Mine dust removing device

A dust removal device and mine-used technology, which is applied in the direction of combination device, safety device, dust prevention, etc., can solve the problems of dust leakage, lower dust removal efficiency, high equipment cost, etc., reduce the number of cleaning times, improve work efficiency, and prevent blockage The effect of reducing the chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

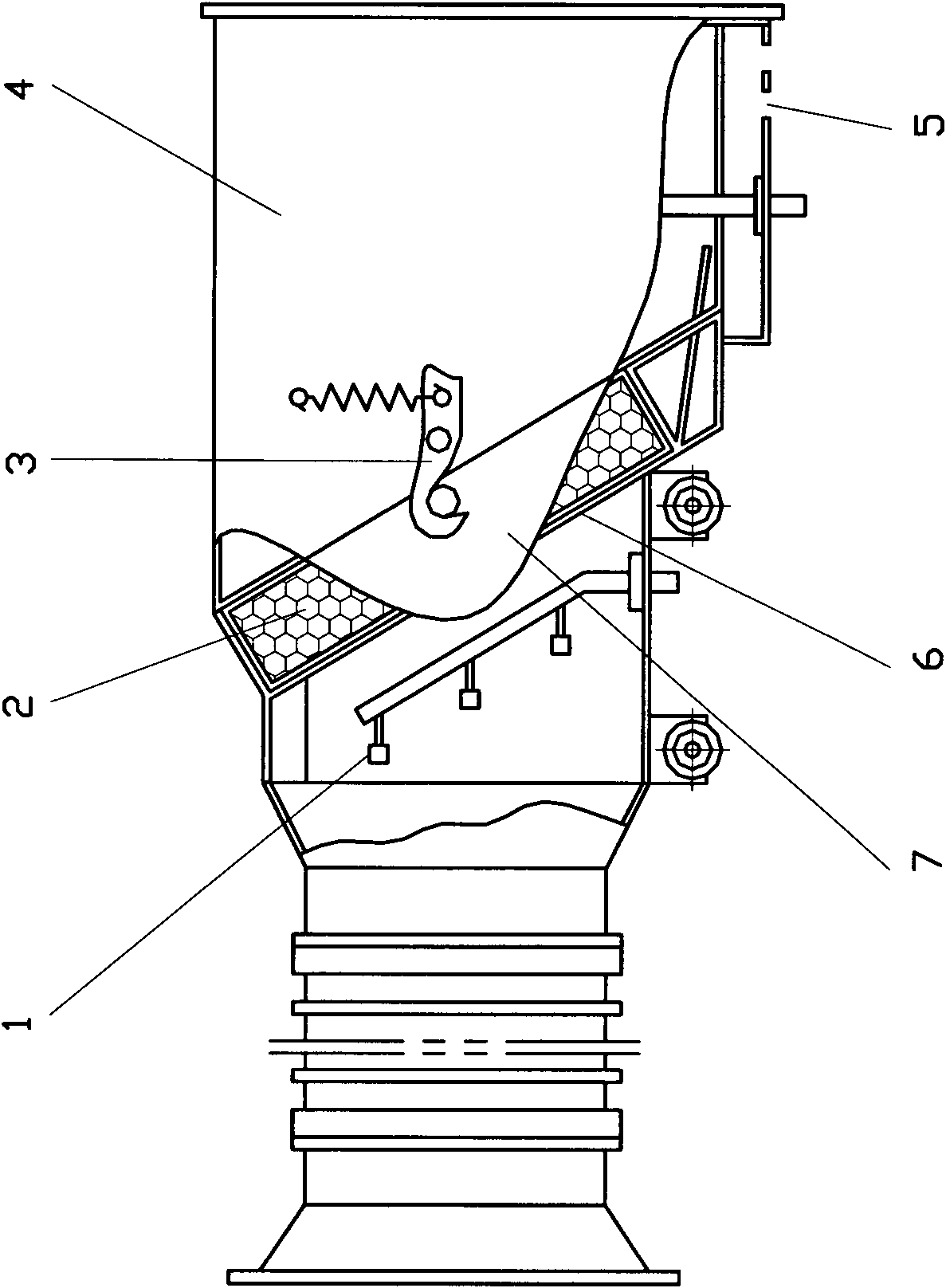

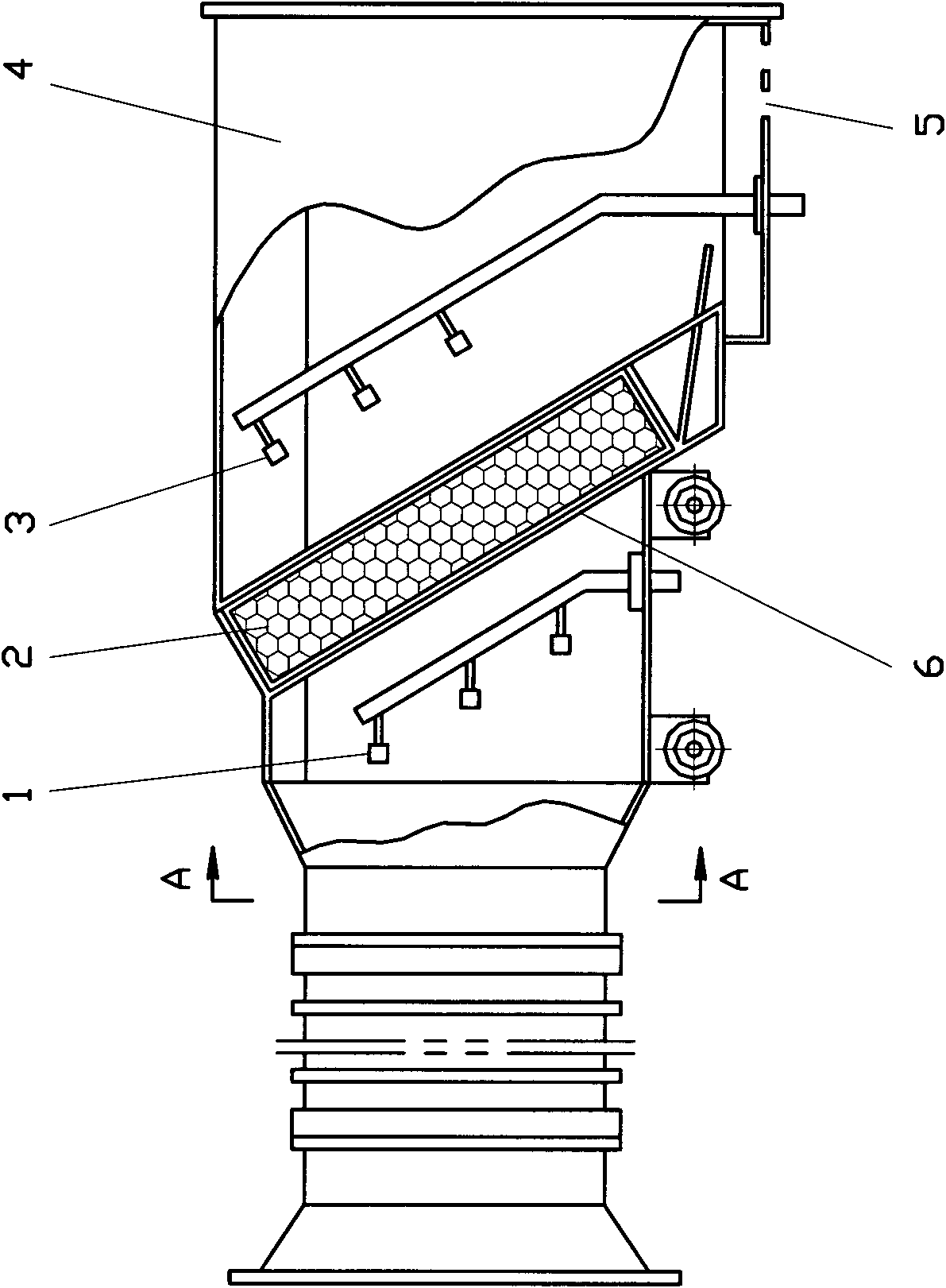

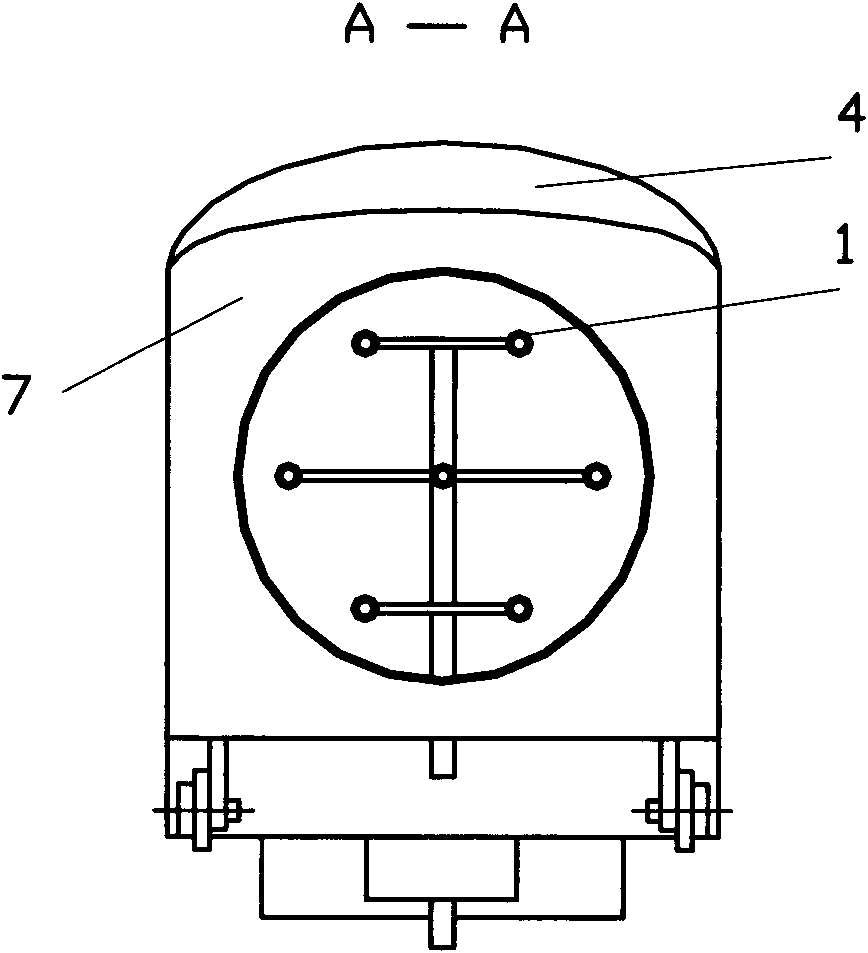

[0011] figure 1 and figure 2 As shown, the present invention includes a box body and a filter screen 2 located in the box body, the box body is composed of a front box body 7 and a rear box body 4, and the front box body 7 and the rear box body 4 are movably matched. This movable fit can be respectively installed chute on front box body 7 and rear box body 4 to carry out sliding fit, also can install hasp on front box body 7 and rear box body 4 to carry out fastening fit respectively, can also adopt A hinge is installed on the side where the front box body 7 and the rear box body 4 join to carry out hinged cooperation. In the present embodiment, the cooperating mode of the drag hook 3 and the hook column is adopted. The above matching methods are all prior art, and are well known to those skilled in the art. Front box body 7 ends among the present invention are filter screen frame 6, and filter screen 2 is positioned at filter screen frame 6, and filter screen frame 6 botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com