Laminated electric connector

A technology of electrical connectors and connectors, which is applied in the direction of connection, fixed connection, and parts of connection devices, etc., can solve the problems of shrinking the motherboard, achieve the effects of shortening thickness, reducing footprint configuration, and preventing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

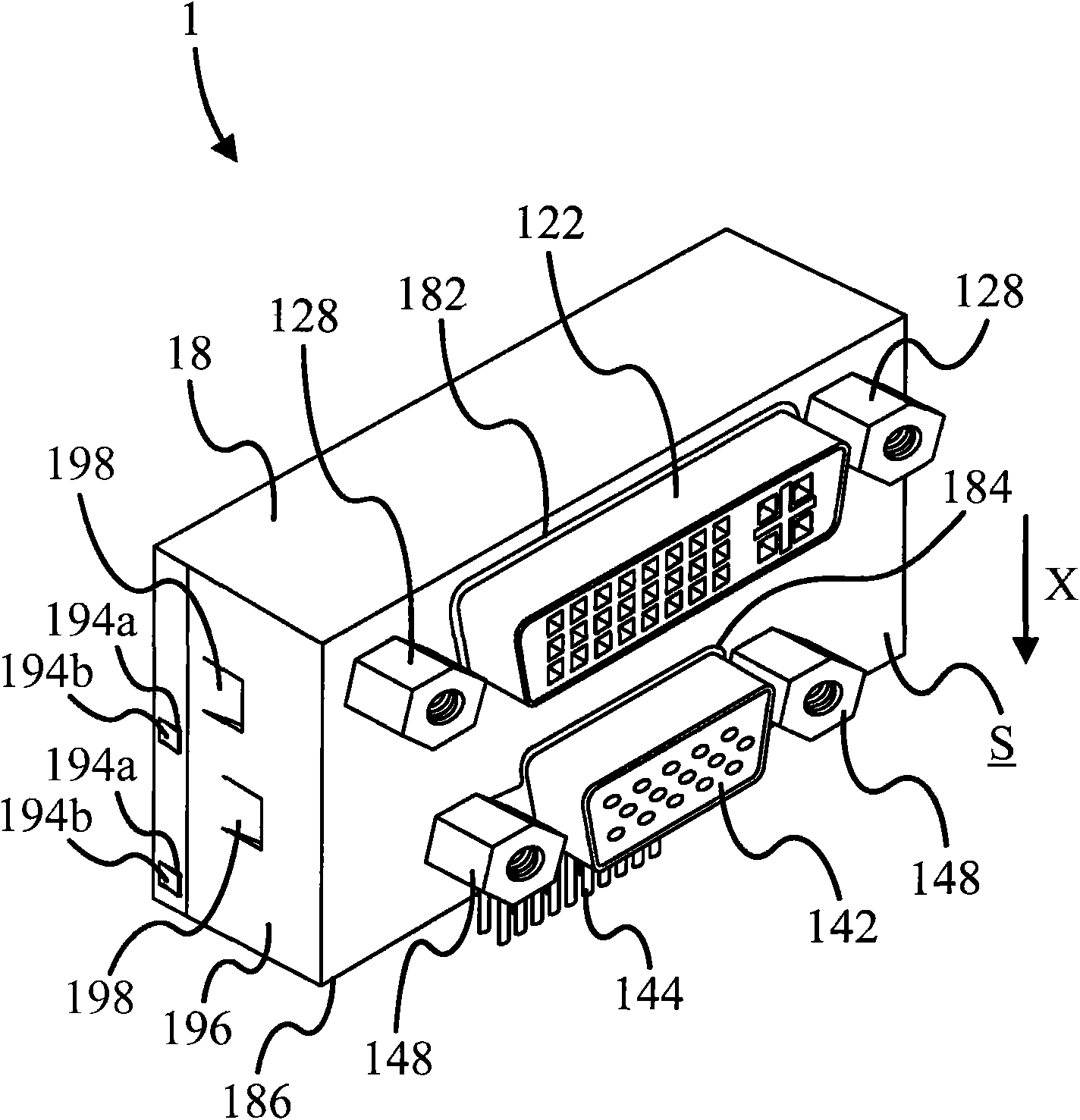

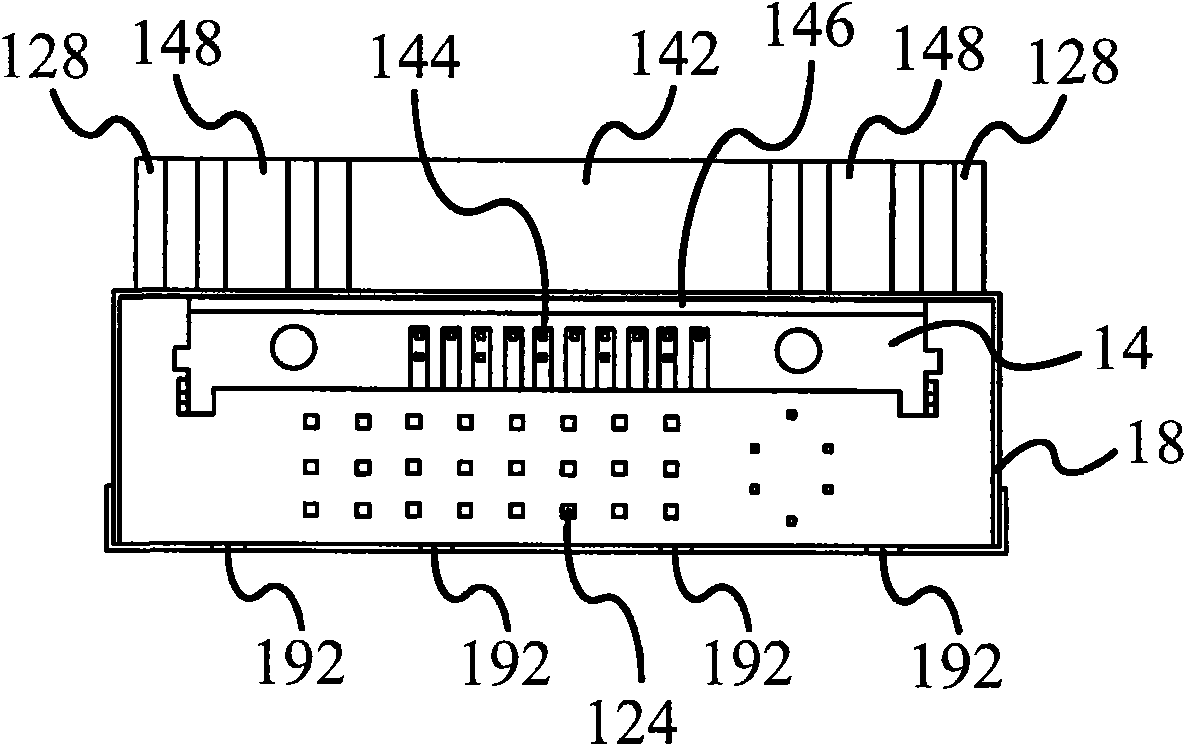

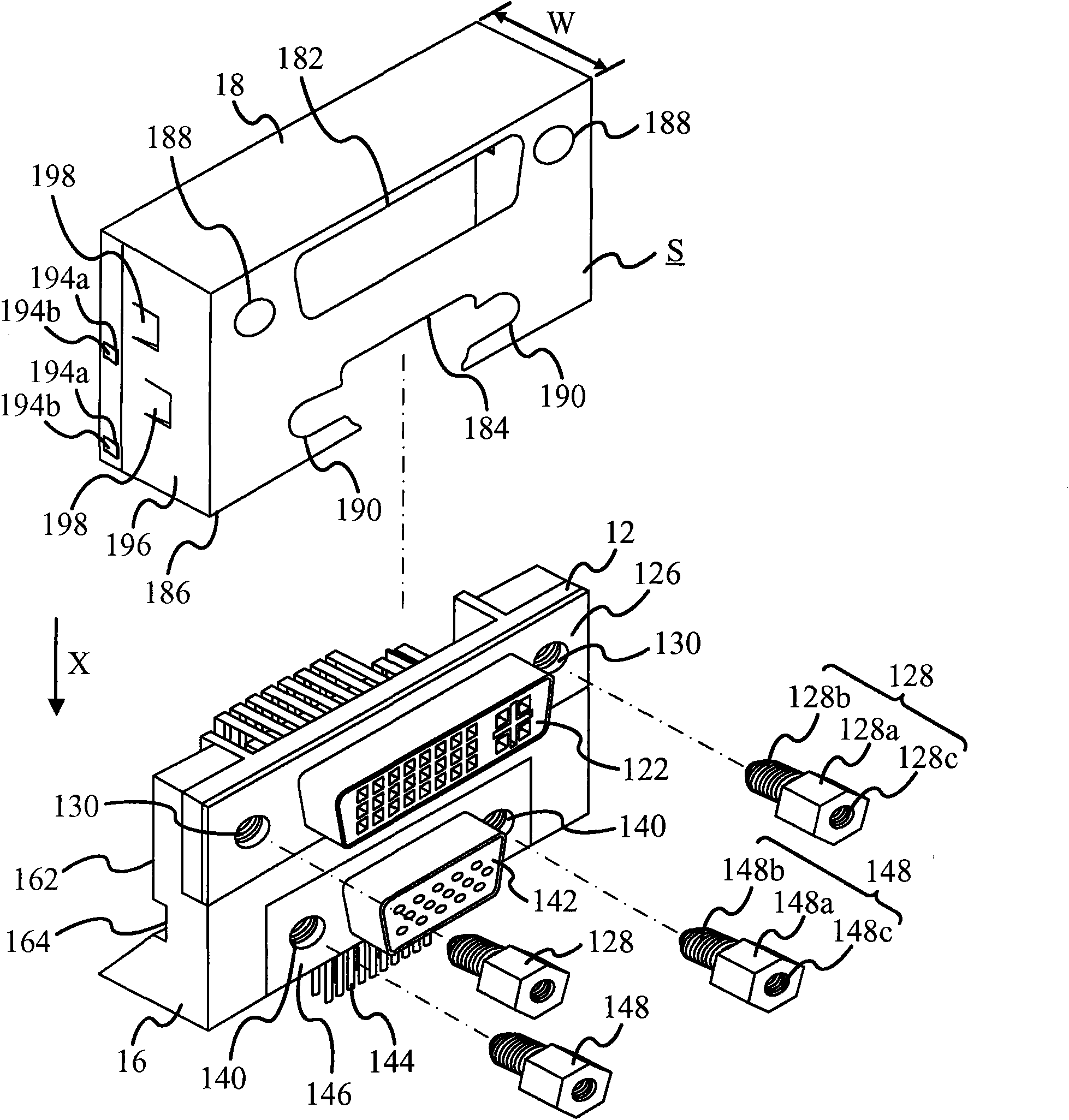

[0015] see figure 1 , figure 2 and image 3 . figure 1 Shown is a perspective view of a stacked electrical connector 1 according to a preferred embodiment of the present invention, figure 2 Shown is a bottom view of the stacked electrical connector 1, image 3 Shown is a partial exploded view of the stacked electrical connector 1 . The stacked electrical connector 1 includes a first connector 12 , a second connector 14 , a frame 16 and a conductive shell 18 . The first connector 12 and the second connector 14 are connected by the frame 16 , and the conductive shell 18 covers the first connector 12 , the second connector 14 and the frame 16 at the same time.

[0016] Wherein, the first connector 12 includes a first signal connection portion 122 and a first group of soldering legs 124 (mark one of them), and the first group of soldering legs 124 extends along the direction X. The second connector 14 includes a second signal connector 142 and a second set of soldering pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com