Electrical connection for semiconductor structures, method for the production thereof, and use of such a connection in a luminous element

A technology of electrical connection structure and conductor structure, applied in the direction of semiconductor devices, semiconductor devices of light-emitting elements, electrical components, etc., can solve problems such as difficulties, achieve good heat dissipation and ensure uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

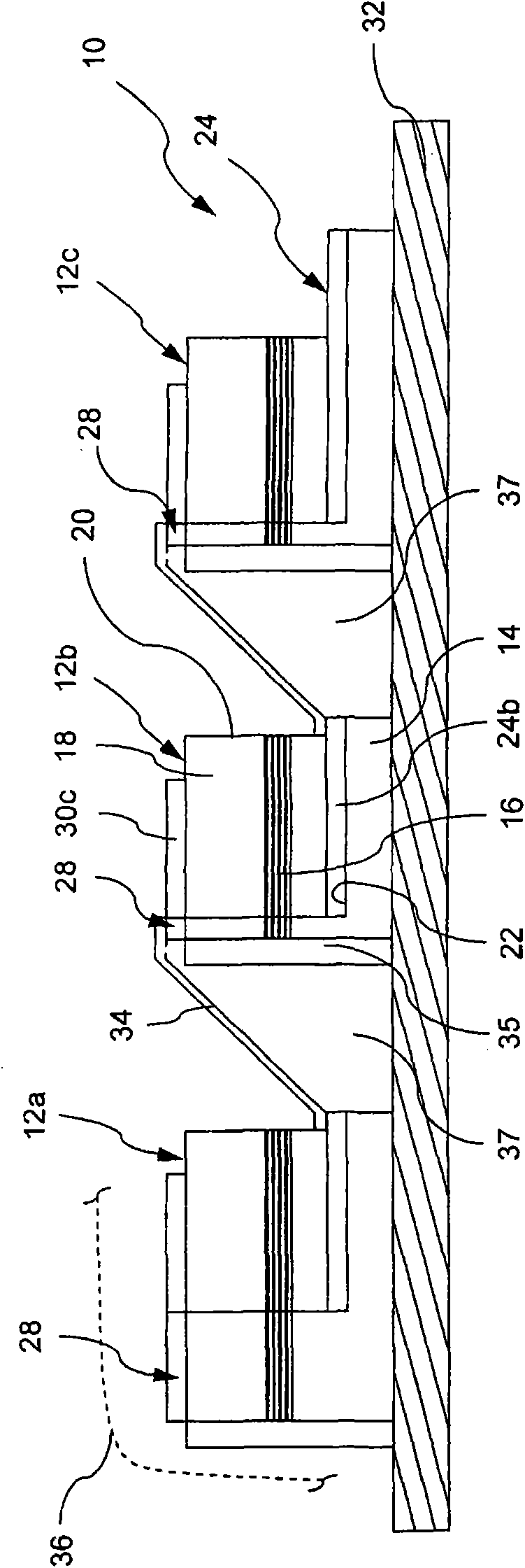

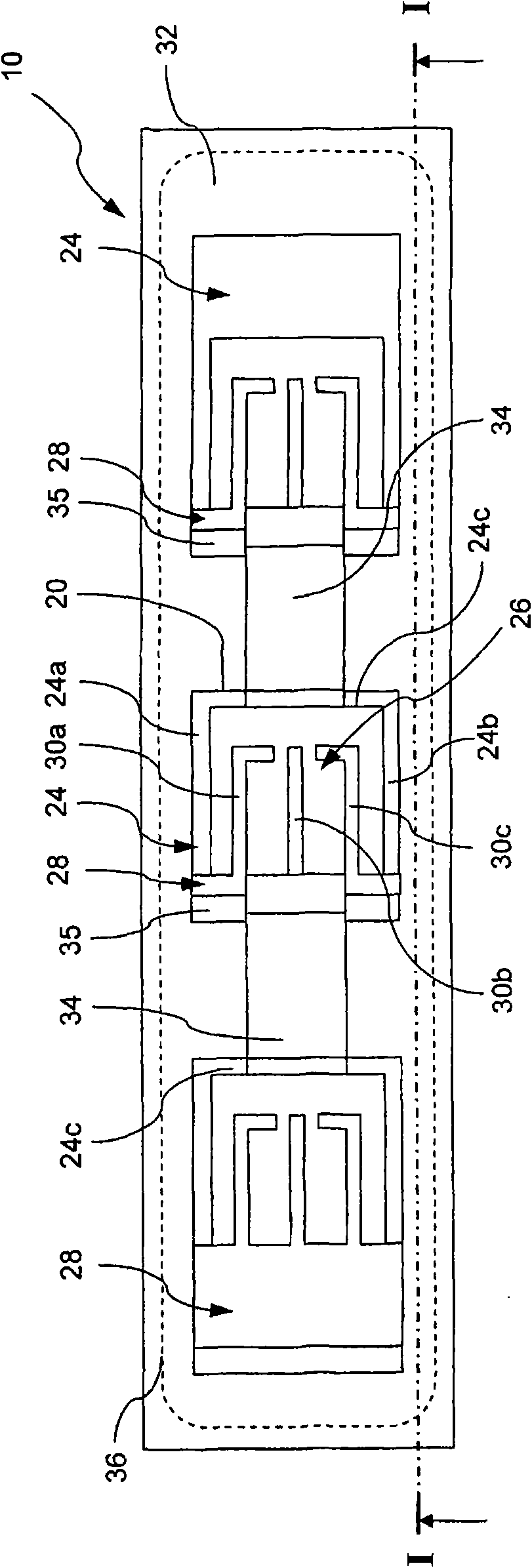

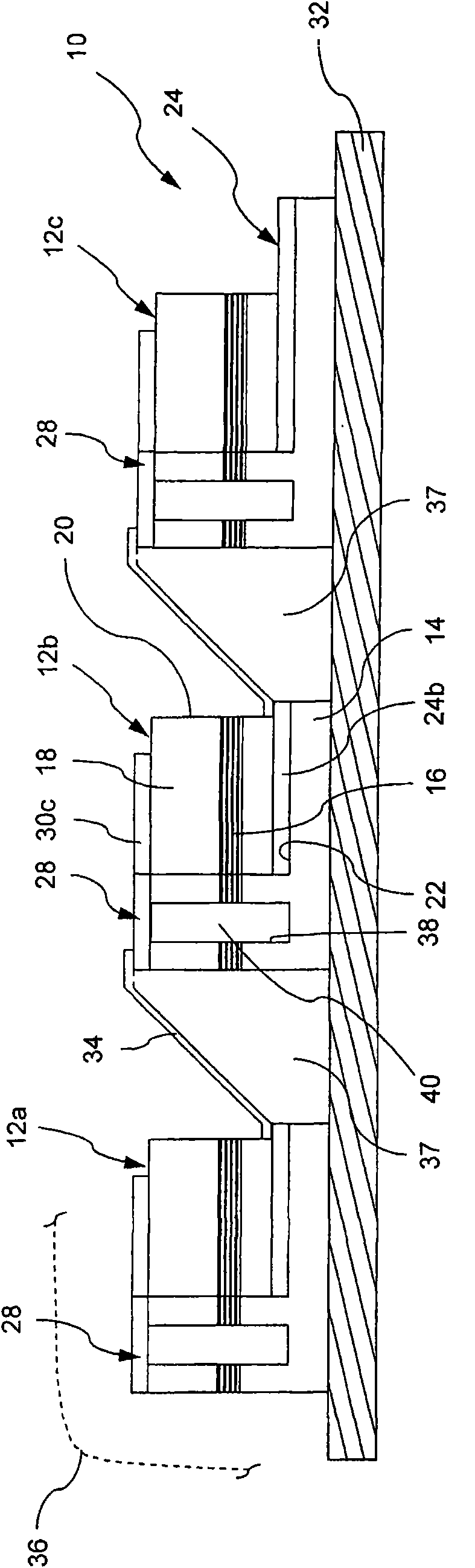

[0033] exist figure 1 and figure 2 In the figure, a light-emitting unit is designated as a whole by the reference number 10, which comprises three semiconductor structures 12a, 12b, 12c. Each semiconductor structure is constructed of three layers, which are only described in the following figure 1 The semiconductor structure 12b arranged in the middle is used as an example for illustration.

[0034] exist figure 1 The lower layer 14 is an n-type layer and is made of, for example, n-GaN or n-InGaN.

[0035] The middle layer 16 is an MQW layer, and MQW is the abbreviation of "Multiplc Quantum Well (Multiple Quantum Well)". MQW material has a superlattice The superlattice has an electronic band structure that varies according to the superlattice structure and correspondingly emits light at different wavelengths. The spectrum of the radiation emitted by the pn-type semiconductor structure 12 can be influenced by the selection of the MQW layer.

[0036] The upper layer 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com