Double tube type superhigh temperature sterilization machine system and sterilization technology

A technology of ultra-high temperature sterilization and sterilizers, which is applied in dairy products, food science, applications, etc., can solve the problems that automatic ultra-high temperature sterilizers cannot work continuously and the production efficiency is not high, so as to reduce production costs and ensure continuous production. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

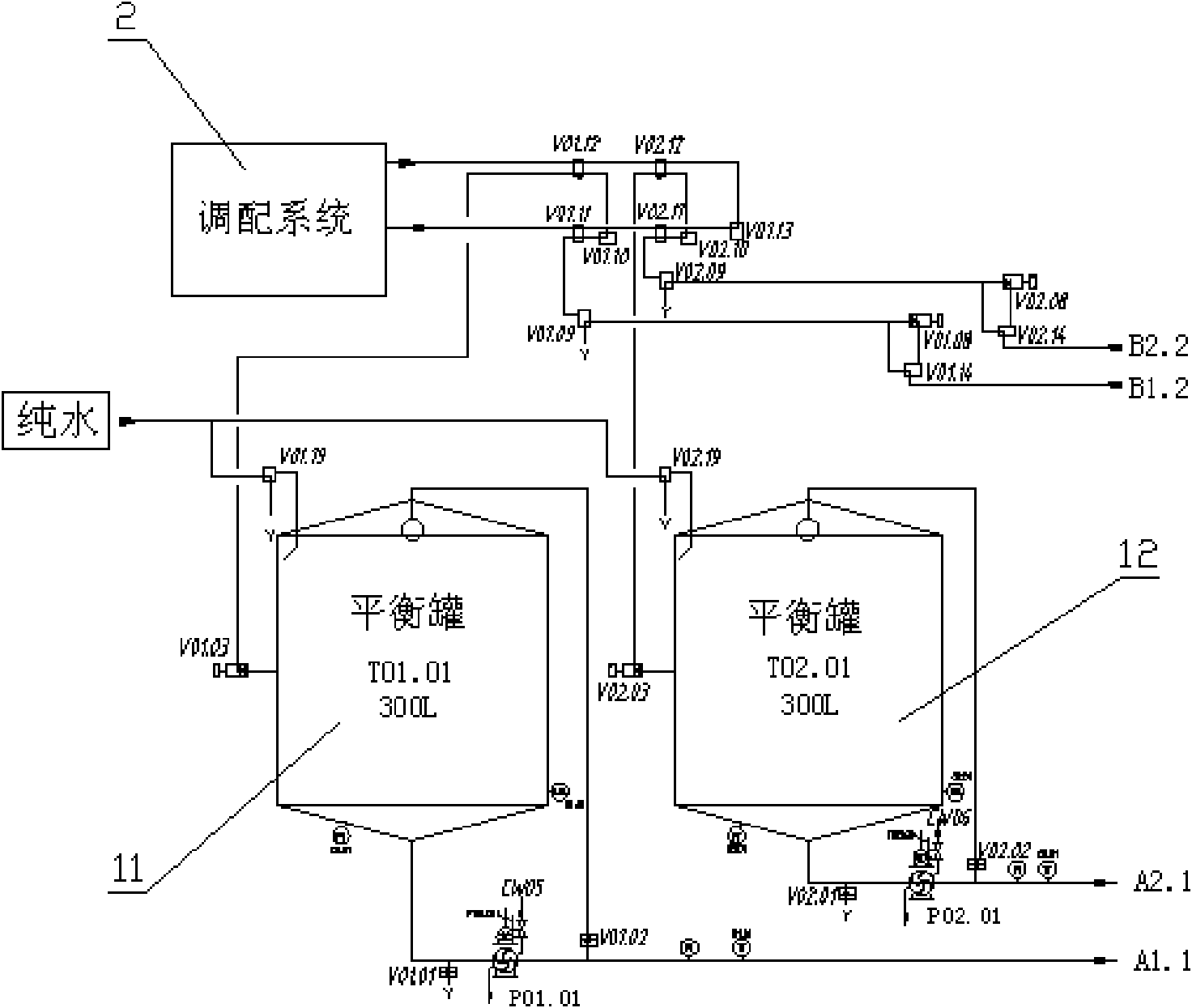

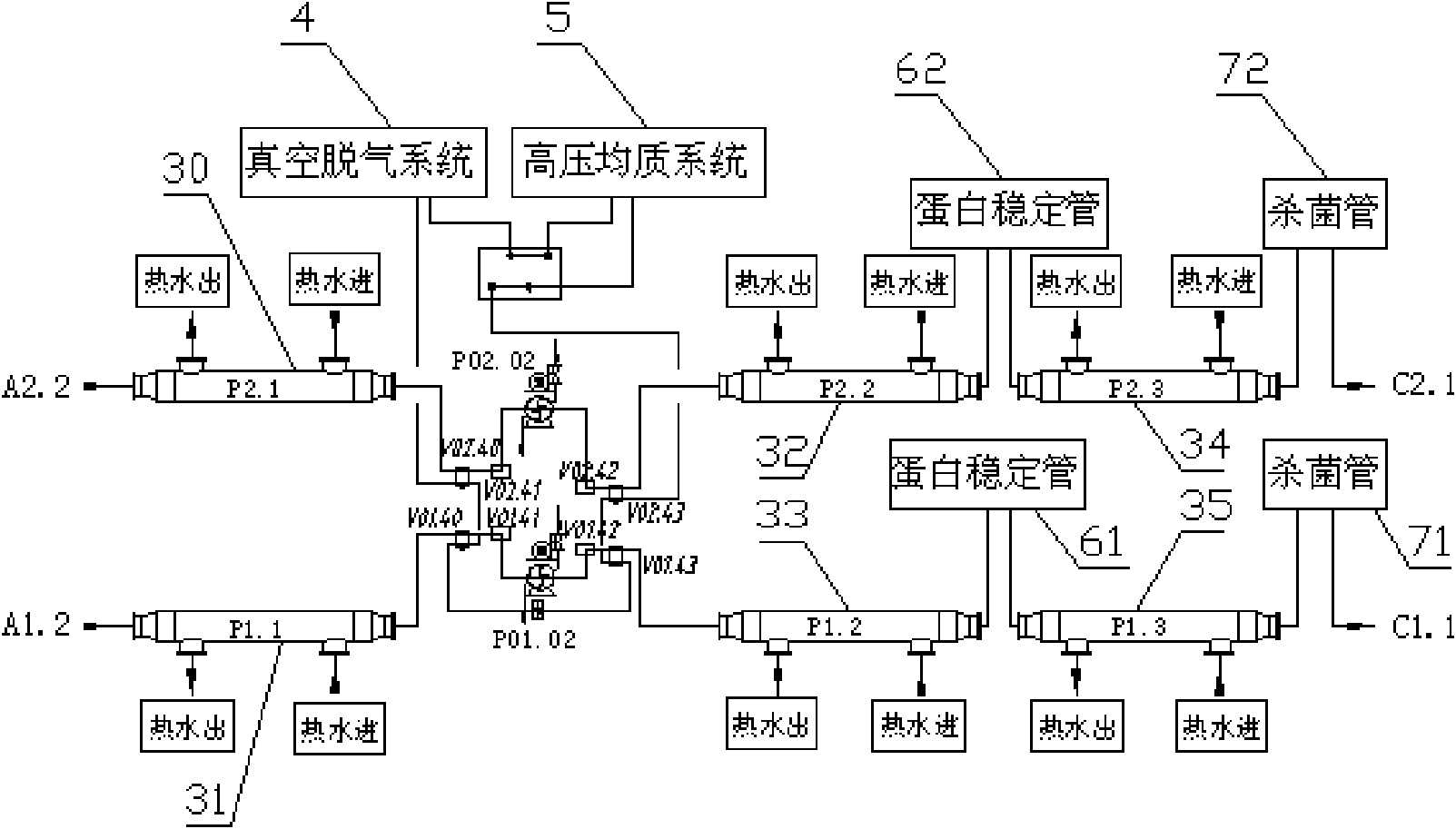

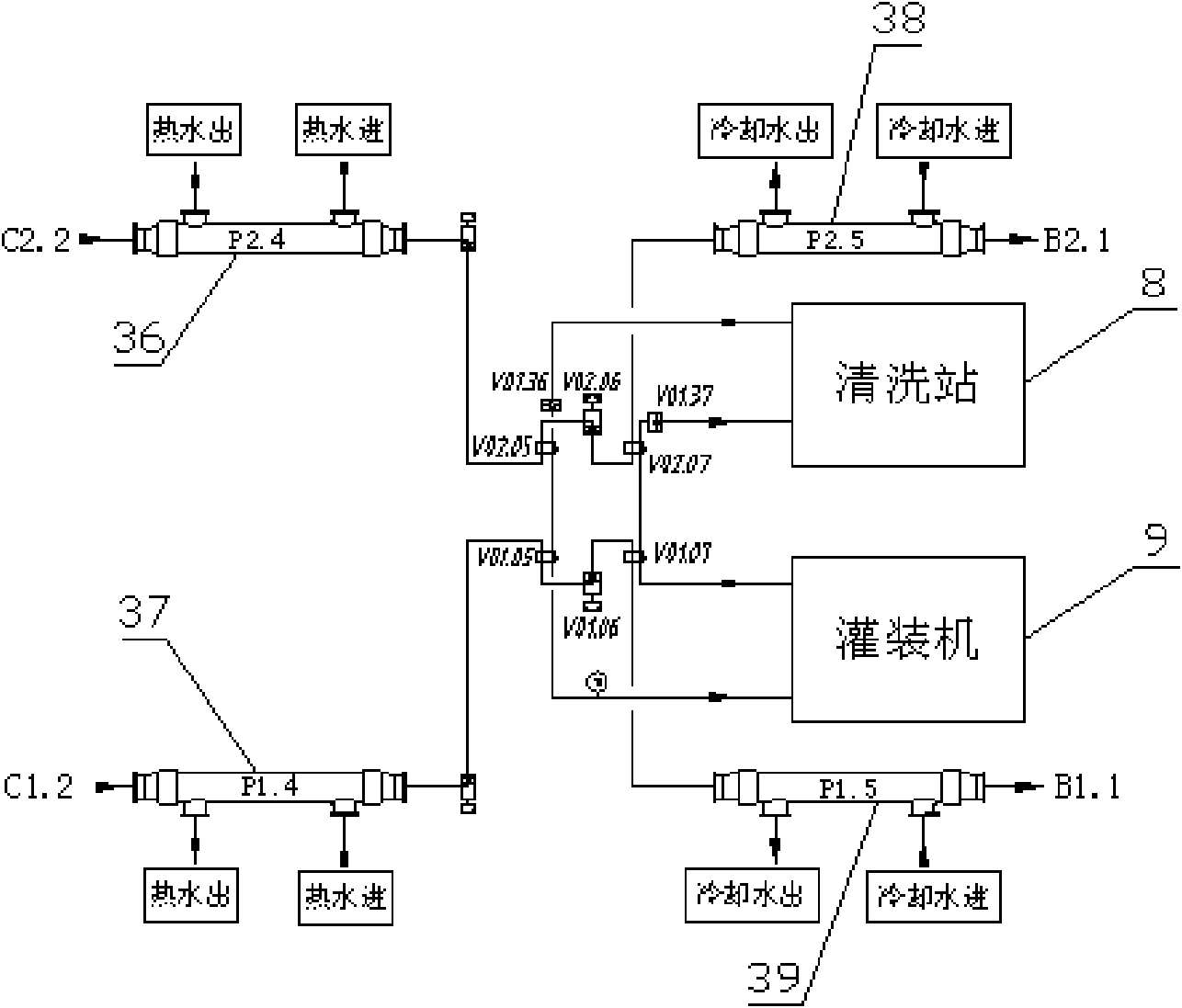

[0024] Such as Figure 1 to Figure 3 As shown, the double-pipe ultra-high temperature sterilizer system includes a balance tank and a tube heat exchanger connected to the balance tank. There are two balance tanks, namely balance tank 11 and balance tank 12, balance tank 11 and balance tank 12 is connected with a deployment system 2; the balance tank 11 is connected to the tubular heat exchanger 31 and then enters the vacuum degassing system 4 and the high-pressure homogeneous system 5, and then sequentially connected to the tubular heat exchanger 33 and the protein stabilization tube 61 , tube heat exchanger 35, sterilizing tube 71, tube heat exchanger 37 and filling machine 9, and filling machine 9 is connected with deployment system 2 through tube heat exchanger 39 again.

[0025] After the balance tank 12 is connected to the tubular heat exchanger 30, it enters the vacuum degassing system 4 and the high-pressure homogeneous system 5, and then successively connects to the tub...

Embodiment 2

[0032] The sterilizing process using the double-pipe ultra-high temperature sterilizer system described in Example 1 includes the following operations:

[0033] Process 1: The first set of sterilizer system is running, and the second set of sterilizer system is on standby, that is, the material enters the tubular heat exchanger 31 after passing through the balance tank 11, and then enters the vacuum degassing system 4, the high-pressure homogenization system 5, and the tube heat exchanger in turn. Type heat exchanger 33, protein stabilization tube 61, tube type heat exchanger 35, sterilization tube 71, tube type heat exchanger 37 and filling machine 9;

[0034] Process 2: After the first set of sterilizer system runs for 16 to 20 hours, start the second set of sterilizer system in advance for pre-sterilization, and then switch the material into the second set of sterilizer system, that is, the material enters the tube type after passing through the balance tank 12 Heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com