Rotating chain plate bottle-standing type straightener

A bottle unscrambler and chain plate technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems affecting the operation efficiency of the unscrambler line, safety and insecurity, and high labor intensity, so as to improve labor productivity and economic benefits. The effect of saving energy consumption and manpower, and fast working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

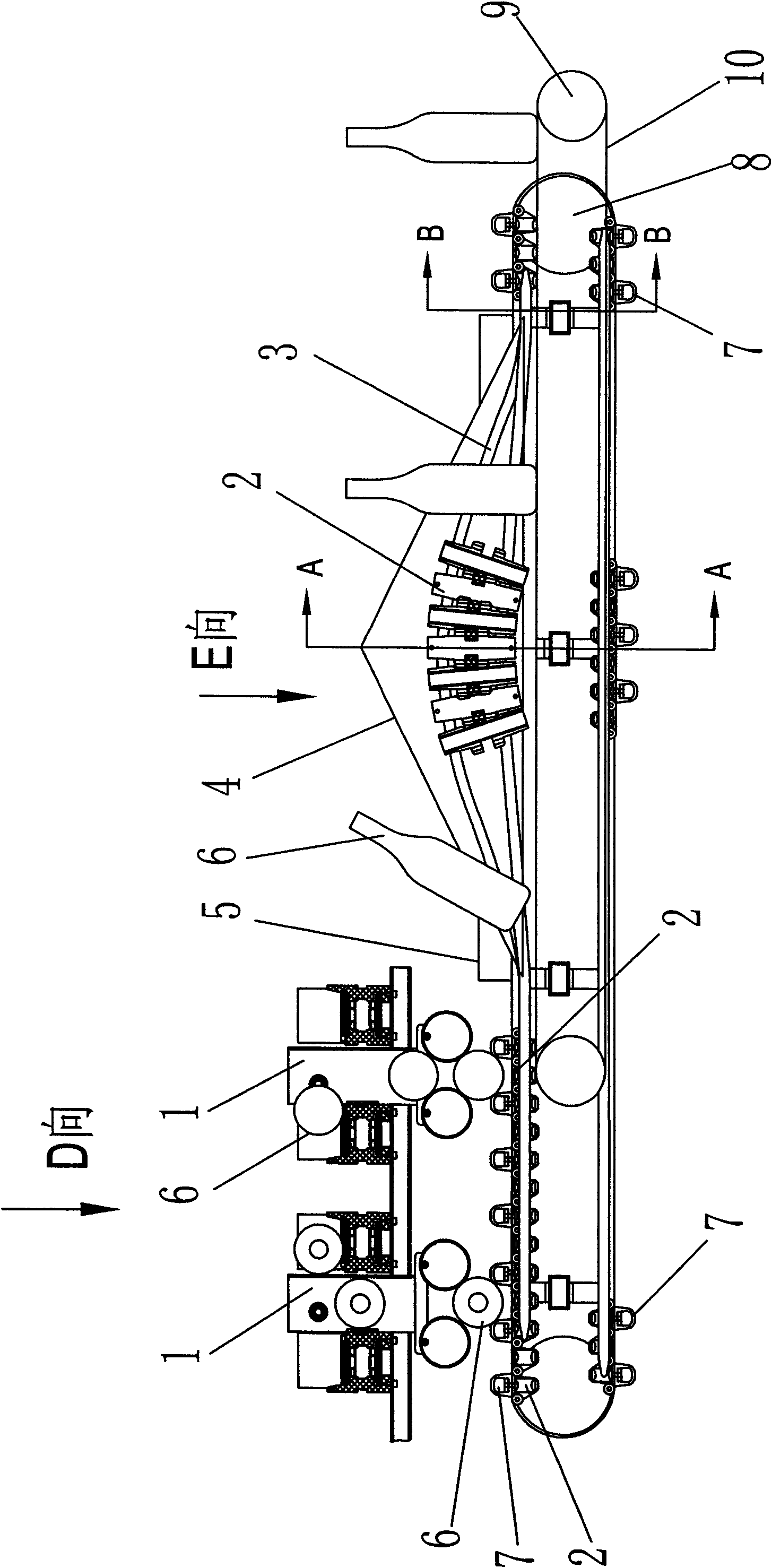

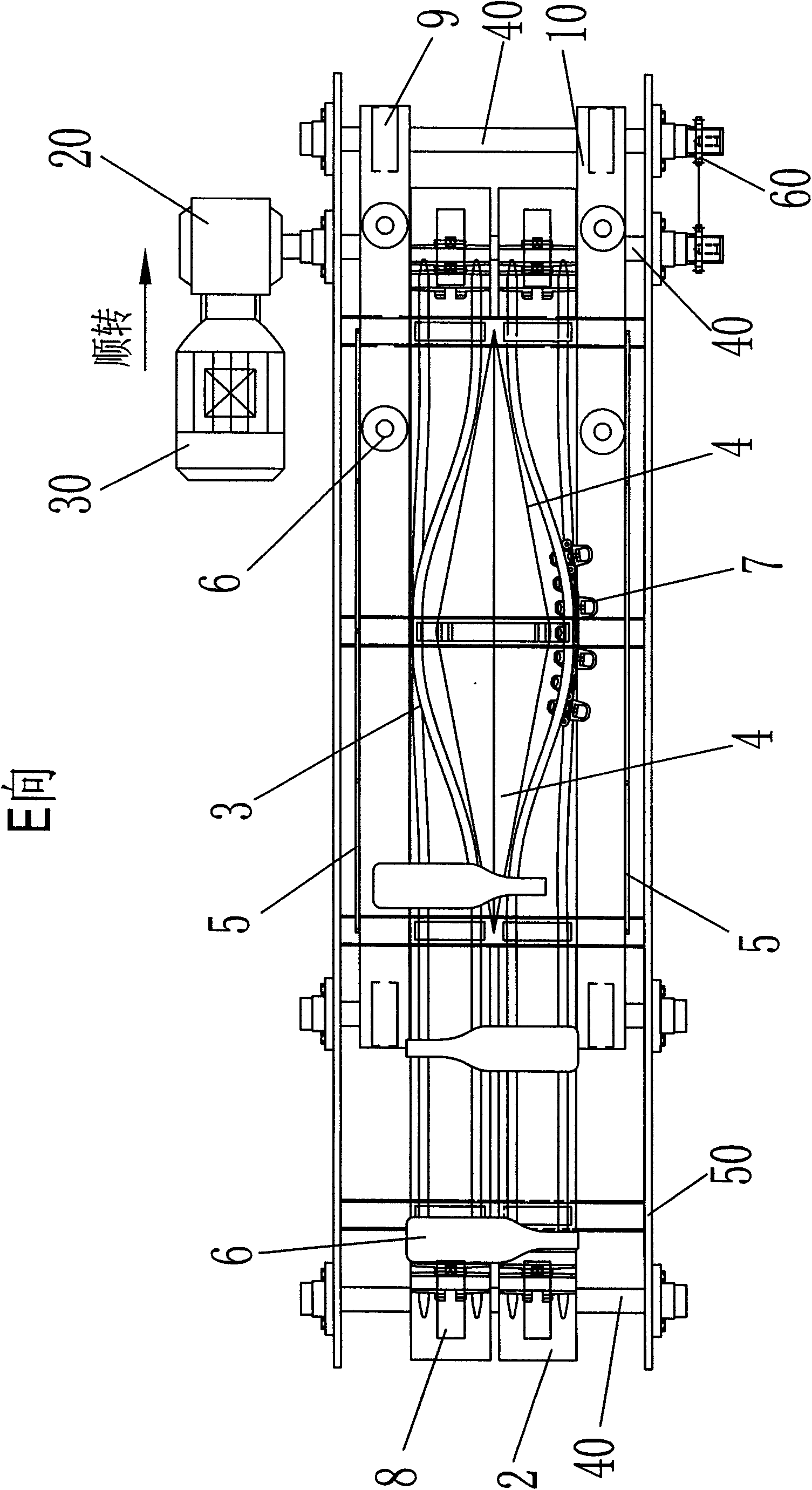

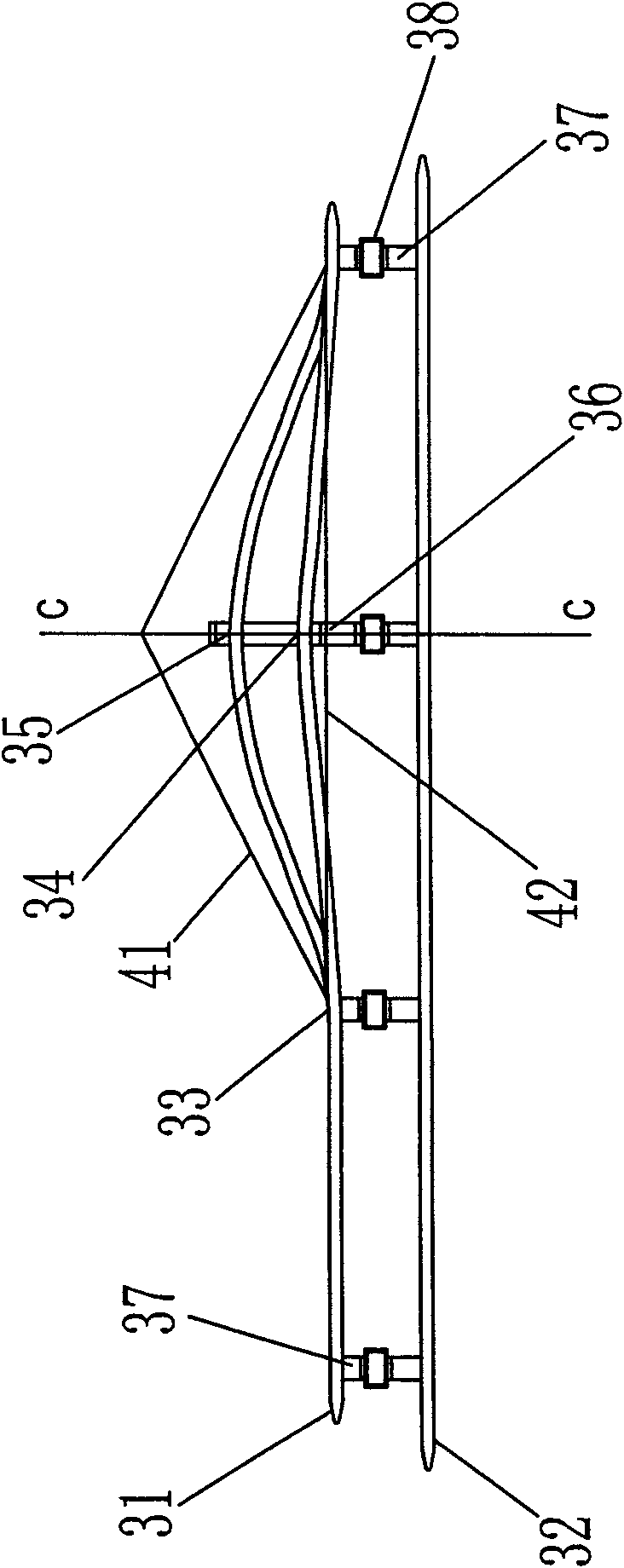

[0015] see figure 1 and figure 2 As shown, the basic structure of the present invention includes a bottle straightening device 1 arranged between the upper conveyor belts, a rotating chain plate 2 arranged in the middle of the two conveyor belts of this layer, and a middle part between the two rotating chain plates. The two sides of the bottle-holding plate 4 are sloped; on each slope of the bottle-holding plate, guide rails 3 that vary in height along the slope are set, and the rotating chain plate 2 that can slide along the guide rails is laid on the guide rails 3 The transmission chain formed in series, the main transmission wheel 8 of the transmission chain is driven by the moving motor 30 through the speed changer 20 to run the transmission chain. Parallel bottle delivery conveyor belt 10 is established on the outside of said rotating chain plate 2 drive chains, and this conveyor belt 10 is slightly lower than the rotating link plate drive chain, and the outside of bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com