Application method of laser bronzing technology on bamboo tea tray

An application method and laser technology, applied in decorative arts, processes for producing decorative surface effects, burning and other directions, can solve the problems of chemical pollution, high failure rate of heat transfer products, easy to learn and difficult to master mechanical heat transfer, etc. Achieving a unique artistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

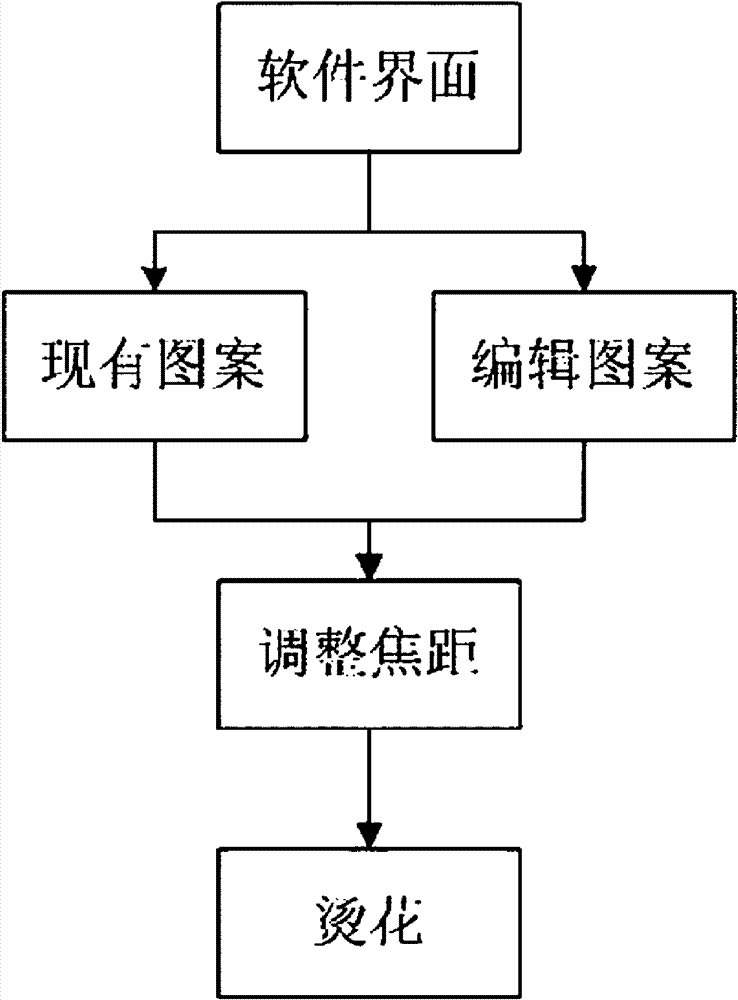

[0010] An application method of laser embossing technology on bamboo tea trays, characterized in that: the following steps are followed: enter the burning interface of the laser marking machine software, use various functions of the software to edit the pattern to be embossed or edit the pre-edited The file is directly input into the software. After the typesetting is completed, the focal length of the laser probe is adjusted, and the processing position is determined to heat the tea tray.

[0011] The main technical indicators of the laser embossing are as follows: the number of marking processes is 1 or 2 or 3, the marking speed is 800-1000mm / s, the jump speed of the laser probe is 100mm / s, the power ratio is 100%, the frequency The proportion is 20-50%, the delay of the start section is 100us, the delay of the end section is 0us, the delay of the jump position of the laser probe is 500us, the delay of the jump distance is 500us, the distance between the filling lines of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com