High-precision maximum power point tracing method

A maximum power point, high-precision technology, applied in photovoltaic modules, adjusting electrical variables, photovoltaic power generation, etc., to achieve the effects of reducing energy loss, improving tracking accuracy, and overcoming misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

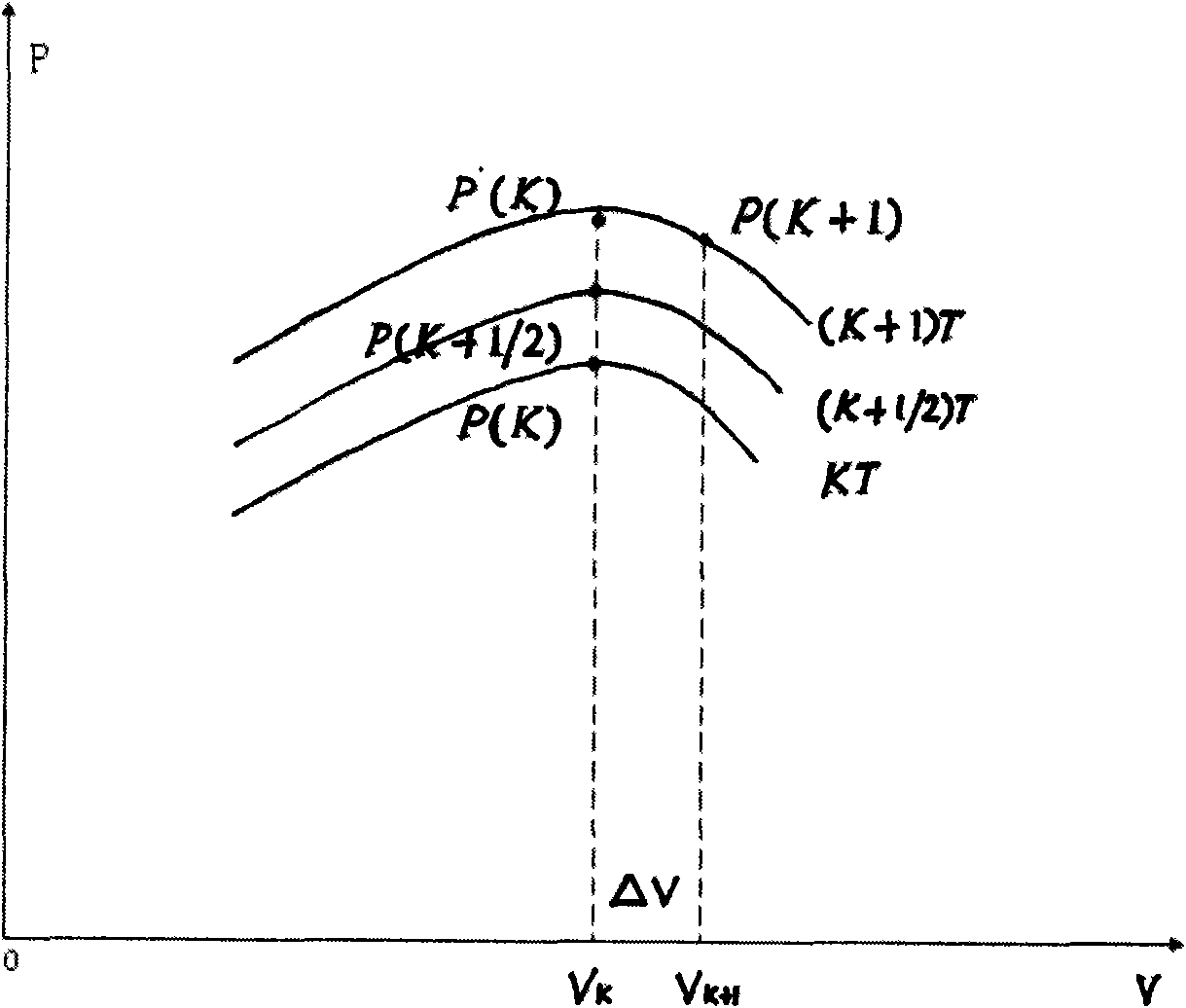

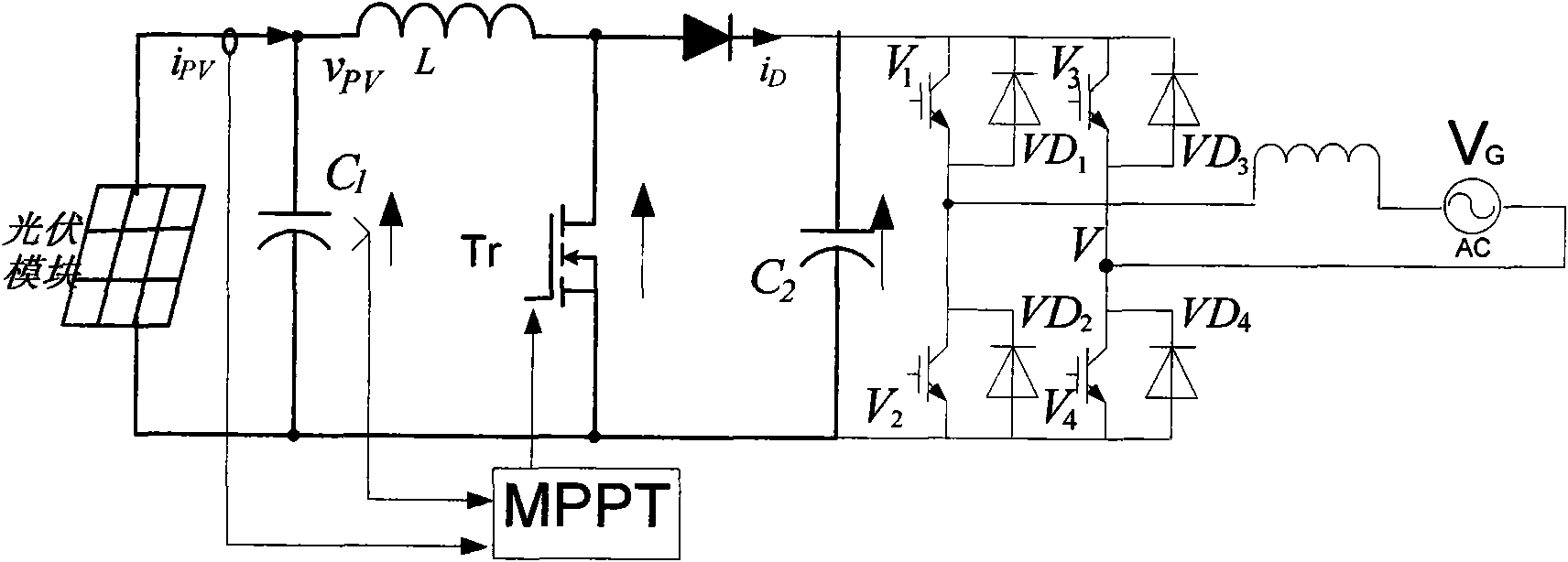

[0011] Such as figure 1 As shown, due to the high switching frequency, here we can assume that in a cycle, the rate of change of illumination is constant. KT moment at the voltage V K The power P(K) is measured at , and the reference voltage is not disturbed at this time, and a measurement is added at (K+1 / 2)T time, the power P(K+1 / 2) is measured, and the predicted power is obtained:

[0012] P'(K)=2P(K+1 / 2)-P(K) (1)

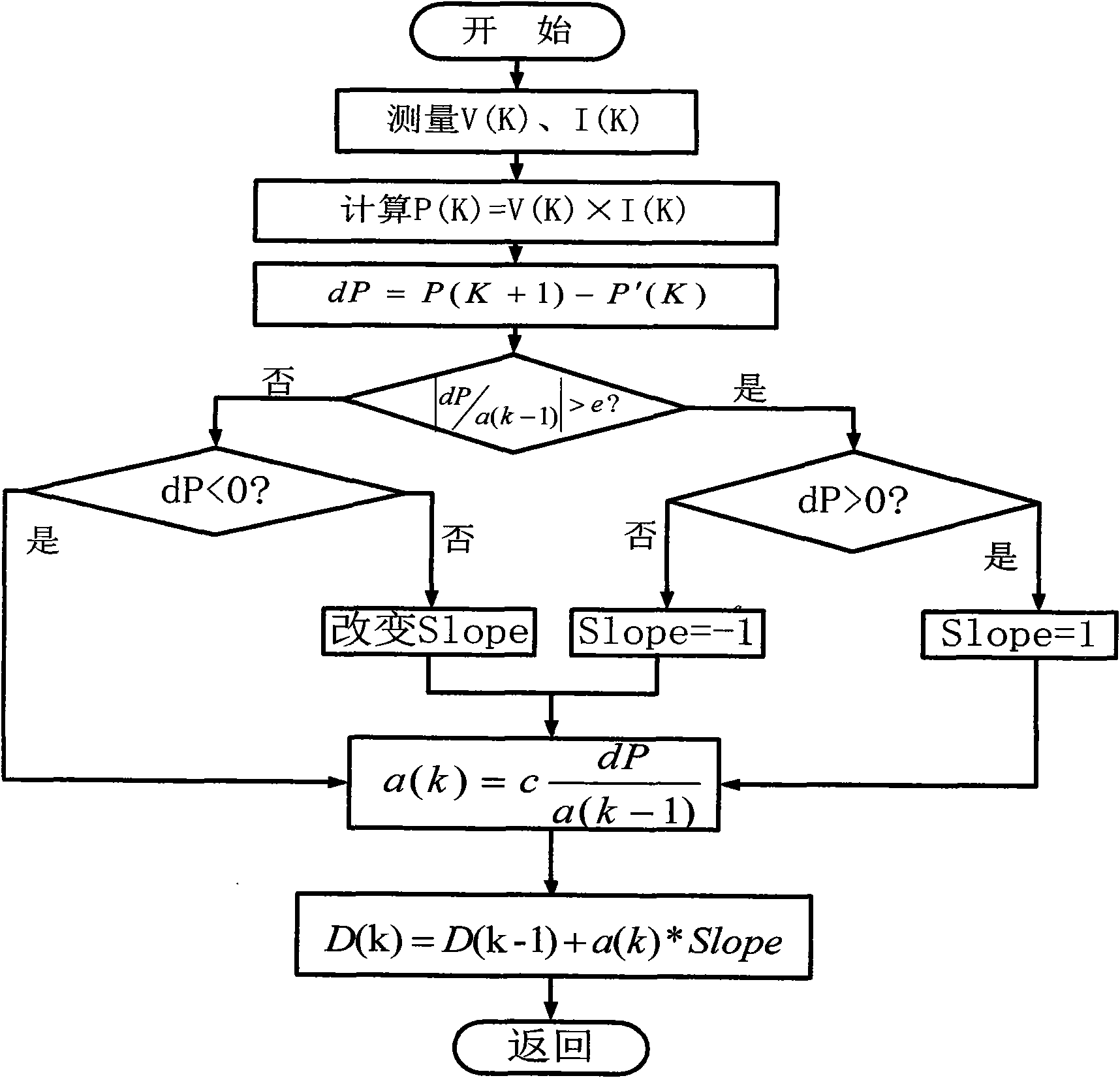

[0013] Then increase the reference voltage by ΔV at (K+1 / 2)T time, and measure the voltage V at (K+1)T time K+1 The power at P(K+1), calculate the power value difference dP=P(K+1)-P'(K).

[0014] When implementing the variable step size algorithm, generally when the current change rate is lower than 7%, it is considered that the photovoltaic array works in a similar constant current source region, and the step size of each voltage change is 10% of the original voltage; and when the current change rate When it is higher than 7%, it is considered that the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com