Defect thermal peeling method of carbon fiber reinforced modified bismaleimide laminate

A bismaleimide layer and carbon fiber technology, applied in the field of failure analysis, can solve the problems such as the inability to directly observe the microscopic morphology of the defect area, the damage to the human body by X-rays, and the large one-time investment, achieving a unique soaking method, The effect of the best peeling effect and accurate process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

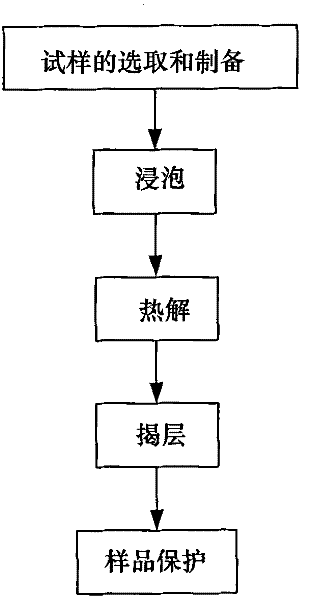

[0044] Apply the method provided by the invention to carry out thermal delamination test, and test procedure is as follows:

[0045] Step 1. Selection and preparation of samples.

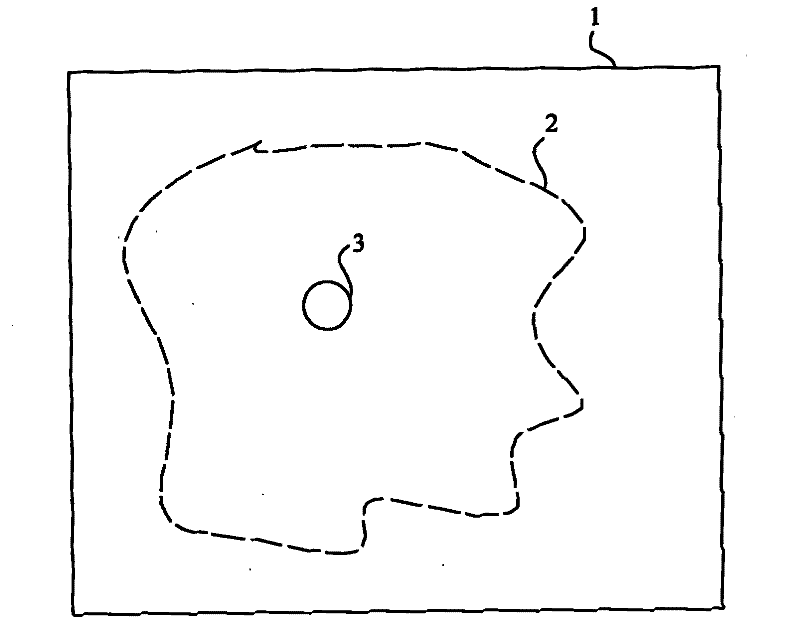

[0046] Firstly, carry out non-destructive testing on the laminate, determine the approximate location of the defect area, and combine the specific conditions of the plate / structural part and the defect, and intercept an appropriate test sample. The area of the sample is 70×80mm 2 .

[0047] Step 2, prepare the labeling solution.

[0048] A gold chloride diethyl ether solution containing 9% gold by weight was prepared. Preparation method: when preparing, put gold chloride crystals into a glass bottle and cover it tightly with a rubber stopper, then use a syringe to inject an appropriate amount of ether solution from the rubber stopper, and then shake the glass bottle to ensure uniform dissolution to obtain the desired mark solution.

[0049] Step three, soaking.

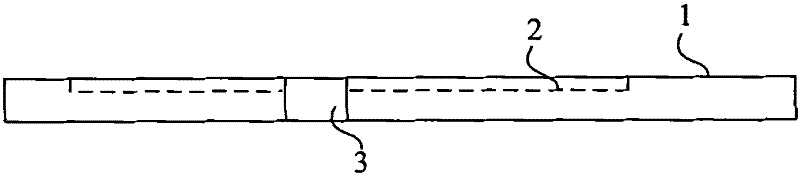

[0050] Soak the sample with 9...

Embodiment 2

[0057] Step 1. Selection and preparation of samples.

[0058] First, carry out non-destructive testing on the laminate, determine the approximate location of the defect area, and combine the specific conditions of the plate / structural part and the defect, and intercept an appropriate test sample. The area of the sample is 40×60mm 2 .

[0059] Step 2, prepare the labeling solution.

[0060] A gold chloride diethyl ether solution containing 11% gold by weight was prepared. Preparation method: when preparing, put gold chloride crystals into a glass bottle and cover it tightly with a rubber stopper, then use a syringe to inject an appropriate amount of ether solution from the rubber stopper, and then shake the glass bottle to ensure uniform dissolution to obtain the desired mark solution.

[0061] Step three, soaking.

[0062] Immerse the sample with 10% gold chloride ether solution, soaking method: fix two open containers to the two sides of the drilled hole on the sample r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com