Method for detecting local corrosion of horizontal well sleeve pipe based on retractor drive current analysis

A technology of local corrosion and driving current, which is applied in the direction of material analysis, analysis materials, instruments, etc. by electromagnetic means, can solve the problems of high cost, difficulty in large-scale promotion of oil fields, and long test cycle, so as to achieve low cost and improve program operation Speed, the effect of short measurement cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

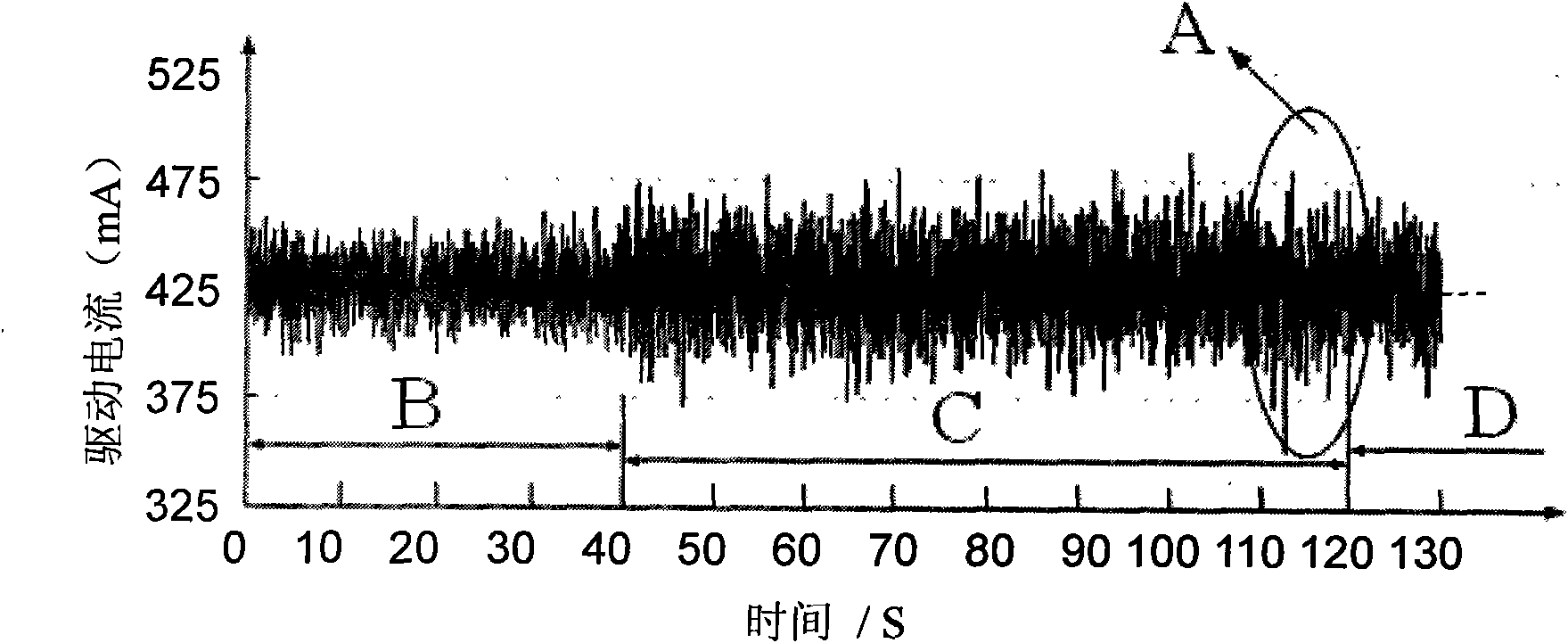

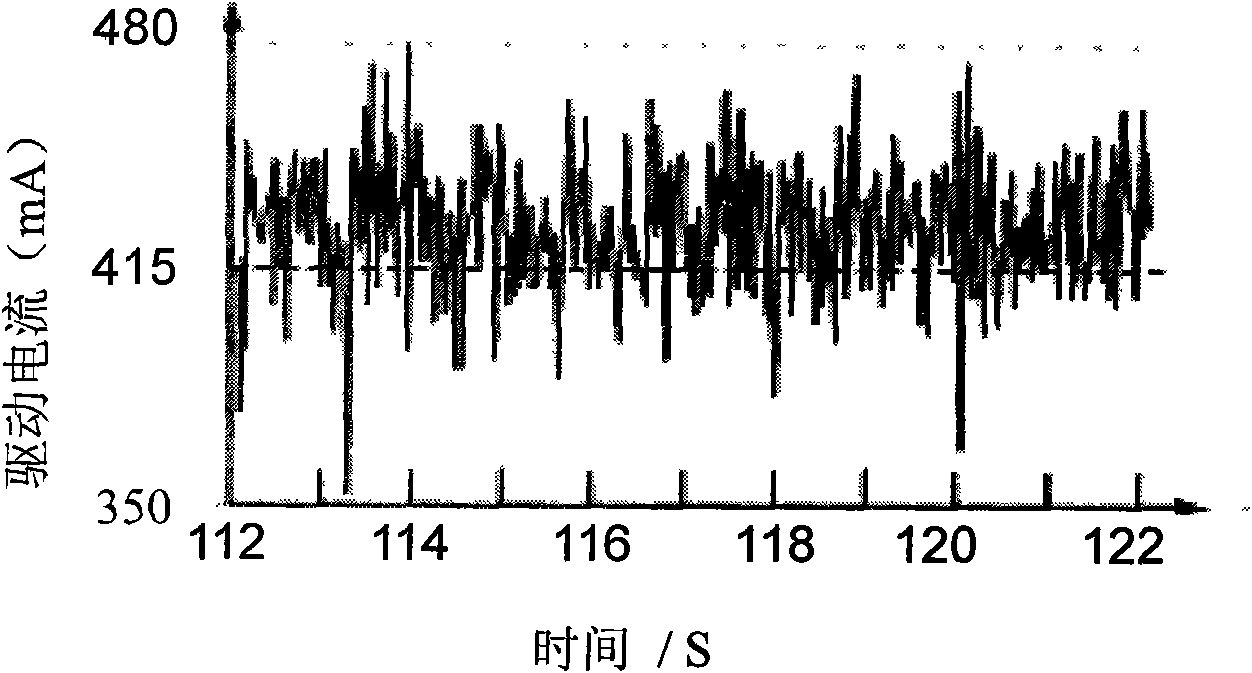

[0022] Specific embodiment one: a kind of detection method of the horizontal well casing localized corrosion based on tractor drive current analysis of this specific embodiment, its specific process is:

[0023] 1. Collect the driving current of the tractor, and convert the current into a 12-bit digital signal, and the tractor is located in the casing of the horizontal well for operation;

[0024] 2. Carry out fast Fourier transform to the obtained 12-bit digital signal, and select the sampling frequency and decomposition scale of wavelet decomposition according to the results of fast Fourier transform;

[0025] 3. Perform wavelet decomposition on the 12-bit digital signal, so that the different frequency components of the 12-bit digital signal are correspondingly distributed in different wavelet scales, and then carry out characteristic information on the wavelet coefficients obtained by wavelet decomposition or the single wavelet reconstruction signal Evaluation, the specifi...

specific Embodiment approach 2

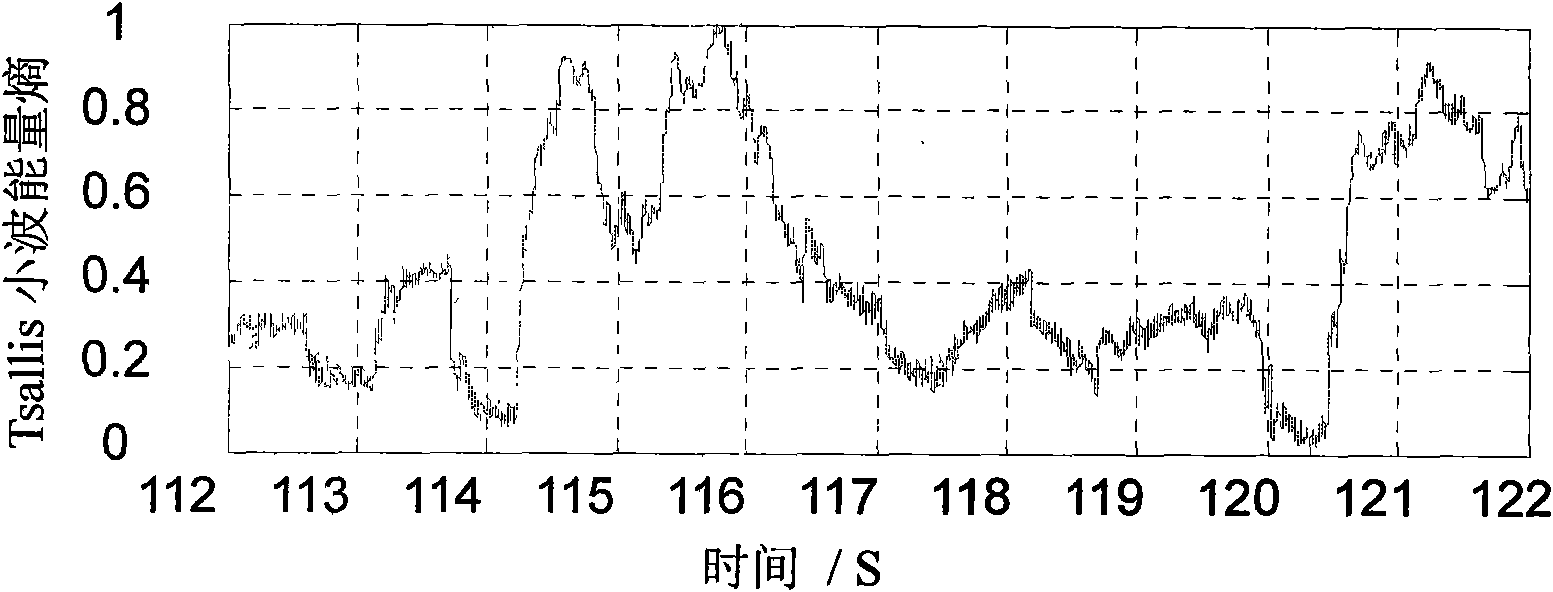

[0029] Specific embodiment 2: This specific embodiment is a further description of the detection method for localized corrosion of horizontal well casing based on tractor driving current analysis described in specific embodiment 1. The specific process of Tsallis wavelet energy entropy calculation is as follows:

[0030] The discrete wavelet coefficients of the multiresolution analysis or the single-branch wavelet reconstruction signal matrix is D={d(k), k=1, 2,..., N}, wherein, d(k) is the kth discrete wavelet coefficients or single-branch Branch wavelet reconstruction signal, k is discrete wavelet coefficient or element position variable in single branch wavelet reconstruction signal matrix, N is data length; define a sliding data window on wavelet coefficient or single branch wavelet reconstruction signal, window width is w∈N, the sliding factor is δ∈N, and the data window is expressed as

[0031] W(m, w, δ) = {d(k), k=1+mδ, ..., w+mδ};

[0032] In the above formula, m=...

specific Embodiment approach 3

[0039] Specific embodiment three: This specific embodiment is a further description of the detection method for localized corrosion of horizontal well casing based on tractor driving current analysis described in specific embodiment one or two, and the third and second steps in step three The specific process of outputting the local corrosion information of the casing according to the input Tsallis wavelet energy entropy calculation result by using the neuron network is as follows:

[0040] Judging the relative size of the local corrosion degree of the casing according to the relative size of the step up jump amplitude value in the result of the Tsallis wavelet energy entropy calculation, and judging the local corrosion position of the casing according to the moment when the step up jump appears and the crawling speed of the tractor , and then output the result of the above judgment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com