Optical detection equipment and method

A technology of optical detection and equipment, applied in the direction of testing optical properties, material analysis through optical means, measuring devices, etc., can solve problems such as affecting results, uneven coating, and difficult quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical means of the present invention will be described in detail as follows. It is believed that the purpose, characteristics and characteristics of the present invention should be able to obtain a deep and specific understanding. However, the following examples and illustrations are only provided for reference and illustration, and are not used to describe the present invention. be restricted.

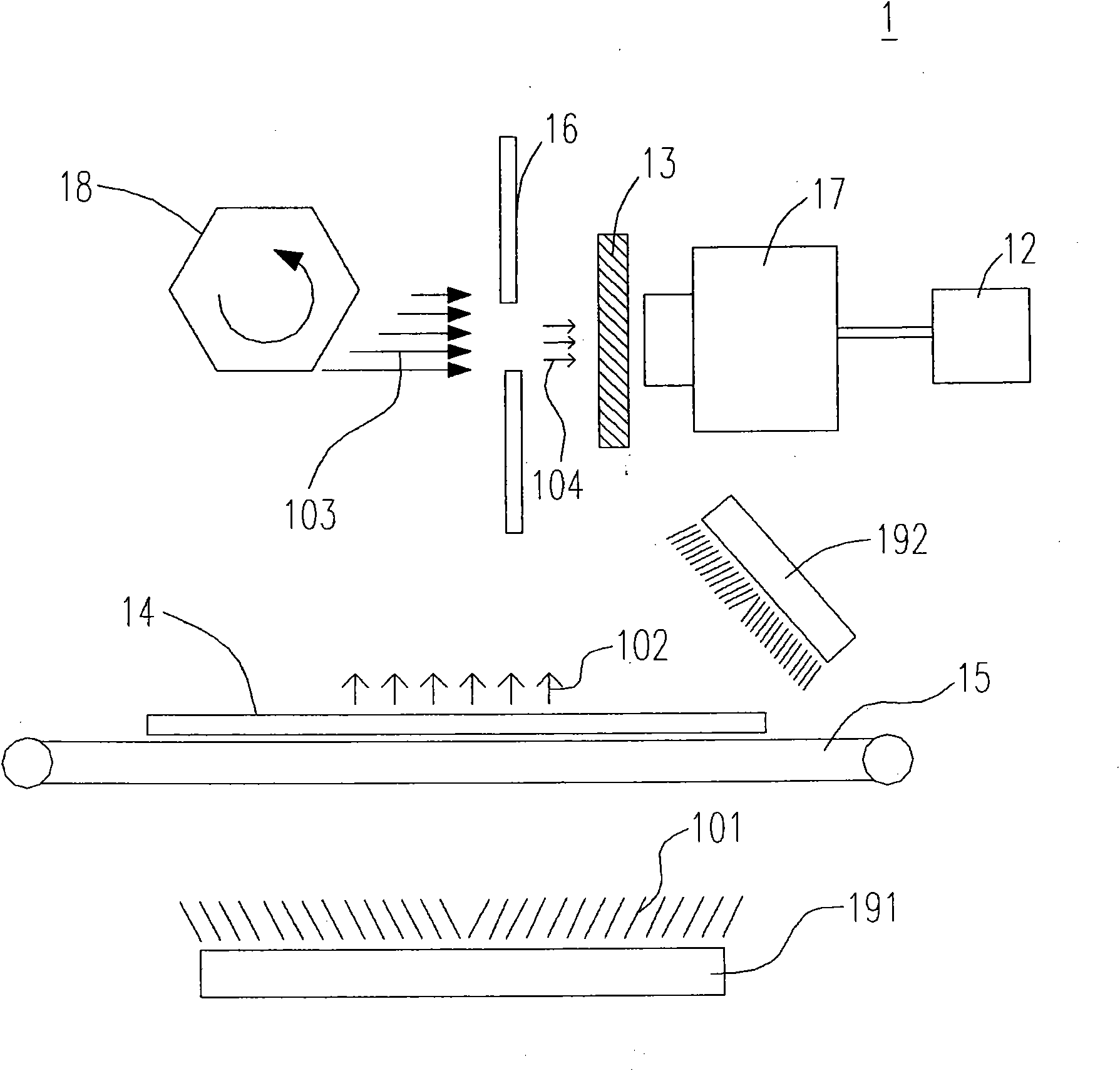

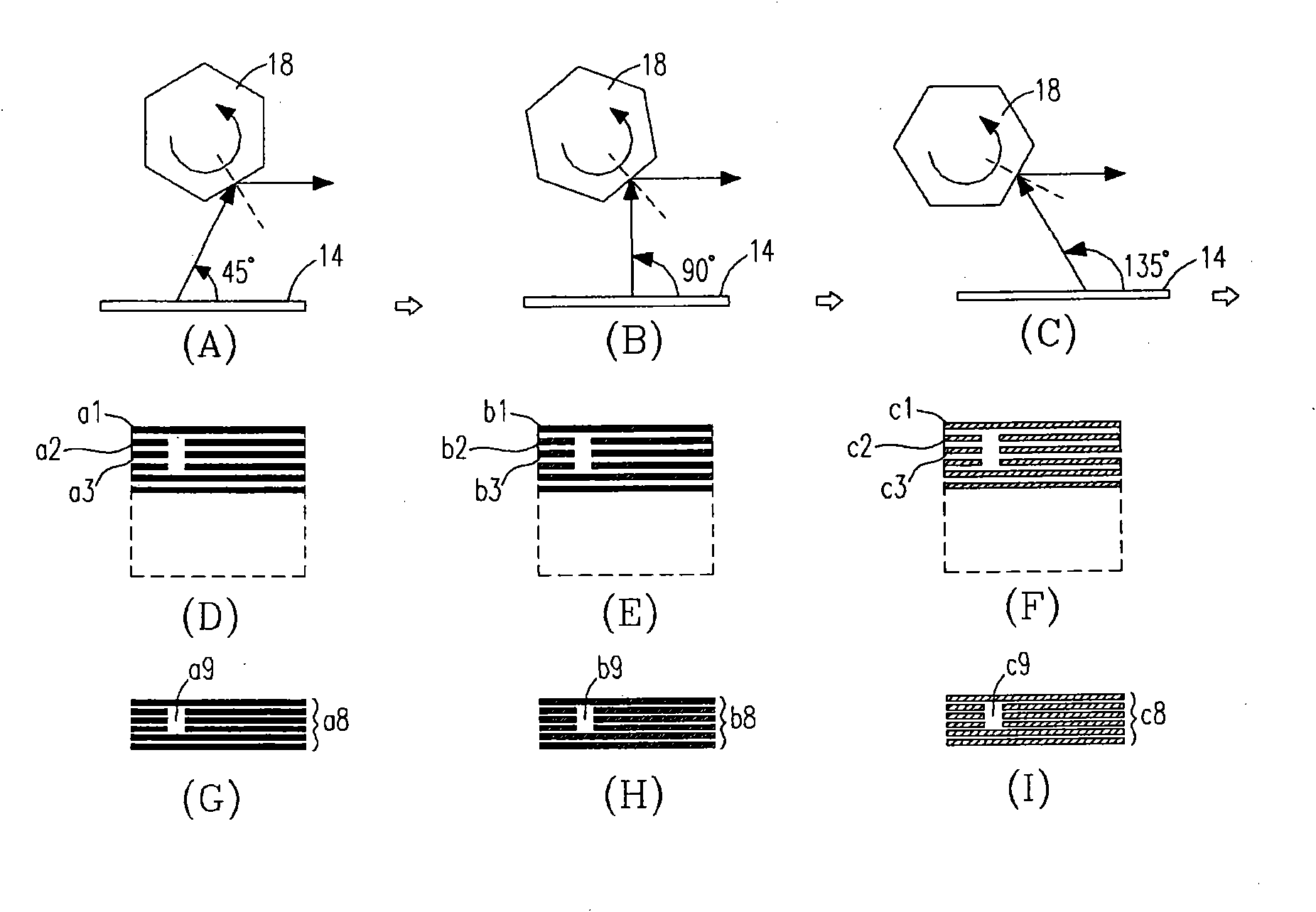

[0066] See first figure 1 , which is a schematic diagram of the configured optical detection device 1 of the first embodiment of the optical detection device of the present invention. exist figure 1 Among them, an optical detection device 1 includes a first light source 191 , a reflective element 18 , a carrier element 15 , a mask element 16 , an optical filter element 13 , an array receiving sensor element 17 and an image acquisition element 12 . In order to achieve the purpose of optical detection, a test object 14 is placed on the carrier element 15, the first ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com