Method for monitoring quality of yarn at workplace of textile machine

A technology of textile machinery and yarn, which is applied in the field of monitoring yarn quality at the workstation of textile machinery, which can solve problems that hinder the productivity of textile machinery and achieve the effect of eliminating yarn defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method according to the invention will be explained below in connection with an air spinning machine, but it can of course also be applied to other textile machines in which checking and / or monitoring devices are provided for controlling the quality of the longitudinally moving yarn.

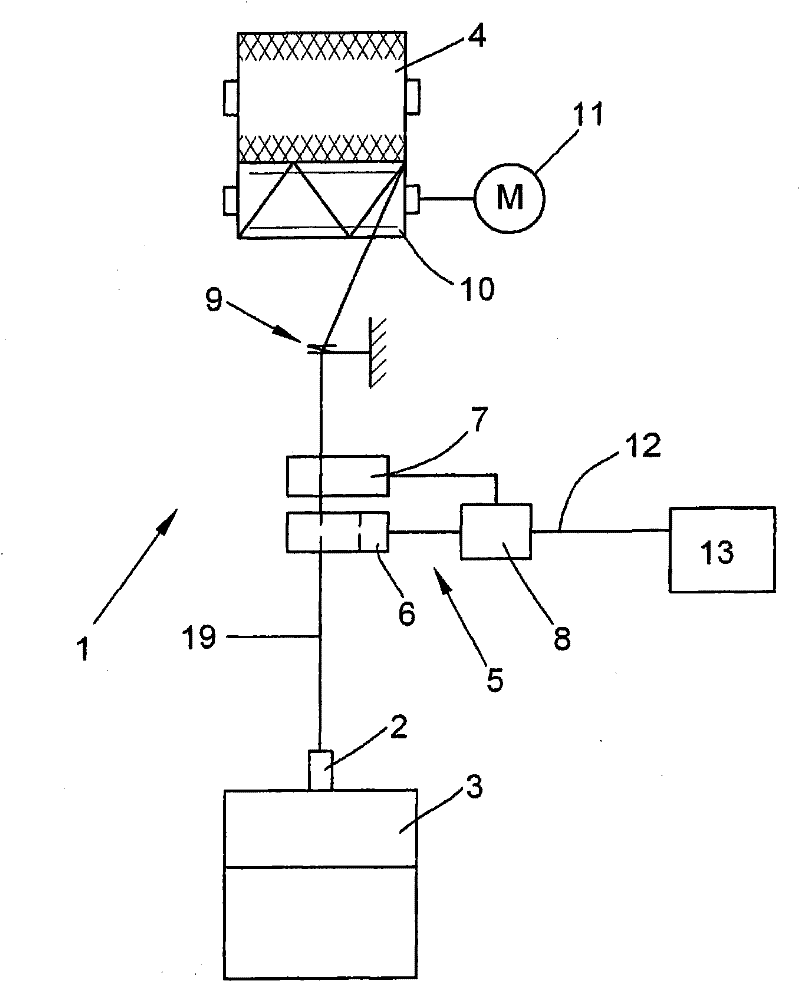

[0018] exist figure 1 In the spinning station 1 of the shown open-end rotor spinning machine, the yarn 19 is wound from the spinning box 3 to the cross-winding bobbin 4 via the yarn unwinding tube 2 . The yarn 19 passes between the unwinding tube 2 and the cross-winding bobbin 4 through a yarn clearer 5 for monitoring quality and then through a yarn guide eye 9, wherein the yarn clearer 5 comprises a measuring head 6, a shearing device 7 and Processor 8. The drive drum 10 drives the cross-wound package 4 by means of a friction fit during the winding process. The motor 11 causes the drive drum 10 to perform the rotational movement required for the winding process.

[0019] The yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com