Permanent magnet synchronous motor rotor integration stamped sheet used for oil-field oil pumper

A technology of permanent magnet synchronous motor and pumping unit, which is applied in the directions of magnetic circuit rotating parts, magnetic circuit shape/style/structure, mining fluid, etc., and can solve the problem of incomplete radial distribution of magnetic poles and increased randomness of magnetic pole distribution , The squirrel cage cannot be formed at one time, etc., to achieve the effect of eliminating the imbalance of the rotor, stable size, and smooth operation of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

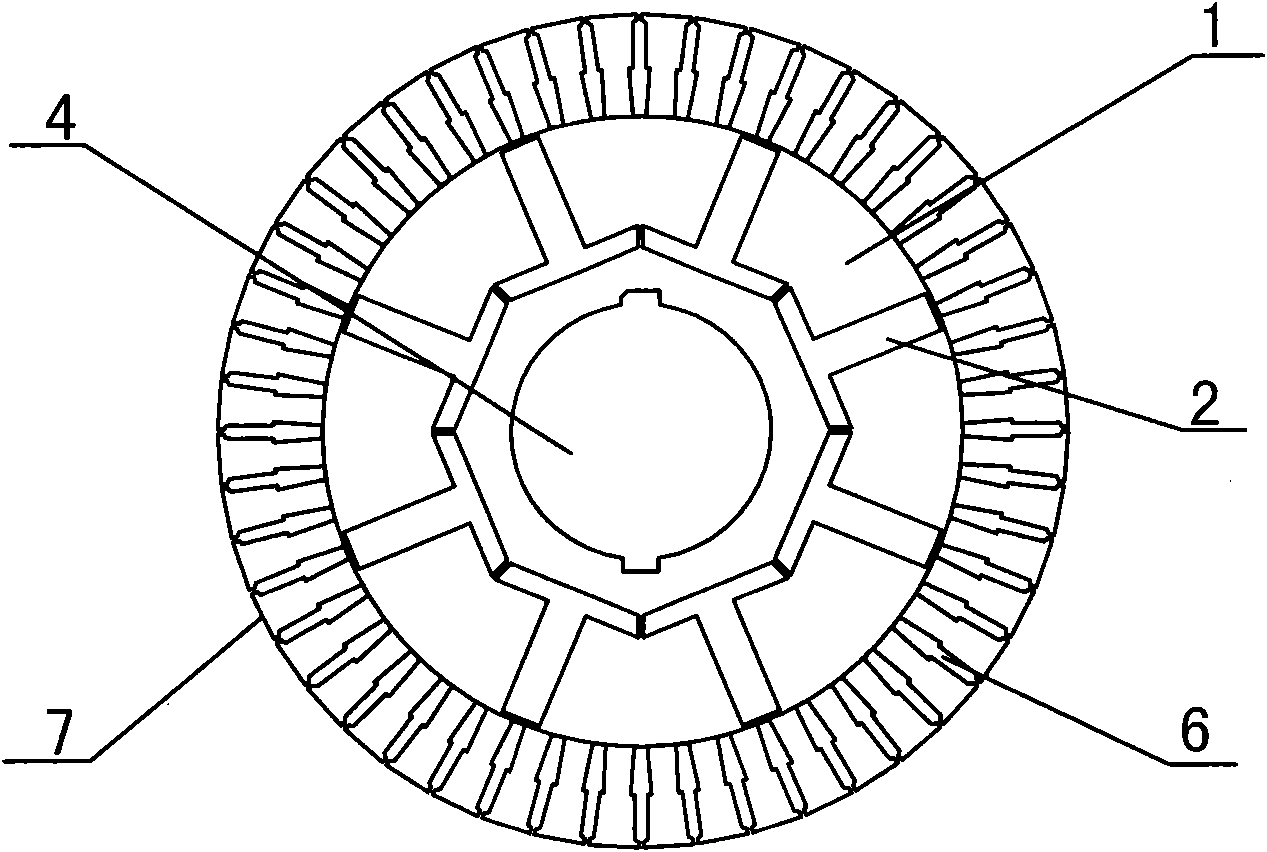

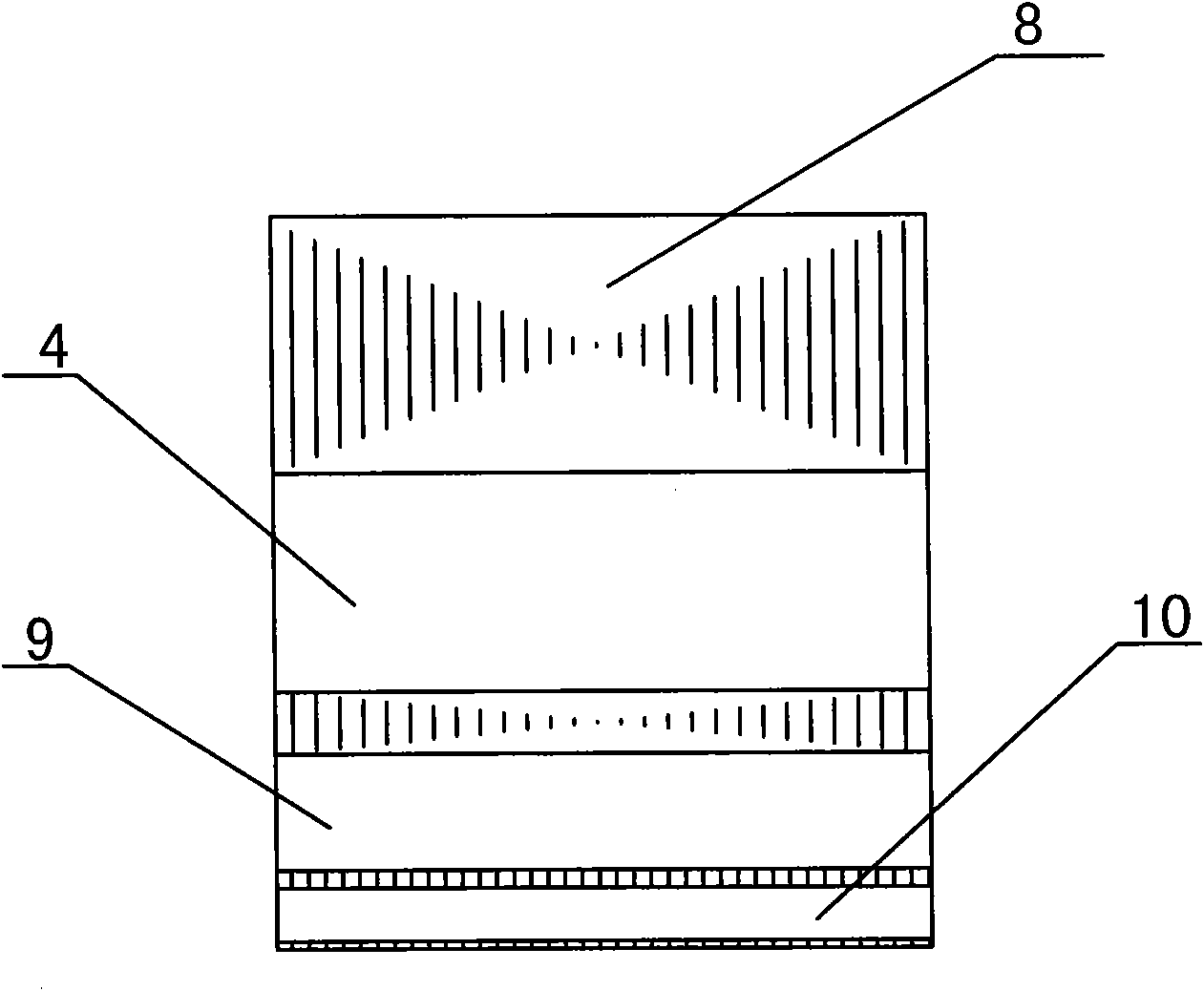

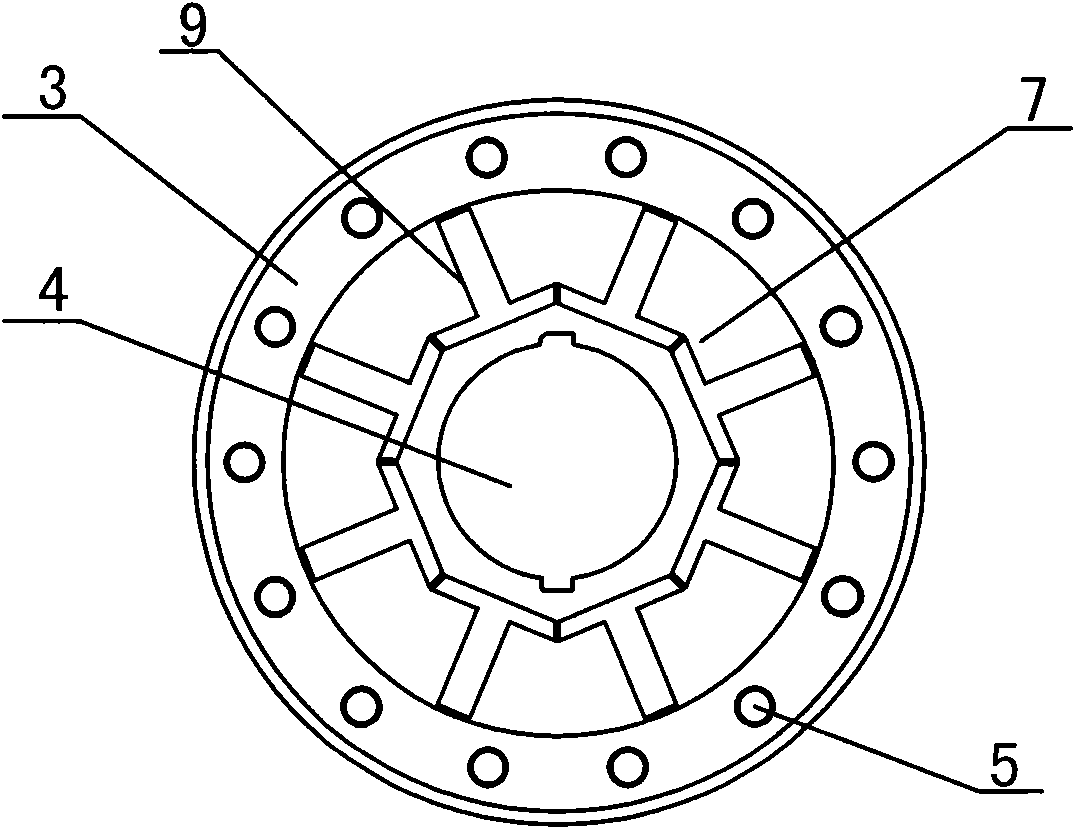

[0017] As shown in Fig. 14, the permanent magnet synchronous motor rotor integrated rotor body 7 for oil pumping units according to the present invention includes a magnetic pole piece 1 and a magnetic steel hole 2, and the magnetic pole piece 1 is along the circumference of the motor shaft hole 4. It is arranged as an integral structure and forms the rotor stamping body 7, a magnetic steel hole 2 is provided between every two adjacent magnetic pole pieces 1, and a ring of squirrel cage guide bar holes 6 is provided on the outer ring of the magnetic pole piece 1. A plurality of rotor stamping bodies 7 are laminated to form a rotor body 8; the rotor body is composed of magnetic steel holes 2 to form magnetic steel slots 9 with open ends; the rotor body is composed of guide bar holes to form guide bar slots 10; The rotor body 8 utilizes a mold to inject aluminum into the guide bar groove, and while the guide bar 11 is formed in the guide bar groove 10, the end ring 3 and the bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com