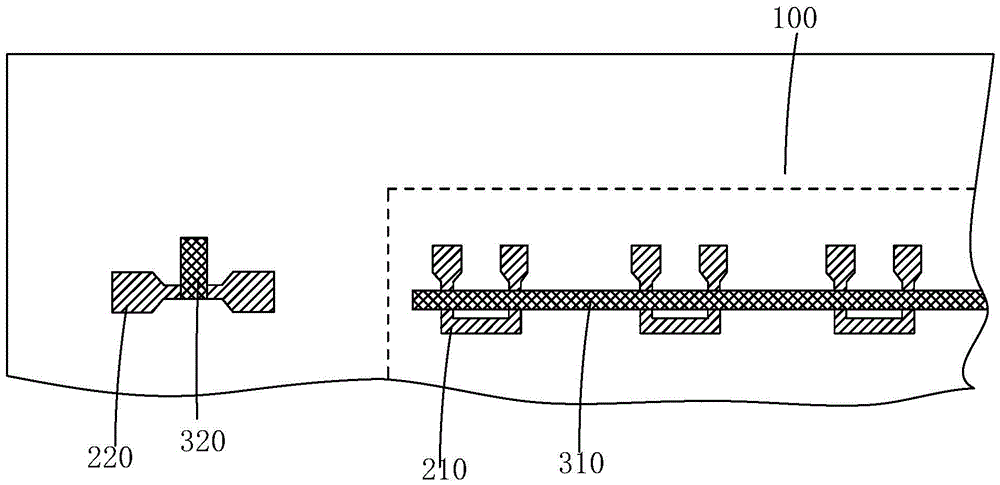

InactiveUS20140192280A1Reduce power consumptionShort response timeSteroscopic systemsNon-linear opticsDark modeEngineering

The present invention discloses shutter glasses and a 3D display system. The shutter glasses include a first polarizer, a second polarizer, a normally-white LCD panel, and a normally-black LCD panel. A thickness of the normally-white LCD panel is not the same as a thickness of the normally-black LCD panel, and an optical compensation film is installed between the first polarizer and the liquid crystal layer of the normally-black LCD panel and / or between the second polarizer and the liquid crystal layer of the normally-black LCD panel in order to compensate for a dispersion occurred when the liquid crystal layer of the normally-black LCD panel is in a dark mode. In this way, the present invention can not only shorten the response time of the shutter glasses to reduce the power consumption, but also reduce the 3D crosstalk.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

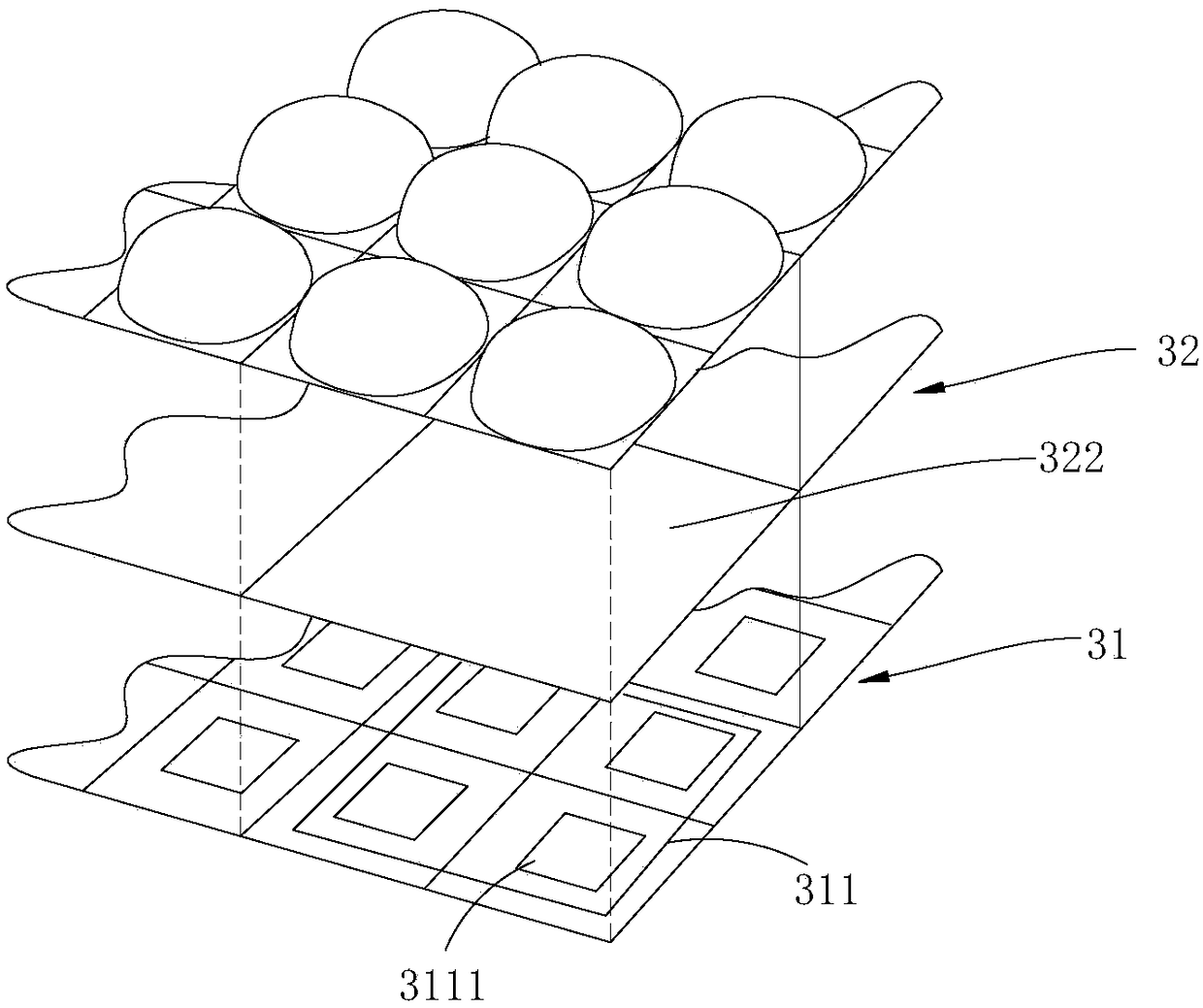

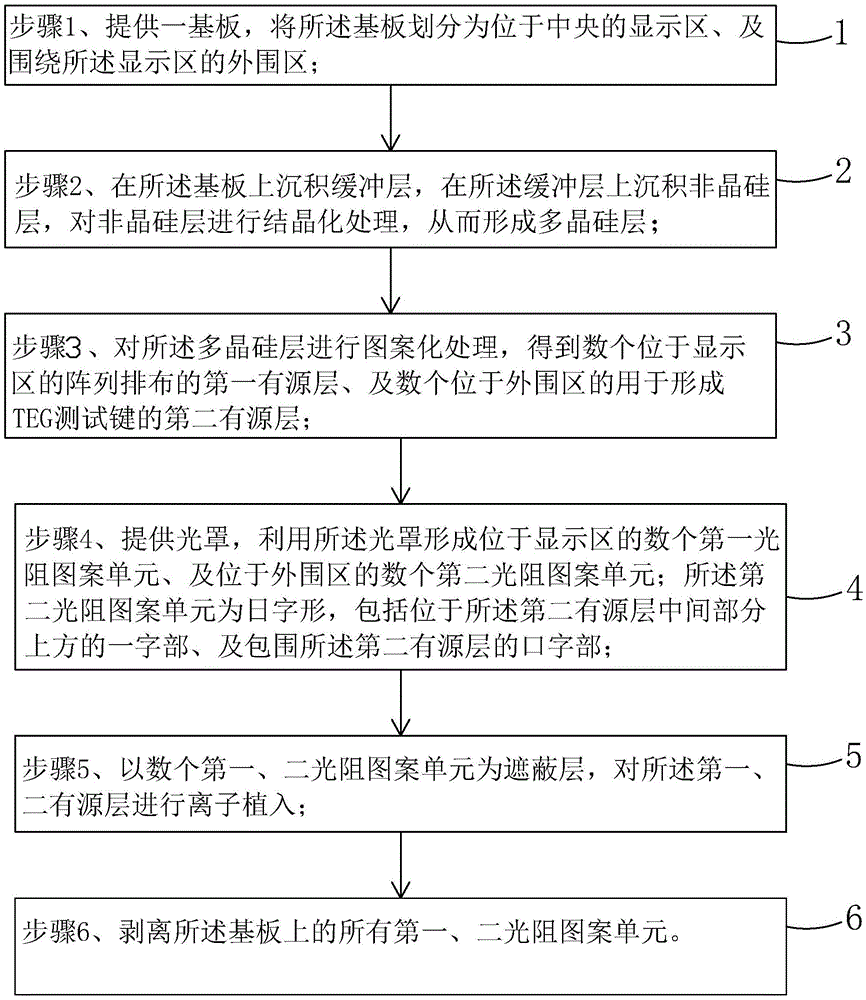

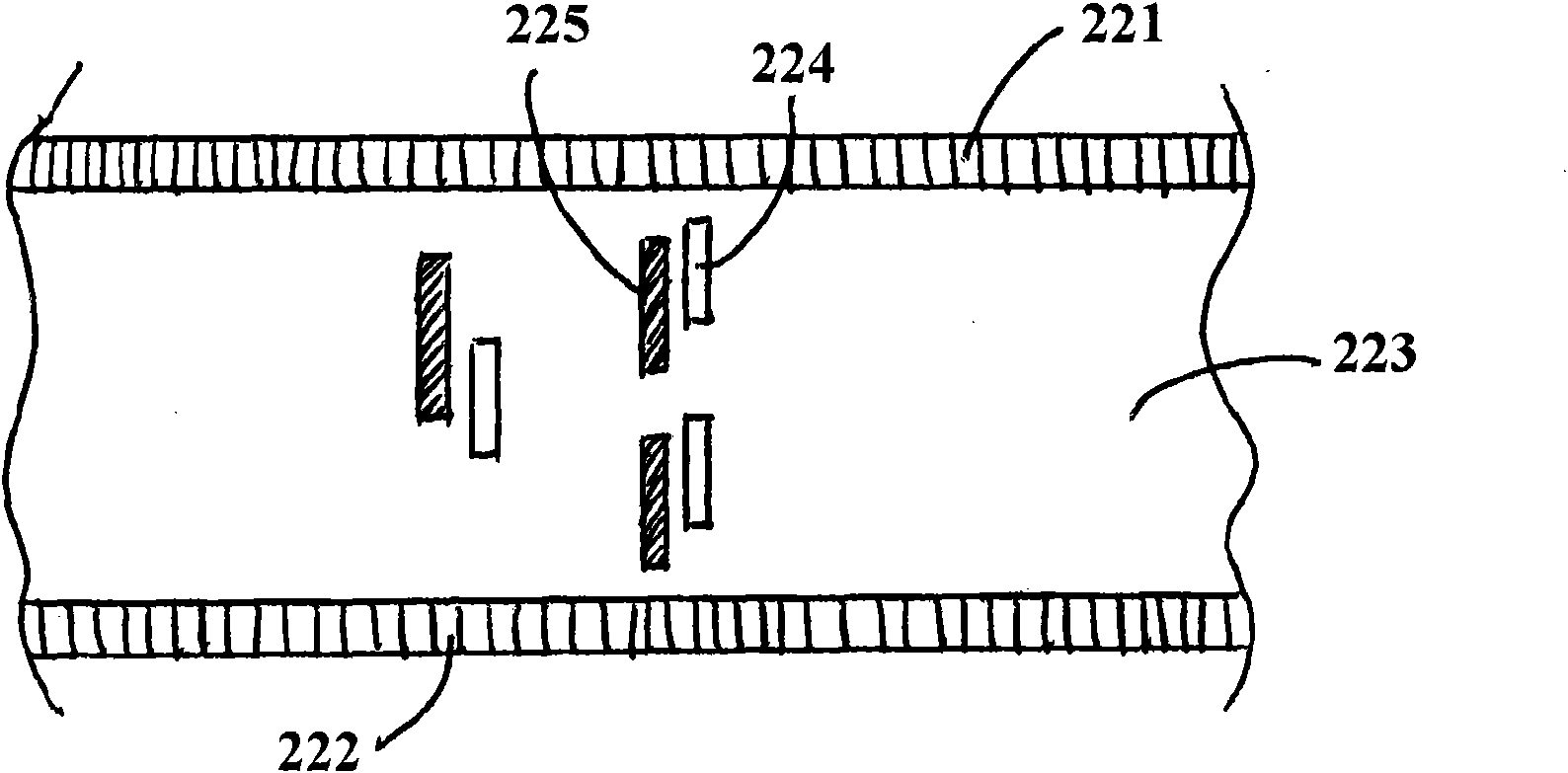

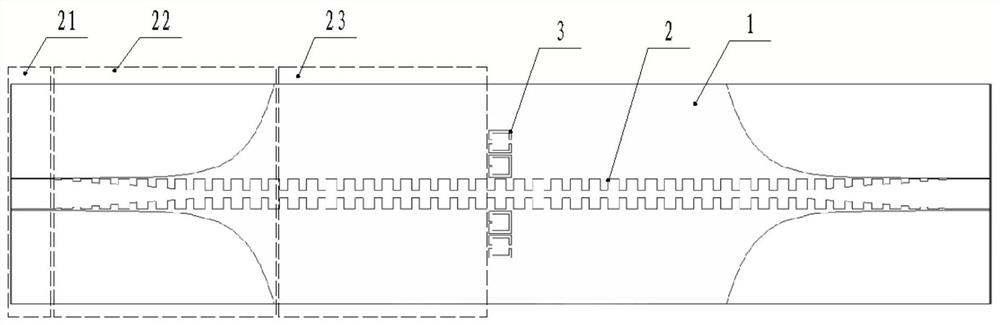

Fabrication method for test element group (TEG) test key on a thin film transistor (TFT) array substrate

ActiveCN105552026AIncrease the areaReduce areaSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusDark modeEngineering

The invention provides a fabrication method for a test element group (TEG) test key on a thin film transistor (TFT) array substrate. The fabrication method comprises the following steps of forming a plurality of first active layers arranged on a display region and a plurality of second active layers arranged on a peripheral region and used for forming the TEG test key on a substrate; and forming a plurality of first photoresist pattern units and a plurality of second photoresist pattern units by using a particularly-designed optical cover, wherein the second photoresist pattern units are in stud link shapes and comprise straight line parts arranged above the middle parts of the second active layers and latticed parts encircling the second active layers. Compared with a conventional optical cover adopting a Dark mode, the area of the photoresist pattern in an ion implantation range of the active layer for defining and forming the TEG test key is expanded, and thus, the too small photoresist area is prevented to cause the problem of difficulty in photoresist removal due to serious coking of a load effect during the subsequent ion implantation process; moreover, compared with a traditional optical cover adopting Clear mode, the area of the photoresist pattern on the whole substrate is reduced, and thus, the subsequent photoresist stripping process is easy to proceed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

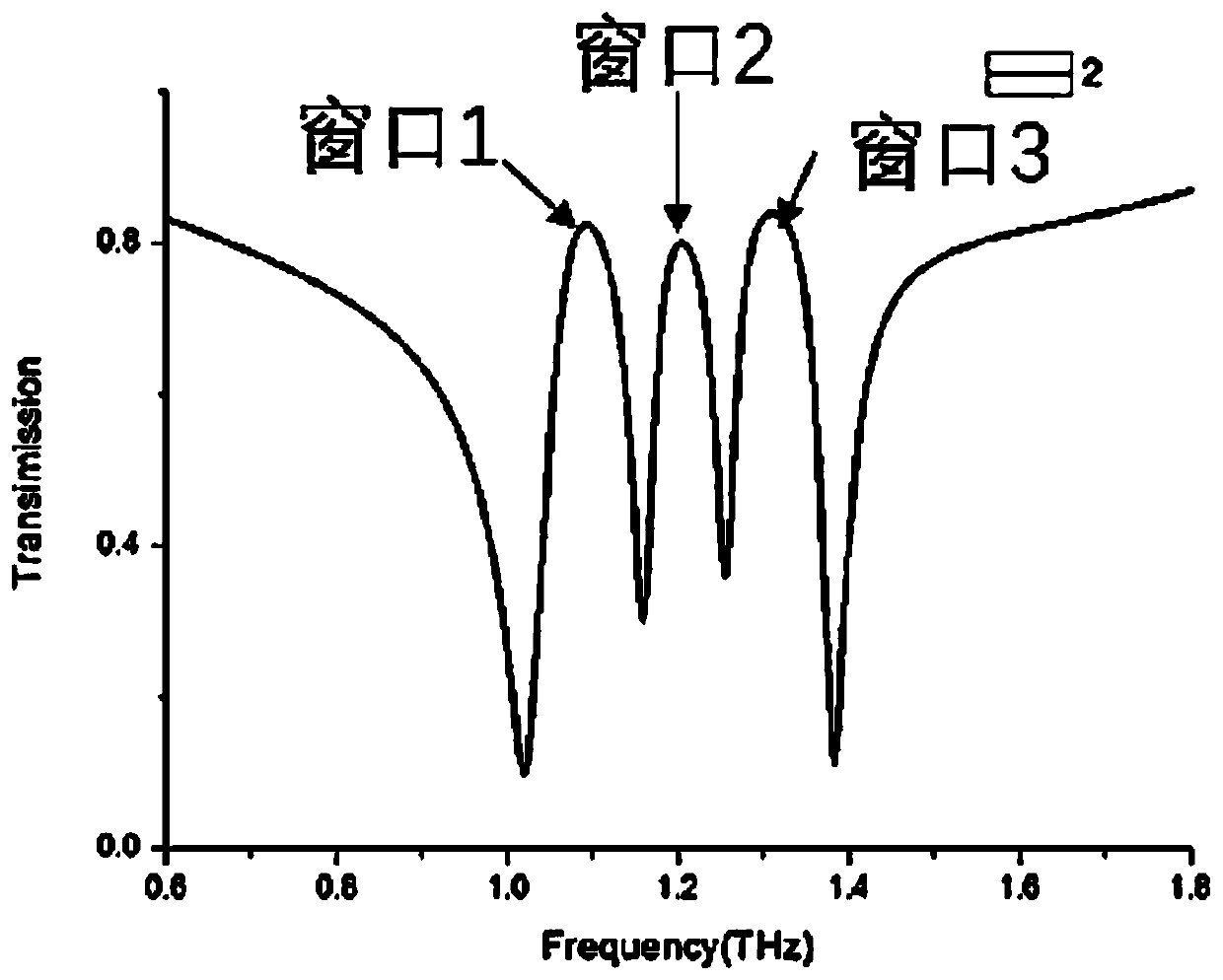

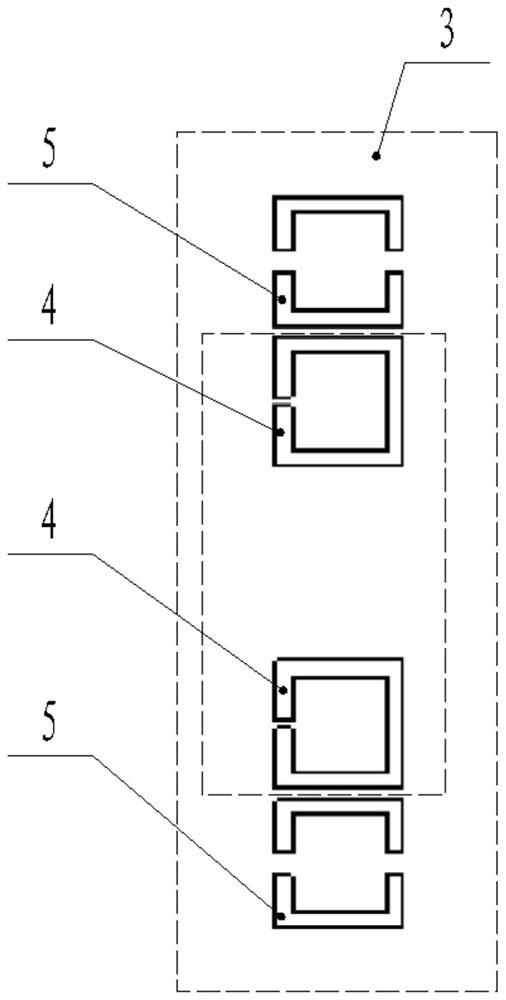

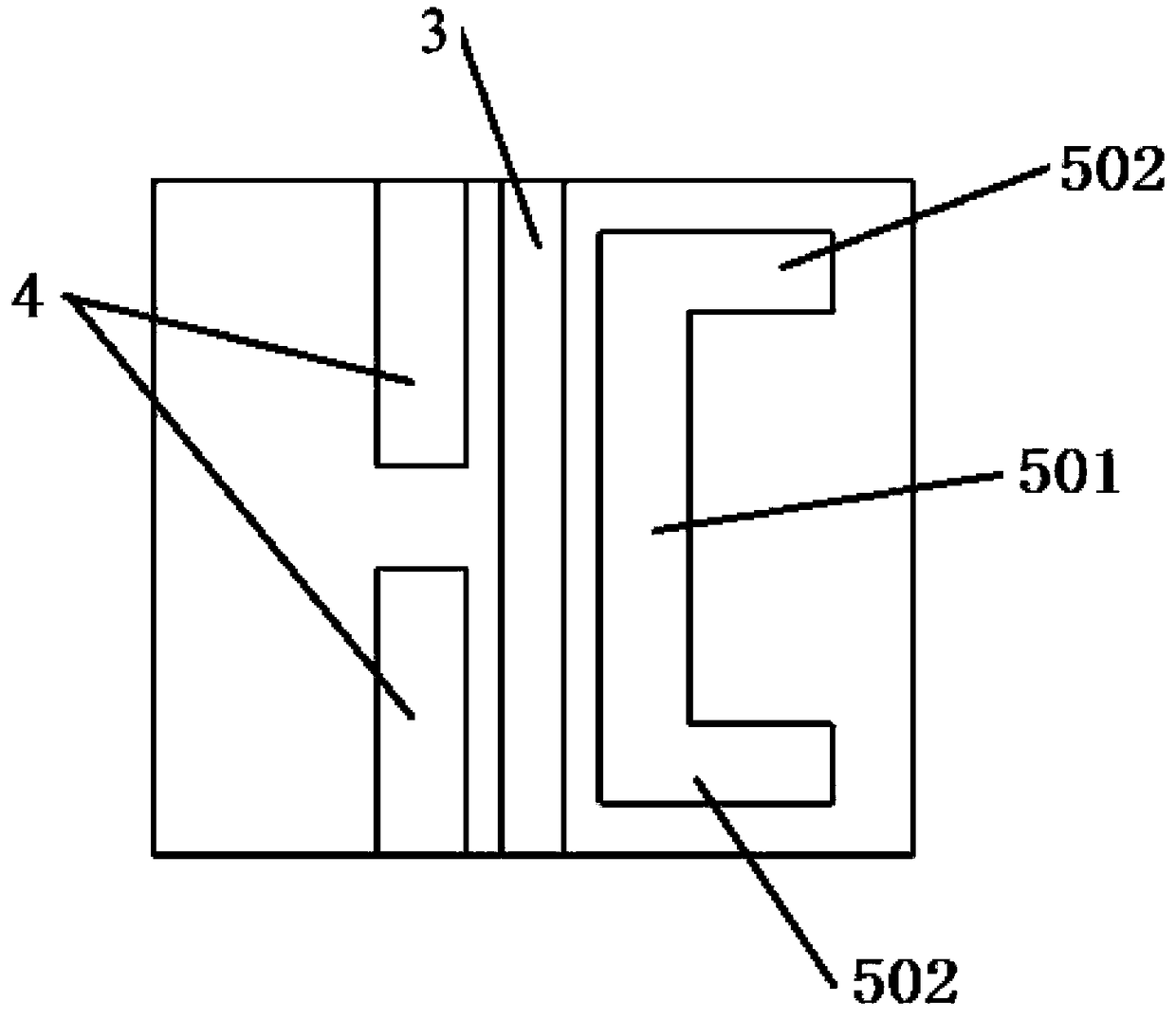

Multi-band electromagnetic induction transparent structure based on terahertz metamaterial

The invention discloses a multi-band electromagnetic induction transparent structure based on a terahertz metamaterial. The structure comprises a first dielectric substrate, a second dielectric substrate, a first metal strip, a second metal strip, a first metal symmetrical split-ring resonator and a second metal symmetrical split-ring resonator, wherein the second dielectric substrate is located below the first dielectric substrate, the first metal symmetrical split-ring resonator is located between the first metal strip and the second metal strip, and the second metal symmetrical split-ring resonator is located on the side, which is away from the first metal symmetrical split-ring resonator, of the second metal strip. Under the condition of incident electromagnetic field excitation, the metal strips and electromagnetic waves are in strong coupling to serve as bright-mode resonance; the metal symmetric split-ring resonators and electromagnetic waves are in weak coupling to serve as dark-mode resonance. Based on the coupling of the multi-band electromagnetic induction transparent structure based on the terahertz metamaterial and the incident electromagnetic field, a multi-band electromagnetic induction transparent phenomenon can be realized by a bright and dark mode near-field coupling principle.

Owner:GUILIN UNIV OF ELECTRONIC TECH

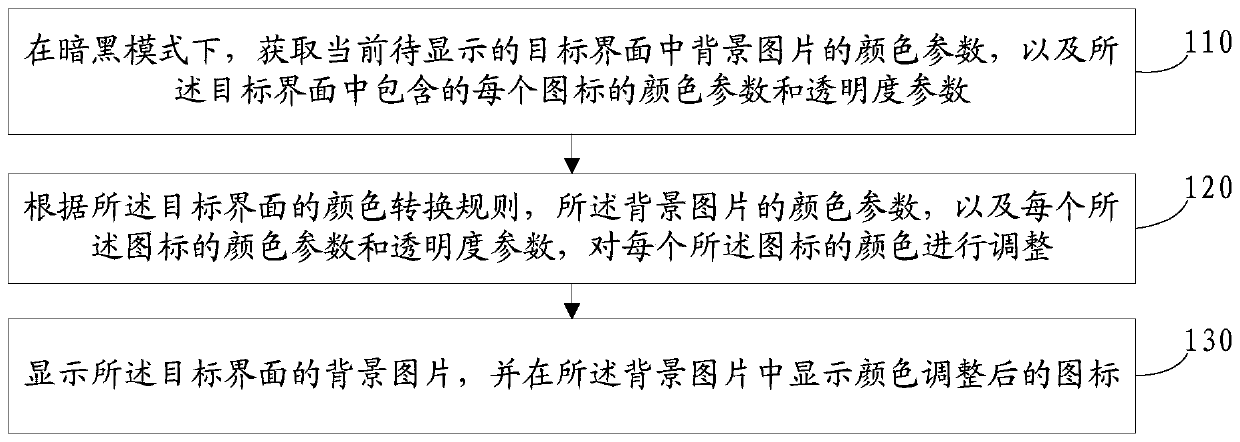

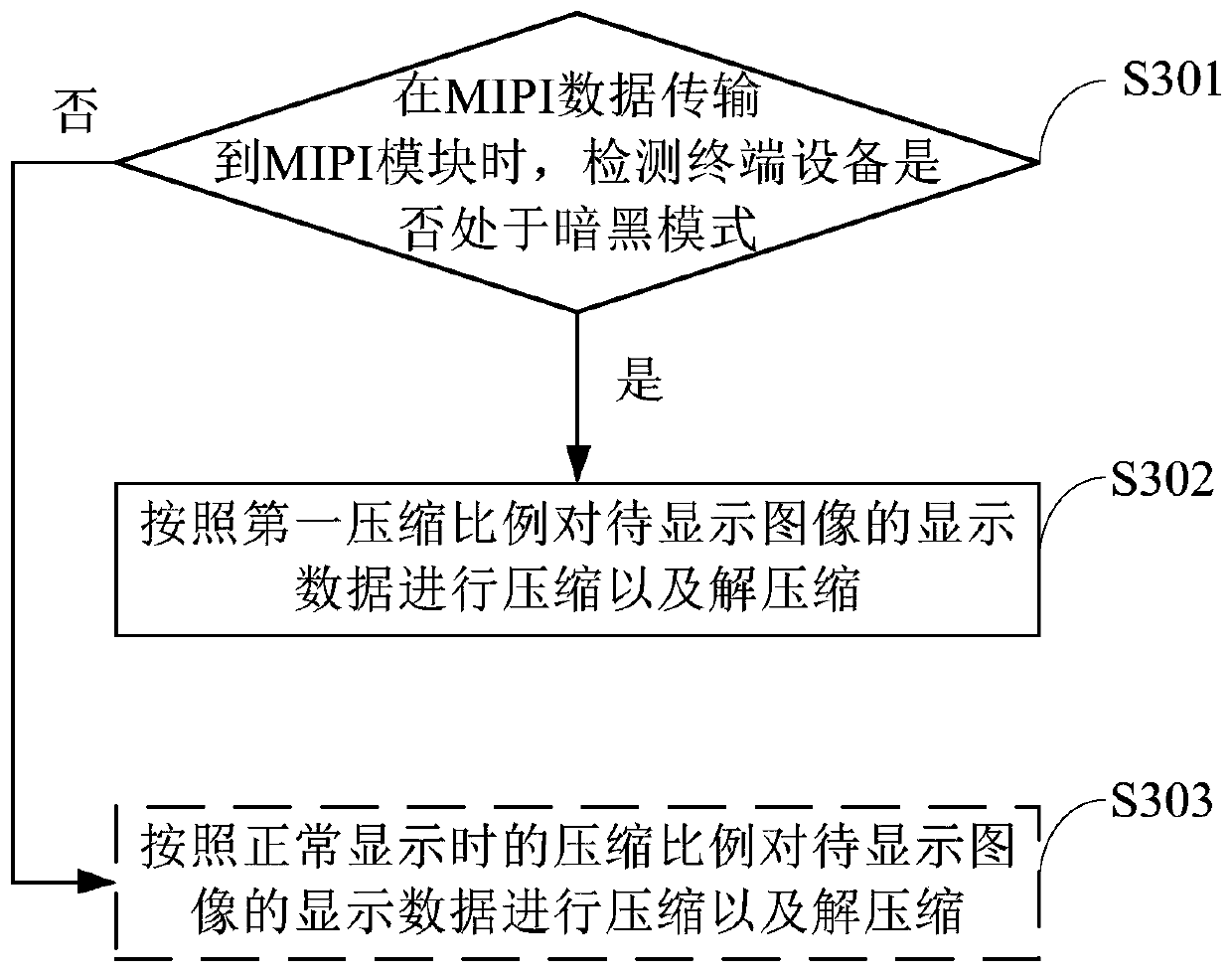

Interface display method and device, terminal equipment and storage medium

PendingCN110908765AImprove the display effectExecution for user interfacesInput/output processes for data processingColor transformationComputer graphics (images)

The invention provides an interface display method and device, terminal equipment and a storage medium. The interface display method comprises the steps of obtaining color parameters of a background picture in a current to-be-displayed target interface and color parameters and transparency parameters of each icon contained in the target interface in a dark mode; adjusting the color of each icon according to the color conversion rule of the target interface, the color parameter of the background picture and the color parameter and transparency parameter of each icon; and displaying a backgroundpicture of the target interface, and displaying the icon after color adjustment in the background picture. The technical problems that according to an existing interface display scheme, the color ofan icon in an interface cannot be rapidly adjusted in time in a dark mode, and the icon and the display effect of the interface in the dark mode are influenced are solved. The beneficial effect of improving the display effect of the icon and the interface by accurately adjusting the icon color in the dark mode in time is achieved.

Owner:WUBA

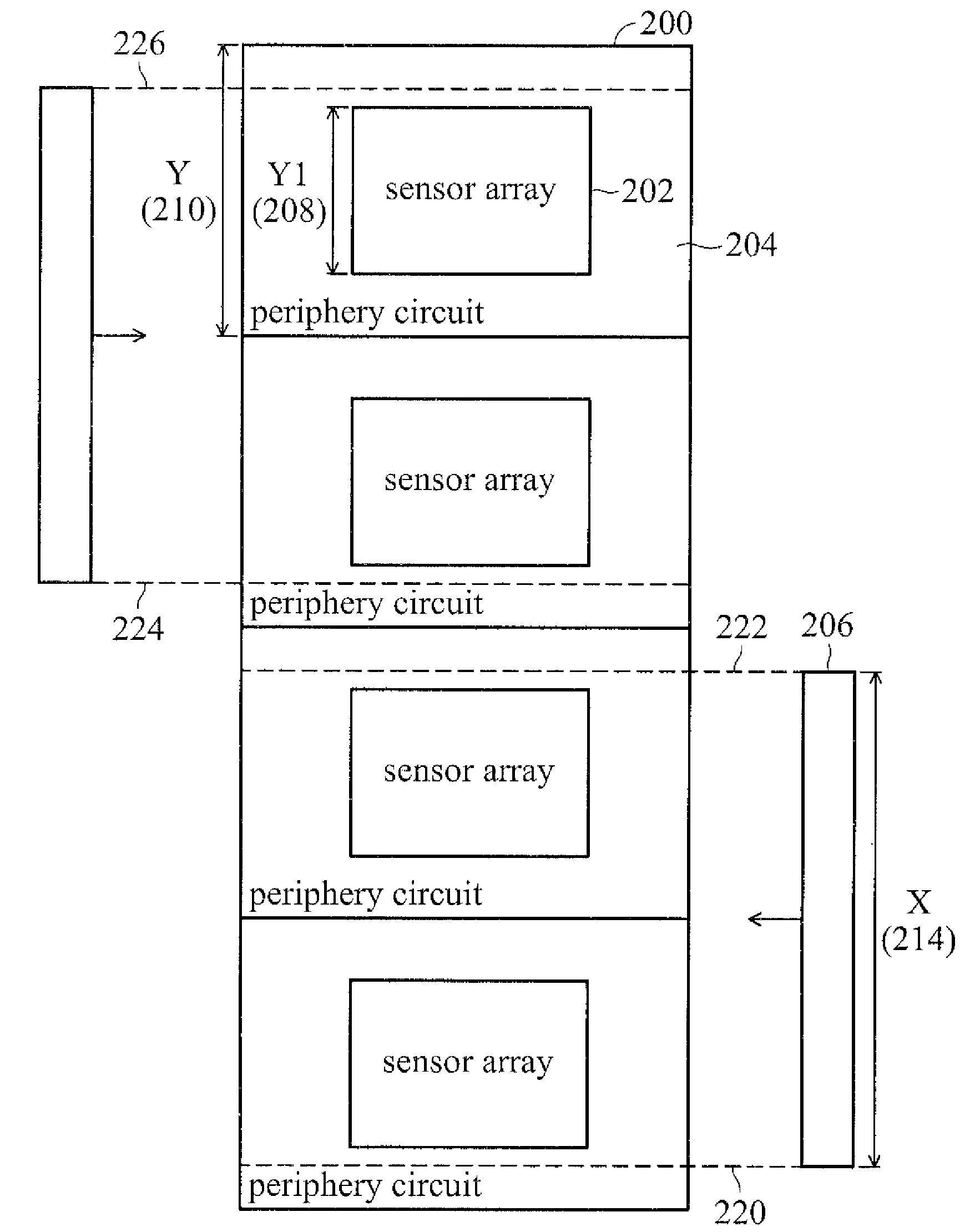

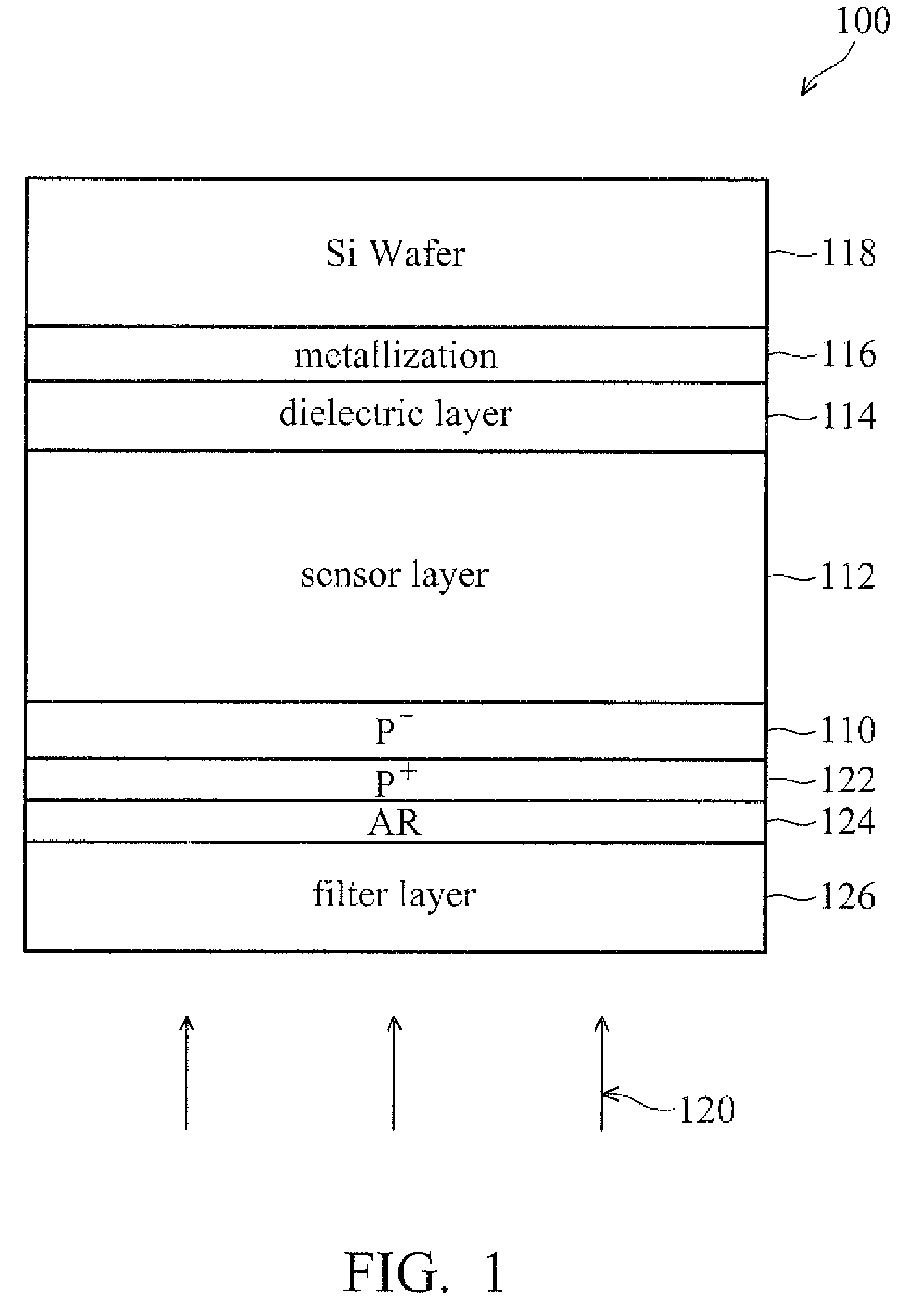

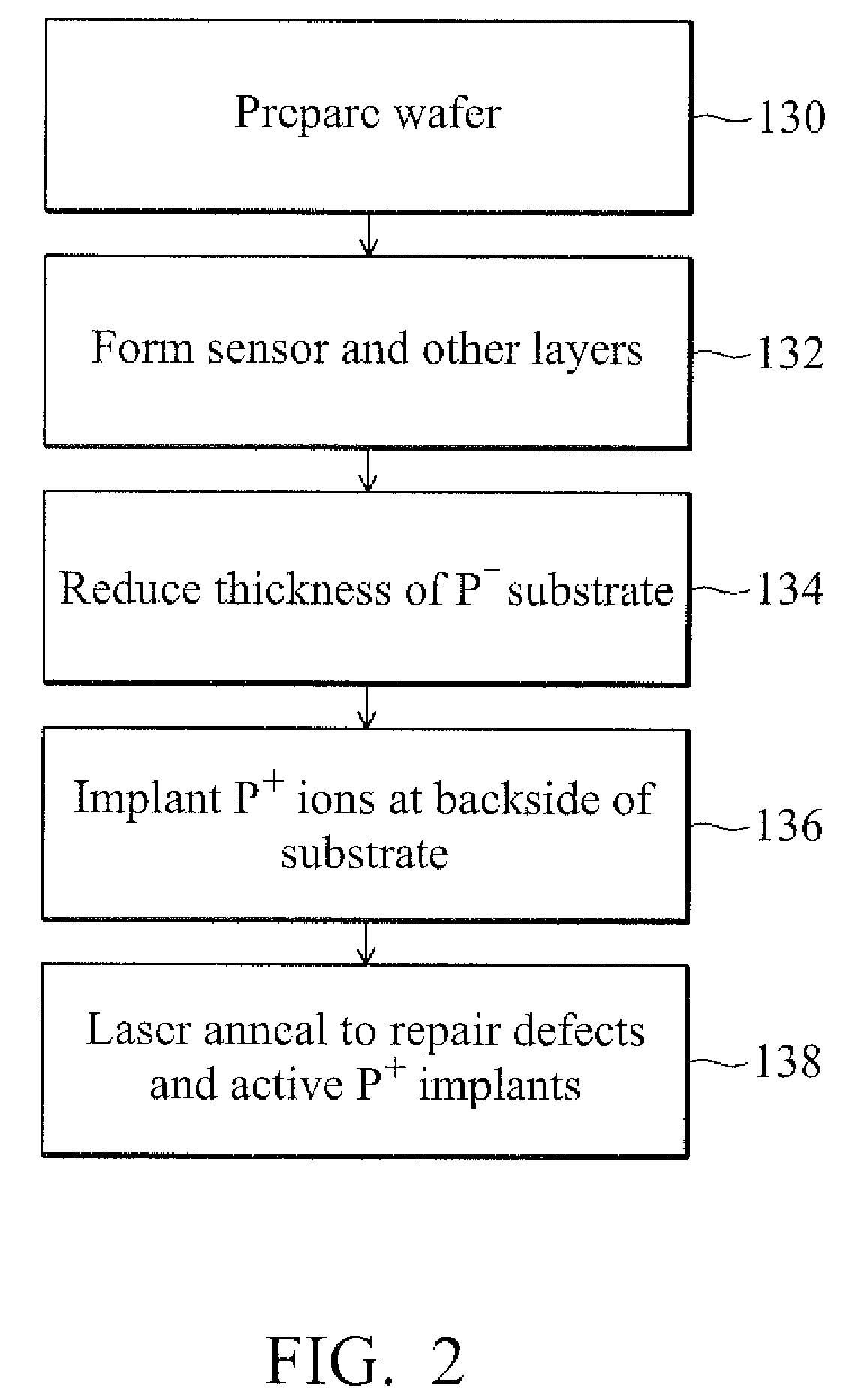

Methods to avoid laser anneal boundary effect within BSI CMOS image sensor array

Methods are disclosed herein for determining the laser beam size and the scan pattern of laser annealing when fabricating backside illumination (BSI) CMOS image sensors to keep dark-mode stripe patterns corresponding to laser scan boundary effects from occurring within the sensor array regions of the image sensors. Each CMOS image sensor has a sensor array region and a periphery circuit. The methods determines a size of the laser beam from a length of the sensor array region and a length of the periphery circuit so that the laser beam covers an integer number of the sensor array region for at least one alignment of the laser beam on the array of BSI image sensors. The methods further determines a scan pattern so that the boundary of the laser beam does not overlap the sensor array regions during the laser annealing, but only overlaps the periphery circuits.

Owner:TAIWAN SEMICON MFG CO LTD

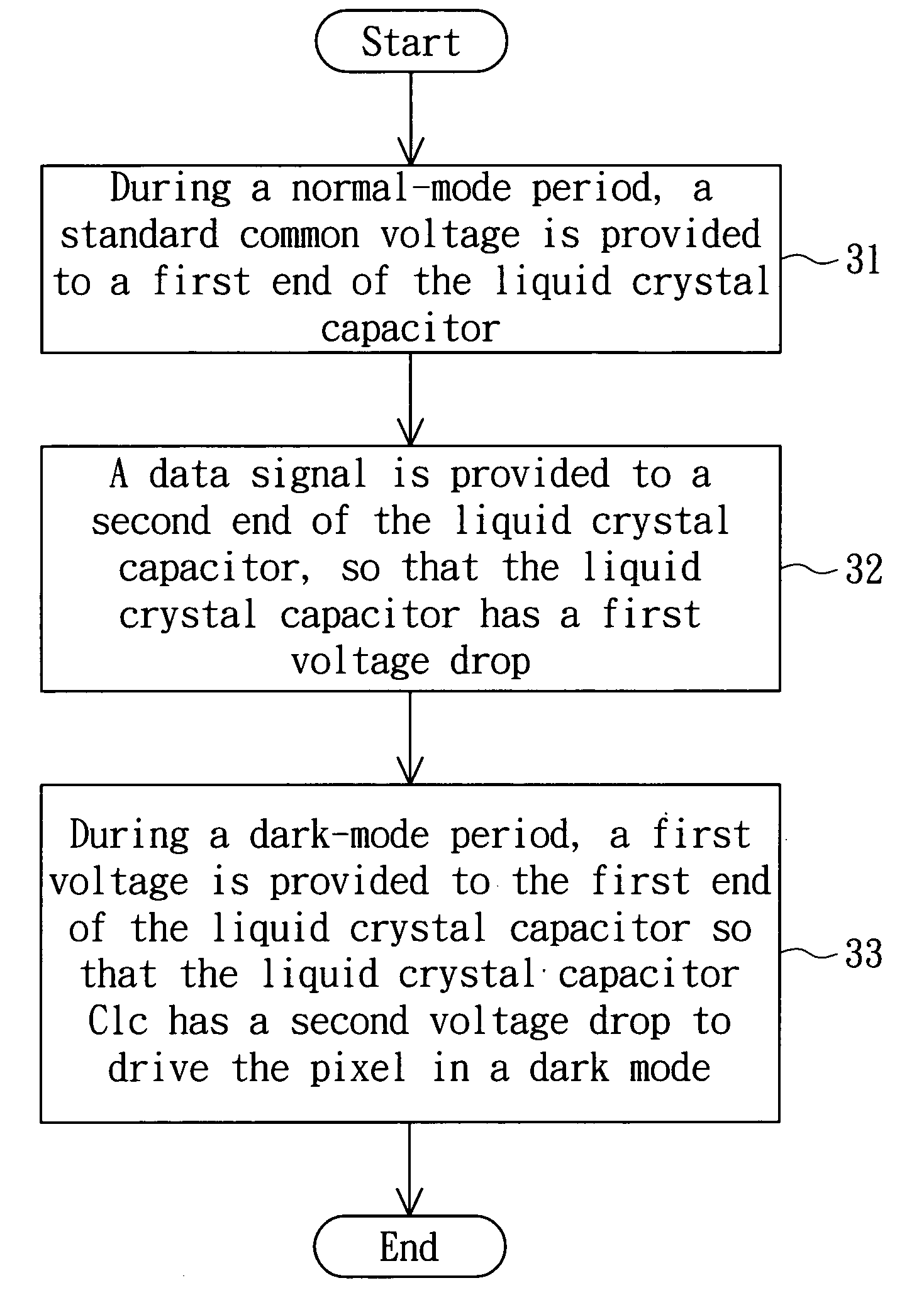

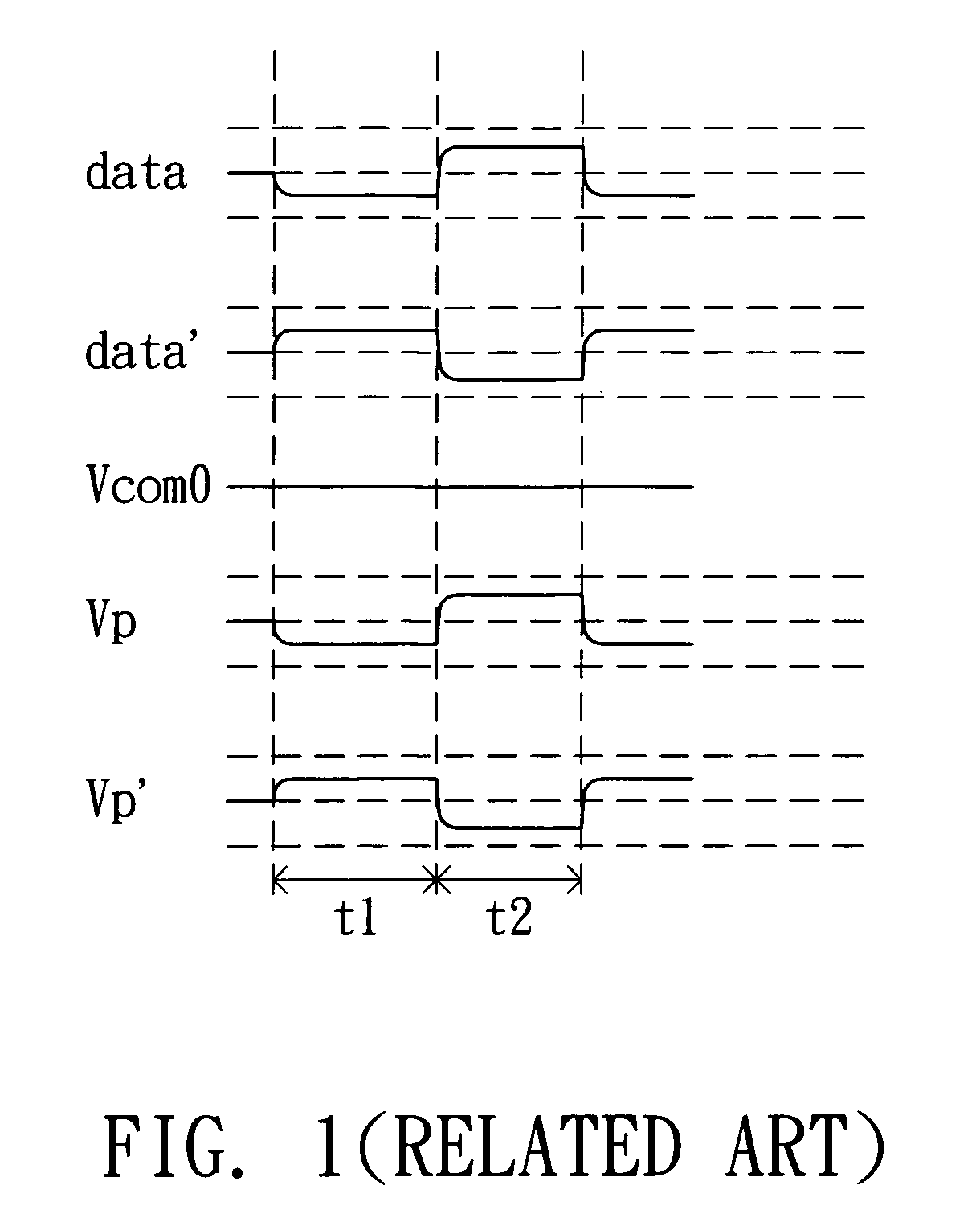

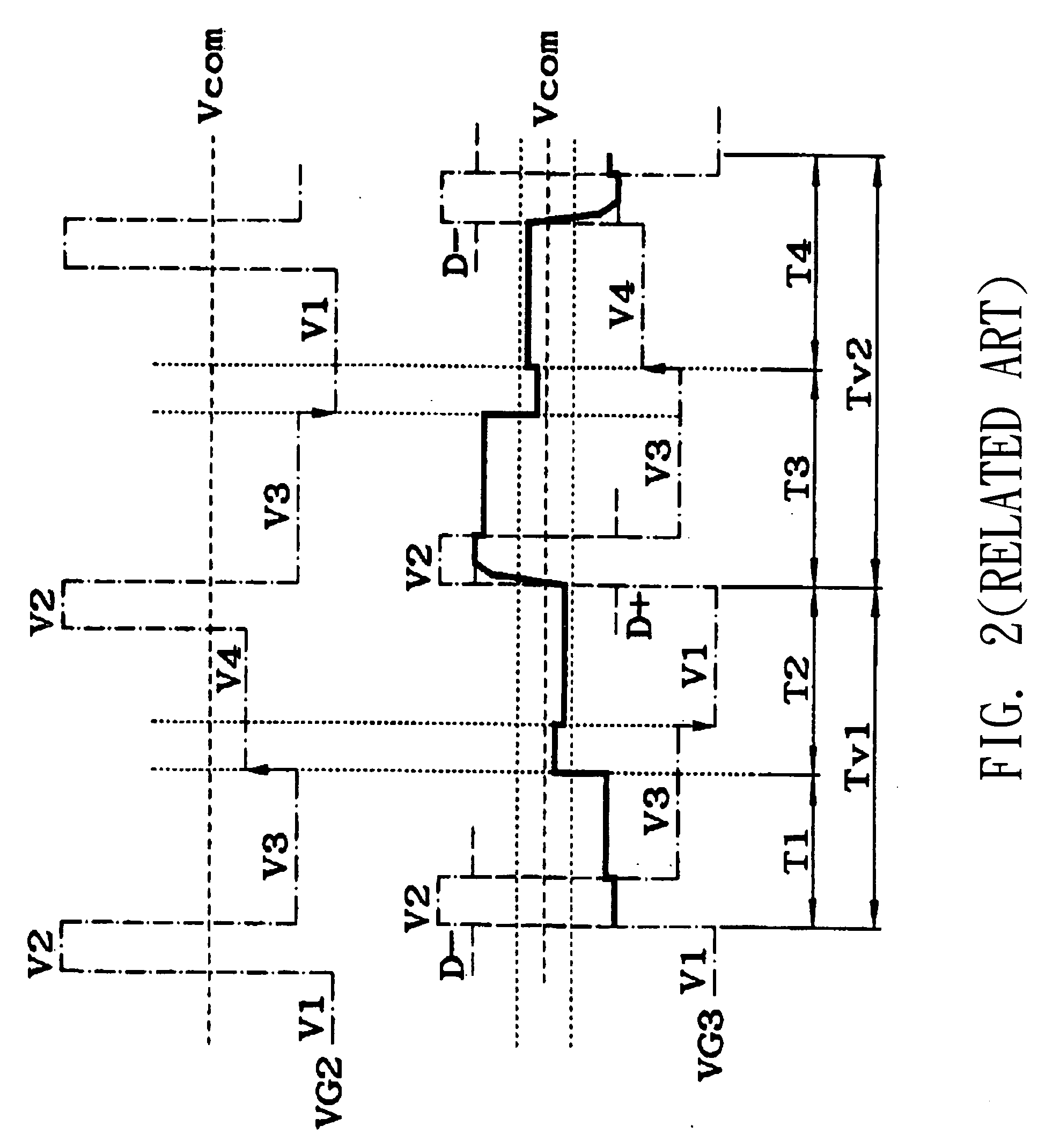

Method for inserting black frames

A method of inserting black frames is provided. The LCD comprises a pixel, and the pixel comprises a liquid crystal capacitor. Firstly, during a normal-mode period, a common voltage is provided to a first end of the liquid crystal capacitor. Next, a data signal is provided to a second end of the liquid crystal capacitor, so that the liquid crystal capacitor has a first voltage drop. Finally, during a dark-mode period, a first voltage different from the common voltage is provided to the first end of the liquid crystal capacitor to change the voltage at the second end of the liquid crystal capacitor, so that the liquid crystal capacitor has a second voltage drop to drive the pixel in a dark mode during the dark-mode period.

Owner:AU OPTRONICS CORP

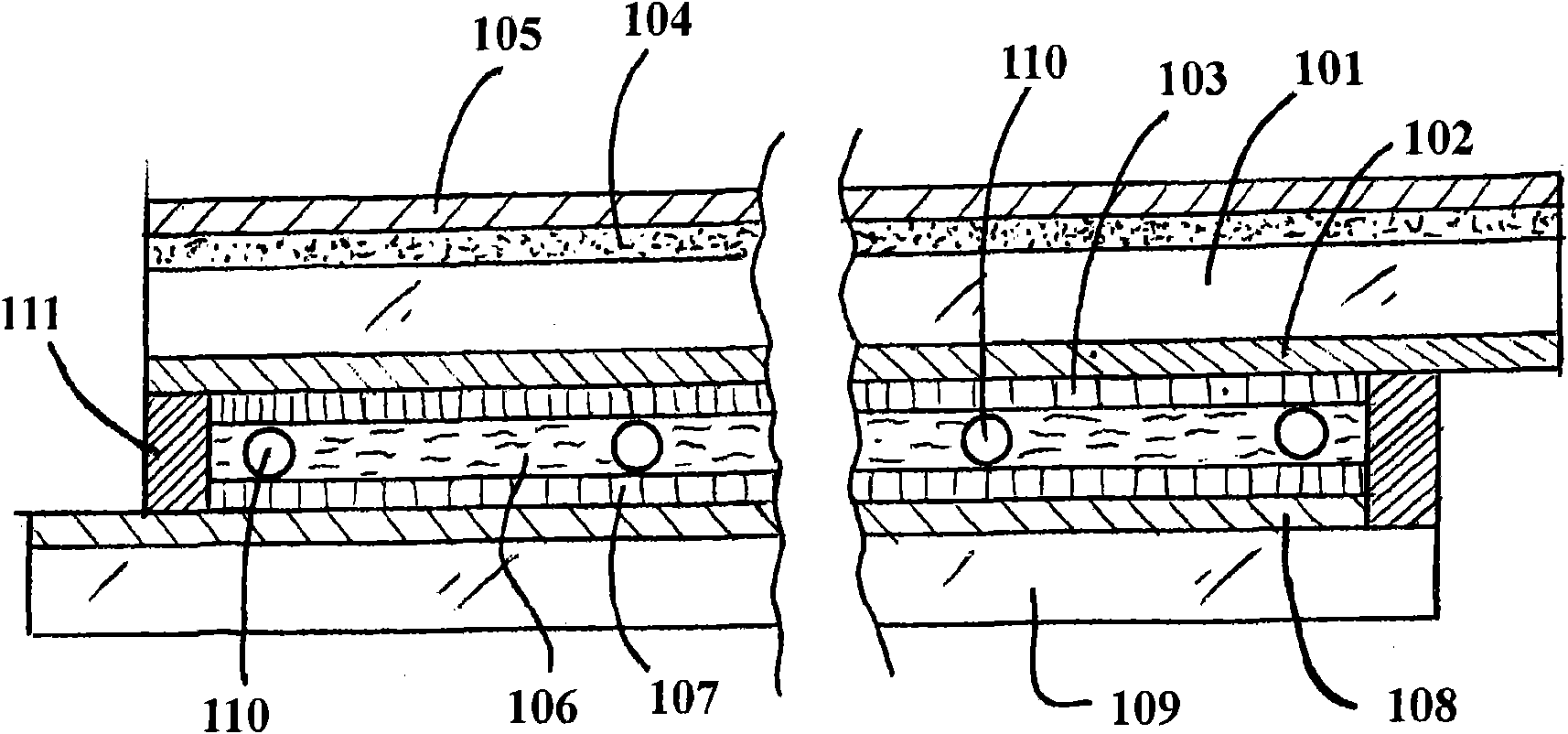

Automatic darkening and glare reducing liquid crystal mirror

An automatic darkening and glare reducing liquid crystal mirror for vehicles is disclosed. The mirror has a front substrate (101) of transparent glass or plastic and a back substrate (109) of glass orplastic with a highly reflective or transflective mirrored coating (108). The front and back substrates are spaced apart a small distance to define a liquid crystal cell between the substrates and aliquid crystal fluid (106) incorporating dichroic dyes is contained within the liquid crystal cell. A conductive thin film (102) is applied onto the interior surface of the front substrate and the reflective or transflective coating (108) of the back substrate also is conductive. An alignment compound is deposited on the conductive thin film (102) and on the reflective or transflective coating (108) and the alignment compound bounds the liquid crystal cell. An electronic control circuit is adapted to apply selectively a voltage signal to the conductive thin film and the reflective or transflective coating (108) to affect the transmittance of the liquid crystal fluid, and thereby the darkness of the mirror. The nature of the alignment compound determines a home or rest alignment of the liquid crystal molecules, either parallel or perpendicular to the substrates, and thus determines whether the mirror is normally dark (a 'dark mode' mirror) or normally bright (a 'bright mode' mirror). Application of a voltage signal to a dark mode mirror lightens it while application of a voltage signal to a bright mode mirror darkens the mirror. A headlight sensor (302) and an ambient sensor (301) are coupled to the electronic control circuit and the circuit is configured to darken the mirror in response to signals from the sensors indicating that the ambient light intensity is below a predetermined threshold (equivalent to nighttime) and the intensity of light from headlights impinging on the mirror is above a predetermined threshold (equivalent to a glare condition).

Owner:OPTI SOURCE

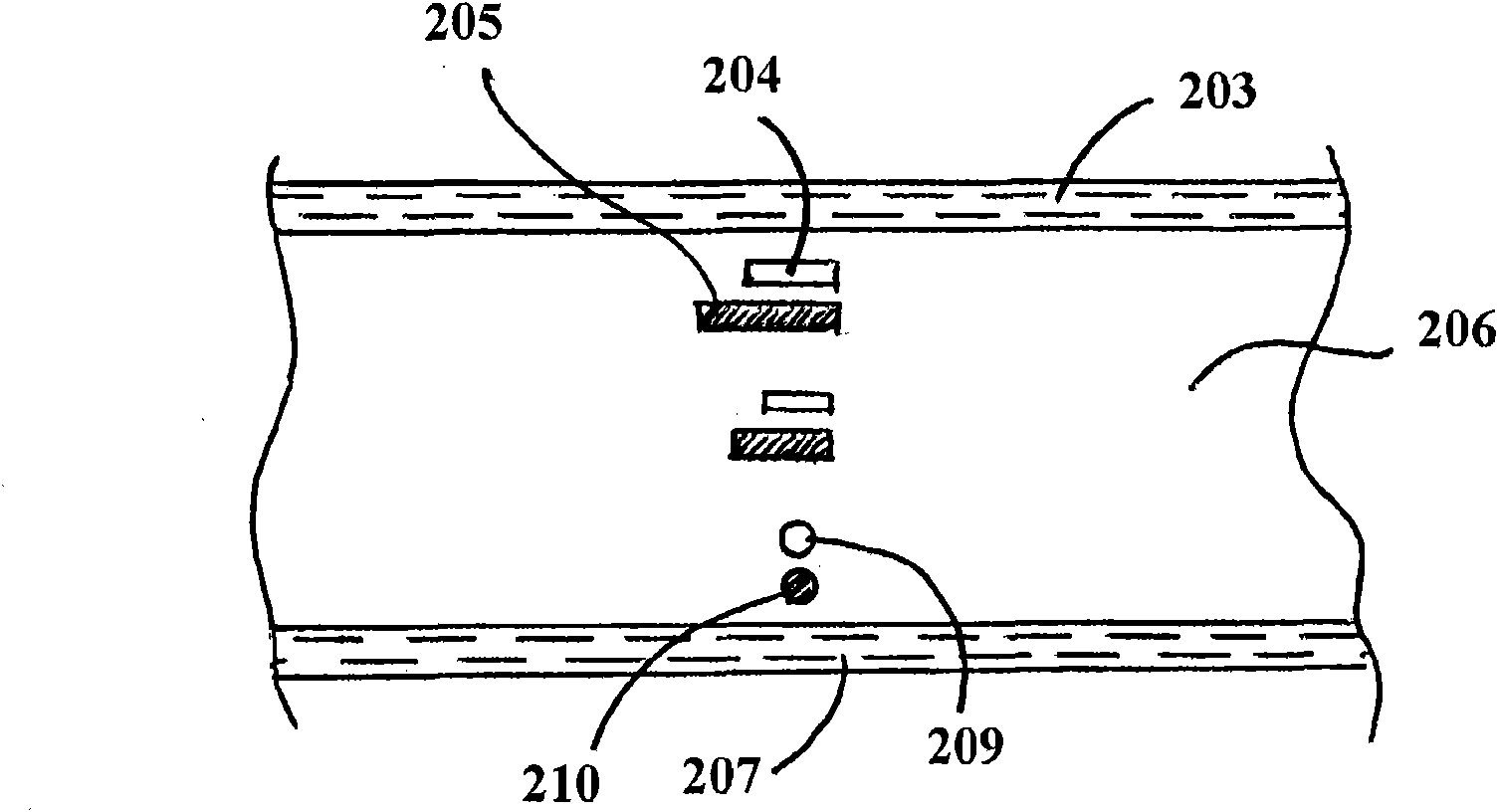

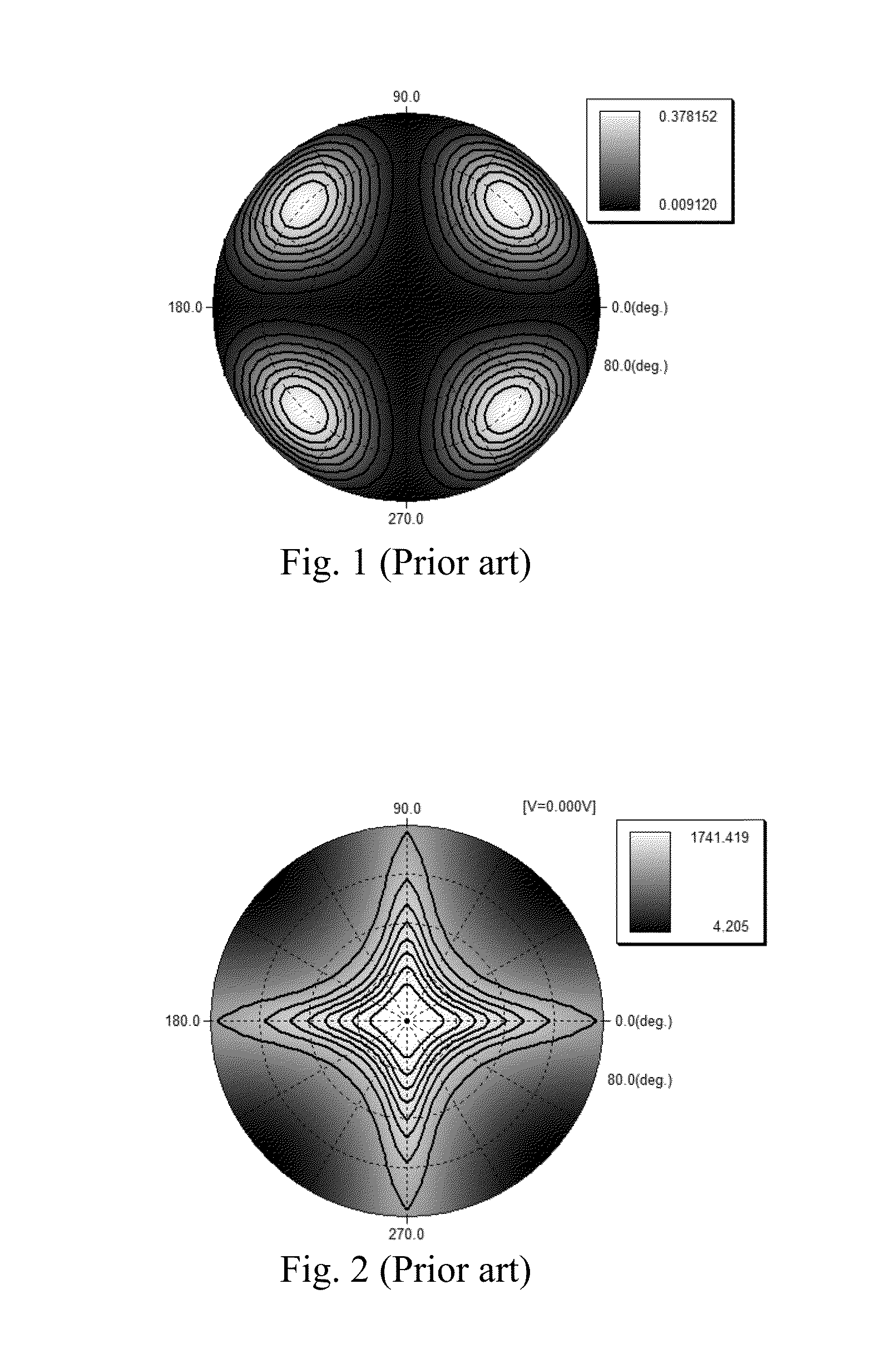

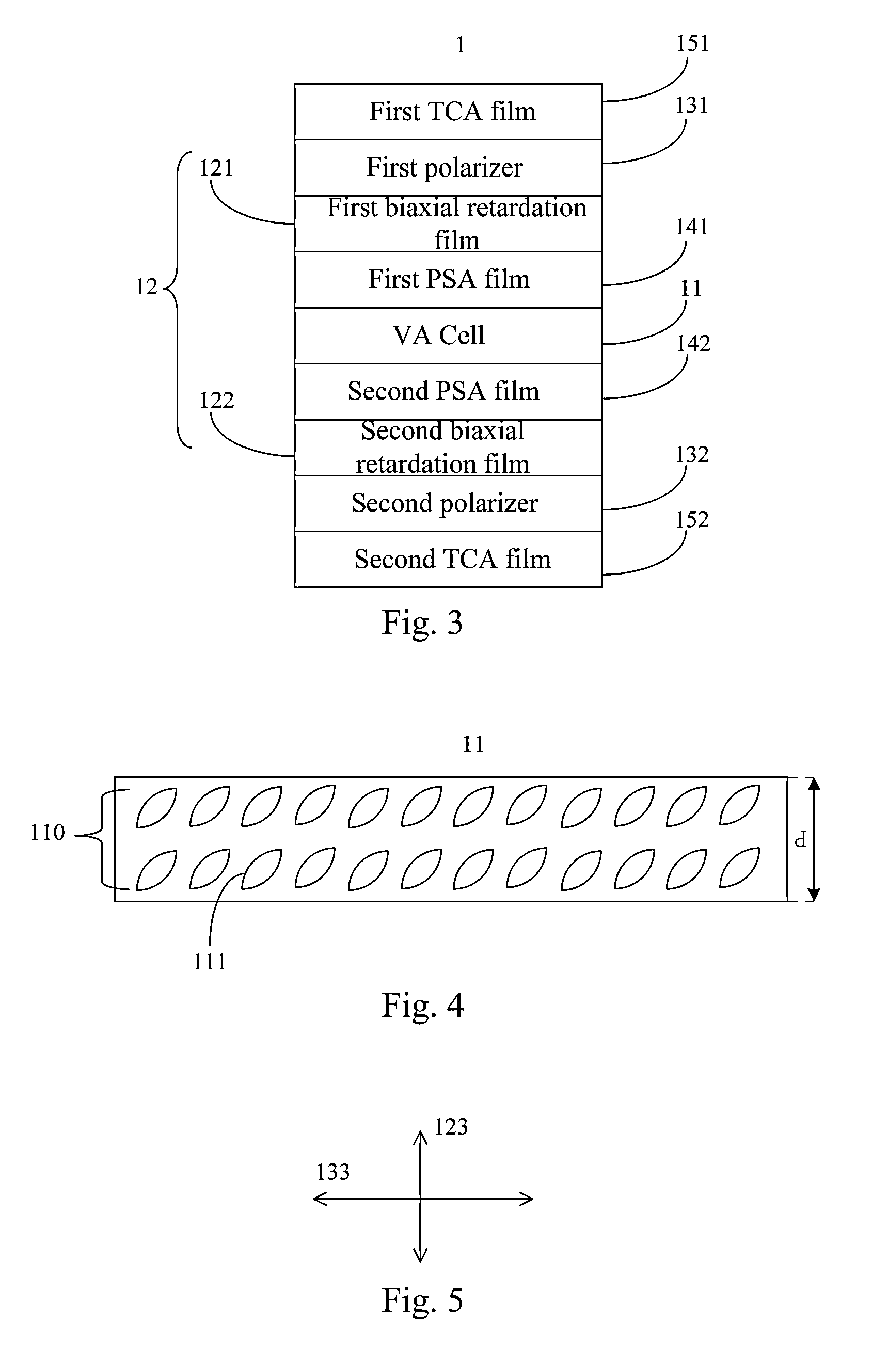

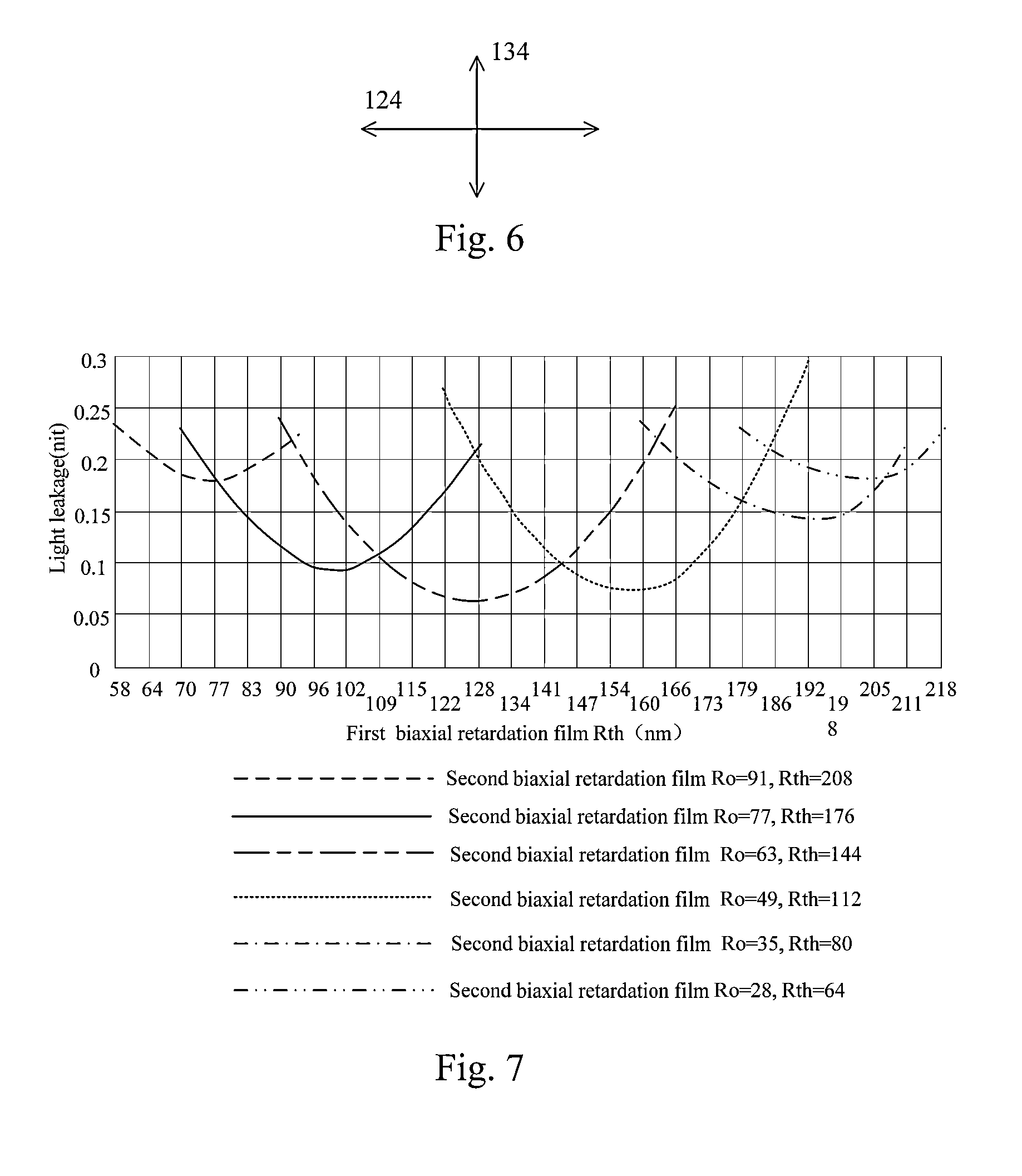

Compensation system and liquid crystal display apparatus for liquid crystal panel

InactiveUS20140139790A1Reduce light leakageWiden perspectivePolarising elementsNon-linear opticsIn planeLiquid-crystal display

The present invention discloses a compensation system and a liquid crystal display apparatus used for a liquid crystal panel. The compensation system comprises a first biaxial retardation film and a second biaxial retardation film respectively disposed on either side of the liquid crystal panel. An in-plane retardation value of the first biaxial retardation film at a wavelength of 550 nm is Ro1. An out-of-plane retardation value in a thickness direction is Rth1. An in-plane retardation value of the second biaxial retardation film at the wavelength of 550 nm is Ro2. An out-of-plane retardation value in a thickness direction is Rth2. Wherein: 30.8 nm≦Ro1≦91 nm; 70.4 nm≦Rth1≦208 nm; 21 nm≦Ro2≦93.8 nm; Y1≦Rth2≦Y2; Y1=0.00424817×Rth12−1.9854256×Rth1+277.7: Y2=−0.003333×Rth12−0.033459×Rth1+234.2. The present invention effectively reduces light leakage of the liquid crystal panel in dark mode by disposing the double-layered biaxial retardation films having reasonable retardation values.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

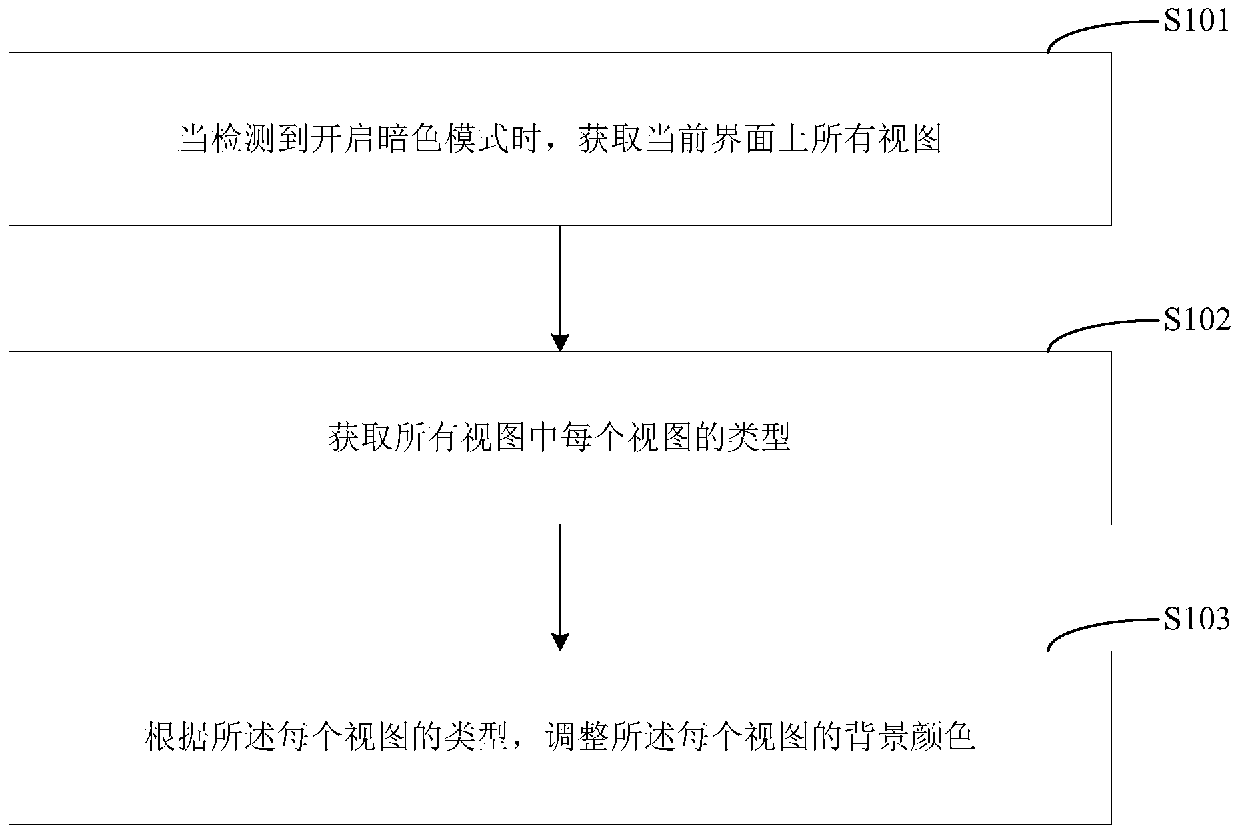

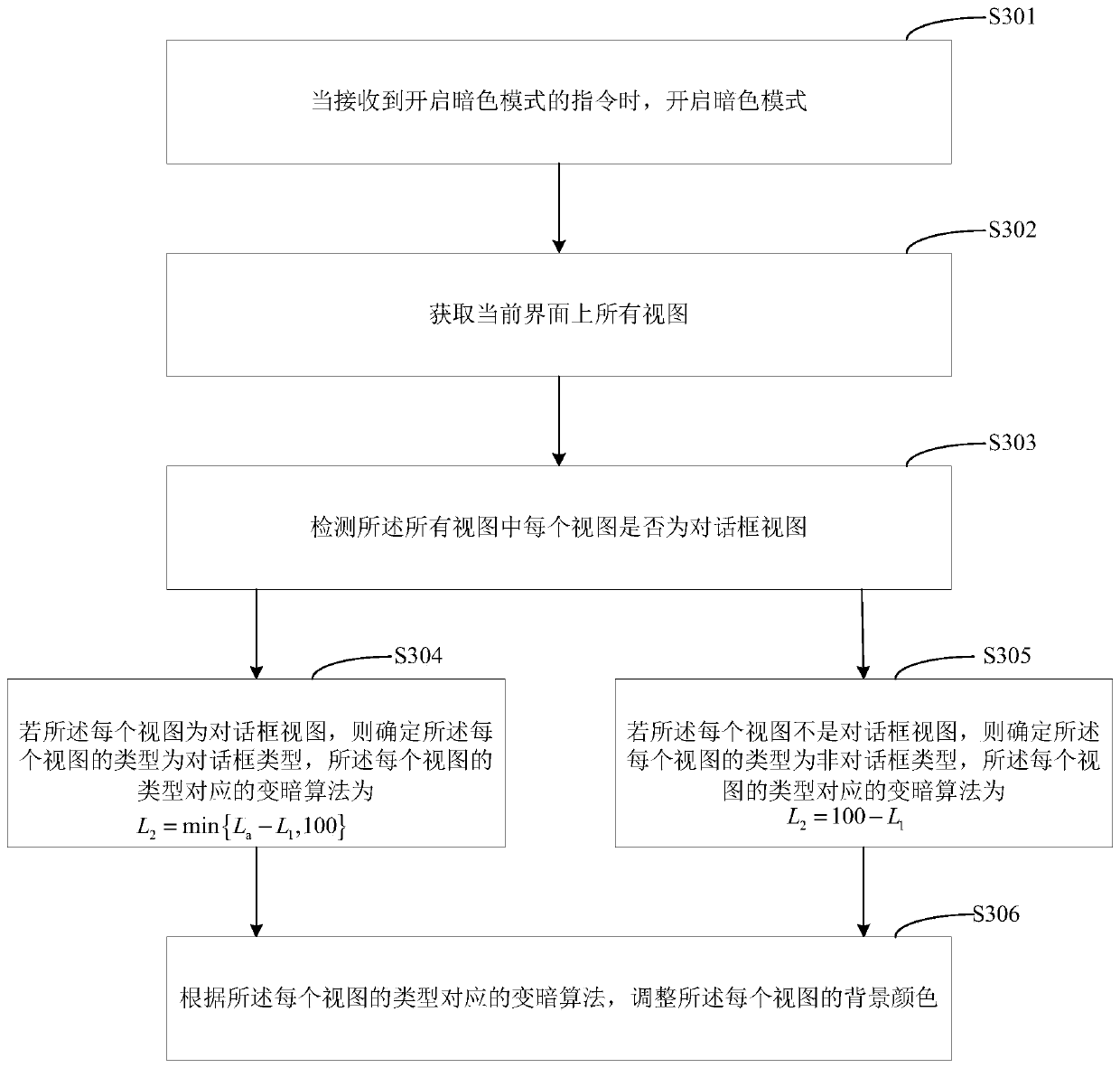

View processing method, view processing device and terminal equipment

PendingCN110618852AIncrease contrastAdd background color levelsExecution for user interfacesDark modeComputer graphics (images)

The invention is suitable for the technical field of terminals, and provides a view processing method, a view processing device and terminal equipment, and the method comprises the steps: obtaining all views on a current interface when a dark color mode is detected to be started; obtaining the type of each view in all views; and adjusting the background color of each view according to the type ofeach view. According to the invention, the problem that the contrast of the interface of the terminal equipment is not obvious in the dark mode in the prior art can be solved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

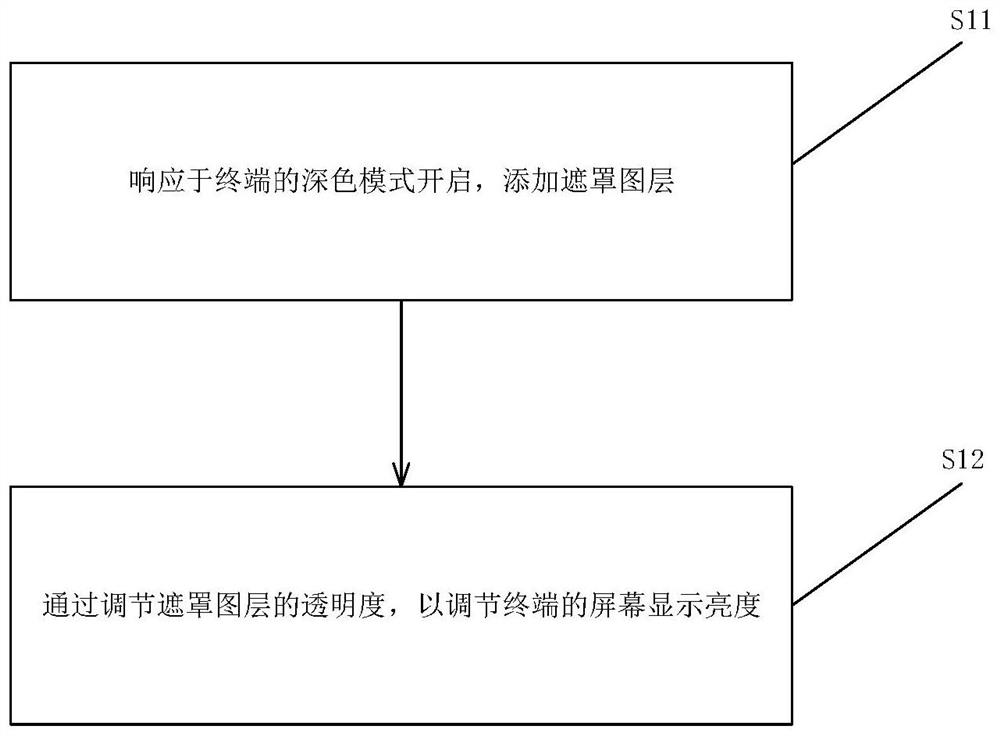

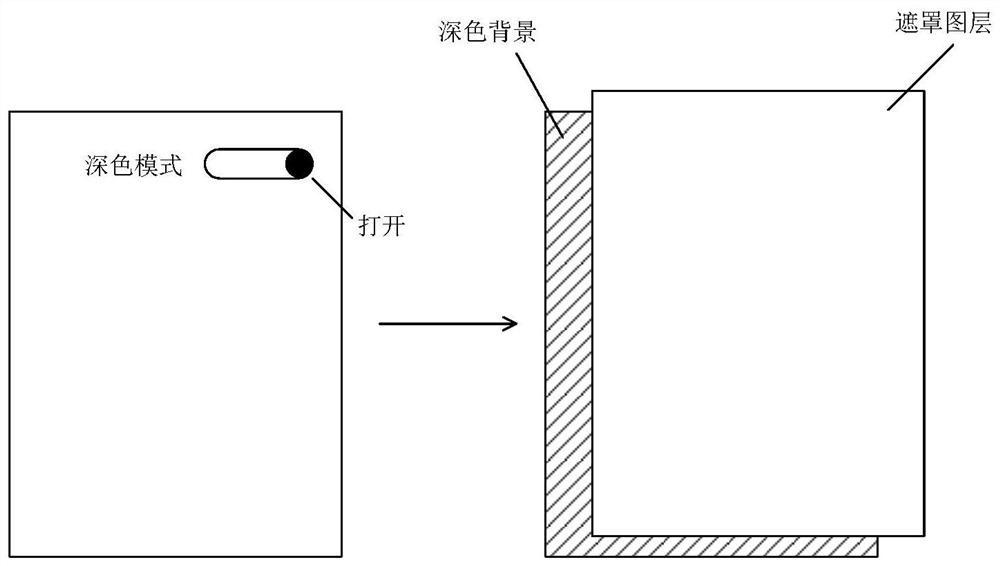

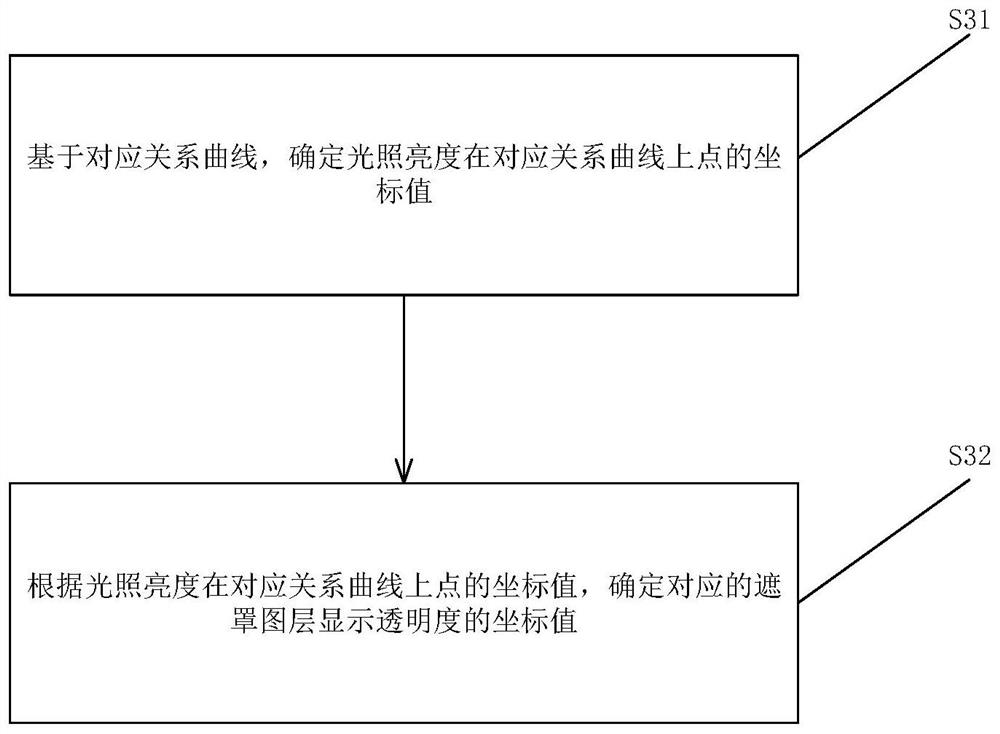

Screen display adjusting method and device and storage medium

PendingCN111611034AReal-time adjustment of display brightnessImprove real-time adjustment intelligenceCathode-ray tube indicatorsExecution for user interfacesDark modeEngineering

The invention relates to a screen display adjusting method and device and a storage medium. The screen display adjustment method is applied to the terminal, and comprises the following steps: adding amask layer in response to the opening of a dark mode of the terminal; and adjusting the screen display brightness of the terminal by adjusting the display transparency of the mask layer. According tothe invention, the real-time adjustment of the screen display brightness is realized, and the real-time adjustment intelligence of the screen display brightness is improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

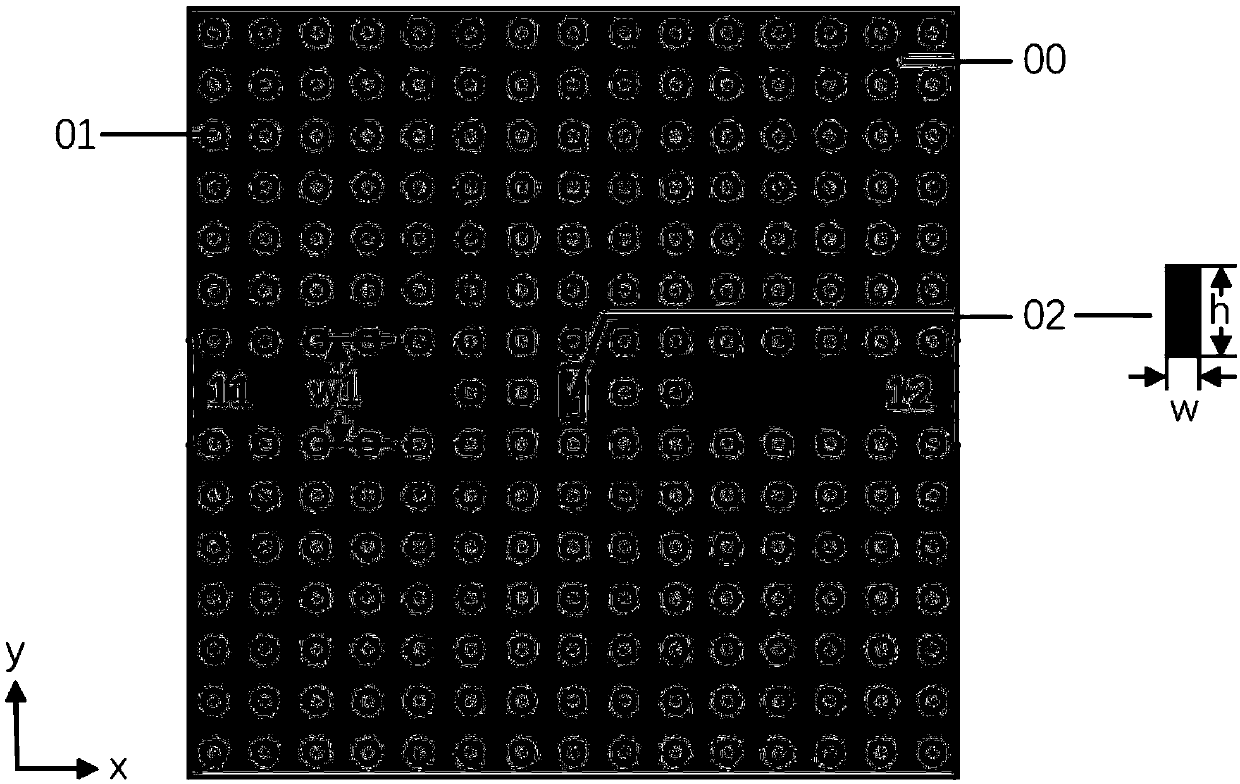

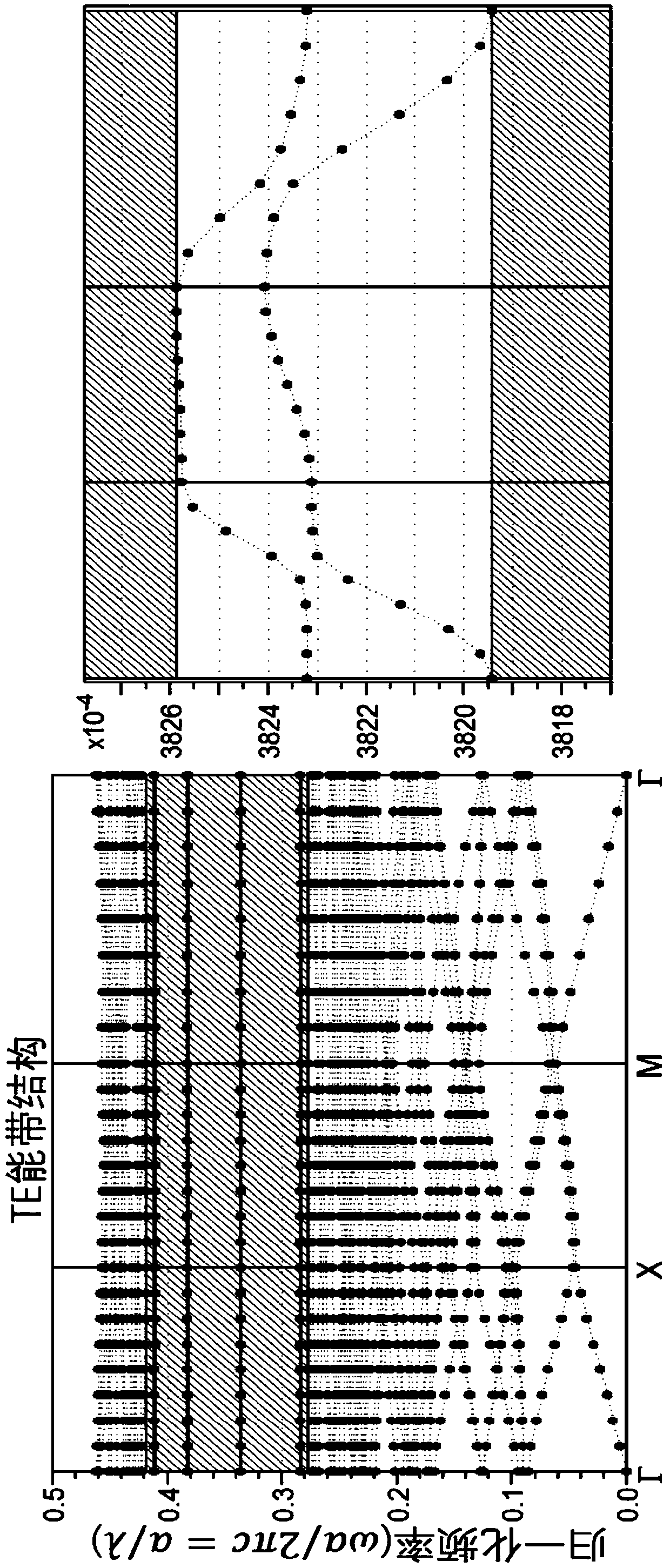

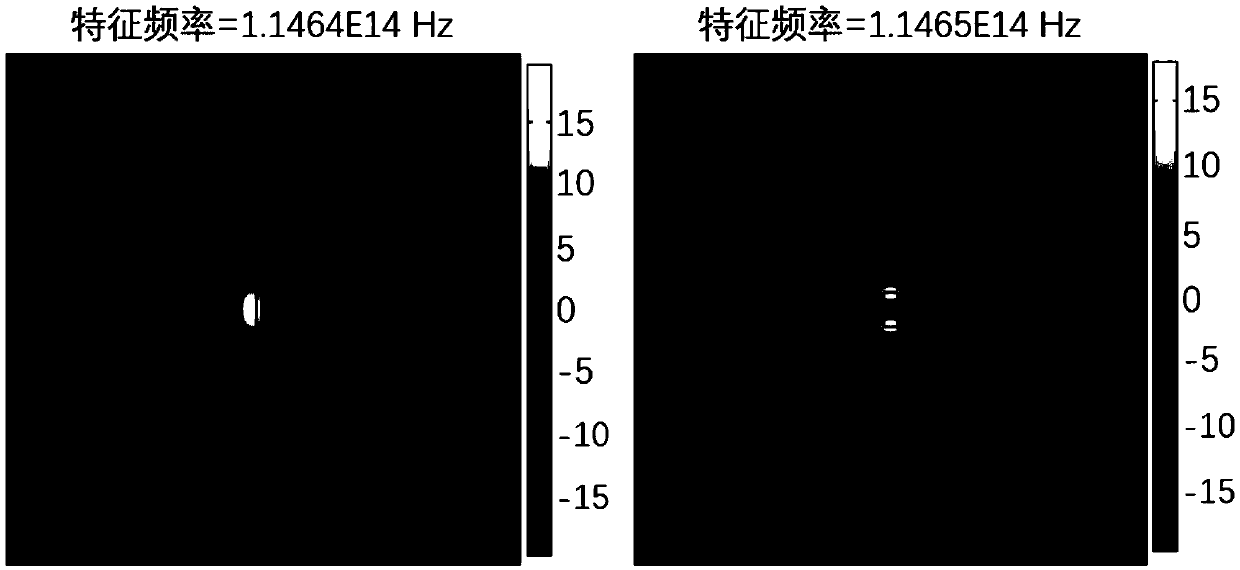

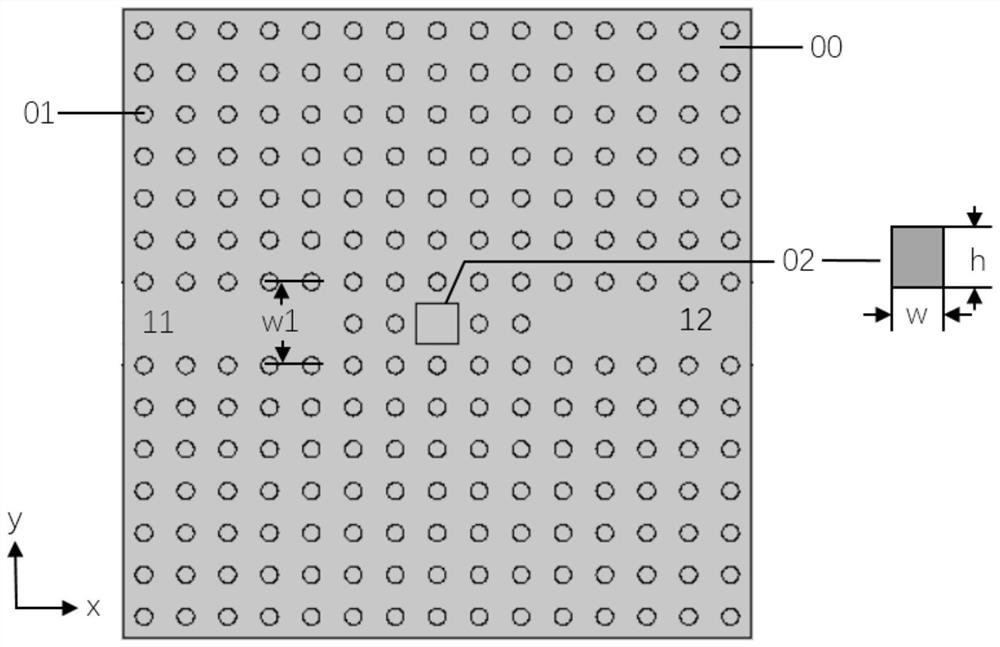

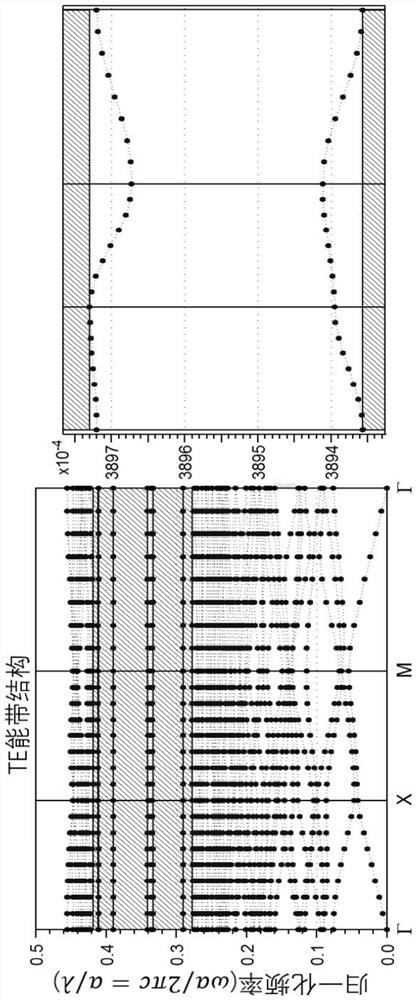

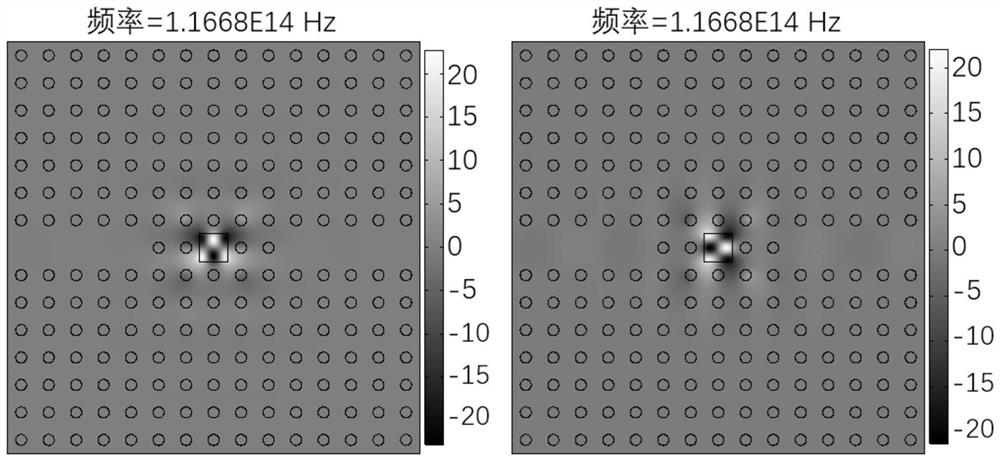

Photonic crystal waveguide orthogonal split mode interference FANO resonant structure

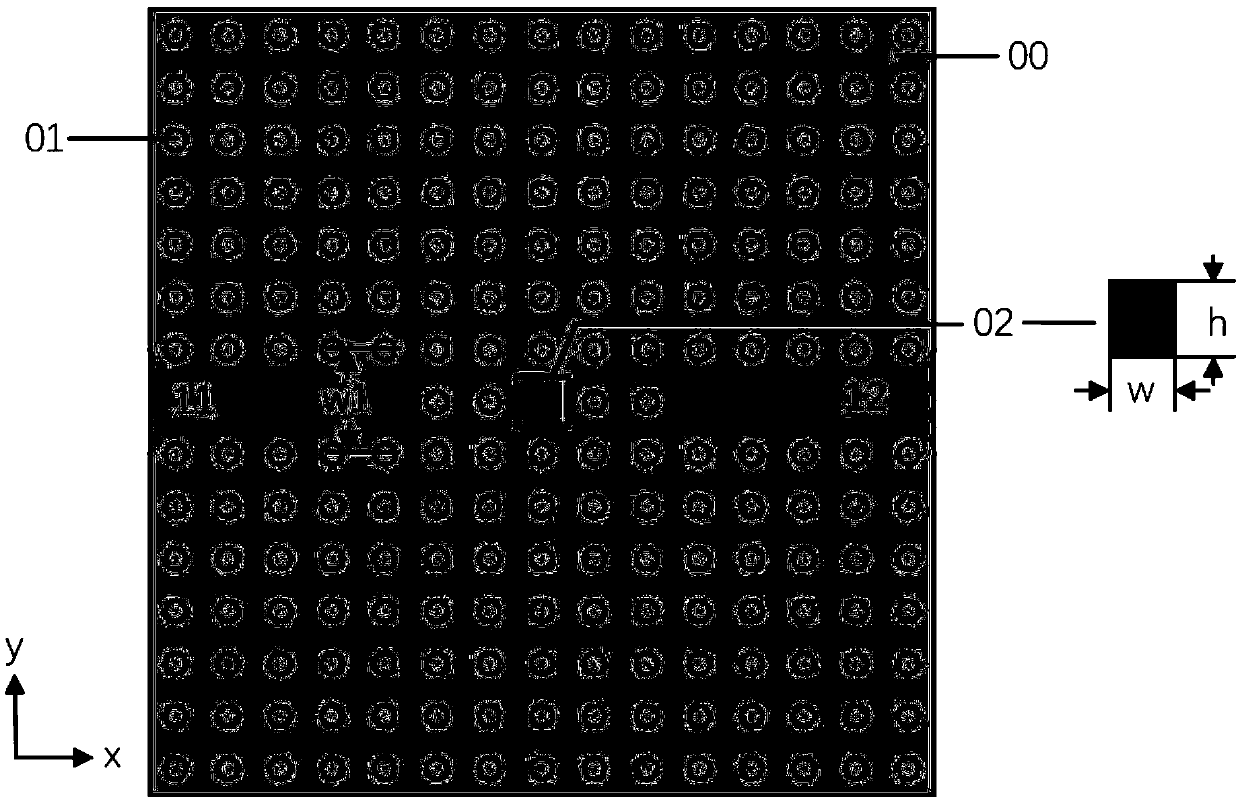

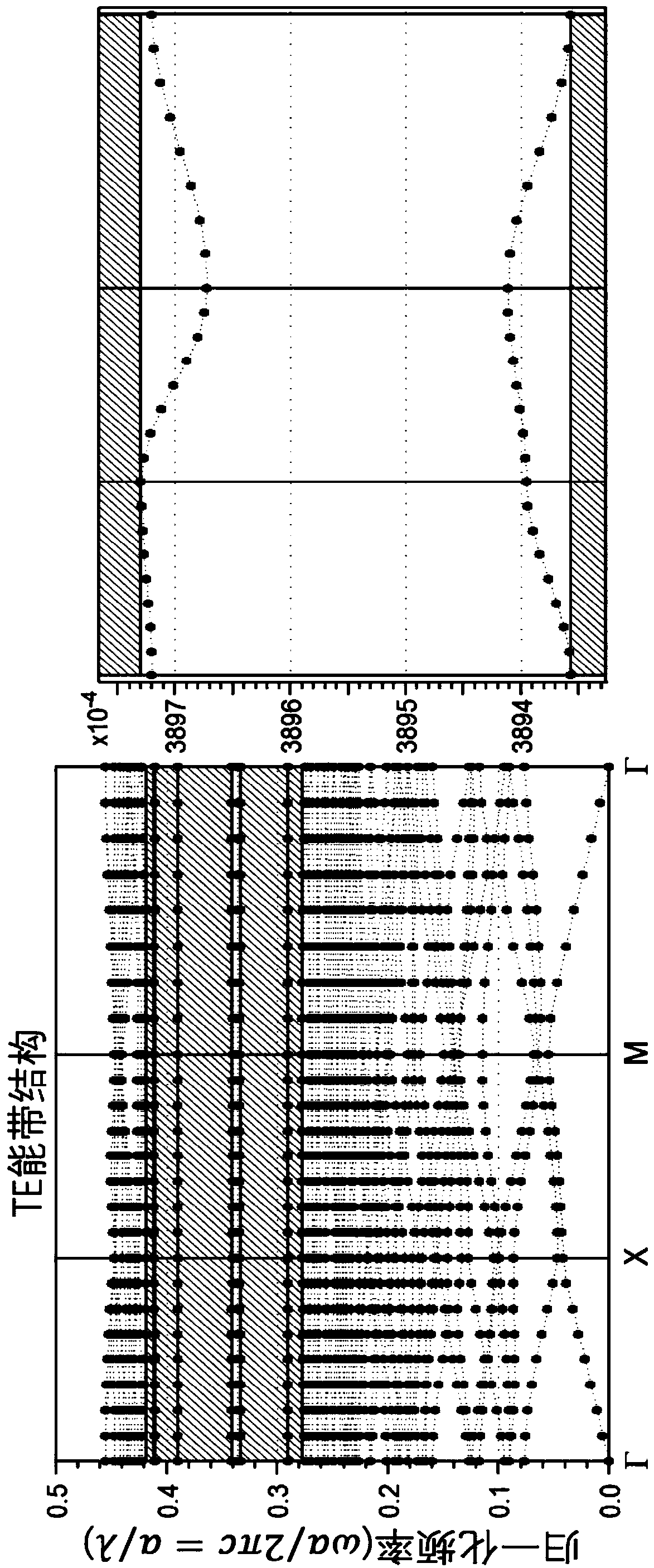

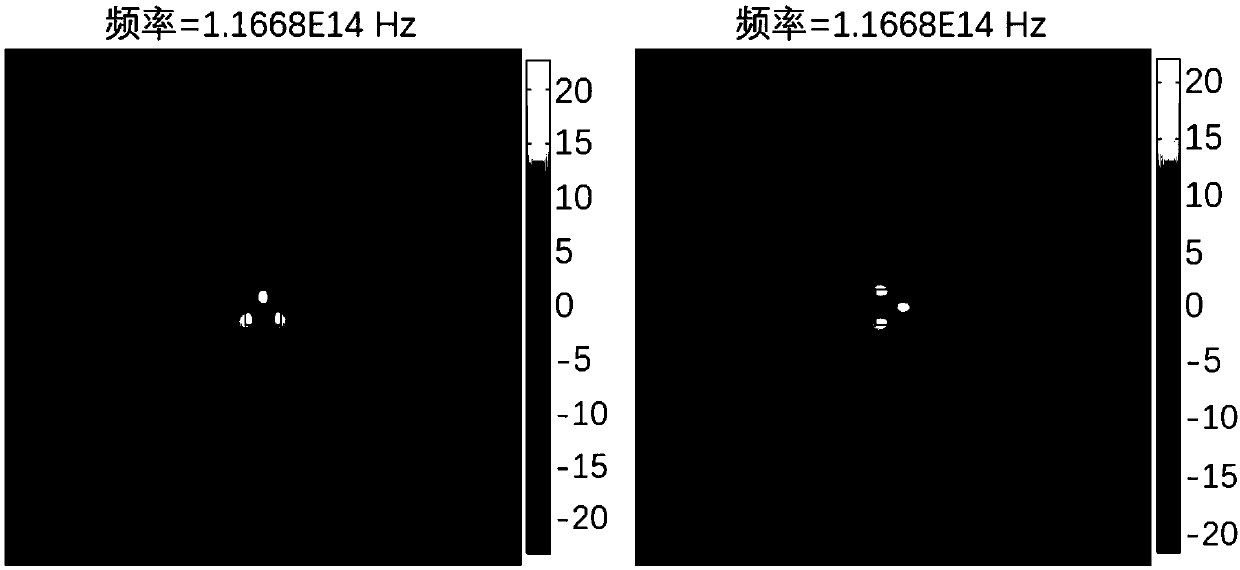

InactiveCN109669239AReduce volumeSimple and symmetrical structureOptical light guidesDark modeDielectric cylinder

The invention discloses a photonic crystal waveguide orthogonal split mode interference FANO resonant structure. The structure comprises a two-dimensional photonic crystal linetype waveguide composedof a plurality of dielectric cylinders with the refractive index, the two-dimensional photonic crystal linetype waveguide comprises two waveguide ports and one point defect resonant cavity, wherein the two waveguide ports are arranged on the two sides of the point defect resonant cavity respectively. The point defect resonant cavity comprises four dielectric cylinders and one point defect dielectric cylinder with the cross section long side being perpendicular to a waveguide axis and the length-width ratio being 2.4-2.6. Two dielectric cylinders are symmetrically arranged on the two sides of the point defect dielectric cylinder respectively, and the centers of the four dielectric cylinders and the point defect dielectric cylinder are distributed and arranged at equal intervals. The structure provided by the invention is compact, bright mode and dark mode of Fano resonance can be conveniently controlled, and Fano resonance is easy to achieve integration with other photonic crystal devices.

Owner:SHENZHEN UNIV

Two-dimensional material plasmonic laser

ActiveUS20190229498A1Integrative technologyOptical wave guidanceLaser optical resonator constructionElectron holeOptical pumping

Owner:NATIONAL TSING HUA UNIVERSITY

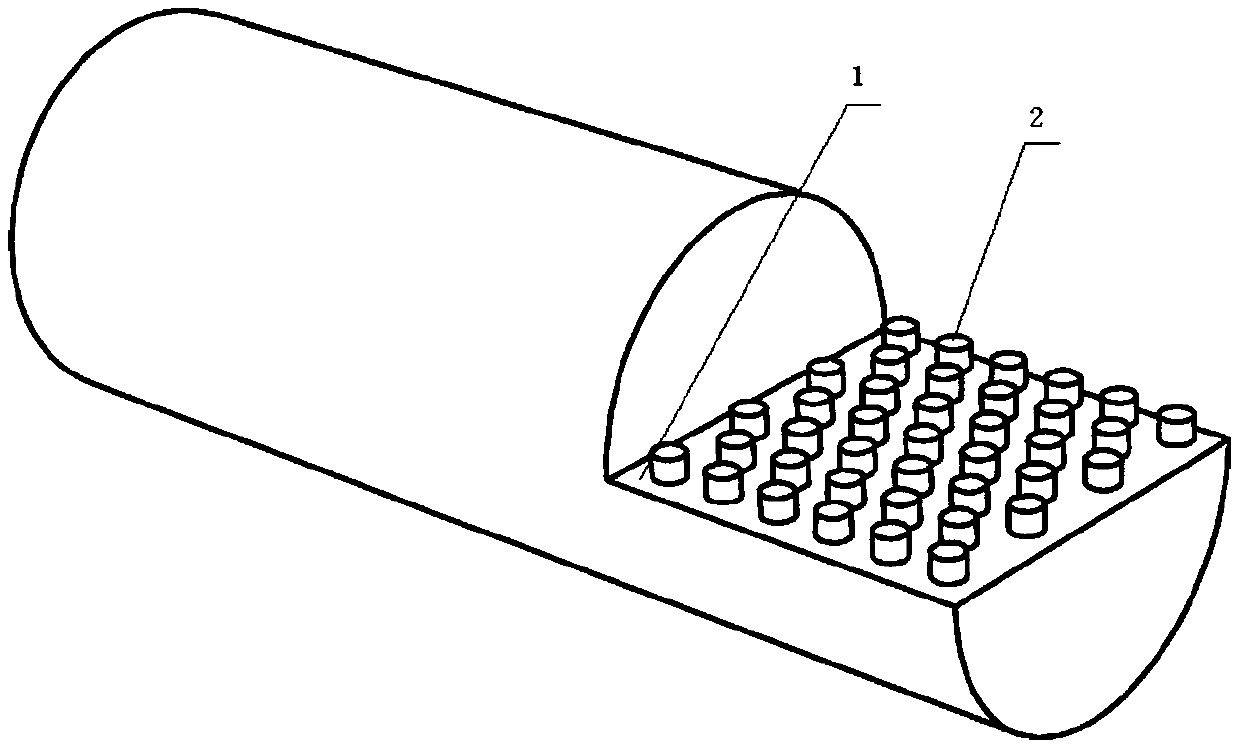

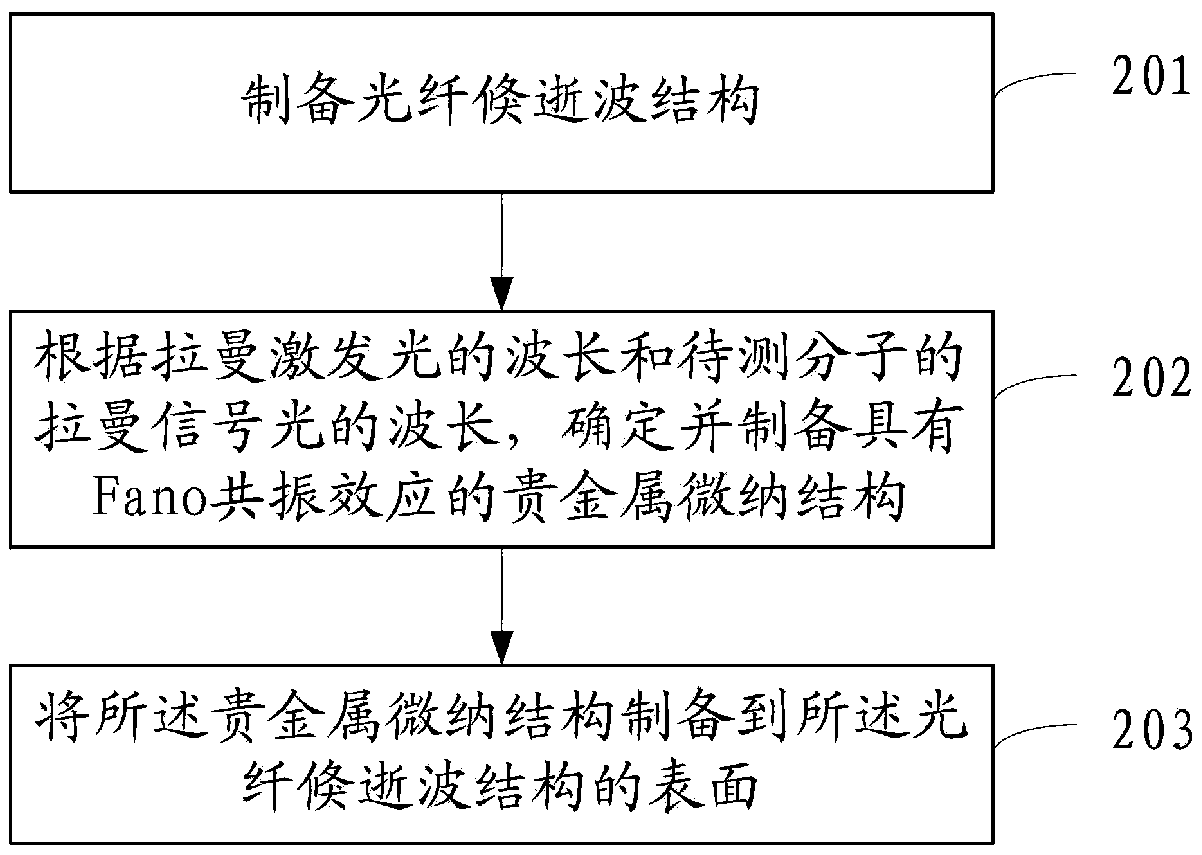

Evanescent-wave-based fiber SERS (Surface Enhanced Raman Scattering) probe and preparation method thereof

ActiveCN109580578ASolve the bottleneck problem of sensitivity improvementCladded optical fibreRaman scatteringMicro nanoDark mode

The invention discloses an evanescent-wave-based fiber SERS probe and a preparation method thereof. The evanescent-wave-based fiber probe comprises an evanescent-wave structure of an optical fiber anda noble metal micro-nano structure having a Fano resonance effect. The noble metal micro-nano structure is arranged on the surface of the evanescent-wave structure of the optical fiber. The Raman excitation light and the Raman signal light of the molecules to-be-detected are respectively arranged at a bright mode and a dark mode of the Fano resonance of the noble metal micro-nano structure, whenthe probe is used. According to the evanescent-wave-based fiber SERS probe and the preparation method thereof, the preparation method sets the noble metal micro-nano structure having the Fano resonance effect on the surface of the evanescent-wave structure of the optical fiber, utilizes the bright mode to realize an effective excitation of the Raman signal light of the molecule to-be-detected, andmeanwhile, utilizes the dark mode to realize the low loss transmission of the Raman signal light of the molecule to-be-detected in the optical fiber, thereby solving the bottleneck problem that the sensitivity of the probe is limited by a SERS saturation phenomenon in the current evanescent-wave-based fiber SERS probe.

Owner:DONGGUAN UNIV OF TECH

Photonic crystal waveguide diagonal mode interference FANO resonant structure

InactiveCN109669242AReduce volumeSimple and symmetrical structureOptical waveguide light guideResonant cavityPhotonic crystal

The invention discloses a photonic crystal waveguide diagonal mode interference FANO resonant structure. The structure comprises a two-dimensional photonic crystal linetype waveguide formed through distribution of a plurality of dielectric cylinders with the refractive index, the two-dimensional photonic crystal linetype waveguide comprises two waveguide ports and one point defect resonant cavity,wherein the two waveguide ports are arranged on the two sides of the point defect resonant cavity, the point defect resonant cavity comprises four dielectric cylinders and one point defect dielectriccylinder with one cross section being square or similar to square, two dielectric cylinders are symmetrically arranged on the two sides of the point defect dielectric cylinder respectively, and the centers of the four dielectric cylinders and the point defect dielectric cylinder are distributed and arranged at equal intervals. The structure provided by the invention is compact, bright mode and dark mode of Fano resonance can be conveniently controlled, and Fano resonance is easy to achieve integration with other photonic crystal parts.

Owner:SHENZHEN UNIV

A Terahertz Band Metamaterial Sensor Based on Electromagnetic-Induced Transparency Effect

ActiveCN108572162BHigh Q valueHigh Refractive Index SensitivityPhase-affecting property measurementsDark modeRefractive index

Owner:CHONGQING UNIV OF POSTS & TELECOMM

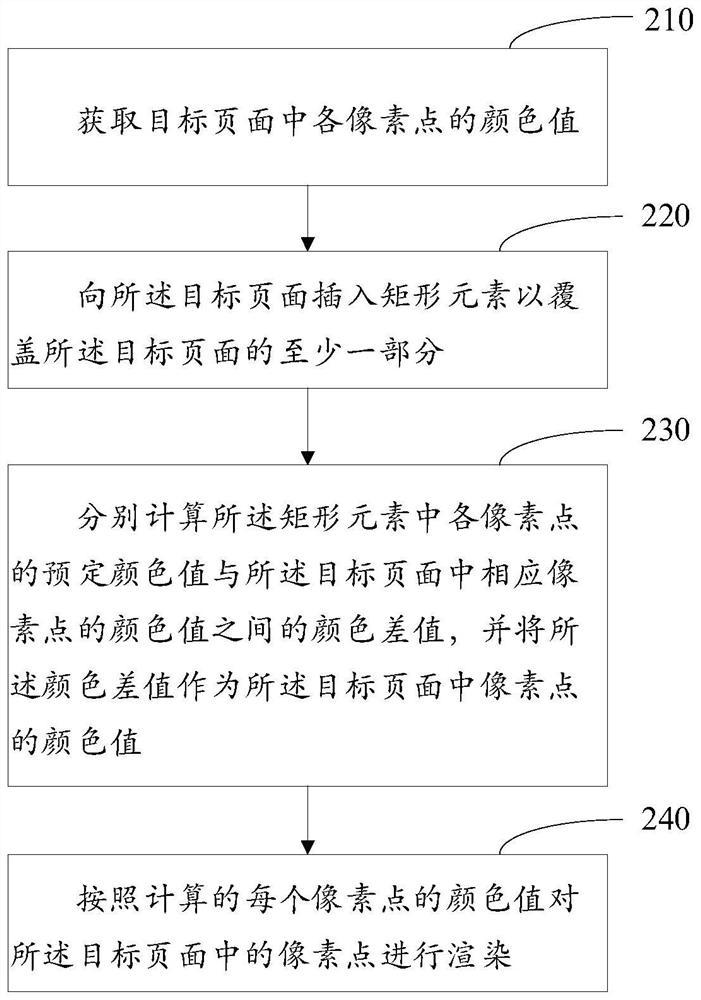

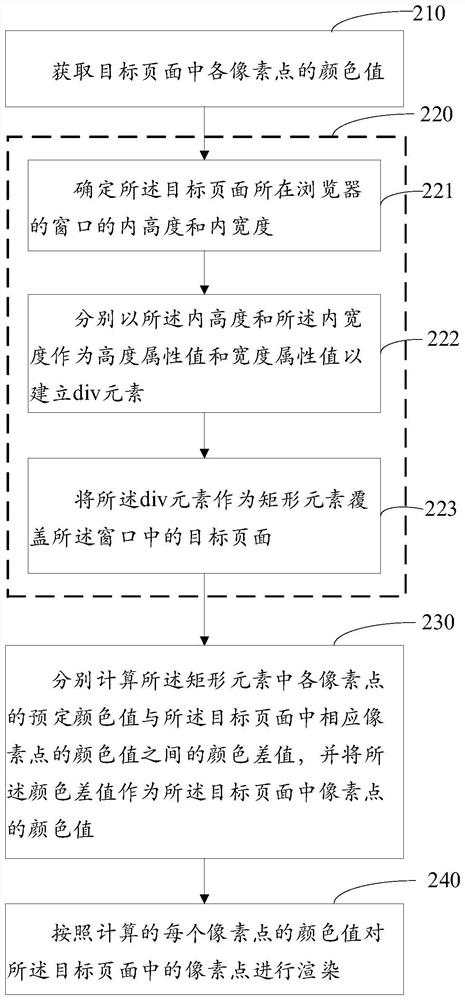

Webpage dark mode implementation method and device, medium and electronic equipment

PendingCN112364282ALow costImprove implementation efficiencyWebsite content managementProgram loading/initiatingDark modeEngineering

The invention relates to the field of webpage configuration, and discloses a webpage dark mode implementation method and device, a medium and electronic equipment. The method comprises the steps of obtaining a color value of each pixel point in a target page; inserting a rectangular element into the target page to cover at least one part of the target page, each pixel point in the rectangular element displaying a predetermined color value; respectively calculating a color difference value between a predetermined color value of each pixel point in the rectangular element and a color value of acorresponding pixel point in the target page, and taking the color difference value as the color value of the pixel point in the target page; and rendering the pixel points in the target page according to the calculated color value of each pixel point. According to the method, the webpage can be automatically converted into the dark mode from the common mode, the implementation cost of the dark mode is reduced, and the implementation efficiency of the dark mode is improved.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

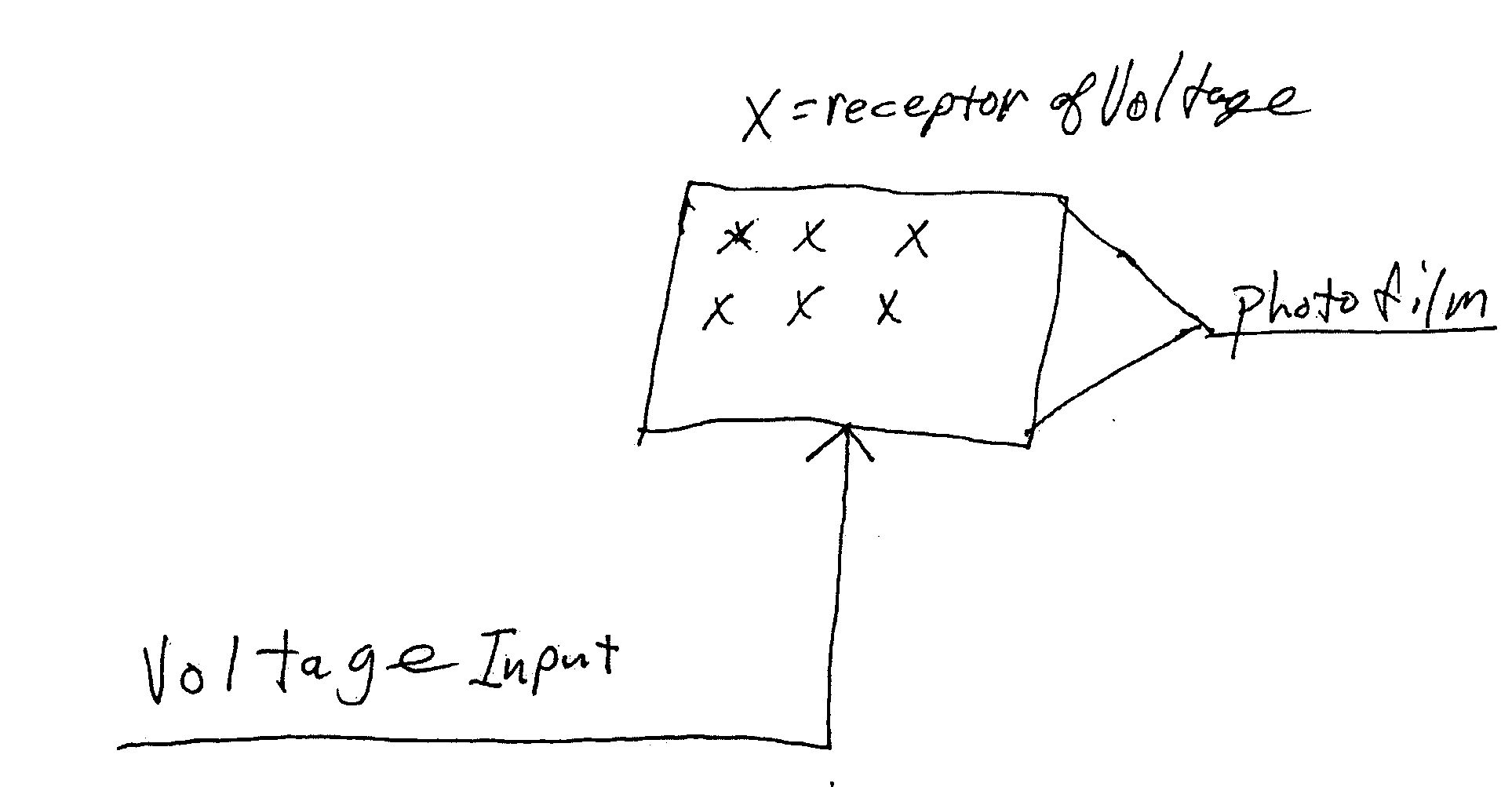

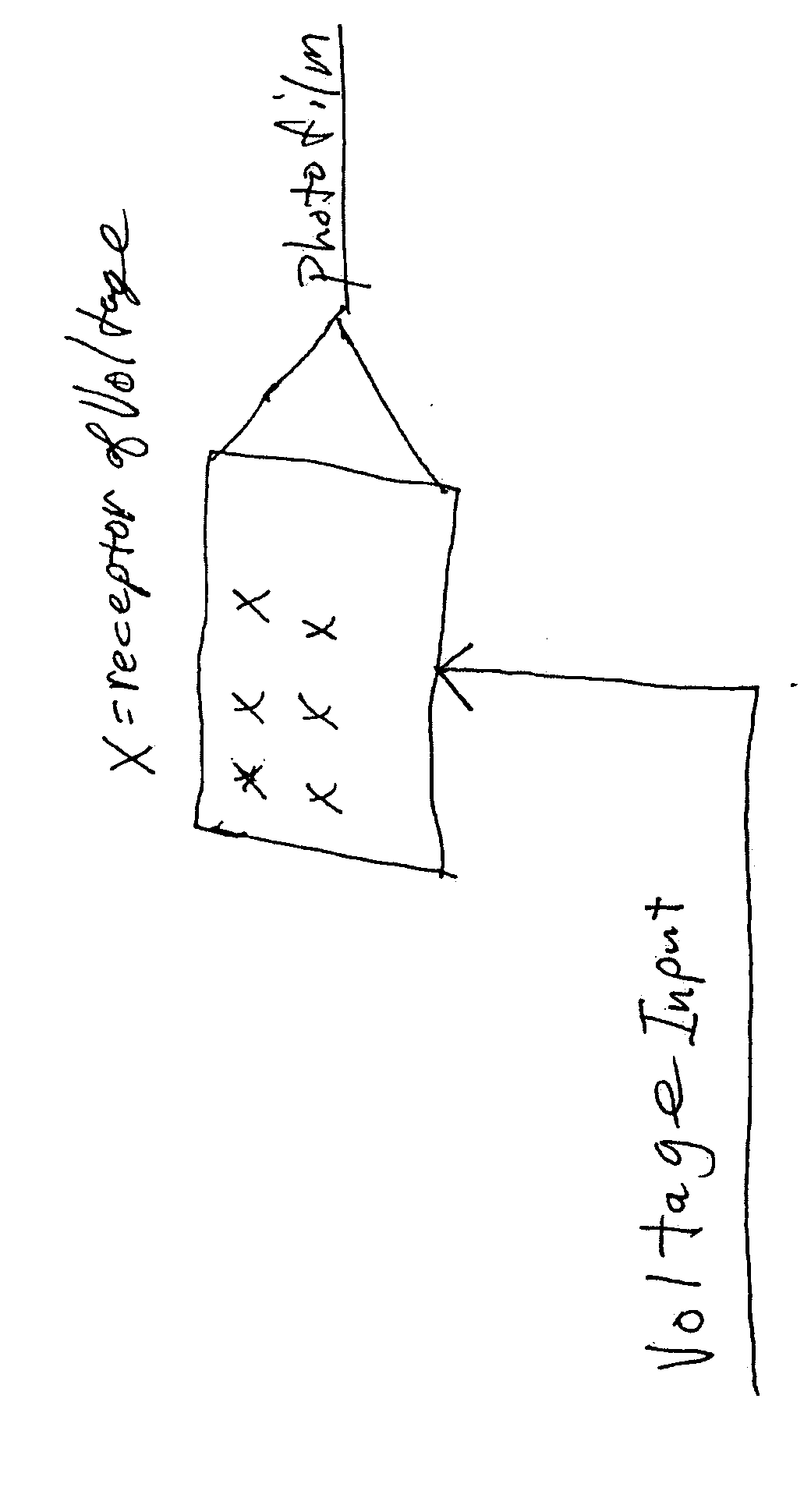

Automatic Window Tint

My invention will be used to cut down utility costs in homes and buildings, be a burglar deterrent, as becoming opaque is one of the features, and replacing car windshield sun blocks as well as blinds in school, buildings, homes, etc. The photosensitivity is manipulated through voltage input. In NYC in January for example, persons would set film to dark mode to activate the darker tint to absorb the heat of the light, whereas white or mirrored mode would be deactivated; visa Versa during the summer in NYC. This is meant to be green as it will cut down utility costs immensely and by being able to manipulate the voltage manually, you set how sensitive the photosensitive film is from no voltage manipulation to opaque.

Owner:BLETTE DEEANNA MELISSA

Shutter glasses and related 3D display system

InactiveUS8976306B2Reduce power consumption3D crosstalk is reducedSteroscopic systemsNon-linear opticsDark modeEngineering

The present invention discloses shutter glasses and a 3D display system. The shutter glasses include a first polarizer, a second polarizer, a normally-white LCD panel, and a normally-black LCD panel. A thickness of the normally-white LCD panel is not the same as a thickness of the normally-black LCD panel, and an optical compensation film is installed between the first polarizer and the liquid crystal layer of the normally-black LCD panel and / or between the second polarizer and the liquid crystal layer of the normally-black LCD panel in order to compensate for a dispersion occurred when the liquid crystal layer of the normally-black LCD panel is in a dark mode. In this way, the present invention can not only shorten the response time of the shutter glasses to reduce the power consumption, but also reduce the 3D crosstalk.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Electrically-controlled resonant coupled artificial surface plasmon cascade slow light device

The invention provides an electrically-controlled resonant coupled artificial surface plasmon cascaded slow light device, which comprises a dielectric substrate which is printed with an artificial surface plasmon transmission line; at least one group of functional units are arranged in the transmission direction of the artificial surface plasmon transmission line; each group of function units comprises bright and dark mode resonance structure pairs symmetrically distributed on two sides of the transmission direction of the artificial surface plasmon transmission line, and each bright and dark mode resonance structure pair comprises a bright mode resonance structure arranged on the inner side and a dark mode resonance structure arranged on the outer side; a PIN diode is arranged on the dark mode resonance structure, and mutual coupling between the dark mode resonance structure and the dark mode resonance structure is controlled by controlling the on-off state of the PIN diode, so that the group velocity and the propagation characteristic of the artificial surface plasmon are changed; the invention has the beneficial effect of dynamic tuning, and is suitable for the field of slow light devices.

Owner:SHANXI DATONG UNIV

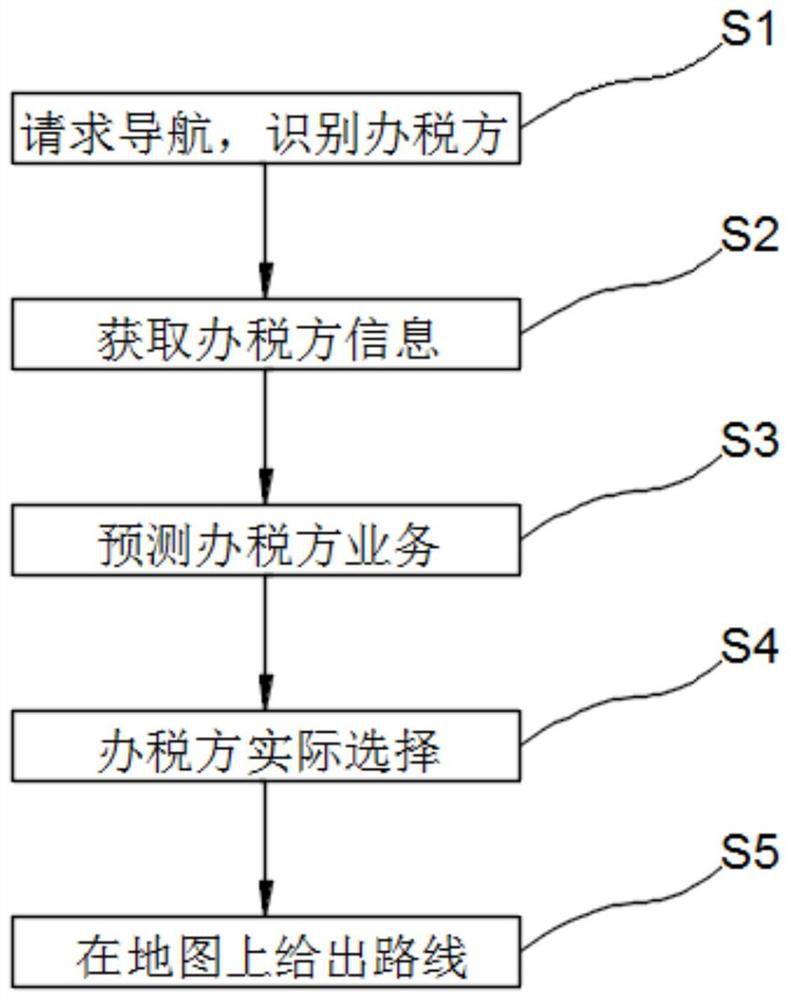

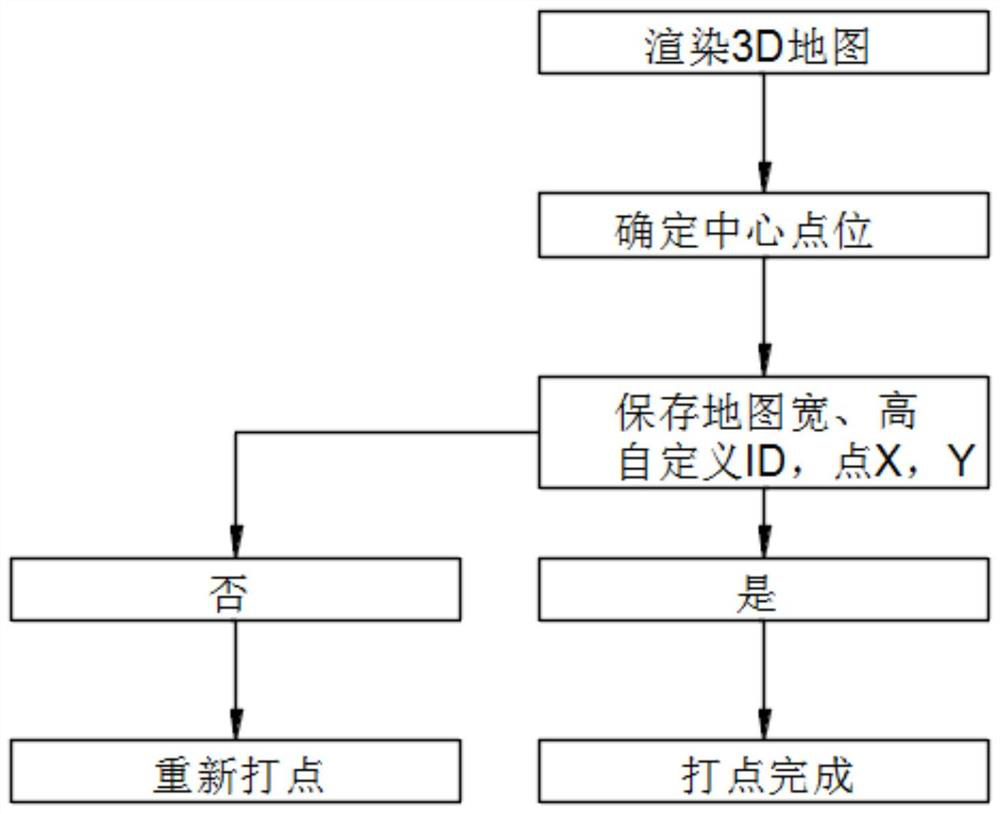

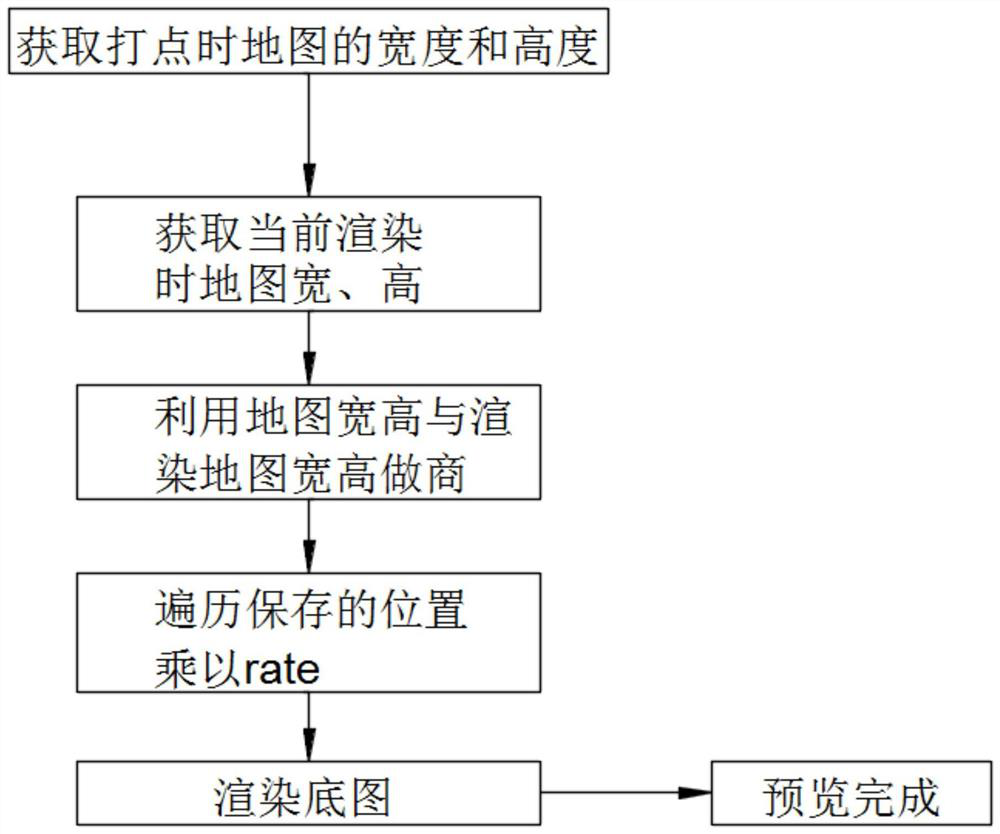

Guiding method and system based on indoor 3D map navigation tax handling and storage medium

The embodiment of the invention provides a guiding method and system based on indoor 3D navigation tax handling and a storage medium, and belongs to the field of navigation. The guiding method comprises the following steps: S1, requesting tax handling navigation, and identifying a tax handling party; s2, obtaining taxpayer information from a database; s3, business handling is predicted according to the taxpayer information, the business handling position and the business name are displayed on the map, the business name predicted to be handled is displayed in a bright mode, and the business name predicted to be unhandled is displayed in a dark mode; s4, the tax party selects the actually handled business, the actually handled business is displayed in a bright mode, and other handled businesses are not displayed; and S5, giving the nearest route of the actual business handling site in the map. According to the invention, the business handling items in each area of the hall can be known more clearly through 3D vision, taxpayers can be vividly guided to the handling points where the taxpayers want to go through dynamic guidance, and great convenience is brought to the taxpayers and the experience of non-inductive tax handling.

Owner:湖北航天信息技术有限公司

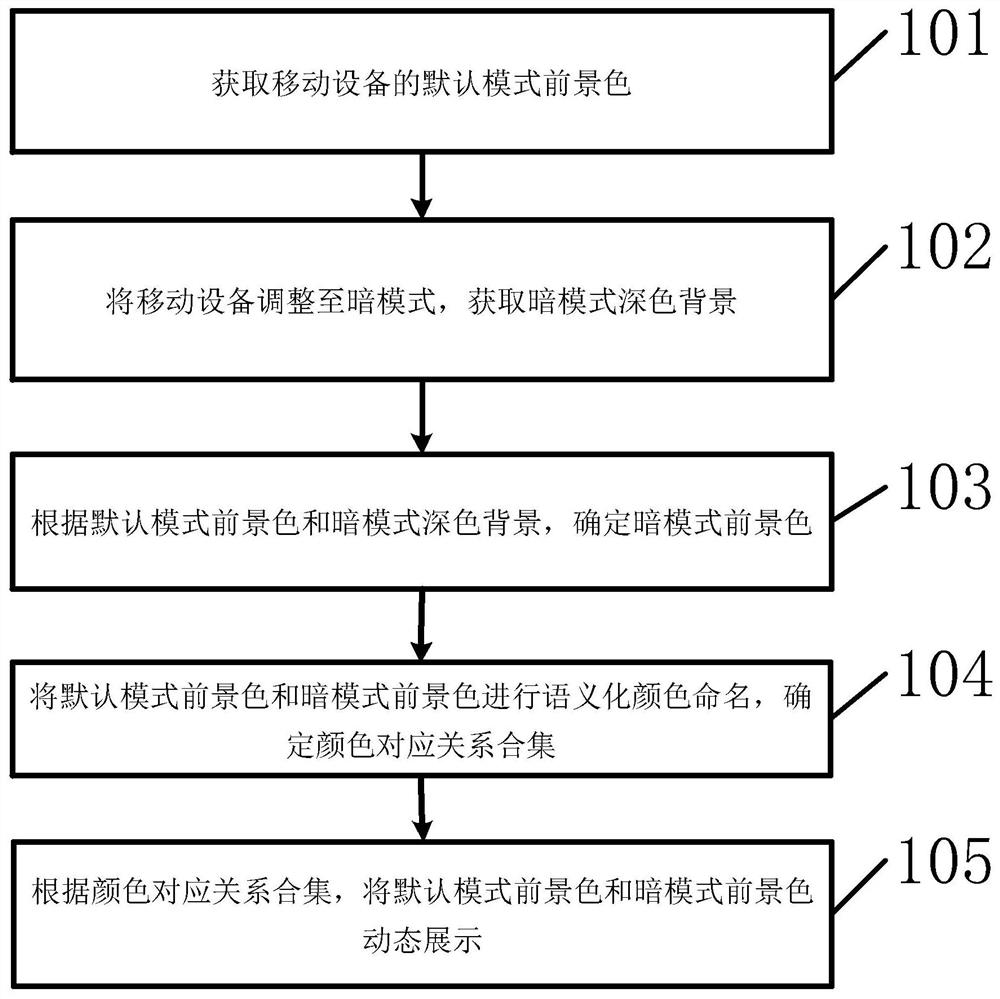

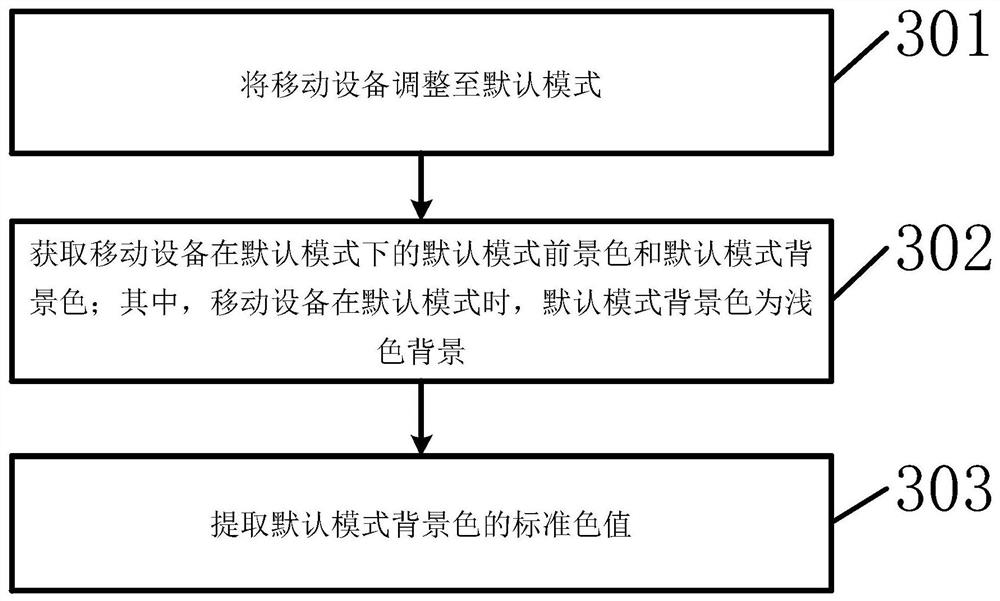

Dark mode color display management method and device

PendingCN113568698AGuaranteed identifiabilityImprove readabilityExecution for user interfacesDark modeDark color

The invention provides a dark mode color display management method and device, and relates to a mobile internet, and the method comprises the steps: obtaining a default mode foreground color of mobile equipment; adjusting the mobile equipment to a dark mode, and obtaining a dark background of the dark mode; according to the default mode foreground color and the dark mode dark color background, determining a dark mode foreground color; naming semantic colors of the default mode foreground color and the dark mode foreground color, and determining a color corresponding relation set; and dynamically displaying the default mode foreground color and the dark mode foreground color according to the color corresponding relation set. The unique and rational color value of the foreground color of the dark mode is obtained by calculating the foreground color of the default mode and the background of the dark color of the dark mode, and the color management efficiency of developers is improved through semantic color naming.

Owner:BANK OF CHINA

Terahertz metamaterials with modulators and slow-light capabilities

ActiveCN108232462BSolve the problem of mutual coupling strength regulationControl the wave transmissionAntennasInsulation layerWave group

The invention provides a terahertz metamaterial with a modulator and a slow light function. The terahertz metamaterial comprises a metal electrode and a metamaterial body, wherein the metamaterial body consists of a substrate, a metal resonance unit and a graphene strip; the substrate is provided with an insulation layer; the metal resonance unit and the graphene strip are arranged on the insulation layer of the substrate; the bias voltage is externally applied to the metamaterial body by the metal electrode, and the Fermi energy level of the graphene is adjusted, so as to regulate and controlthe transmittance of terahertz electromagnetic waves and the slow light effect. The terahertz metamaterial has the advantages that the problem of regulating and controlling on the mutual-coupling strength of open and dark-mode resonance structures in the metamaterial is solved, so as to realize the space modulation of the terahertz waves; the strong dispersion characteristic is produced by electromagnetically induced transparency, the delay of the electromagnetic wave group is produced, the slow light function is realized, and the slow light effect can be regulated and controlled by externally applying offset bias to change the Fermi energy level of the graphene; in the modulation process, the wave transmittance condition at the transparent peak frequency point is changed, the other frequency points are not affected, and the possible modulation noise can be effectively avoided.

Owner:CHENGDU FOURIER ELECTRONICS TECH

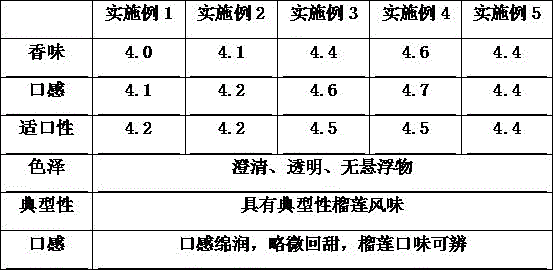

A kind of durian health-care wine and preparation method thereof

InactiveCN104450469BReduce sulfide levelsRemove bitter odorDigestive systemAlcoholic beverage preparationLiquid ratioDark mode

Owner:郑忠义

A Photonic Crystal Waveguide Diagonal Mode Interference Fano Resonant Structure

InactiveCN109669242BReduce volumeSimple and symmetrical structureOptical waveguide light guideResonant cavityPhotonic crystal

The invention discloses a photonic crystal waveguide diagonal mode interference FANO resonant structure. The structure comprises a two-dimensional photonic crystal linetype waveguide formed through distribution of a plurality of dielectric cylinders with the refractive index, the two-dimensional photonic crystal linetype waveguide comprises two waveguide ports and one point defect resonant cavity,wherein the two waveguide ports are arranged on the two sides of the point defect resonant cavity, the point defect resonant cavity comprises four dielectric cylinders and one point defect dielectriccylinder with one cross section being square or similar to square, two dielectric cylinders are symmetrically arranged on the two sides of the point defect dielectric cylinder respectively, and the centers of the four dielectric cylinders and the point defect dielectric cylinder are distributed and arranged at equal intervals. The structure provided by the invention is compact, bright mode and dark mode of Fano resonance can be conveniently controlled, and Fano resonance is easy to achieve integration with other photonic crystal parts.

Owner:SHENZHEN UNIV

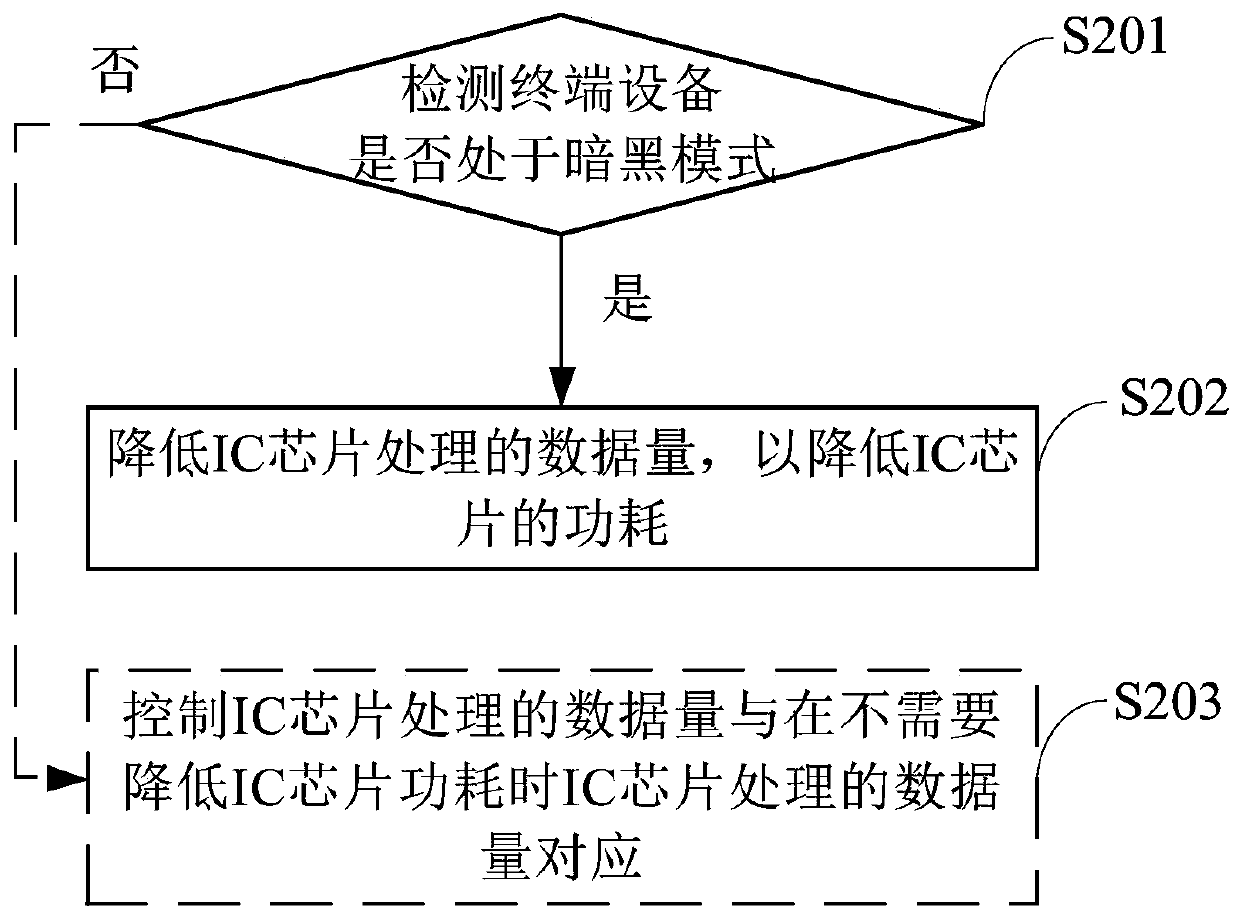

Power consumption reduction method, chip, display screen and terminal equipment

ActiveCN111586818AReduce power consumptionReduce detail requirementsPower managementSubstation equipmentDark modeTerminal equipment

The embodiment of the invention provides a power consumption reduction method, a chip, a display screen and terminal equipment. The power consumption reduction method comprises the steps that when theterminal equipment is in a dark mode, the requirement for details of a display picture on a display screen is low, and therefore when the terminal equipment is in the dark mode, the data volume processed by an IC chip is reduced, and optimization of the details of the display picture is reduced. Thus, on the basis of not influencing the watching experience of a user in the dark mode, the power consumption of the IC chip is reduced, the service life of the electric quantity of the terminal equipment is prolonged, and the user experience is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com