Oil collecting structure of range hood

A range hood and oil collection technology, which is applied in the range hood field, can solve the problems of cumbersome assembly, easy blockage of oil stains on hoses, and inability to collect and dispose of oil stains, etc., achieving a simple, reasonable and effective design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

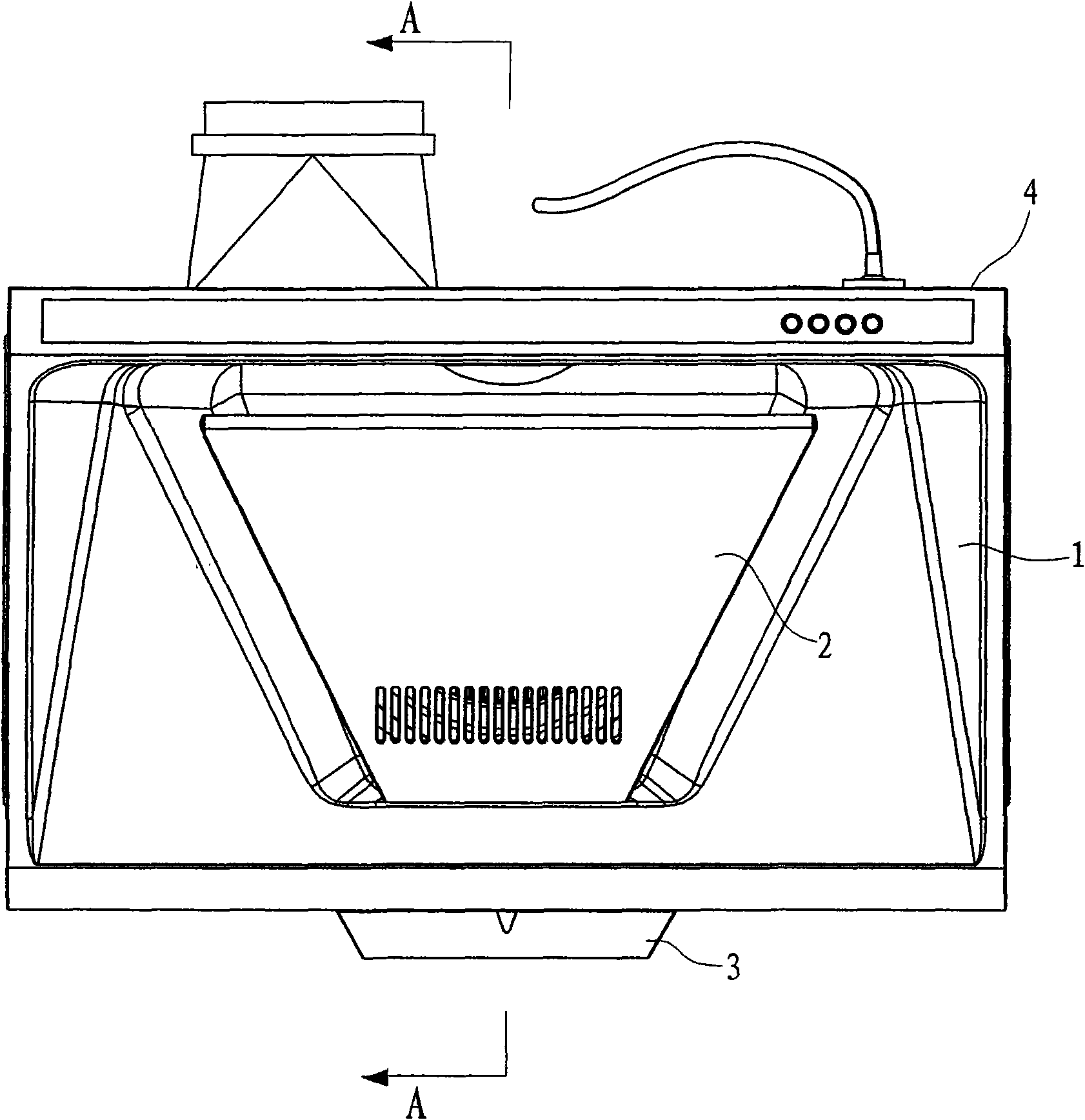

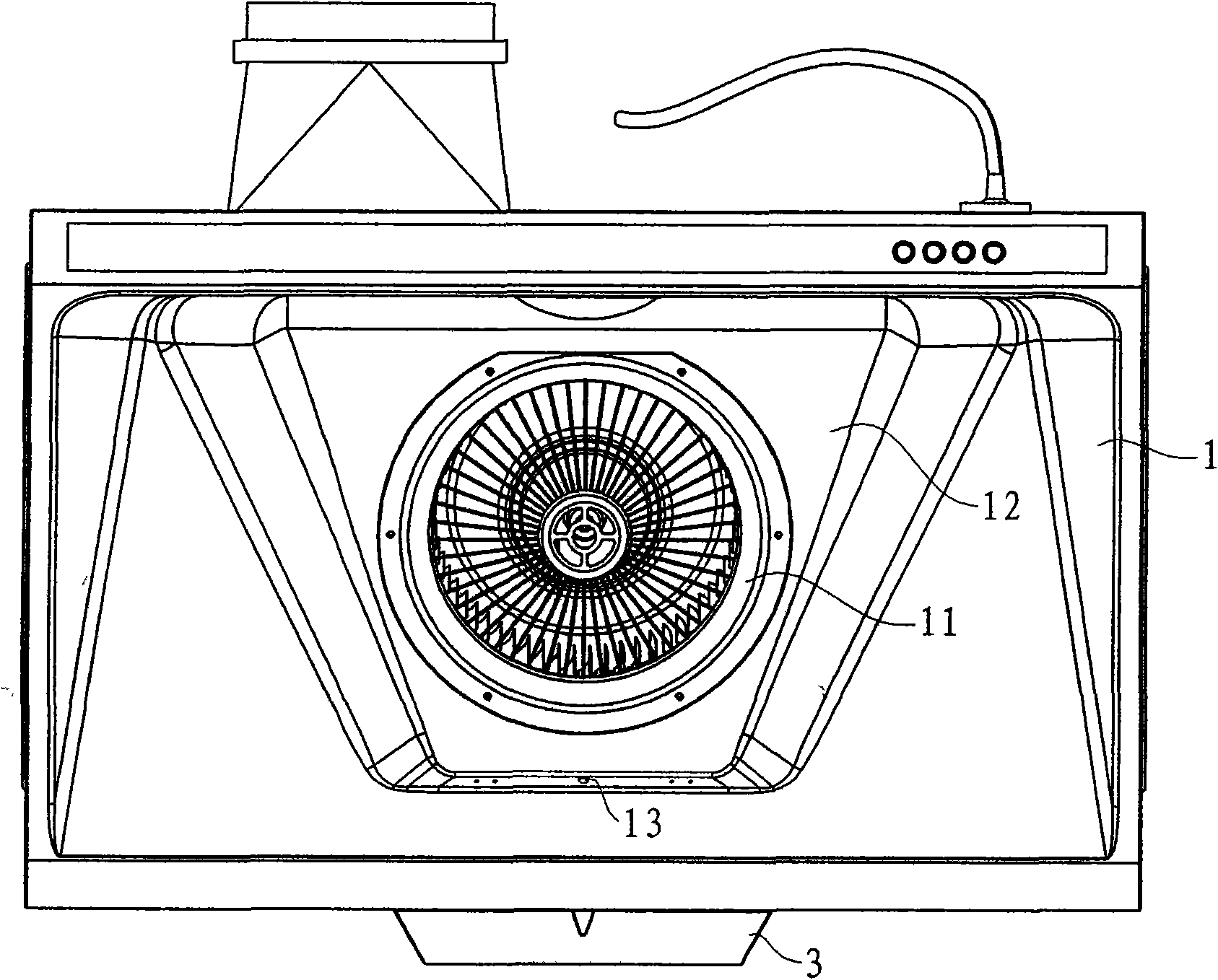

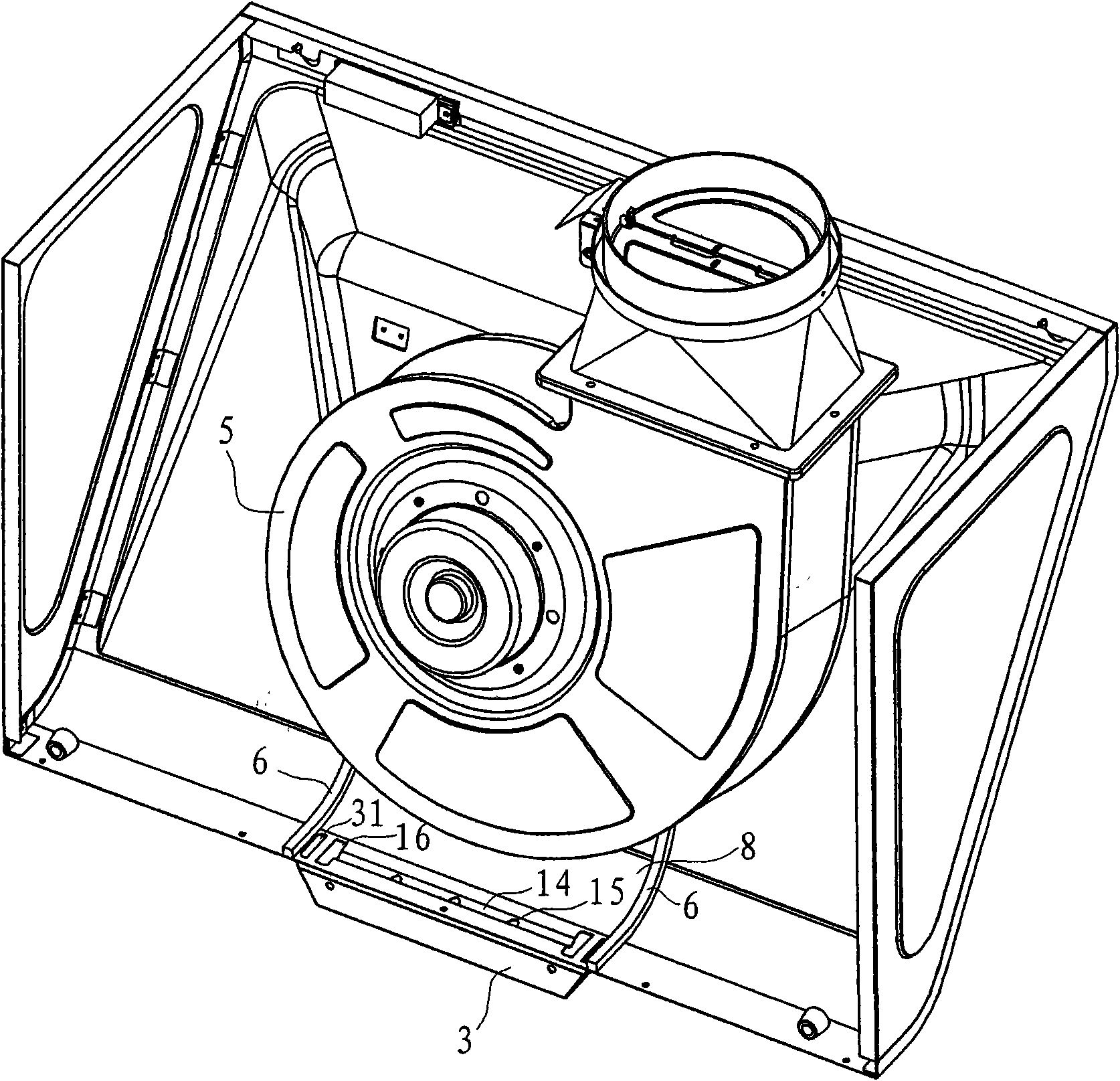

[0022] Such as figure 1 , figure 2 and image 3 As shown, the oil collecting range hood in this embodiment includes a fume collecting hood 1, an oil collecting cup 3 located at the bottom of the fume collecting hood 1, a rectifying plate 2 and a volute fan 5, and the rectifying plate 2 is located on the front end of the fume collecting hood 1. It is set facing the air inlet 11 and maintains a predetermined distance from the fume collecting hood 1 for the oil fume to pass through. The volute fan 5 is arranged at the air inlet 11 of the fume collecting hood.

[0023] Such as figure 2 As shown, a groove 12 is formed in the middle part of the front end face of the smoke collecting hood 1, and the bottom of the groove 12 is provided with an oil drip hole 13 (see also the attached Figure 5 ), and the air inlet 11 is located at the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com