Cross purge valve and container assembly

A container and cross technology, applied in semiconductor/solid-state device manufacturing, multi-way valves, valve devices, etc., can solve problems such as pollution, rust, and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

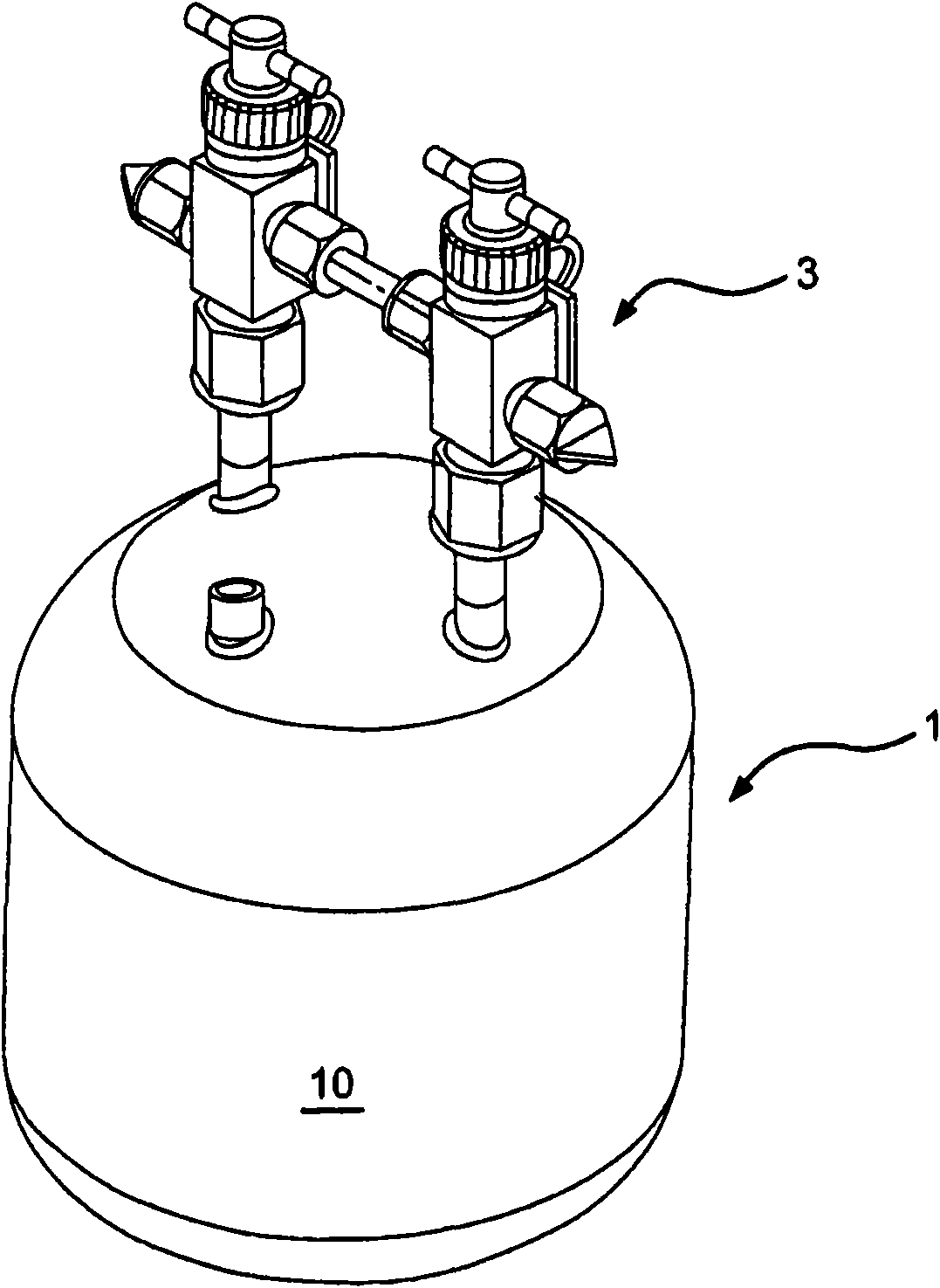

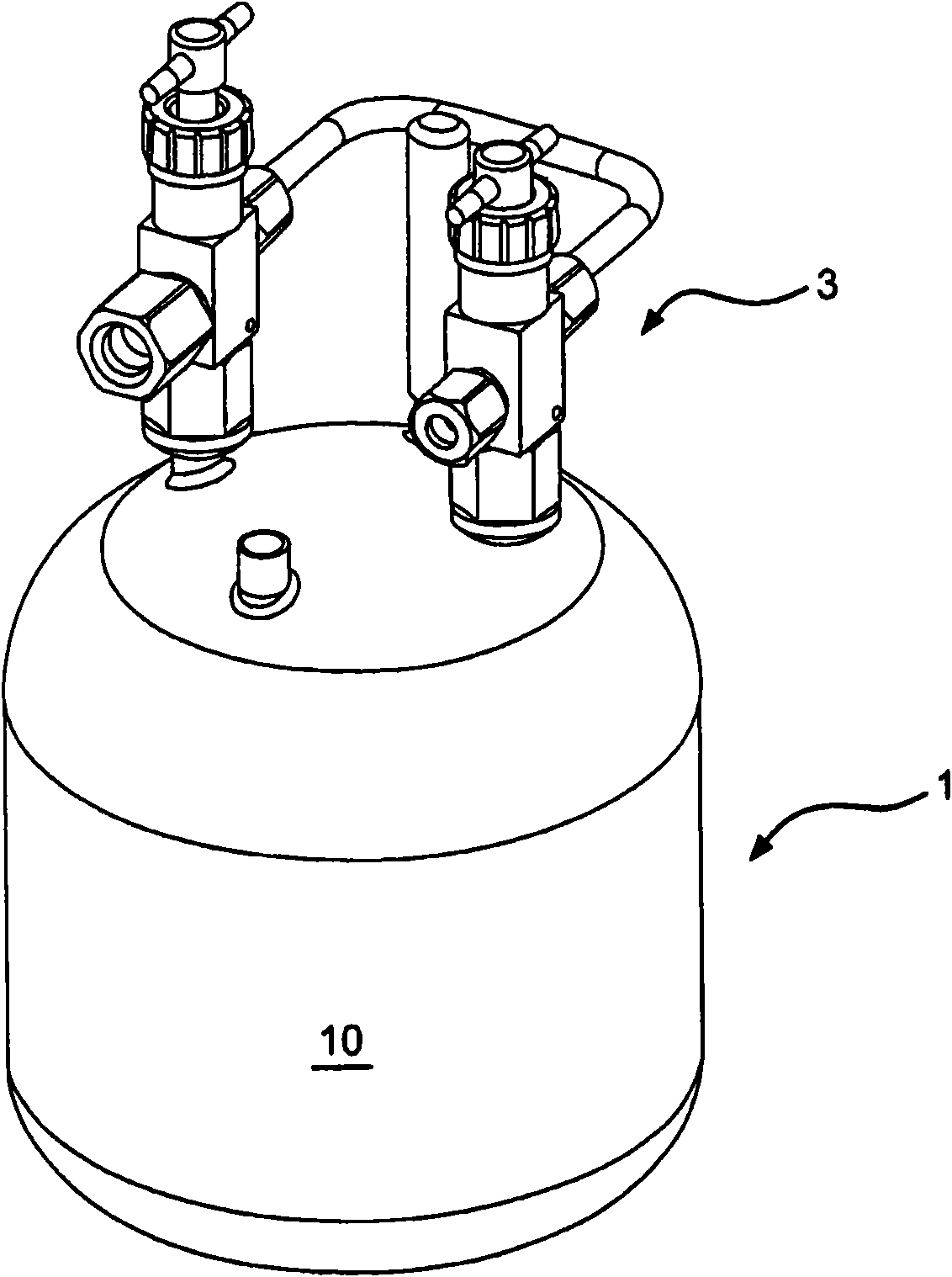

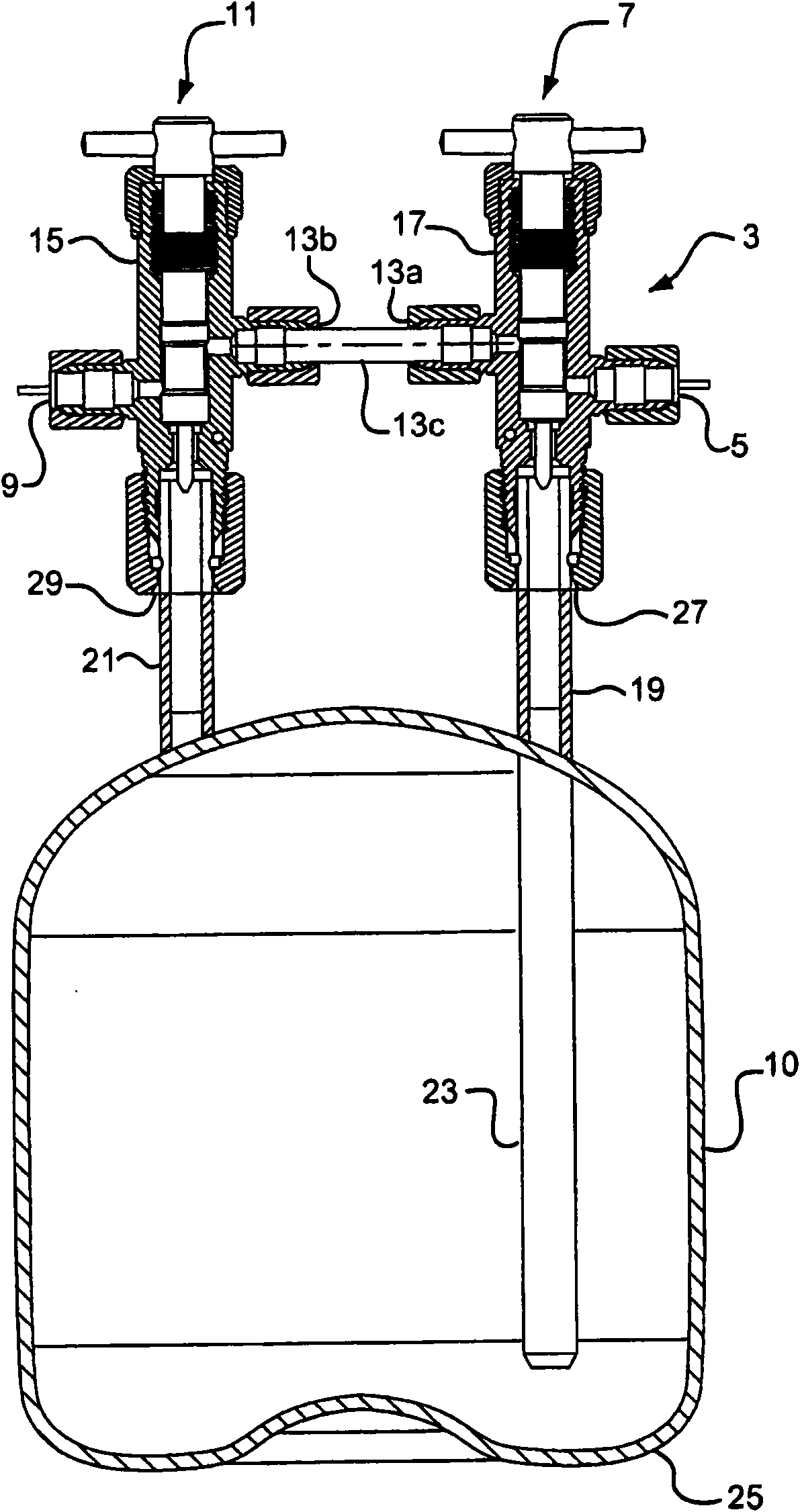

[0015] The present invention relates to a container for high purity process chemicals having improved valves and improved purge purge in the non-dispensing mode of the container.

[0016] Such containers are frequently used in the semiconductor manufacturing industry, the photovoltaic industry and other industries where precise control and a high degree of cleanliness and purity of the process chemicals are very important.

[0017] In the semiconductor manufacturing industry, these containers are typically constructed of glass, especially quartz, or metal, such as stainless steel. Steel containers are typically electropolished or surface treated to remove particles and produce a smooth surface that is easy to clean and prevents unwanted surface adsorption of the process chemicals.

[0018] High purity process chemicals in the semiconductor manufacturing industry typically have metal impurity specifications preferably no greater than parts per billion (ppb) levels and preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com