Cast iron type water-cooling furnace cover of refining furnace

A technology for a water-cooled furnace cover and a refining furnace, which is applied in the field of refining furnaces in the metallurgical industry, can solve the problems of serious slag sticking, prone to water leakage, affecting the refining process, etc., and achieves the effect of long service life and less slag sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through a preferred embodiment in conjunction with the accompanying drawings.

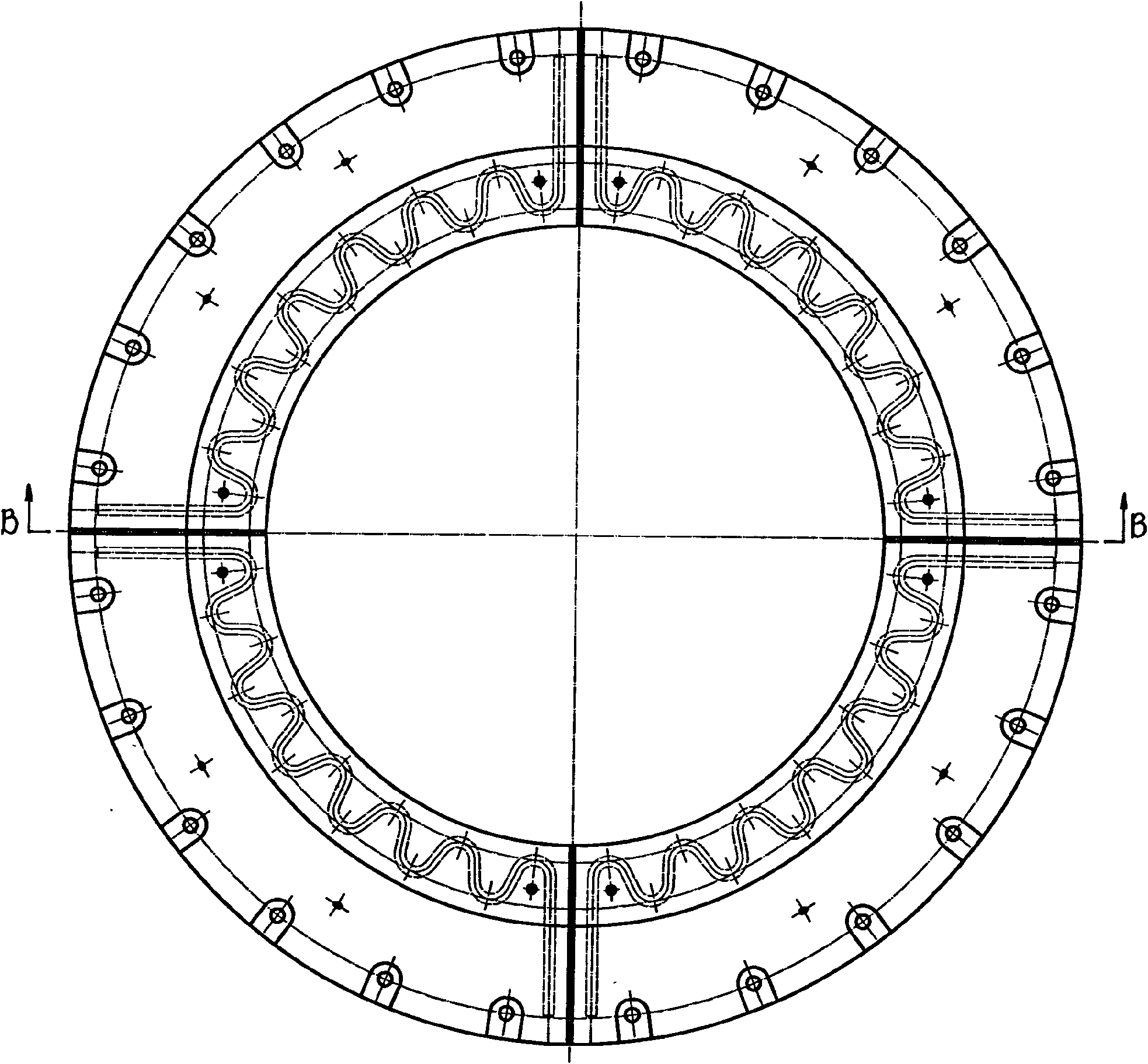

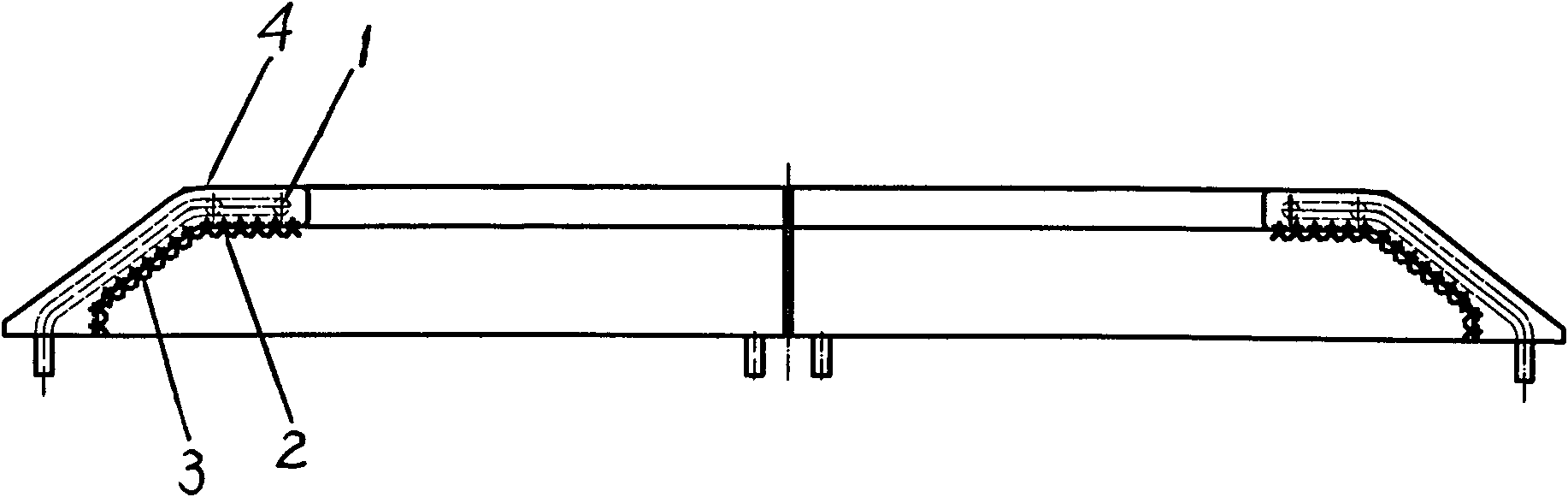

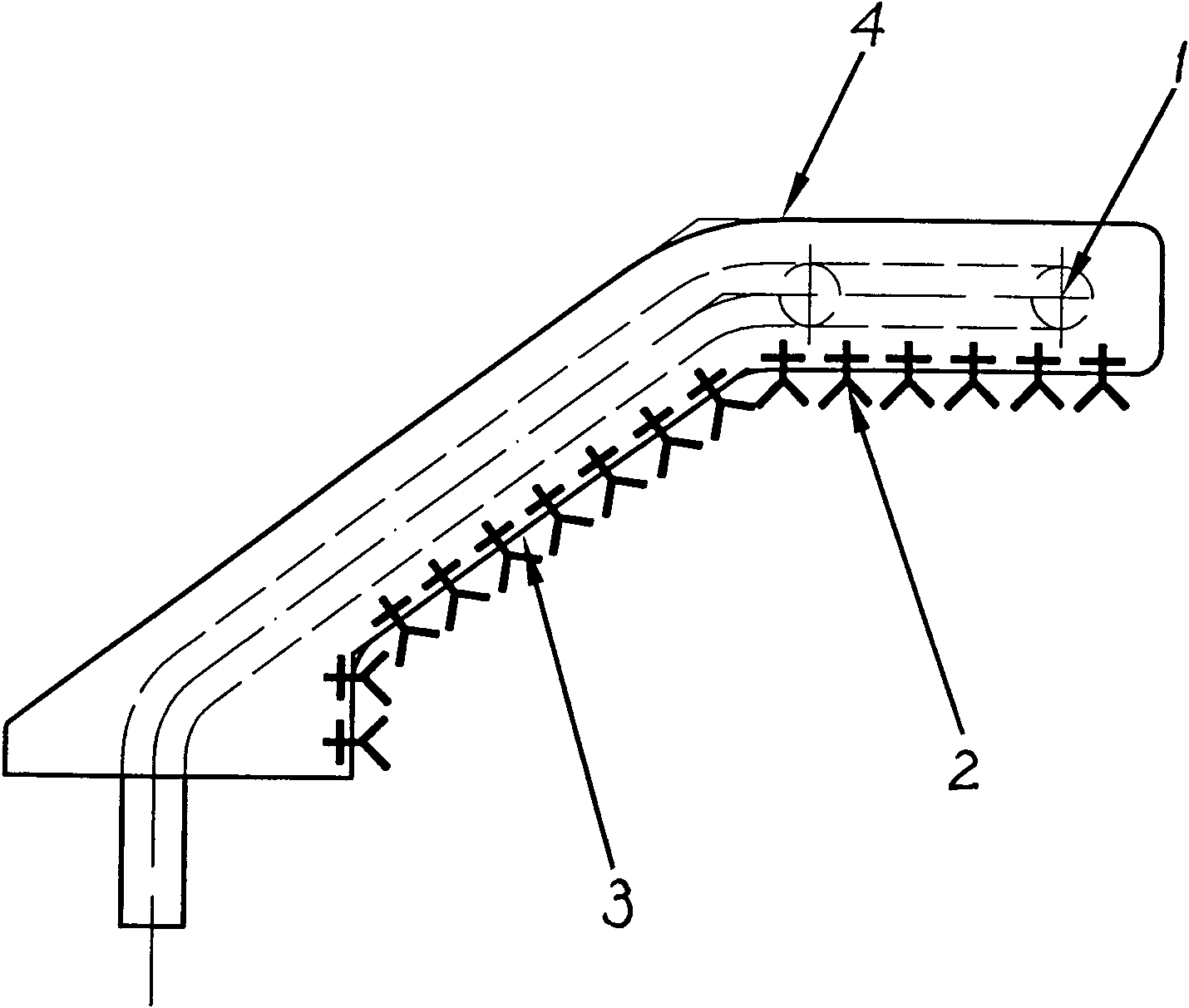

[0023] see Figure 1 to Figure 3 , The present invention is a cast iron type water-cooled furnace cover of a refining furnace, the furnace cover uses castings instead of welding parts. The furnace cover can be an integral structure or a split structure. When the furnace cover with split structure is used, all parts of the furnace cover should be assembled together.

[0024] More than one water-cooled pipe 1 is embedded inside the furnace cover, and the water-cooled pipe 1 is a steel water-cooled pipe. The water-cooling tubes 1 are arranged in a ring shape, and the ring-shaped water-cooling tubes are arranged in a curved shape. Each water cooling tube 1 is provided with a water inlet and a water outlet. When it is a furnace cover with a split structure, each part of the furnace cover is provided with a water inlet and a water outlet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com