Aplanatism pentahedral visual detecting process

A technology of visual appearance and light source, applied in the field of optical devices and visual inspection systems, can solve the problems of inability to eliminate optical path difference deformation and complex system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

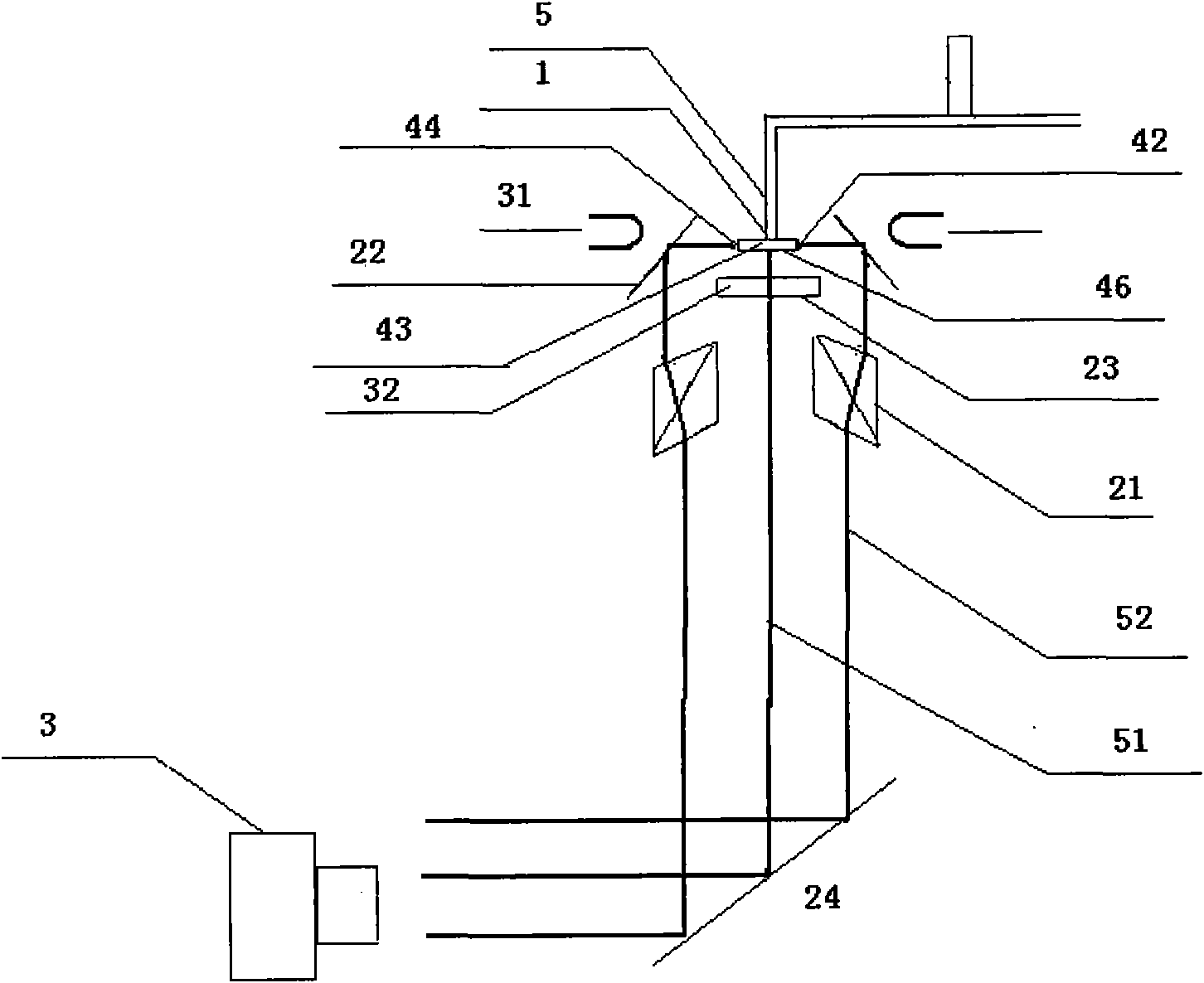

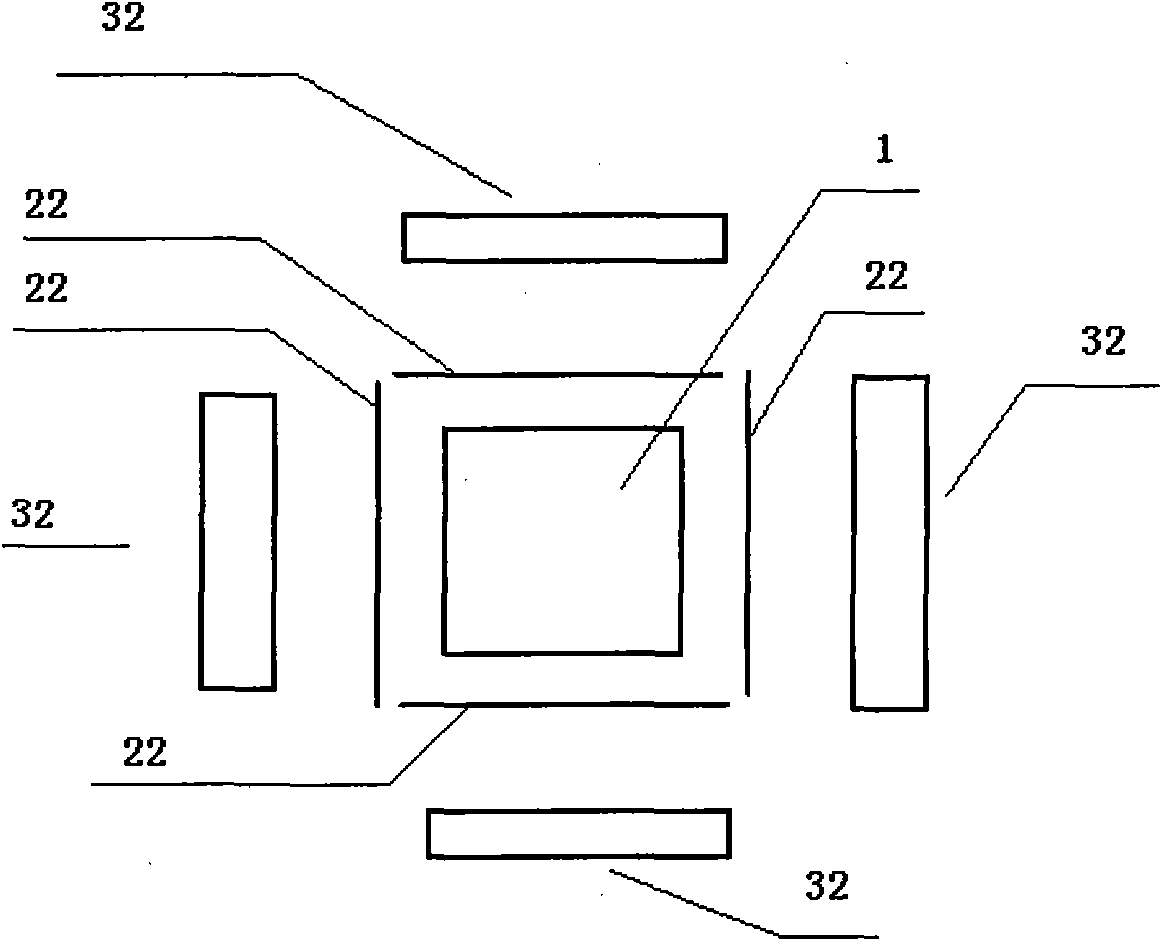

[0016] figure 1 The example shown is that the electronic component 1 is sent by the suction nozzle to the inspection station through the conveying device. The frontal image 46 passes through the optical path 51 generated by the low-angle shadowless light source 31 , passes through the polarizer 23 , and then enters the camera 1 after being reflected by the side-view mirror 24 . At least one lateral side image 42, 43, 44, 45 generates an optical path 52 after the light source is provided by the side spotlight 32, is reflected by the coated glass 22, enters the polarization beam splitter prism 21, and enters the camera 3 after being reflected by the side-view mirror 24 .

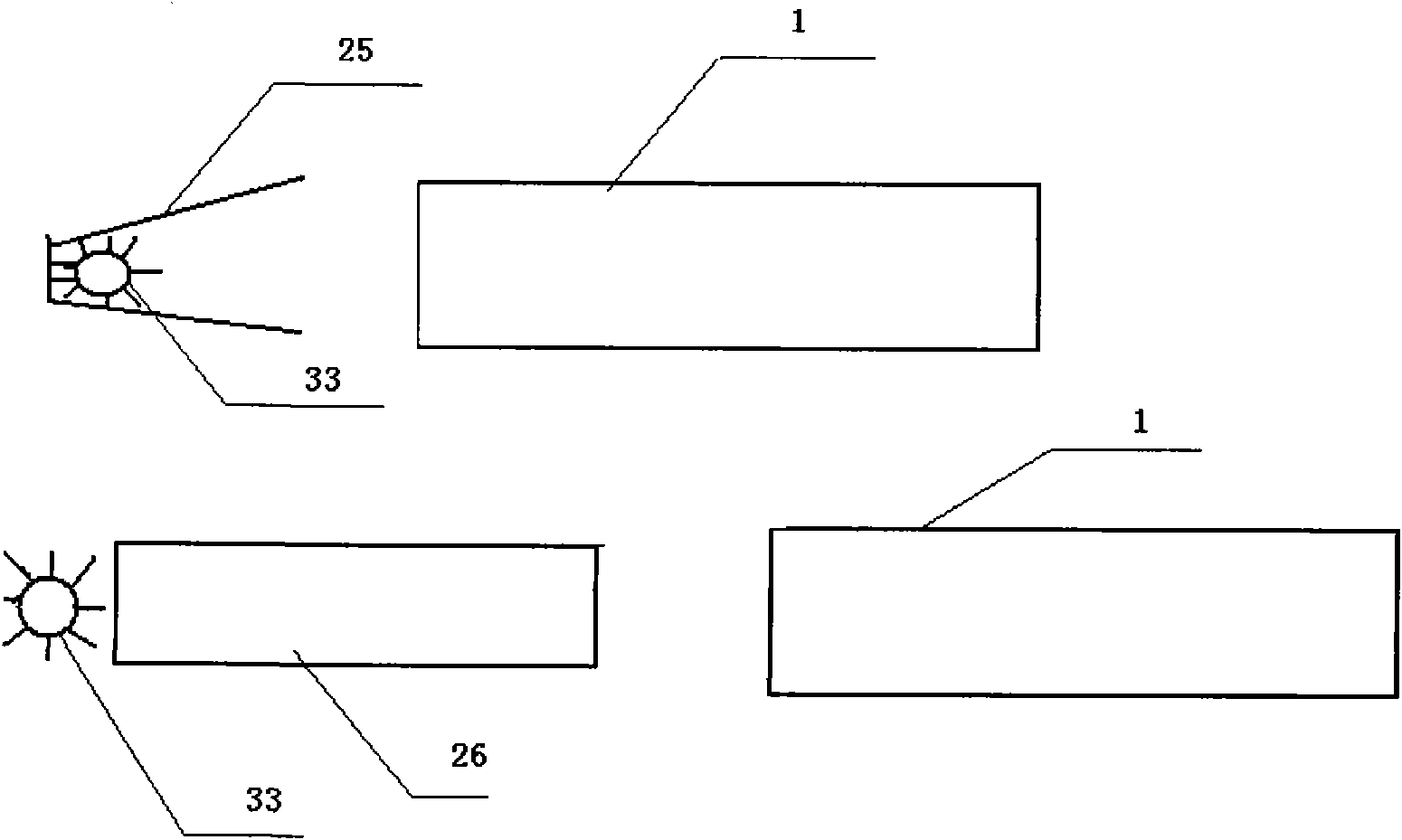

[0017] Figure 5 In the example shown, the electronic component 1 is put into the workbench 4 by the suction nozzle, and then clamped by the clamp 6 after being put into it. Turning to the bottom of the camera 2, the light source 33 provides a light source, and the top surface image 41 is taken by it. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com