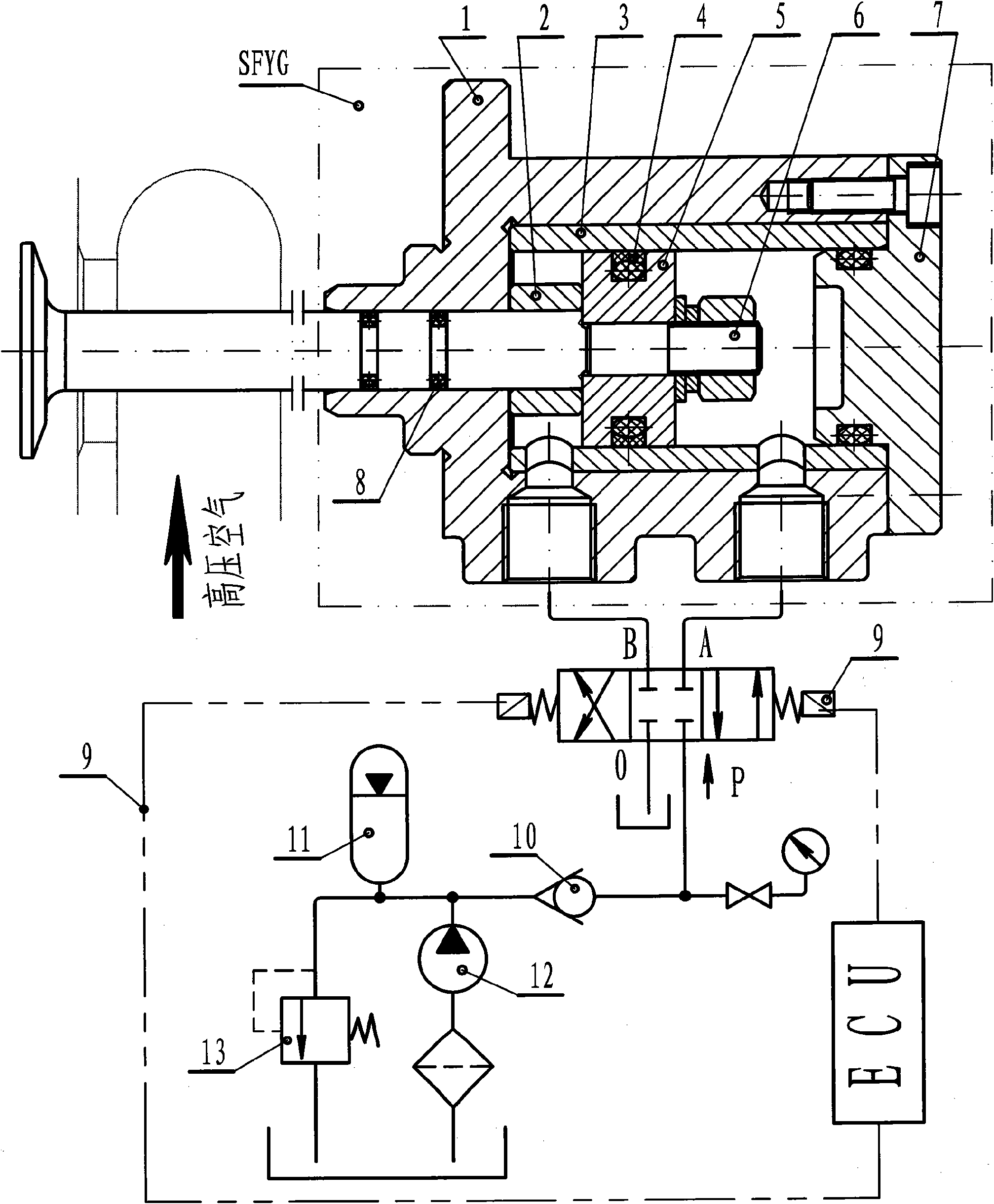

Hydraulic servo high-pressure valve

A hydraulic servo, high-pressure air technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problem of no high-pressure air on the intake side or high-pressure combustible gas mixture, etc., to achieve simple structure, compact structure, and avoid waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Each cylinder of the engine needs to be equipped with two hydraulic servo high-pressure valves and two three-position four-way solenoid valves (9). exhaust.

[0017] 1. Hydraulic servo high pressure valve for intake operation

[0018] When the exhaust stroke of the engine ends and turns to the power stroke, high-pressure air or high-pressure combustible mixture needs to be injected into the engine combustion chamber, and the ECU controls the three-position four-way solenoid valve (9) to inject pressure into the upper chamber of the hydraulic servo cylinder through the oil supply pipeline. oil, and introduce the pressure oil trapped in the lower cavity of the hydraulic servo cylinder into the oil tank; the valve (6) is quickly opened under the pressure of high-pressure air (or high-pressure combustible mixture) and pressure oil on the upper end of the piston (5), and burns to the engine The high-pressure air or high-pressure combustible mixture is injected into the comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com